- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

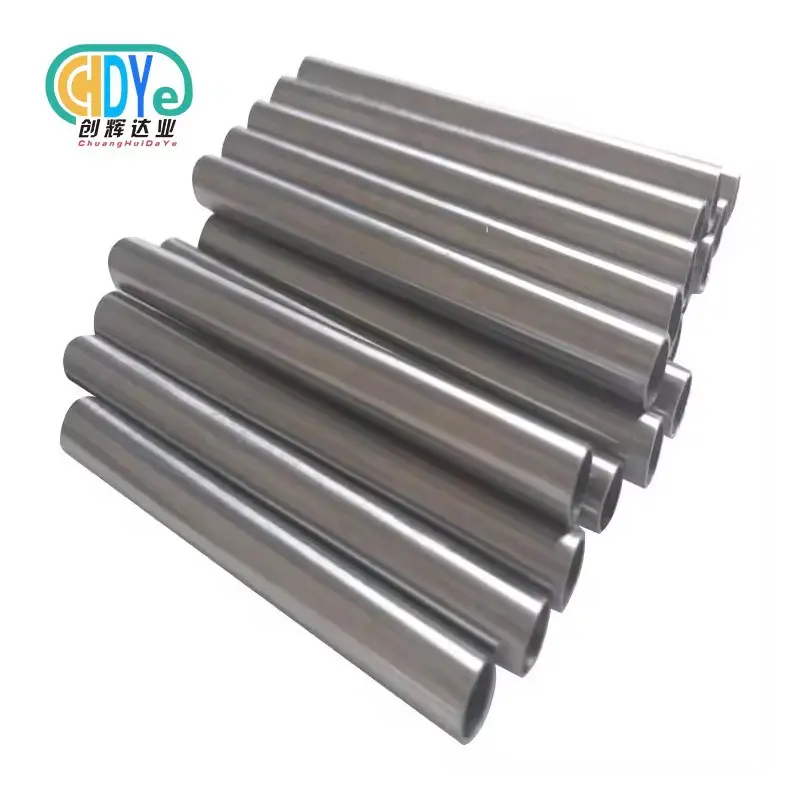

Titanium Tube For Heat Exchanger

2.Standard:ASTM B337 338

Product Introduction

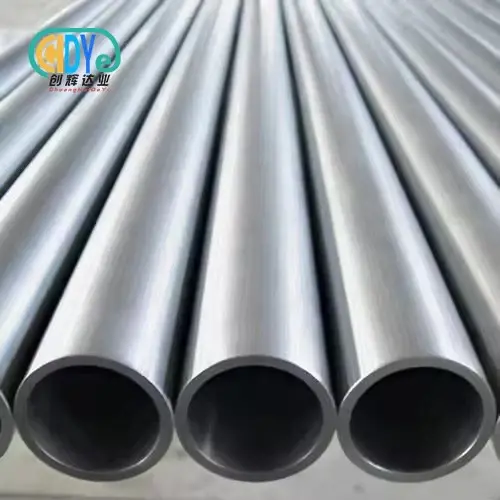

Titanium tube for heat exchanger is a specialized titanium product designed to transfer heat efficiently in corrosive and high-temperature environments. Its unique combination of high thermal conductivity, lightweight nature, and excellent corrosion resistance makes it an ideal solution for condensers, evaporators, and heat recovery systems.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. produces titanium tubes specifically optimized for industrial heat exchangers. Using precision extrusion and annealing technologies, our products ensure uniform wall thickness, stable heat transfer efficiency, and long service life even under extreme working conditions.

Titanium tube features:Titanium tubes are lightweight, have high strength, and superior mechanical properties

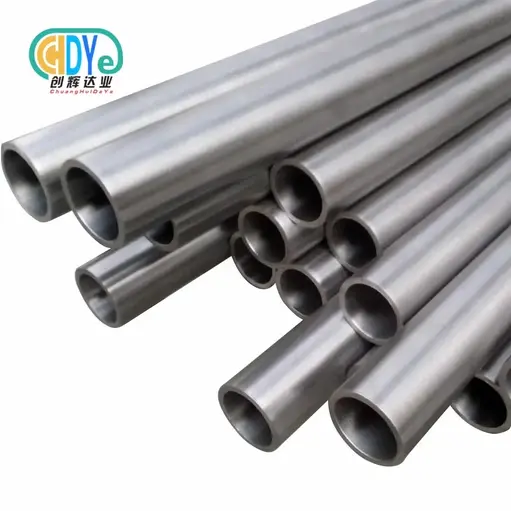

Titanium tube grade: Gr1,Gr2 Gr3,Gr4, Gr7,Gr9,Gr12

Titanium tube standard:ASTM B337 338

Dimension: OD10-300xWT0.5-10x L100-18000 MM

|

Permissible deviation of outer diameter of titanium tube(mm) |

||||||

|

Outer Diameter |

3~10 |

>10~30 |

>30~50 |

>50~80 |

>80~100 |

>100 |

|

Permissible deviation |

±0.15 |

±0.30 |

±0.50 |

±0.65 |

±0.75 |

±0.85 |

Titanium tube testing

1. Appearance inspection: Check the outer diameter, wall thickness, and surface quality of the titanium tube.

2. Mechanical performance testing: including tensile strength, yield strength, elongation, and other indicators to ensure that the titanium tube has sufficient mechanical strength.

