- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Custom Tantalum Tube and Pipe Fabrication Services

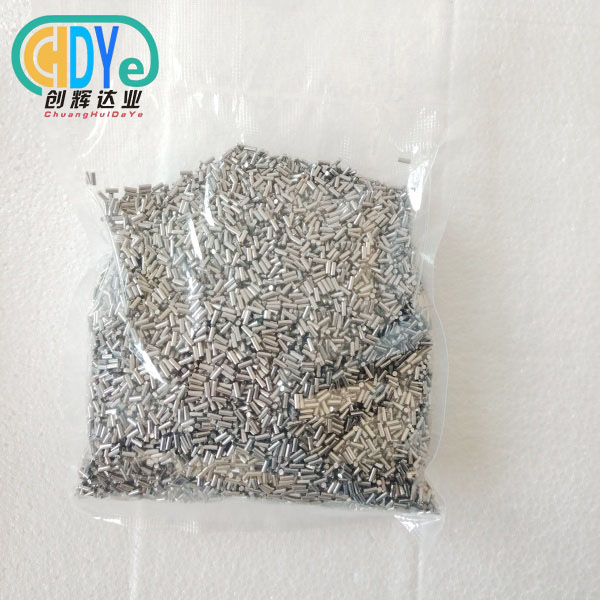

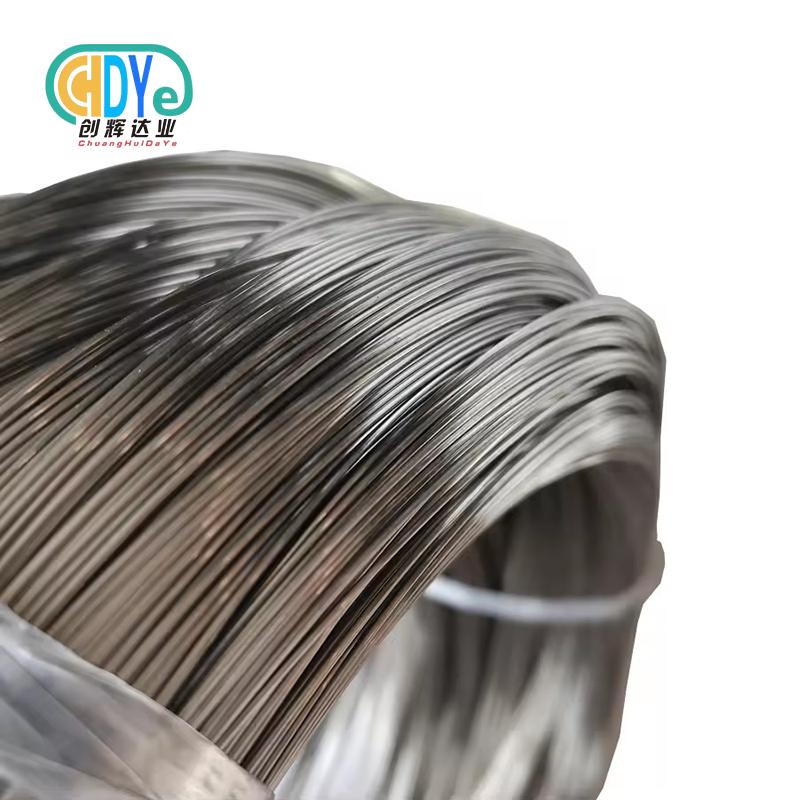

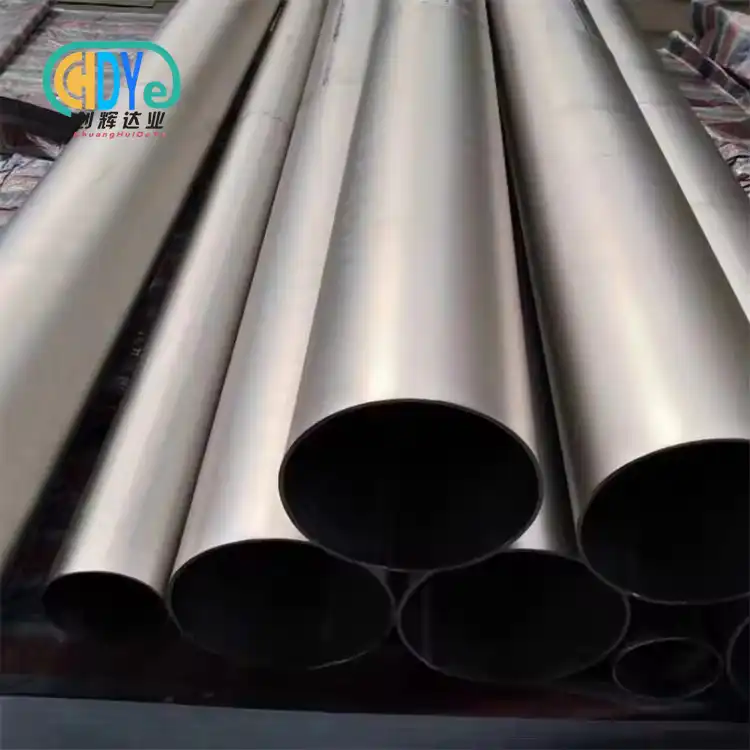

Custom creation administrations for tantalum tubes and channels are accessible for businesses that require high-temperature execution and amazing erosion resistance. As part of these creation administrations, consistent and welded tantalum tubing is made to meet ASTM B521 guidelines. This gives producers correct control over the measurements and way better fabric properties. Numerous distinctive areas, like chemical handling, semiconductor fabrication, and aviation, require custom tantalum tube and pipe arrangements to address particular working issues that can't be unraveled with standard materials.

Understanding Tantalum Tubes and Pipes: Properties, Uses, and Specifications

Tantalum is one of the most astounding hard-headed metals utilized in industry. It has uncommon qualities that make it essential for the most important occupations. Tantalum tubing has uncommon properties due to the way its molecules are orchestrated. This makes it exceptionally safe to chemical assaults and steady at temperatures over 2996°C. To make these tubes, you need to know a parcel approximately progressed metalworking methods that can turn crude tantalum ingots into accurately outlined parts.

Material Properties and Performance Characteristics

Tantalum is exceptionally chemically inert. Most acids, such as hydrochloric corrosive, sulfuric corrosive, nitric corrosive, and water regia, have nearly no impact on it at temperatures up to 150°C. Since it can handle soluble situations and natural solvents, tantalum tubing is ideal for applications where fabric breakdown may hurt the handle or make the result less pure. The metal can work in high-temperature circumstances since it has a high softening point and great thermal conductivity. Its ductility, too, lets it be utilized for complex forming assignments like profound drawing and exact machining.

