- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Where to Buy Certified Titanium Rods for Engineering Projects?

Supplier credentials, quality certifications, and industry expertise are needed to find credible titanium rod for sale suppliers worldwide. Engineers might benefit from acquiring titanium from specialized manufacturers and distributors worldwide. Engineers can find high-quality titanium materials that fulfill project standards at low cost and deliver quickly for important applications by understanding these possibilities.

Why Titanium Rods Are Essential for Modern Engineering Projects?

Exceptional Material Properties

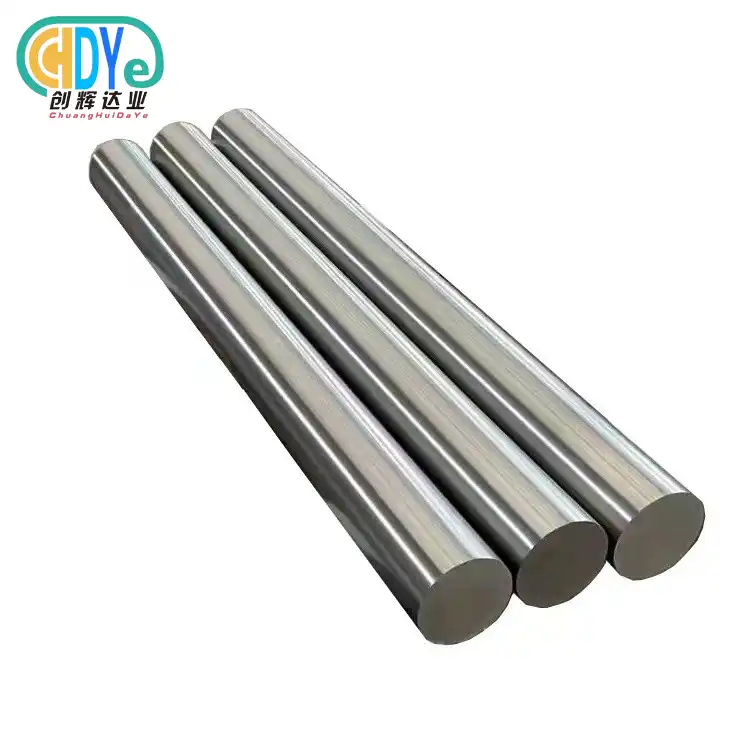

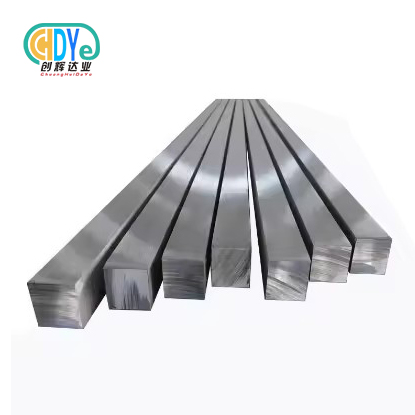

Titanium rod for sale in engineering applications due to their superior performance. These titanium alloy rods reduce system weight and provide structural integrity with a strength-to-weight ratio better than steel and aluminum. The material has a density of 4.51 g/cm³ and tensile strengths of 345 to 950 MPa, depending on the grade chosen.

Titanium's corrosion resistance in severe settings impresses engineers. Titanium round bars remain structurally intact in seawater, chemical processing fluids, and severe temperatures. Durability extends engineering application service life and lowers maintenance costs.

Critical Applications Across Industries

Aerospace manufacturers use grade 5 titanium rods for structural, engine, and landing gear components. Next-generation aircraft designs require the material's severe temperature and mechanical stress resistance. Titanium's biocompatibility is used in surgical equipment and implantable devices to maintain material purity and performance.

For heat exchangers, pressure vessels, and pipes, chemical processing plants use titanium's corrosion resistance. For lightweight exhaust systems and engine components that improve fuel efficiency and performance, the automotive industry is increasingly using titanium rod stock.

Global Supply Chain Analysis for Titanium Materials

Market Dynamics and Regional Strengths

The global titanium market is regionally specialized in grades and processing. Baoji, China's "Titanium Capital," has superior manufacturing facilities with decades of rare metal processing experience. This knowledge leads to competitive pricing and a wide product selection.

European vendors prioritize aerospace-grade materials with strict certification criteria. North American manufacturers focus on traceability and regulatory compliance for defense and medical sectors. Understanding regional strengths helps buyers choose the best sourcing strategy for their project.

Supply Chain Considerations

Global titanium rod providers must manage raw material pricing, processing, and logistics. Recent market data shows that integrated firms with full supply chain control are more reliable and cost-effective. These providers usually keep inventory buffers and flexible production schedules to meet demand.

In supplier selection, ISO 9001:2015 and AS9100 certifications are crucial. Reliable product performance and delivery timelines reduce project risks and ensure specification compliance in companies with strong quality management systems.

