- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

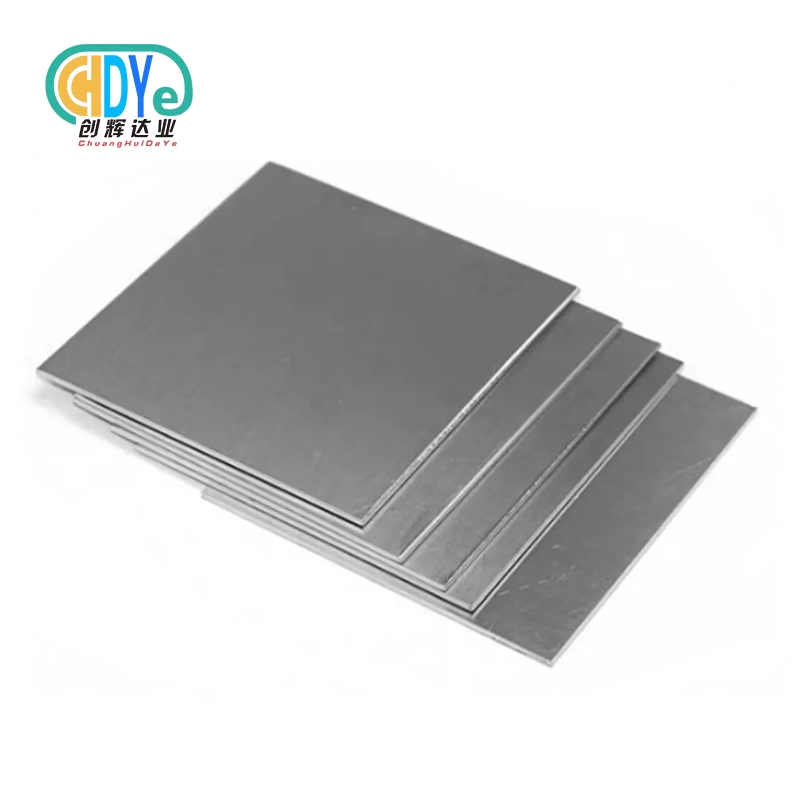

pure niobium plate

2. Thickness: 0.5–50 mm

3. Width: up to 1000 mm

4. Length: up to 3000 mm

5. Density: 8.57 g/cm³

6. Tensile strength: 200–350 MPa

7. Applications: Aerospace, chemical

When you need exceptional corrosion resistance and high-temperature performance, our delivers unmatched reliability. As a leading manufacturer with over 30 years of experience in rare metals, Shaanxi Chuanghui Daye Metal Material Co., Ltd. provides premium-grade niobium plates that meet your most demanding applications. Our plates offer superior mechanical properties, excellent workability, and outstanding chemical resistance for aerospace, chemical processing, and advanced manufacturing industries.

Key Features and Benefits

Our niobium plates stand out for their remarkable properties. You'll benefit from exceptional corrosion resistance that outperforms many other metals in harsh environments. The plates maintain structural integrity at elevated temperatures while offering excellent ductility for forming operations.

The biocompatible nature makes these plates perfect for medical applications. You can rely on their stable performance in acidic conditions and their resistance to most chemicals at room temperature.

