- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

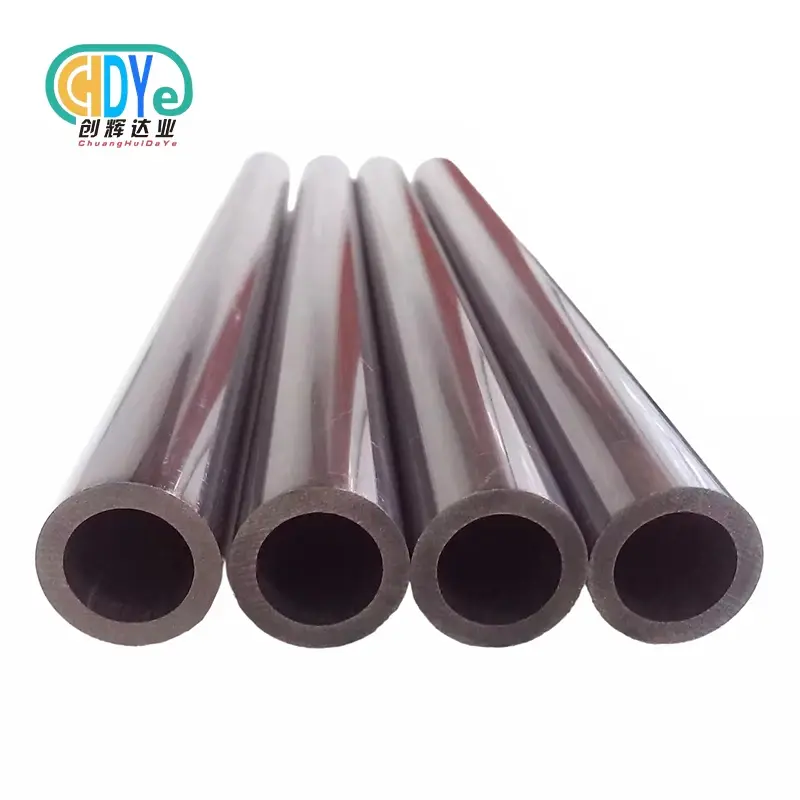

Tungsten Alloy Tube

Product Introduction

The Tungsten Alloy Tube from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a premium component made from high-quality tungsten alloys, designed to withstand extreme temperatures, corrosive environments, and mechanical stress. These tubes provide exceptional thermal conductivity, high strength, and chemical inertness, making them suitable for demanding industrial, scientific, and aerospace applications.

With a carefully engineered composition, the tube combines the advantages of tungsten’s high melting point with enhanced mechanical performance offered by alloying elements. The Tungsten Alloy Pipe ensures dimensional stability under thermal cycling and maintains structural integrity during prolonged exposure to harsh conditions. Manufactured to meet ASTM, AMS, ISO, and GB standards, the tube is suitable for both standard applications and highly customized industrial solutions.

Tungsten copper alloy tube is an alloy tube made of high-purity tungsten powder and high-purity copper powder through powder metallurgy method. The manufacturing process includes processes such as static pressure forming, high-temperature sintering, and copper infiltration

|

Product name |

Tungsten alloy tube |

|

Model Number |

Tungsten copper |

|

Shape |

Seamless tube |

|

Material |

tungsten-copper |

|

Chemical Composition |

wcu,cuw |

|

Surface |

Grinding Polished,ground |

|

Cu content |

10%-50%copper |

|

Density |

16.5-18.5 |

|

Feature |

high resistance temperature |

|

Certificate |

ISO9001:2015 |

|

Appearance |

copper metal,tungsten metal,gold metal |

Characteristics

1. High strength: Tungsten alloy pipes have a strength 5-10 times higher than steel, while also possessing good toughness and plasticity.

2. High wear resistance: Tungsten alloy pipes exhibit excellent wear resistance in harsh environments such as high speed, high temperature, and high pressure.

3. High temperature corrosion resistance: Tungsten alloy pipes can be used stably for a long time in corrosive environments such as high temperature, strong acid, and strong alkali.

4. Good thermal conductivity: Tungsten alloy pipes have good thermal conductivity and are suitable as materials for high-temperature heat exchangers.

5. High density: The density of tungsten alloy pipe is 18.5g/cm ³, which is more than twice the density of steel, making it excellent in radiation shielding.

6. High melting point: The melting point of tungsten is as high as 3410 ℃, making tungsten alloy pipe perform well in high temperature environments.

7. Easy to process: Tungsten alloy has good ductility and can be processed in various ways.

8. Environmental Protection: Tungsten alloy is non-toxic and pollution-free, gradually replacing harmful materials such as lead.

Application Advantages

1. Electrical Discharge Machining (EDM) Electrodes: Tungsten-copper tubes are widely used in EDM due to their high electrical erosion rate, low wear rate, and precise electrode shapes, making them ideal for applications such as die-sinking EDM.

2. High-Voltage Vacuum Discharge Tubes: In high-voltage vacuum discharge tubes, tungsten-copper tubes serve as contact materials,providing necessary conditions for stable tube operation with their high erosion resistance, high toughness, and good electrical and thermal conductivity.