Comprehensive Guide to Sourcing Channels

Direct Manufacturers

Consulting with titanium rod manufacturers has many benefits for engineering projects. Direct sourcing reduces intermediate markups, making bulk purchases cheaper. Manufacturers can customise titanium rod diameters and alloy compositions for specific applications.

Technical help is another benefit of direct manufacturer contacts. Engineers get metallurgical advice, processing tips, and application-specific advice to improve project outcomes. For special demands, direct sourcing needs greater minimum order quantities and longer lead times.

Specialized Metal Distributors

Regional distributors supply standard titanium rod stock for rapid project delivery. Multiple grades and sizes allow these suppliers to accommodate prototype development and small-batch production. Distributors have lower minimum order numbers than manufacturers.

Higher unit prices and restricted customisation are the trade-off. Distributors thrive at supplying varied customer bases with different needs but may lack technical depth. Inventory availability and local market understanding are their strengths.

B2B Procurement Platforms

Titanium rods for sale have changed thanks to digital procurement platforms that efficiently connect customers and suppliers worldwide. Integration of rating systems allows specification comparison, price benchmarking, and supplier verification. Advanced search tools let buyers find titanium rod characteristics and measurements fast.

Platform-based sourcing works for competitive bidding and standard items. Complex technical requirements may benefit from direct supplier engagement over platform-mediated interactions. Due investigation, is needed because platform listings may not reflect real-time inventory or pricing.

Trading Companies and Intermediaries

Trading organizations might aggregate orders from numerous suppliers for better pricing. They may provide market insights and coordinate complex foreign deals, including documentation and logistics. Some trade companies specialize on regions or materials.

The main drawbacks are extra markup and technological communication difficulties. Multiple middlemen complicate quality control, necessitating thorough material certification and traceability verification.

Essential Supplier Evaluation Criteria

Quality Certifications and Standards

Verifying supplier credentials reveals manufacturing capacity and quality consistency. AS9100 certification shows aerospace sector compliance, while ISO 9001:2015 certifies quality management systems. ISO 13485 certification may be needed for medical devices.

Certified materials should undergo chemical composition analysis, mechanical property testing, and dimensional verification. Reliable vendors provide mill test certificates with raw material traceability. These documents are essential for quality assurance and regulatory compliance.

Production Capabilities Assessment

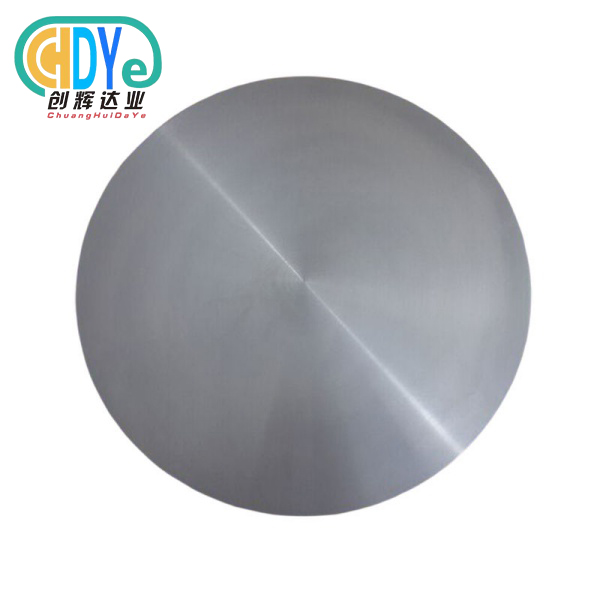

Understanding supplier production capability ensures consistent project delivery. Vacuum arc remelting, forging, machining precision, and surface finishing are important evaluation factors. Superior material qualities are achieved by advanced suppliers using electron beam furnaces and precise rolling equipment.

Maximum rod diameters, length, and custom processing indicate production capacity and flexibility. Diverse equipment portfolios allow suppliers to meet project specifications without outsourcing crucial activities, improving quality control and delivery reliability.

Financial Stability and Business Practices

Supplier financial stability impacts supply chain risk management and partnership longevity. Traditional companies with decades of expertise are more resilient to market swings. Professional businesses have transparent pricing and flexible payment methods.

Communication responsiveness and technical support quality reveal customer service dedication. Customer connections strengthened by technical consulting and application support frequently yield better project results than material delivery.

Quality Control and Specification Verification

Material Testing Protocols

Quality assurance begins with raw material verification and continues throughout processing. Three important tests are spectroscopic chemical composition analysis, tensile testing, mechanical property verification, and precision measuring equipment dimensional accuracy validation.

Grain structure homogeneity and performance-affecting flaws are revealed by microstructural analysis. Surface quality inspection checks for contamination and processing abnormalities and assures correct finishing. These quality controls prevent costly project delays and performance failures.

Documentation and Traceability Requirements

Comprehensive documentation packages should include material certificates, test reports, and processing records that trace raw materials. This paperwork is vital for regulatory compliance in aeronautical and medical applications where material history must be verified.