3. Chemical composition analysis: Detect the content of chemical elements in titanium tubes to ensure that they meet the corresponding standards and specifications.

4. Non destructive testing, such as eddy current testing and ultrasonic testing, is used to check for defects inside titanium tubes.

5. Corrosion resistance testing: Although this testing may not be conducted in all cases, it may be necessary to evaluate the corrosion resistance of titanium tubes for specific applications in specific environments.

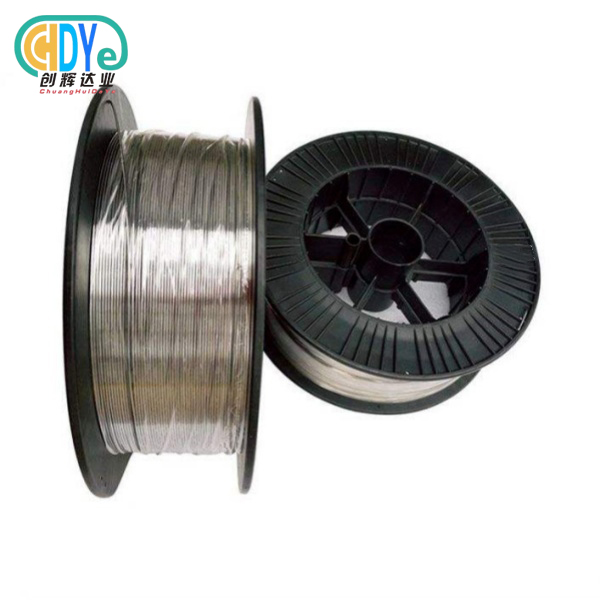

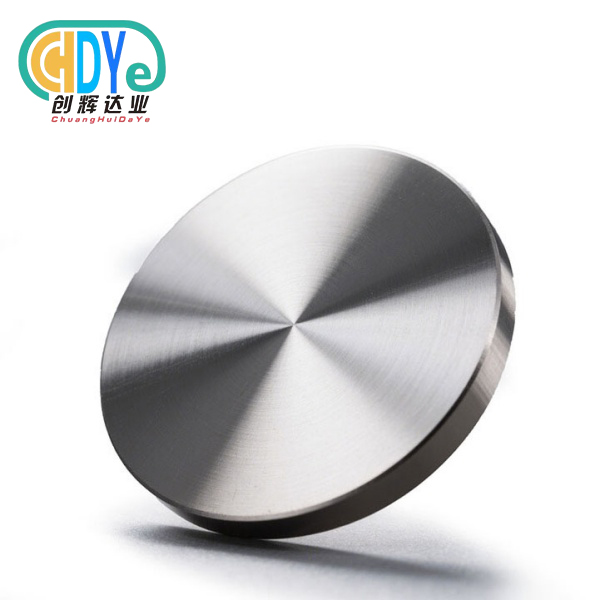

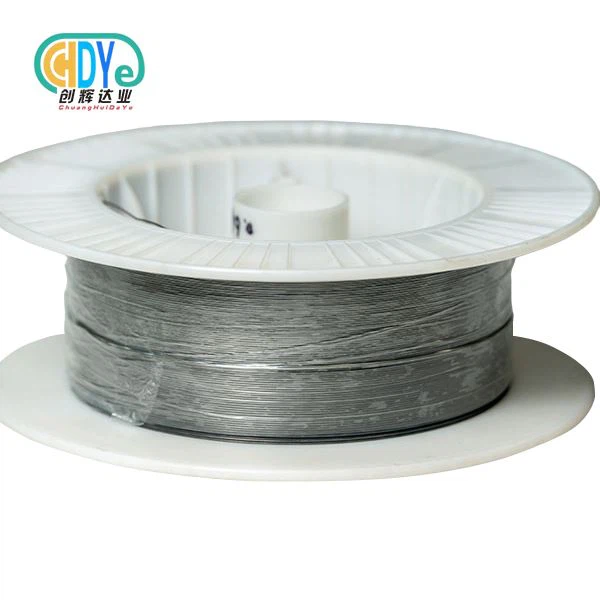

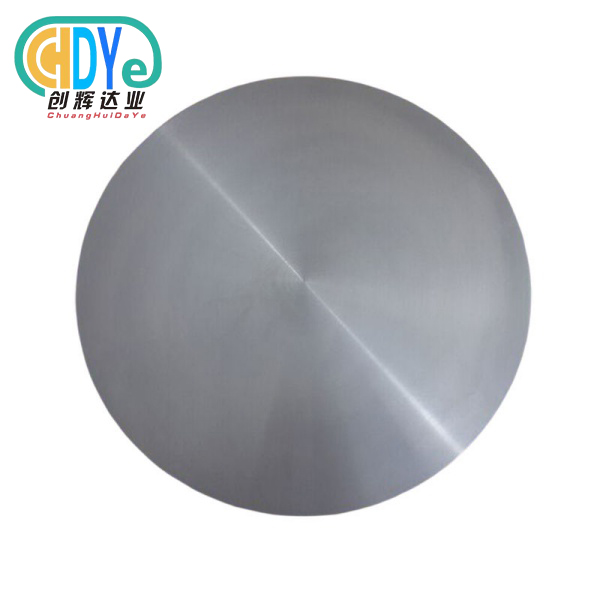

Titanium tube related products

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Grades | Gr1, Gr2, Gr7, Gr9, Gr12 (as per ASTM B338/B861) |

| Standards | ASTM B338 / ASME SB338 / ISO 9001 / DIN 17861 |

| Outer Diameter | 6 mm – 76 mm |

| Wall Thickness | 0.4 mm – 3.0 mm |

| Tube Length | ≤ 12000 mm or customized |

| Condition | Annealed (O), Cold Worked, Pickled, Bright Finished |

| Surface Finish | Bright, Polished, Acid Cleaned, Smooth Inside |

| Straightness | ≤ 1.0 mm/m |

| Heat Transfer Coefficient | Up to 16.5 W/m·K (depending on medium) |

| Certification | EN 10204 3.1 / SGS / ISO 9001:2015 |

All titanium tubes for heat exchangers are tested for dimensional accuracy, leak-proof performance, and corrosion resistance before shipment.

Product Features & Advantages

-

High Corrosion Resistance: Titanium is naturally resistant to seawater, chlorine, and most acid environments, making it ideal for condensers and marine systems.

-

Excellent Heat Transfer Efficiency: Maintains stable performance across wide temperature ranges and varying flow rates.

-

Anti-fouling Properties: The oxide film on the titanium surface prevents scaling and biological fouling, ensuring consistent thermal conductivity.

-

Long Operating Life: Titanium heat exchanger tubes can last over 20 years with minimal maintenance in harsh environments.

-

Lightweight & Strong: Offers high strength-to-density ratio for compact and efficient equipment design.

-

Environmentally Friendly: 100% recyclable and contributes to sustainable engineering practices.

