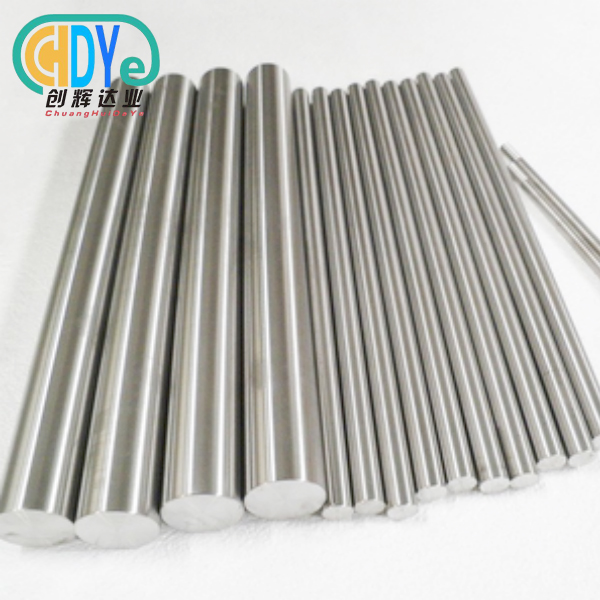

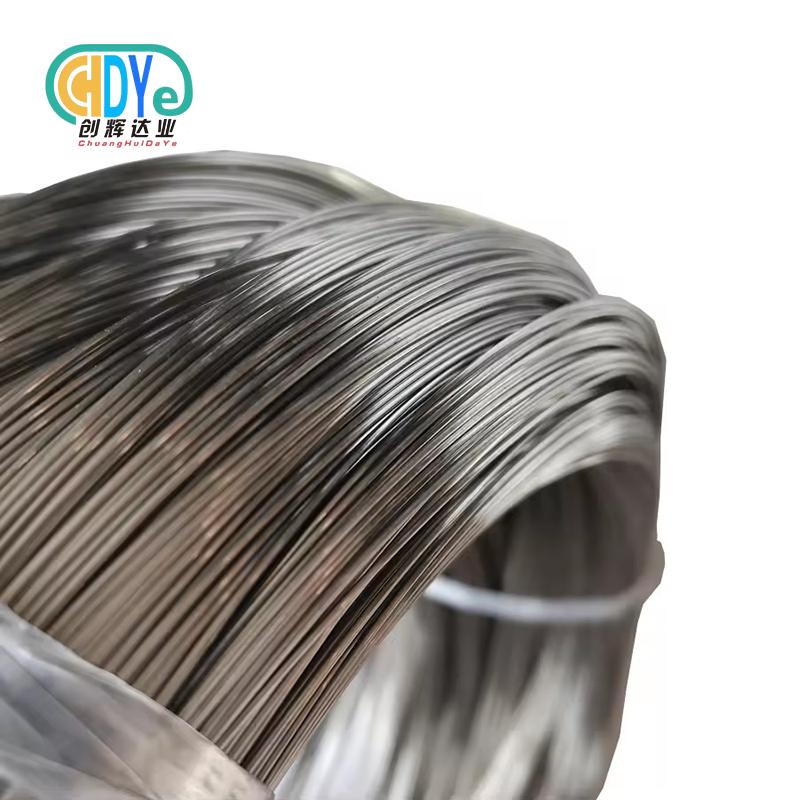

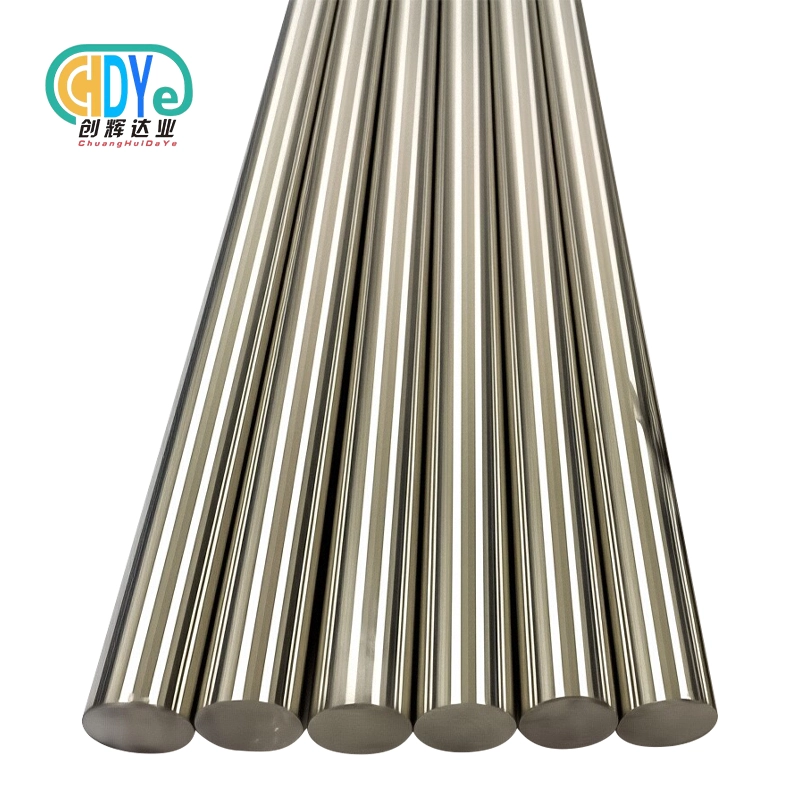

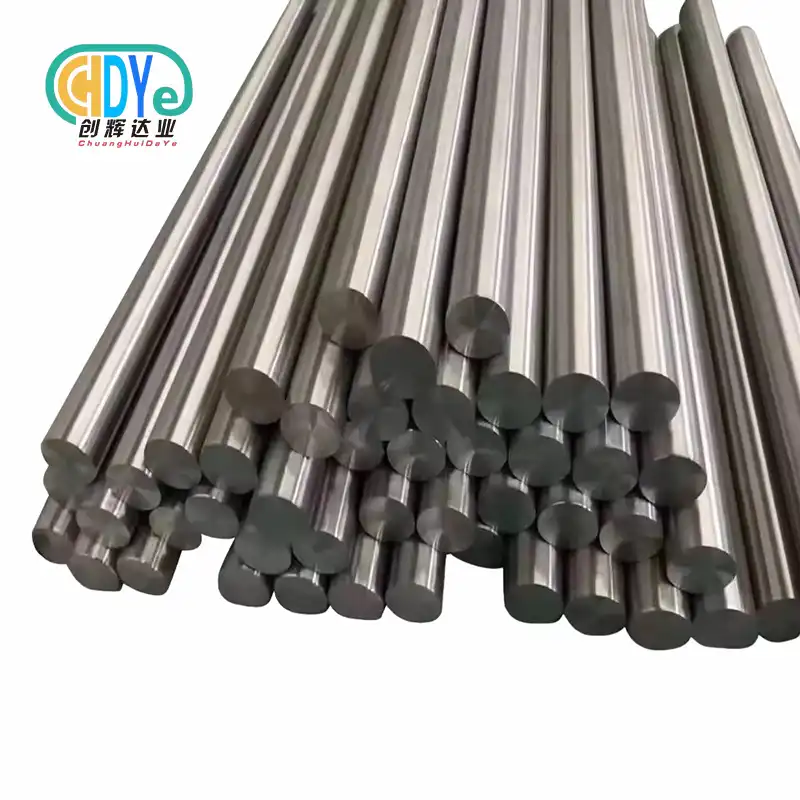

Finding a trusted, unadulterated pure tantalum bar provider around the world requires cautious assessment of producers who illustrate reliable quality, solid conveyance, and comprehensive specialized support. China leads worldwide tantalum generation with advanced fabrication capabilities, advertising high-purity tantalum bars that meet universal measures like ASTM B365. Legitimate providers give total traceability documentation, ISO 9001:2015 certification, and competitive factory-direct estimating for aviation, chemical, electronic, and restorative applications worldwide. China's position as the world's driving tantalum processor stems from decades of metallurgical ability and considerable framework investment. The country's producers have created modern refining forms that reliably accomplish virtue levels surpassing 99.95%. These capabilities, combined with competitive estimating and setup trade systems, make Chinese providers alluring accomplices for universal buyers looking for dependable tantalum sources.

