- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

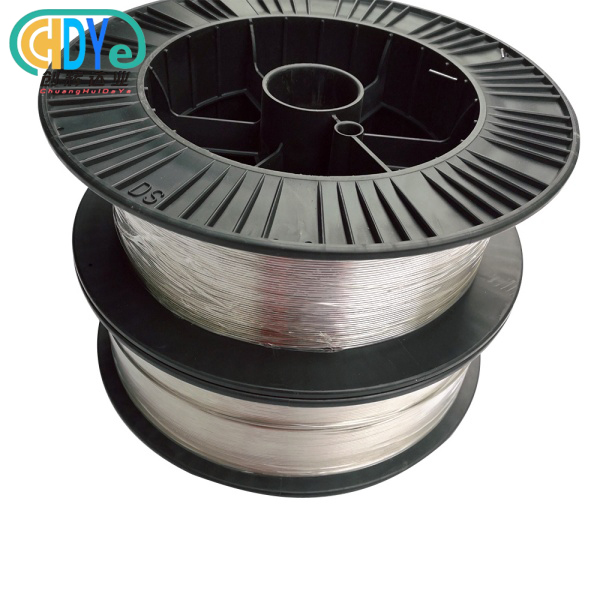

titanium wire for anodizing

2. Diameter 0.2-7mm

3. Excellent corrosion resistance

4. Suitable for anodizing

5. Lightweight and strong

6. Chemical and industrial use

Product Introduction

When you need reliable and high-performance materials for your anodizing projects, titanium wire for anodizing delivers exceptional results. Our premium-grade titanium wire combines superior corrosion resistance with excellent electrical conductivity, making it the perfect choice for electrochemical applications. With diameters ranging from 0.1mm to 5mm, our lightweight yet strong titanium wire ensures consistent performance in demanding industrial environments. Whether you're working on chemical processing, electronics manufacturing, or specialized coating applications, this versatile material provides the durability and reliability your projects demand.

Key Features and Benefits

Our titanium wire offers outstanding advantages for your anodizing operations:

Superior Corrosion Resistance: Withstands aggressive chemical environments and acidic solutions without degradation

Excellent Electrical Conductivity: Ensures efficient current flow during anodizing processes

Lightweight Design: 40% lighter than steel while maintaining superior strength

Biocompatible Properties: Safe for medical and food-grade applications

Temperature Stability: Performs consistently across wide temperature ranges

Long Service Life: Reduces replacement costs and maintenance downtime

Technical Specifications

|

Grade |

Gr1, Gr2, Gr4, Gr5, Gr23 |

|

Standard |

GB/T13810-2017、ASTM F67、ASTM F136 |

|

Diameter(mm) |

0.2~7.0mm |

|

size |

straight wire, in coil, in spool |

|

Condition |

Annealed (M) |

|

Surface treatment |

Bright surface, pickling |

| Property | Value | Unit |

|---|---|---|

| Diameter Range | 0.1 - 5.0 | mm |

| Tensile Strength | 240-550 | MPa |

| Density | 4.51 | g/cm³ |

| Melting Point | 1668 | °C |

| Electrical Resistivity | 42 | µΩ·cm |

| Thermal Conductivity | 17 | W/m·K |

| Elastic Modulus | 114 | GPa |

| Elongation | 15-24 | % |

Available Grades and Materials

We offer two primary grades to meet your specific requirements:

Grade 2 (Commercially Pure): Ideal for general anodizing applications requiring excellent corrosion resistance and formability. This grade provides optimal balance of strength and ductility.

Grade 5 (Ti-6Al-4V): Perfect for high-strength applications where enhanced mechanical properties are essential. Contains 6% aluminum and 4% vanadium for superior performance.