Applications

Titanium heat exchanger tubes are widely used in industries that demand durability, efficiency, and resistance to corrosion and fouling.

-

Seawater Desalination Plants: Condenser and evaporator tubes exposed to high salinity environments.

-

Power Generation: Cooling systems in nuclear, thermal, and geothermal power stations.

-

Petrochemical Industry: Heat exchangers in refineries and acid recovery systems.

-

HVAC Systems: Titanium tubes in energy-efficient heat recovery units.

-

Shipbuilding and Marine Engineering: Engine cooling, condensers, and oil coolers.

-

Food & Pharmaceutical Processing: Clean and non-toxic performance in hygienic heat exchangers.

Our titanium heat exchanger tubes are trusted by global EPC contractors and OEM manufacturers for their reliability and energy efficiency.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye is equipped with a complete titanium tube production line that integrates melting, forming, and finishing processes.

- Vacuum Arc Melting & Forging: Produces ultra-clean titanium billets with uniform structure.

- Cold Drawing & Precision Rolling: Ensures smooth surface and accurate dimensional tolerance.

- Annealing & Straightening: Relieves internal stress and enhances mechanical performance.

- Eddy Current & Hydrostatic Testing: Guarantees leak-free and crack-free tubes.

- CNC Cutting & Finishing: Delivers customized lengths and ready-to-install tubes for industrial systems.

Our advanced manufacturing control enables consistent production for both small-batch prototypes and large-scale heat exchanger projects.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality control is implemented at every stage to meet international standards for heat exchanger tube reliability.

Inspection Procedures:

- Raw material chemical analysis

- Mechanical property testing (tensile, yield, elongation)

- Hydrostatic and air tightness test

- Surface and straightness measurement

- Heat treatment and grain size verification

- Final inspection with 100% traceability

All products are supplied with EN 10204 3.1 certification and comply with ASTM and ASME codes for pressure equipment.