3. Military High-Temperature Materials: Tungsten-copper tubes also find extensive application in military high-temperature materials, such as military nozzles, where their high hardness, strength, and resistance to softening at high temperatures make them the preferred choice.

4. Other Fields: Additionally, tungsten-copper tubes are widely utilized across industries like aerospace, aviation, electronics,

electricity, metallurgy, machinery, and sports equipment, serving as components and elements.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Raw material preparation: High purity tungsten and its alloys are selected as raw materials, and processed into blanks through multiple processes such as melting, forging, and extrusion.

Hot processing: Heat processing the blank, including hot rolling, hot drawing, hot extrusion and other processes, to form the required size and shape.

Cold processing: Cold processing of tungsten alloy pipes after hot processing, such as cold rolling, cold drawing, cold extrusion, etc., to improve their accuracy and surface quality.

Heat treatment: Heat treatment is performed on tungsten alloy pipes after cold processing to eliminate internal stress and improve their performance.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is critical for the reliable performance of these components:

- Chemical Composition Testing: Confirms tungsten alloy purity and proper element ratios.

- Dimensional Accuracy Verification: Ensures tubes meet precise internal and external diameter tolerances.

- Mechanical and Thermal Performance Testing: Evaluates structural stability under extreme heat and stress.

- Surface Inspection: Detects micro-cracks, defects, or surface irregularities.

- Traceability & Documentation: Each tube is labeled with batch numbers and specifications for quality tracking.

These steps ensure that every Tungsten Alloy Tube meets international quality and safety standards for industrial and scientific applications.

R&D and Customization

Shaanxi Chuanghui Daye offers dedicated research and development, along with full customization for Tungsten Alloy Tube:

- Custom Dimensions & Wall Thickness: Tailored to fit specific machinery or experimental setups.

- Prototype & Small-Batch Production: Supports R&D projects or pilot production runs.

- Material Selection Guidance: Expert recommendations on alloy composition, thermal management, and process optimization.

- Design Enhancements: Improved thermal conductivity, mechanical strength, and corrosion resistance based on client requirements.

These services allow clients to receive components precisely suited to their industrial or research needs.

Packaging & Global Logistics

To ensure safe delivery, all tubes are carefully packaged for international transport:

- Wrapped in vacuum or anti-rust films to prevent oxidation.

- Foam padding and reinforced wooden crates provide protection against impact.

- Clear labeling with specifications, batch numbers, and handling instructions.

- Reliable shipping options via air, sea, or land, reaching over 50 countries including the USA, Germany, France, South Korea, and Singapore.

This ensures that the Tungsten Alloy Tube reaches clients in pristine condition and ready for use.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Chuanghui Daye offers comprehensive OEM and customization support for Tungsten Alloy Tube:

- Full customization of tube diameters, wall thicknesses, and lengths.

- Small-batch or prototype production for testing and development.

- Technical consultation for material selection, thermal optimization, and performance enhancement.

- After-sales support to ensure continued performance and reliability in client operations.

Clients benefit from tailored solutions that integrate seamlessly into high-performance industrial and scientific applications.

Inspection Process

Every Tungsten Alloy Tube undergoes meticulous inspection procedures:

- Material Verification: Confirms high-purity tungsten and correct alloy composition.

- Dimensional Accuracy Testing: Ensures the tube meets precise tolerances.

- Thermal and Mechanical Testing: Assesses performance under extreme conditions.

- Surface Inspection: Identifies cracks, roughness, or defects.

- Final Review and Packaging: Ensures readiness for global shipping and operational use.

This rigorous inspection guarantees consistent, high-quality tubes suitable for the most demanding applications.

Why Choose Us

Shaanxi Chuanghui Daye is a leading supplier of tungsten and rare metal products:

- Over 30 years of expertise in non-ferrous and refractory metals.

- ISO 9001:2015 certified quality management system.

- Advanced production capabilities including electron beam furnaces, CNC lathes, and precision rolling.

- Exported to more than 50 countries with an excellent reputation in the global market.

- Comprehensive OEM/ODM services and technical support.

- Commitment to on-time delivery, competitive pricing, and consistent product quality.

Clients can trust that every Tungsten Alloy Tube from Chuanghui Daye meets stringent industrial and scientific standards.

|

|

|

|

|

|

FAQs

Q1: What material is used in the tubes?

A1: The tubes are made from high-purity tungsten alloys for excellent thermal, mechanical, and chemical performance.

Q2: Can I request custom dimensions or wall thicknesses?

A2: Yes, full customization is available to meet specific industrial or research requirements.

Q3: Which industries commonly use these tubes?

A3: Electronics, semiconductors, aerospace, metallurgy, energy engineering, and research laboratories.

Q4: How are the tubes packaged for shipping?

A4: Tubes are vacuum-sealed, cushioned with foam, and packed in reinforced wooden crates to prevent damage.

Q5: Do you provide technical consultation?

A5: Yes, expert guidance is available for material selection, thermal management, and processing optimization.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email