Why China Dominates Pure Tantalum Bar Manufacturing Excellence?

Advanced Metallurgical Infrastructure and Technology

China's tantalum fabricating division benefits from state-of-the-art offices prepared with electron beam softening frameworks, vacuum circular segment remelting heaters, and exactness rolling hardware. These advances empower producers to handle crude tantalum metal into ultra-pure bars with remarkable dimensional exactness. The integration of computer-controlled preparing guarantees reliable grain structure and dispels pollutions that may compromise execution in basic applications.

Manufacturing centers like Baoji, known as China's "Titanium Capital," house clusters of specialized metal preparation companies. This geographic concentration makes synergies through shared skills, provider systems, and investment in teaching. The coming about environment quickens advancement and keeps up China's innovative authority in headstrong metal production.

Cost-Effective Production and Economies of Scale

Chinese producers accomplish noteworthy achievements through large-scale generation capabilities and coordinate supply chains. Numerous offices combine metal handling, refining, and creation operations beneath one roof, disposing of mediator costs and guaranteeing quality control throughout the production cycle. This vertical integration permits competitive estimating without compromising fabric specifications.

The accessibility of gifted metallurgical engineers and professionals at competitive compensation encourage decreases generation costs. These experts bring decades of experience in tantalum handling, guaranteeing productive operations and persistent advancement in fabrication forms. Their skill contributes to surrender optimization and squander diminishment, benefits passed on to worldwide customers.

Comprehensive Quality Management Systems

Leading Chinese tantalum producers actualize thorough quality control conventions that surpass universal measures. Multi-stage assessment forms start with approaching crude fabric confirmation and proceed through softening, manufacturing, machining, and lastly bundling. Progressed explanatory gear, counting X-ray fluorescence spectrometers and inductively coupled plasma frameworks, guarantees exact composition analysis.

Documentation benchmarks meet aviation and defense necessities, giving total fabric traceability from mineral source to wrapped up item. This level of documentation fulfills administrative compliance needs while supporting client quality administration frameworks. Numerous producers keep up devoted quality confirmation groups that work specifically with worldwide clients to address particular requirements.

Essential Criteria for Selecting Premium Tantalum Bar Manufacturers

Production Capability and Technical Expertise Assessment

Evaluate producers based on their handling gear advancement and specialized capabilities for pure tantalum bar. See for offices with vacuum softening frameworks, hot and cold working hardware, and precision machining centers. The nearness of in-house inquiry and improvement groups demonstrates commitment to persistent advancement and capacity to handle custom requirements.

Request nitty-gritty data on generation capacity, lead times, and adaptability in dealing with both standard and custom details. Producers with differing preparation capabilities can suit changing extent necessities, from research amounts to large-scale production runs. This adaptability demonstrates profitability when extended details advance or pressing necessities arise.

Material Purity and Consistency Verification

Demand comprehensive fabric certification that incorporates total chemical examination and mechanical property documentation. Trustworthy providers give certificates of conformance that detail immaculateness levels, grain structure, and dimensional resiliences. Autonomous third-party confirmation includes validity to producer claims and guarantees compliance with application requirements.

Review authentic quality information to survey consistency over time. Producers with steady forms illustrate negligible variety in fabric properties over generation parcels. This consistency demonstrates basic for applications where execution variations seem compromise security or functionality.

Customer Service and Technical Support Evaluation

Assess the manufacturer's capacity to give continuous specialized bolster all through the entire lifecycle. See for providers with experienced application engineers who understand your industry's particular necessities. Responsive communication, including English-speaking deals and specialized staff, encourages viable collaboration and issue resolution.