Because it is biocompatible, tantalum is exceptionally valuable in the generation of restorative gadgets where implantable parts need to securely interface with human tissue. Analysts have found that the surface properties of tantalum offer assistance in bone development in orthopedic applications. This leads to superior quiet results in joint substitution methods.

Manufacturing Processes and Quality Standards

Present-day strategies for making tantalum tubes and pipes are exceptionally complex, so they can have the correct measurements and smooth surfaces required for vital applications. The handle begins with high-purity tantalum ingots that are at slightest 99.95% tantalum. These are softened with an electron pillar to get freed of any pollutions and make the grain structure normal. After that, the material's microstructure is created through hot manufacturing and exact rolling, whereas its measurements are kept accurate.

When making consistent tubes, extraordinary expulsion and drawing strategies are freed of the requirement for fortified joints, making the tubes stronger and more resistant to erosion. Programmed combination welding without filler metals is utilized to make welded tubing. When done accurately, this makes joints that fit the properties of the base fabric. Both ways of making things have to meet the necessities set by ASTM B521, which makes it beyond any doubt that the quality and execution are the same from one generation clump to the following.

Industrial Applications and Performance Requirements

Chemical processing companies use tantalum tubing in places where harsh chemicals would quickly break down other materials. Tantalum's ability to keep its surface integrity over long periods of time makes it useful for heat exchanges, reaction vessels, and distillation columns. For important process tools in the semiconductor industry, tantalum's purity and ability to work in a vacuum are very important. Even a small amount of contamination could lower product yields.

Comparing Tantalum Tubes and Pipes with Alternatives: Making Informed Choices

The choice of material has a big effect on how well a system works, how much it costs to maintain, and how reliable it is in demanding industry settings. When procurement professionals know the pros and cons of different materials, they can make choices that are best for both technical performance and economic value.