Surface & Mechanical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| Gr1 | ≥ 240 | ≥ 170 | ≥ 24 | ≤ 80 |

| Gr2 | ≥ 345 | ≥ 275 | ≥ 20 | ≤ 100 |

| Gr7 | ≥ 340 | ≥ 275 | ≥ 20 | ≤ 110 |

| Gr12 | ≥ 485 | ≥ 380 | ≥ 18 | ≤ 130 |

Each tube is heat-treated and mechanically tested to ensure reliable service under continuous thermal cycling and corrosive media.

Packaging & Global Logistics

We understand the importance of protection and traceability during transport.

- Inner Packaging: PE plastic wrapping, anti-rust film, or foam cushioning

- Outer Packaging: Export-standard wooden boxes or steel-framed crates

- Labeling: Product grade, dimensions, batch number, and heat number clearly marked

- Shipping Options: Air freight, sea transport, or multimodal logistics according to customer needs

Our logistics partners ensure safe and timely delivery to ports worldwide, with documentation support for customs clearance.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

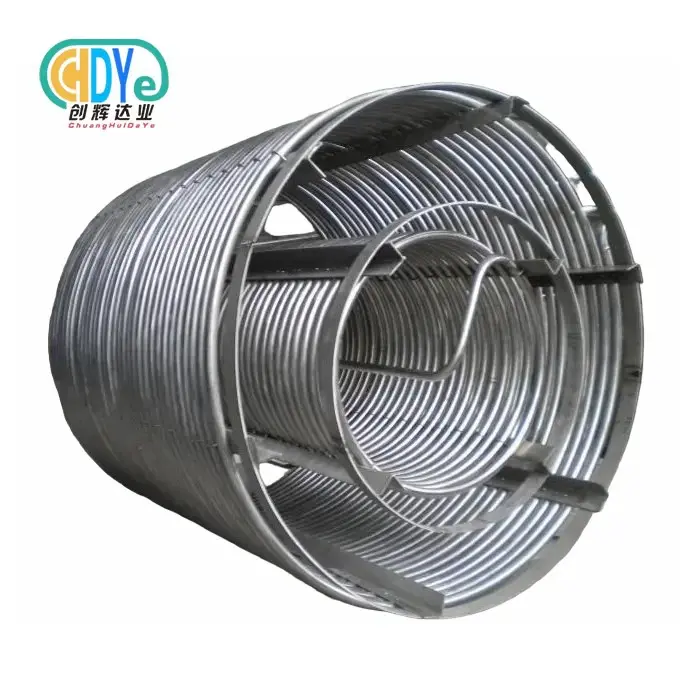

Our customization capabilities cover all key dimensions and requirements for heat exchanger applications:

- Tube diameter and wall thickness matching existing bundle layouts

- Tailored material grades for seawater, oil, or acid service

- Finned or corrugated tube structures for enhanced heat transfer

- Pre-bent U-type or coil-shaped configurations

- Custom lengths and surface treatments for plug-and-play installation

- Engineering support for design optimization and testing

We provide technical drawings, 3D models, and full documentation to support OEM cooperation globally.

Inspection Process

1. Appearance and dimension inspection to ensure every titanium tube meets tolerances,no cracks, pits or other defects on the surface.

2. 100% Straightness inspection.

3. 100% Hydro Testing.

4. Ultrasonic and eddy current testing make sure the product without cracks and scratch.

5. Testing Tensile strength, yield strength by our Tension Tester and the Third party lab to double check the quality.

Why Choose Us

- Over 30 years of experience in titanium and heat exchanger tubing production

- Strict adherence to ASTM, ASME, and ISO standards

- In-house melting, extrusion, and inspection capability for complete control

- Stable export to 50+ countries, including the USA, Germany, and Japan

- OEM/ODM support for heat exchanger manufacturers

- Technical engineering team providing installation and performance consultation

- Fast response and flexible customization for urgent projects

We deliver titanium heat exchanger tubes that combine precision, reliability, and efficiency—helping customers reduce operational costs and extend equipment lifespan.

|

|

|

|

|

|

FAQs

Q1: What makes titanium heat exchanger tubes superior to stainless steel tubes?

A1: Titanium offers better corrosion resistance, longer lifespan, and lower maintenance in seawater and chemical systems.

Q2: Are your titanium tubes compatible with plate-fin or shell-and-tube exchangers?

A2: Yes, our tubes can be integrated into both types of heat exchanger structures.

Q3: Can you supply titanium U-tubes for condensers?

A3: Absolutely, we can fabricate U-bent tubes with precise bending radius and end finishing.

Q4: What is the maximum working temperature of your titanium tubes?

A4: Titanium heat exchanger tubes can operate reliably up to 400°C under continuous service.

Q5: Do you provide pre-inspection certificates and test reports?

A5: Yes, all shipments include mill test reports, hydrostatic test data, and third-party inspection certificates if required.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email