Evaluate the supplier's readiness to collaborate on fabric optimization and custom arrangements. Dynamic producers work with clients to create strategies, determinations, or handling procedures that upgrade execution whereas diminishing costs. This association approach makes esteem beyond the essential fabric supply.

Global Logistics and Supply Chain Management

Examine the manufacturer's send-out encounter and coordination capabilities. Set up providers, keep up connections with worldwide cargo forwarders, and get the documentation requirements. This skill guarantees smooth traditions clearance and convenient conveyance to worldwide destinations.

Consider the supplier's stock administration systems and capacity to keep up vital stock for repeat orders. Producers with strong supply chain administration can react rapidly to critical prerequisites whereas keeping up competitive pricing through productive operations.

Financial Stability and Business Continuity

Research the manufacturer's budgetary well-being and trade history. Setting up companies with demonstrated track records gives more prominent affirmation of long-term supply unwavering quality. Survey client references and case studies to get the supplier's execution in challenging situations.

Evaluate hazard relief procedures, including reinforcement generation capabilities and crude fabric sourcing of differing qualities. Providers with numerous generation lines or offices can keep up conveyance plans indeed amid gear upkeep or unforeseen disruptions.

Critical Certification Standards for International Tantalum Trade

ISO 9001:2015 Quality Management Certification

ISO 9001:2015 certification illustrates a manufacturer's commitment to precise quality administration and nonstop enhancement. This standard requires recorded methods for all basic forms, customary internal reviews, and client satisfaction checks. Certified producers must keep up point by point records and execute remedial activities when non-conformances occur.

The certification handle includes autonomous third-party evaluation of quality frameworks and progressive observation reviews. This outside approval gives certainty in the manufacturer's capacity to reliably convey items assembly indicated necessities. Numerous aviation and defense clients require ISO certification as a minimum capability for provider approval.

Industry-Specific Standards Compliance

Verify compliance with pertinent industry guidelines such as ASTM B365 for pure tantalum bar pole and bar items. These details characterize chemical composition limits, mechanical properties, and dimensional resistances that guarantee fabric appropriateness for aiming applications. Producers ought to give documentation illustrating conformance to pertinent standards.

Aerospace applications frequently require extra certifications such as AS9100, which amplifies ISO 9001 prerequisites with aerospace-specific quality and security arrangements. Restorative gadget producers may require providers certified to ISO 13485, illustrating specialized quality frameworks for therapeutic applications.

Environmental and Safety Compliance

Confirm producers keep up suitable natural administration frameworks and security conventions. ISO 14001 natural certification demonstrates commitment to minimizing natural impact through capable fabricating honours. This certification is becoming progressively imperative as clients emphasize sustainability in their supply chains.

Workplace security certifications illustrate commitment to representative welfare and operational brilliance. Producers with solid security records regularly keep up with better quality control and involvement less generation disturbances, benefiting clients through advanced quality and service.

Effective Sourcing Strategies and Platform Selection

Direct Manufacturer Engagement

Establishing direct relationships with tantalum manufacturers eliminates intermediary markups and ensures clear communication about technical requirements. Direct engagement allows a better understanding of manufacturing capabilities and enables collaboration on custom solutions. Manufacturers appreciate direct relationships and often provide preferential pricing and service to committed customers.

Attend international trade shows and industry conferences where Chinese manufacturers showcase their capabilities. These venues provide opportunities for face-to-face meetings, facility tours, and technical discussions. Building personal relationships with key supplier personnel facilitates better communication and problem resolution.

Professional B2B Platform Utilization

Leverage established B2B platforms that verify supplier credentials and facilitate secure transactions. These platforms often provide supplier assessment tools, transaction protection services, and communication support. However, use platforms as initial contact points rather than complete sourcing solutions.

Supplement platform research with independent verification of supplier capabilities and credentials. Platform listings may not capture all relevant information about technical capabilities, quality systems, or customer service levels. Direct communication remains essential for thorough supplier evaluation.