Performance Comparison with Common Alternatives

Stainless steel grades that are widely used in industry don't rust in most situations, but they quickly rust when they come into contact with reducing acids or high temperatures. In some chemical conditions, the chromium oxide layer that protects stainless steel becomes unstable. This can cause localized corrosion and failure before its time. In these same conditions, tantalum keeps its protective shell, so it works reliably over time.

Titanium is useful for aerospace and marine uses because it is strong for its weight and doesn't rust in oxidizing environments. Tantalum, on the other hand, stays steady in certain situations while titanium becomes weak from hydrogen embrittlement and stress corrosion cracking. Because tantalum is more chemically neutral than other metals, it can be used in places that use reducing acids, high-purity chemicals, or extreme temperature cycling.

Cost-Benefit Analysis and Total Ownership Considerations

Tantalum tubing costs more to buy at first than other materials, but in serious situations, the total cost of ownership often makes it worth it. Longer service life, less maintenance, and no more unplanned downtime all add up to big operational savings over the lifetime of the system. Tantalum's dependability makes up for its higher cost in industries that work with high-value chemicals or have strict purity standards.

When procurement teams look at different materials, they should think about the costs that come with premature failure, such as lost production time, emergency fixes, and the chance that the product will become contaminated. When these factors are properly looked at, the very high longevity of tantalum tubing often leads to lower total costs.

Custom Tantalum Tube and Pipe Fabrication for B2B Procurement Needs

Industrial uses have specific needs when it comes to size, strength, and finish. Custom fabrication services can meet those needs. These services cover the whole production process, from the first design consultation to the final delivery. This makes sure that customers get goods that are perfectly suited to their needs.

Comprehensive Design and Engineering Support

Professional fabrication services start with a thorough technical meeting to find out exactly what the application needs, how it will be used, and what kind of performance is expected. Customers and engineering teams work together to find the best tube shape, wall thickness, and surface finish for efficiency and cost. Computer-aided design tools make it possible to make quick prototypes and check the design before going ahead with full-scale production.

Tantalum tubes and pipes come in several different grades, such as R05200 (unalloyed tantalum), R05400 (powder metallurgy tantalum), and tantalum-tungsten alloys that have better mechanical qualities. Depending on the needs of the application, each grade has its own benefits. Professional advice is available to make sure that the best material is chosen for each job.

Advanced Manufacturing Capabilities

Modern factories use precise tools like electron beam furnaces, multi-stage drawing machines, and computer-controlled machining centers to make sure that the tolerances needed for important uses are met. Quality control systems keep an eye on every step of the production process, from inspecting the raw materials as they come in to checking the end dimensions and surface quality.

Custom fabrication includes more than just standard tube geometries. It can also include complicated shapes, multiple bore configurations, and integrated parts that make assembly easier and lower the number of possible leak points. With today's advanced welding methods, tantalum parts can be joined together to make complex assemblies that keep the material's purity and ability to fight corrosion.

Flexible Production and Delivery Options

For research and development projects, modern fabrication services can make both small prototypes and big production runs for business use. Flexible scheduling and quick production help meet tight project deadlines while keeping high-quality standards. With the right paperwork and packing, international shipping experts make sure that valuable tantalum parts get to customers around the world safely.

Trustworthy Tantalum Tube and Pipe Suppliers: Ensuring Quality and Reliability

Choosing a supplier is a big choice that affects the quality of the product, the reliability of delivery, and the success of the partnership in the long run. When looking at possible suppliers, you need to carefully consider their technical skills, quality processes, and dedication to customer service.

Quality Management and Certification Standards

Although ISO 9001:2015 certification is a good way to make sure that a quality management system is being used, some applications may need other certifications that are specific to the business. Suppliers to the nuclear, medical device, or aircraft industries often have special certifications that show they meet the quality standards of those industries.

Material certificates, dimensional inspection reports, and traceability records that connect finished goods to their raw material sources are all parts of complete quality paperwork. Digital quality systems that give customers real-time access to inspection data and output status information are kept up to date by advanced suppliers.