Technical Specifications

|

Product Name |

Pure Niobium plate |

|

Material |

Pure niobium and niobium alloy |

|

Dimension |

0.1-10mm |

|

Grade |

R04200.R04210 |

|

Characteristic |

Melting point : 2468℃ Boiling point : 4744℃ |

|

Application |

Widely used in chemical, electronics, aviation and aerospace fields |

|

Product Features |

Excellent Corrosion Resistance Good resistance to effect of heat |

|

Packing |

Foam material inside, wooden box outside |

|

Payment terms |

30% TT in advance, 70% balance before shipment |

|

Delivery time |

stock size within 1-5days, production time 15 working days |

|

Sample |

Sample order are supported |

Chemical composition

|

Material |

Main elements(%) |

Impurities (Maximum %) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

RO4200 |

Remainder |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.07 |

0.015 |

0.0040 |

0.0015 |

0.003 |

|

RO4210 |

Remainder |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.10 |

0.02 |

0.01 |

0.0015 |

0.01 |

Mechanical Properties

|

Grade |

Tensile strength psi(MPa), ≥ |

Yield strength δ0.2, psi (MPa),≥ |

Elongation in 1"/2" gage length, %, ≥ |

|

|

>=0.010 |

<0.010 |

|||

|

RO4200 RO4210 |

18000 (125) |

12000 (85) |

25 |

20 |

Available Grades and Materials

We offer high-purity niobium plates with minimum 99.9% purity. Our standard grades include:

- Commercial grade (99.9% min)

- High-purity grade (99.95% min)

- Ultra-high purity grade (99.99% min)

Each grade undergoes strict quality control to ensure consistent properties and performance in your applications.

Manufacturing Process

Our manufacturing process begins with high-quality niobium feedstock. We use vacuum melting techniques to maintain purity levels. The ingots undergo controlled rolling processes to achieve desired thickness and surface finish.

Heat treatment follows to optimize mechanical properties. Final inspection ensures dimensional accuracy and surface quality before packaging.

|

|

|

|

|

|

|

|

Applications and Industries

Aerospace Industry: Heat shields, rocket nozzles, and high-temperature components benefit from niobium's thermal properties.

Chemical Processing: Reaction vessels, heat exchangers, and piping systems utilize the excellent corrosion resistance.

Electronics: Capacitor applications and superconducting devices rely on niobium's electrical properties.

Medical Devices: Implants and surgical instruments take advantage of biocompatibility.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard thickness tolerance: ±0.05mm for plates under 5mm, ±0.1mm for thicker plates.

Width tolerance: ±2mm for widths up to 500mm, ±5mm for larger widths.

Length tolerance: ±5mm for standard lengths.

Custom dimensions available upon request to meet your specific requirements.

Quality Assurance and Testing

Every batch undergoes comprehensive testing including:

- Chemical composition analysis

- Mechanical property testing

- Dimensional inspection

- Surface quality assessment

- Non-destructive testing when required

Our quality management system ensures traceability from raw materials to final products.

|

|

|

OEM & Customization Services

We provide customized solutions for your specific needs. Our engineering team works with you to develop plates matching your exact specifications.

Services include:

- Custom alloy compositions

- Specialized surface treatments

- Precision machining

- Technical consultation

Packaging and Shipping

Careful packaging protects your niobium plates during transit. We use protective films and cushioning materials to prevent surface damage.

Standard packaging includes:

- Individual protective wrapping

- Wooden crates for larger quantities

- Moisture protection

- Clear identification labels

|

|

|

Why Choose Us

With over three decades in rare metals, we understand your requirements. Our location in China's "Titanium Capital" provides access to advanced processing facilities and skilled workforce.

You benefit from:

- Competitive pricing

- On-time delivery

- Technical support

- Global shipping to 50+ countries

- Consistent quality standards

|

|

|

|

|

|

FAQs

Q: What makes your pure niobium plate superior?

A: Our plates feature >99.9% purity with consistent mechanical properties and excellent surface finish.

Q: Can you provide custom dimensions?

A: Yes, we offer customization services for thickness, width, and length based on your specifications.

Q: What industries commonly use niobium plates?

A: Aerospace, chemical processing, electronics, and medical device industries are primary users.

Q: How do you ensure quality?

A: We conduct comprehensive testing including chemical analysis, mechanical testing, and dimensional inspection.

Contact Us

Ready to discuss your niobium plate requirements? Our technical team stands ready to help you select the right grade and specifications for your application.

Contact us today for quotes, technical specifications, or any questions about our products. We look forward to becoming your trusted partner for high-quality rare metal solutions.

E-mail: info@chdymetal.com

Mob./what'sapp: 86-18049386902

Learn about our latest products and discounts through SMS or email