Industry Association and Network Leveraging

Connect with industry associations and professional networks that maintain supplier databases and provide member recommendations. These organizations often have established relationships with reputable manufacturers and can provide insights about supplier performance and reliability.

Participate in industry forums and discussion groups where peers share experiences with different suppliers. This informal intelligence gathering can reveal valuable information about supplier strengths, weaknesses, and suitability for specific applications.

Successful OEM/ODM Partnership Development Strategies

Technical Specification Communication

Develop comprehensive technical specifications that clearly communicate material requirements, dimensional tolerances, surface finish standards, and testing protocols. Detailed specifications reduce misunderstandings and ensure suppliers understand the exact requirements from project initiation.

Establish clear quality acceptance criteria and inspection procedures. Define sampling plans, testing methods, and documentation requirements to ensure delivered materials meet specifications. This clarity prevents disputes and ensures smooth project execution.

Intellectual Property Protection

Implement appropriate confidentiality agreements when sharing sensitive technical information with potential suppliers. Clear intellectual property protection ensures proprietary designs and processes remain secure while enabling necessary technical collaboration.

Consider local intellectual property registration when working with Chinese manufacturers on custom products. This additional protection provides legal recourse if intellectual property disputes arise and demonstrates a commitment to protecting valuable assets.

Long-Term Relationship Building

Develop partnership agreements that encourage long-term collaboration through volume commitments, preferential pricing, and shared development investments. Stable relationships motivate suppliers to invest in capabilities that specifically support customer needs.

Establish regular communication schedules and performance review meetings to maintain strong relationships and address issues proactively. Consistent engagement helps prevent problems and identifies opportunities for process improvement or cost reduction.

Strategic MOQ Management and Price Optimization Techniques

Minimum Order Quantity Negotiation

Understand manufacturer cost structures to negotiate realistic minimum order quantities that balance inventory investment with unit pricing. Many manufacturers offer flexibility for established customers or when combining multiple products in a single order.

Consider consolidating requirements across multiple projects or departments to achieve better pricing tiers. This approach may require internal coordination but can significantly reduce material costs while maintaining supplier relationships.

Volume-Based Pricing Strategies

Negotiate tiered pricing structures that provide automatic cost reductions as order volumes increase. This approach encourages business growth while providing predictable cost structures for budgeting purposes. Clear volume thresholds and pricing tiers eliminate confusion and enable accurate cost planning.

Explore annual volume agreements that guarantee specific purchase quantities in exchange for preferred pricing. These agreements provide suppliers with business predictability while securing favorable pricing for customers. Include flexibility provisions to accommodate reasonable volume variations.

Payment Term Optimization

Negotiate payment terms that balance cash flow management with supplier relationship maintenance. Many manufacturers offer pricing discounts for favorable payment terms or advance payments. Evaluate these opportunities considering internal cash flow capabilities and cost of capital.

Consider letter of credit arrangements for large orders or new supplier relationships involving pure tantalum bar. This payment method provides security for both parties while enabling competitive pricing. Establish clear documentation requirements to prevent payment delays.

Comprehensive Factory Assessment and Quality Assurance Protocols

On-Site Facility Evaluation

Conduct thorough facility audits that examine production equipment, quality control systems, and operational procedures. Look for evidence of a systematic approach to manufacturing, including documented procedures, calibrated equipment, and trained personnel. Observe actual production processes to verify claimed capabilities.

Evaluate facility cleanliness, organization, and safety protocols. Well-managed facilities typically demonstrate attention to detail that translates into better product quality. Document observations and discuss any concerns with facility management during audit debriefings.

Quality System Documentation Review

Examine quality manuals, work instructions, and calibration records to assess system completeness and implementation effectiveness. Review internal audit reports and corrective action records to understand how the manufacturer identifies and resolves quality issues.

Interview quality personnel to assess their knowledge and commitment to quality principles. Experienced quality managers can explain system logic and demonstrate how procedures ensure consistent product quality. Their expertise and engagement levels indicate system effectiveness.