Manufacturing Process

Our advanced manufacturing process ensures consistent quality:

- Raw Material Selection: We source high-purity titanium ingots from certified suppliers

- Wire Drawing: Precision drawing through diamond dies creates uniform diameter

- Heat Treatment: Controlled annealing optimizes mechanical properties

- Surface Treatment: Clean, oxide-free surface preparation

- Quality Testing: Comprehensive inspection ensures specification compliance

- Final Packaging: Protective packaging prevents contamination during transport

|

|

|

|

|

|

|

|

Applications and Industries

Your titanium wire for anodizing serves diverse industrial applications:

Electroplating Industry: Anodes for precious metal plating and hard chrome applications

Chemical Processing: Equipment components in corrosive environments

Electronics Manufacturing: Circuit board processing and semiconductor applications

Medical Device Production: Biocompatible components requiring surface treatments

Aerospace Components: Lightweight parts with enhanced surface properties

Jewelry Manufacturing: Decorative anodizing for color variations

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional control for consistent performance:

- Diameter Tolerance: ±0.02mm for diameters up to 1mm

- Diameter Tolerance: ±0.05mm for diameters above 1mm

- Straightness: 0.5mm per meter maximum deviation

- Surface Finish: Ra 0.8µm or better

- Length Options: Custom lengths up to 1000m continuous

Product Features in Detail

Enhanced Conductivity: Our wire features optimized grain structure for improved electrical performance during anodizing processes.

Uniform Surface: Precision manufacturing ensures consistent surface quality, eliminating hot spots and ensuring even current distribution.

Flexible Configuration: Available in straight lengths or spooled configurations to match your equipment requirements.

Chemical Purity: 99.6% minimum titanium content ensures predictable anodizing behavior and consistent results.

Quality Assurance and Testing

Every batch undergoes comprehensive testing:

- Chemical Composition Analysis: Spectroscopic verification of alloy content

- Mechanical Property Testing: Tensile strength and elongation verification

- Dimensional Inspection: Precision measurement of diameter and straightness

- Surface Quality Assessment: Visual and microscopic examination

- Electrical Testing: Conductivity verification for anodizing performance

OEM & Customization Services

We understand your unique requirements. Our customization services include:

- Custom diameter specifications

- Special length requirements

- Modified surface treatments

- Packaging modifications

- Technical consultation and support

- Application-specific testing

Packaging and Shipping

Your products arrive in perfect condition through our protective packaging system:

Primary Packaging: Individual wire protection with foam wrapping

Secondary Packaging: Moisture-resistant sealed containers

Shipping Containers: Sturdy plywood cases for international transport

Documentation: Complete certificates of analysis and handling instructions

Standard delivery times range from 2-4 weeks depending on specifications and quantity.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of experience in rare metal processing, we deliver unmatched expertise:

- Industry Leadership: Located in China's "Titanium Capital" with access to premium raw materials

- Global Reach: Successfully serving customers in 50+ countries worldwide

- Quality Focus: Rigorous quality control ensures consistent product performance

- Technical Support: Expert guidance for your specific anodizing applications

- Competitive Pricing: Direct manufacturer pricing with no intermediary markups

|

|

|

|

|

|

Feedback from customers

|

|

FAQs

Q: What diameter is best for my anodizing application?

A: Diameter selection depends on current density requirements. Our technical team can recommend optimal sizing based on your specific process parameters.

Q: Can I get samples before placing a large order?

A: Yes, we provide samples for testing and evaluation. Contact us to discuss your requirements.

Q: What's the minimum order quantity?

A: Minimum orders vary by diameter and grade. Contact us for specific quantity requirements.

Q: Do you provide technical support for anodizing processes?

A: Absolutely. Our experienced team offers comprehensive technical consultation for optimal titanium wire for anodizing performance.

Contact Us

Ready to enhance your anodizing operations? Our team is here to help you select the perfect solution for your needs.

Email: info@chdymetal.com

Contact us today to discuss your requirements and receive a customized quote. Let our decades of expertise in rare metals help you achieve superior results in your anodizing applications.

Learn about our latest products and discounts through SMS or email