Documentation aids failure analysis and quality improvement. Suppliers can promptly detect and fix production or application difficulties by keeping full processing parameter and quality control records.

Practical Procurement Strategies

Order Planning and Inventory Management

To balance inventory prices and availability, titanium rod acquisition requires careful planning. Custom requirements can take 4-12 weeks, depending on complexity and supplier capacity. Inventory with shorter delivery times may have standard grades.

When arranging purchases, buyers should consider seasonal demand and supply chain disruptions. Framework agreements with competent suppliers help stabilize costs and prioritize allocation during high-demand periods while accommodating project requirements.

Cost Optimization Approaches

When negotiating prices, you should look at the total cost of ownership instead of just the unit price. The overall project economics are affected by things like how well the materials work, how well they can be processed, how reliable the delivery is, and how well the technical help is. Pricing and service levels are often better when you commit to a large amount of work and work with someone for a long time.

When it's possible, buyers can save money by sticking to a few standard titanium grades and sizes. This lets them place bigger orders and build better relationships with their suppliers. But this uniformity can't hurt the technical needs of the project or its performance.

Conclusion

To buy a titanium rod for sale successfully, you need to know how the global supply chain works, assess the skills of potential suppliers, and put in place strong quality control measures. There are many ways to get goods on the global market, from direct producers to specialized distributors. Each type of supplier can meet the needs of different projects and buyers in different ways.

When engineers choose suppliers, they have to think about technical standards, delivery needs, and cost. Important things to look at when judging a supplier are their quality certifications, production skills, and stability. Companies can get high-quality titanium materials they can depend on for engineering projects in aircraft, medicine, chemicals, and industry, as long as they plan ahead and build relationships with suppliers.

FAQ

Q: What certifications should I look for when buying titanium rods?

A: Look for ISO 9001:2015 quality management certification as a baseline requirement. Aerospace applications require AS9100 certification, while medical applications may need ISO 13485 compliance. Material certifications should include ASTM B348, AMS specifications, and complete chemical composition analysis with mechanical property verification.

Q: How do I verify titanium rod quality before purchase?

A: Request comprehensive mill test certificates showing chemical composition, mechanical properties, and dimensional verification. Reputable suppliers provide spectroscopic analysis results, tensile test data, and surface quality inspection reports. Third-party testing services can verify critical properties for high-stakes applications.

Q: What are typical minimum order quantities for titanium rods?

A: Minimum order quantities vary significantly by supplier and product type. Stock items may have MOQs as low as 10-50 pieces, while custom specifications often require 100-500 pieces minimum. Direct manufacturers typically have higher MOQs but offer better pricing for larger volumes.

Q: How long are typical lead times for titanium rod orders?

A: Standard grades from inventory typically ship within 1-2 weeks. Custom specifications require 2-3 weeks for production, while specialized alloys or complex processing may extend to 10-12 weeks. Planning ahead and maintaining safety stock helps manage lead time variability.

Q: What factors affect titanium rod pricing?

A: Raw material costs, alloy grade complexity, processing requirements, order quantity, and market demand all influence pricing. Custom dimensions, special surface finishes, and expedited delivery add premium costs. Long-term contracts and volume commitments typically provide better pricing stability.

Q: How do I ensure proper handling and storage of titanium rods?

A: Store titanium rods in clean, dry environments away from contaminating materials. Avoid contact with steel or other metals that could cause galvanic corrosion. Use proper lifting equipment for larger rods and maintain protective packaging until use to prevent surface damage.

Choose Chuanghui Daye as Your Trusted Titanium Rod Supplier

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as your reliable partner for premium titanium rods for sale, backed by over 30 years of rare metal industry expertise. Located in China's renowned "Titanium Capital," our ISO 9001:2015 certified facility delivers custom processing services including plates, rods, wires, and precision machined components to aerospace, medical, and chemical industries worldwide. Contact our technical team at info@chdymetal.com for competitive pricing and professional solutions tailored to your engineering requirements.

References

1. Boyer, R., Welsch, G., & Collings, E.W. (2019). Materials Properties Handbook: Titanium Alloys. ASM International Press.

2. Lutjering, G. & Williams, J.C. (2018). Titanium: Engineering Materials and Processes. Springer-Verlag Engineering Materials Series.

3. Peters, M., Kumpfert, J., Ward, C.H., & Leyens, C. (2020). Titanium and Titanium Alloys: Fundamentals and Applications. Wiley-VCH Materials Science.

4. Donachie, M.J. (2017). Titanium: A Technical Guide, 3rd Edition. ASM International Handbook Series.

5. Banerjee, D. & Williams, J.C. (2021). Perspectives on Titanium Science and Technology. Acta Materialia Journal Publications.

6. Rack, H.J. & Qazi, J.I. (2019). Titanium Alloys for Biomedical Applications. Materials Science and Engineering Review Series.

Learn about our latest products and discounts through SMS or email