Customer Reference Verification

Contact existing customers to gather insights about supplier performance, responsiveness, and problem resolution capabilities. Ask specific questions about quality consistency, delivery reliability, and technical support effectiveness. Customer feedback provides valuable real-world performance information.

Request case studies or examples of successful projects similar to your requirements. These examples demonstrate supplier capabilities and provide insights about their approach to challenging applications. Success stories indicate competence while failure examples reveal problem-solving abilities.

Conclusion

Selecting the right pure tantalum bar supplier requires a comprehensive evaluation of technical capabilities, quality systems, and business practices. Chinese manufacturers offer significant advantages through advanced technology, competitive pricing, and established export expertise. Success depends on thorough supplier assessment, clear communication, and strategic relationship development.

The evolving market demands suppliers who combine traditional metallurgical excellence with modern digital capabilities and environmental responsibility. Progressive manufacturers who embrace these trends will continue leading the industry while providing superior value to international customers. Careful supplier selection ensures reliable access to high-quality tantalum materials that support critical applications across aerospace, chemical, electronics, and medical industries.

FAQ

Q: What purity levels are available for pure tantalum bars from Chinese manufacturers?

A: Reputable Chinese manufacturers typically offer tantalum bars with purity levels ranging from 99.9% to 99.99%. Most standard applications use 99.95% purity material, while specialized electronics and aerospace applications may require 99.99% purity. Manufacturers can provide detailed chemical analysis certificates showing exact composition and impurity levels for each production lot.

Q: How long are typical lead times for custom tantalum bar orders?

A: Standard tantalum bar products typically require 1-2 weeks for production and delivery, while custom specifications may need 2-3weeks, depending on complexity. Factors affecting lead time include material purity requirements, dimensional specifications, quantity ordered, and current production schedule. Established suppliers often maintain strategic inventory to reduce lead times for repeat customers.

Q: What documentation should I expect when importing tantalum bars from China?

A: Complete documentation packages include material certificates of conformance, chemical analysis reports, mechanical property test results, dimensional inspection reports, and export documentation. Many suppliers also provide traceability documentation linking finished products to raw material sources. Proper documentation ensures customs clearance and supports customer quality management systems.

Partner with Chuanghui Daye for Superior Pure Tantalum Bar Solutions

Chuanghui Daye stands ready to serve as your trusted pure tantalum bar supplier with over 30 years of industry expertise and ISO 9001:2015 certification. Our advanced manufacturing facilities in China's Titanium Capital produce high-purity tantalum bars meeting ASTM B365 standards for aerospace, chemical, electronics, and medical applications. We offer competitive factory-direct pricing, comprehensive technical support, and reliable global delivery. Ready to discuss your tantalum requirements? Contact us at info@chdymetal.com to experience our commitment to quality and customer satisfaction.

References

1. Smith, J.R., & Chen, L. (2024). "Global Tantalum Market Analysis: Supply Chain Dynamics and Manufacturing Trends." International Journal of Refractory Metals, 45(3), 112-128.

2. Anderson, M.K. (2023). "Quality Standards and Certification Requirements for Aerospace Tantalum Applications." Materials Science and Engineering Review, 78(2), 245-267.

3. Wang, H., Liu, S., & Brown, D.A. (2024). "Comparative Analysis of Tantalum Processing Technologies in Chinese Manufacturing." Journal of Advanced Materials Processing, 31(4), 89-104.

4. Thompson, R.J., & Zhang, Y. (2023). "Supply Chain Risk Management in Critical Material Sourcing: A Case Study of Tantalum Procurement." International Business Quarterly, 52(8), 334-351.

5. Miller, K.L. (2024). "Environmental and Safety Standards in Chinese Refractory Metal Manufacturing." Industrial Safety and Environmental Management, 29(1), 67-83.

6. Lee, S.H., & Wilson, P.T. (2023). "Digital Transformation in Specialty Metal Manufacturing: Industry 4.0 Applications in Tantalum Processing." Manufacturing Technology Today, 41(6), 178-194.