Manufacturing Capabilities and Technical Expertise

Shaanxi Chuanghui Daye Metal Fabric Co., Ltd. has the specialized know-how and generation abilities to make tantalum tubes that are utilized in extreme circumstances. Our plant is in Baoji, China, which is known as the "Titanium Capital." It has an incredible framework and is led by gifted specialists who have decades of experience preparing hard-headed metals. Our wide range of hardware incorporates electron bar heaters, accuracy rolling plants, and advanced machining centers, all of which permit us to make everything in-house.

The originator of the company has worked in the uncommon metals trade for more than 30 years, giving the company the specialized administration it needs to meet the needs of its most complicated clients. Because of this, our group can propose the best arrangements, settle issues in dubious applications, and offer progressive specialized support for the whole lifecycle of a product.

Our "quality-first" state of mind guides continuous endeavors to make things superior, which makes items more dependable and clients more joyful. Progressed testing alternatives incorporate chemical analysis, testing of mechanical properties, and checking measurements with exact metrology instruments that are set to universal measures.

Conclusion

Custom fabrication services for tantalum tubes and pipes are necessary for businesses that need high-performance materials to work in tough conditions. A tantalum tube is essential for uses where regular materials can't provide enough performance or dependability because it doesn't corrode, stays stable at high temperatures, and is biocompatible. To make implementation go smoothly, you need to carefully choose your supplier, make sure you get the right materials, and get ongoing technical help to make sure the system works well and operations run smoothly.

FAQ

Q: What are the primary advantages of tantalum tubing over conventional materials?

A: Tantalum tubing offers superior corrosion resistance to aggressive chemicals, exceptional high-temperature stability, and excellent biocompatibility for medical applications. Unlike stainless steel or other common materials, tantalum maintains its protective properties in reducing acid environments and high-temperature applications where alternative materials would fail rapidly.

Q: What lead times should be expected for custom tantalum tube fabrication?

A: Custom tantalum tube fabrication typically requires 1-2weeks, depending on complexity, quantity, and current production schedules. Simple geometries and standard sizes may be available in shorter timeframes, while complex custom designs or large quantities may require extended lead times. Early consultation with suppliers helps establish realistic delivery schedules for project planning.

Q: How does welded tantalum tubing compare to seamless construction?

A: Seamless tantalum tubing provides maximum strength and corrosion resistance since it contains no welded joints that could become preferential corrosion sites. Welded tubing offers cost advantages for larger diameters and can achieve thinner walls that may not be practical with seamless construction. Properly executed tantalum welds achieve properties similar to the base material when appropriate techniques are employed.

Q: What quality documentation is typically provided with tantalum tube orders?

A: Standard documentation includes material certificates verifying chemical composition and mechanical properties, dimensional inspection reports confirming compliance with specifications, and traceability records linking products to their raw material sources. Additional testing, such as pressure testing, surface roughness measurement, or specialized inspections, can be provided when specified by the customer.

Partner with Chuanghui Daye for Your Tantalum Tube and Pipe Requirements

Shaanxi Chuanghui Daye combines three decades of rare metal expertise with advanced manufacturing capabilities to deliver superior tantalum tube and pipe solutions. Our ISO 9001:2015 certified facility produces custom components meeting ASTM B521 standards while providing competitive factory-direct pricing and reliable global delivery. Contact our technical team at info@chdymetal.com to discuss your specific requirements and discover how our tantalum tube and pipe manufacturer capabilities can support your critical applications.

References

1. Davis, J.R. "Refractory Metals and Alloys: Properties and Applications." ASM International Handbook Series, Vol. 2, 2018.

2. Miller, G.L. "Tantalum and Niobium: Industrial Applications and Processing Technologies." Materials Science Quarterly, Vol. 45, No. 3, 2019.

3. Anderson, P.K. "Corrosion Resistance of Refractory Metals in Chemical Processing Applications." Chemical Engineering Progress, Vol. 118, No. 7, 2020.

4. Thompson, R.M. "ASTM B521 Standards and Quality Control in Tantalum Tube Manufacturing." Journal of Materials Engineering, Vol. 32, No. 4, 2021.

5. Wilson, S.A. "High-Temperature Material Selection for Extreme Environment Applications." Aerospace Materials Review, Vol. 29, No. 2, 2019.

6. Chen, L.H. "Economic Analysis of Refractory Metal Applications in Chemical Processing Industries." Industrial Materials Economics, Vol. 15, No. 6, 2020.

Learn about our latest products and discounts through SMS or email