- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

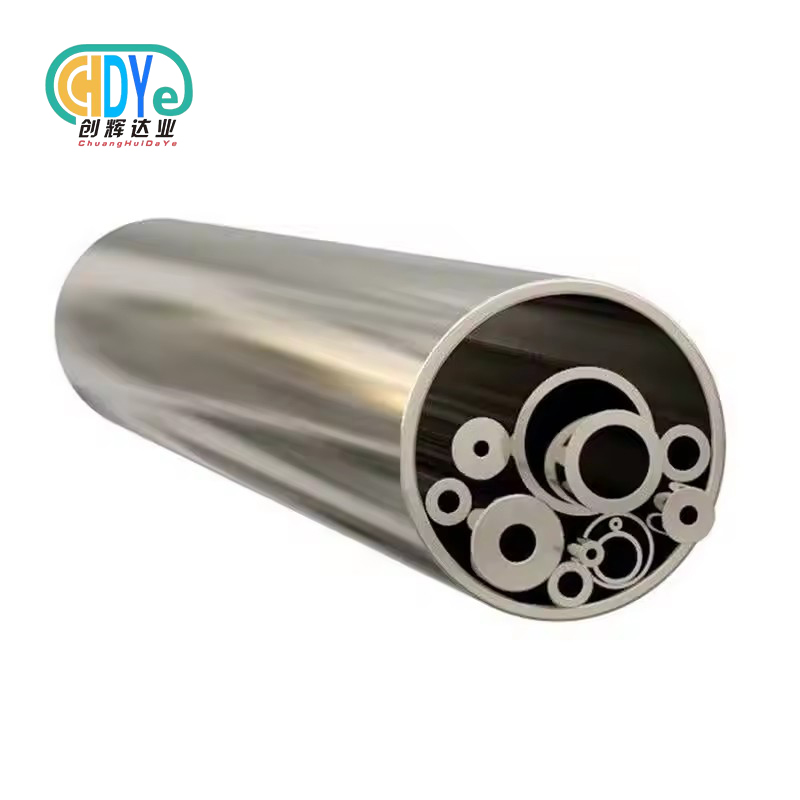

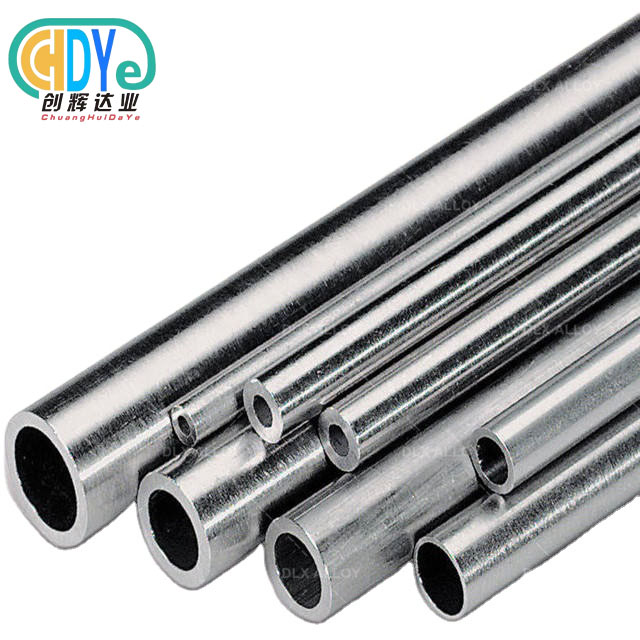

titanium tube for sale

2.Standard: ASTM B338 ASTM B337 B861 B862

3.Dimension:OD10-300xWT0.5-10x L100-18000 MM

4.Condition: annealed

5.Type: seamless and welded

Product Introduction

titanium tube for sale is a seamless and welded tubular product made from commercially pure titanium Grade 2. It is widely recognized for its excellent corrosion resistance, superior formability, and outstanding performance in both oxidizing and mildly reducing environments.

Chdymetal is a global metal supplier of titanium alloy tube, we can provide various grade and type, As its unique combination of high strength, light weight, corrosion resistance, bio-compatibility, and higher temperature performance, Titanium alloy tube is widely used in aerospace, medical, industrial, and oil and gas industries.

More details pls check below information:

|

Product name |

titanium tube for sale |

|

Material |

Pure titanium and Titanium Alloy |

|

Grade |

Gr1, Gr2, Gr7, Gr9, Gr12 |

|

Application |

Construction/ Building/ Industry/Marine anti-corrosion |

|

Type |

Seamless and Welded |

|

Outer Diameter |

10--300mm |

|

Thickness |

0.5--20mm |

|

Sample |

Free samples are available |

|

Standard |

ASTM B337/338, AMSESB337/338 ASTM F67 ASTM F136 JIS |

|

Processing Service |

Cold rolling |

|

Port |

Shanghai or Tianjin |

|

Advantage |

Factory price,Fast delivery and can be customized |

|

Packing term |

Foam packing inside,export wooden box outside |

|

Payments terms |

30%TT in advance, 70% balance before shipment according to the actual weight |

Chemical composition:

|

Grades |

N |

C |

H |

Fe |

O |

Al |

V |

Pd |

Mo |

Ni |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

|

Gr 11 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

0.12-0.25 |

/ |

/ |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

Product Features & Benefits

- Outstanding Corrosion Resistance: Performs exceptionally in oxidizing and mildly reducing environments such as seawater, acids, and chlorides.

- Excellent Weldability: Can be easily welded by TIG, MIG, and plasma methods without losing mechanical properties.

- High Strength with Low Weight: Offers a superior strength-to-density ratio for lightweight engineering systems.

- Non-Magnetic and Non-Toxic: Ideal for sensitive applications in medical and electronic industries.

- Thermal and Electrical Stability: Maintains stable performance under temperature extremes and variable electric conditions.

- Easy Fabrication: pure titanium tube can be bent, flanged, and machined without cracking, ensuring design flexibility.

Applications

Our pure titanium tube are widely used in various industrial systems that demand both reliability and corrosion protection:

-

- Aerospace: Titanium is used in aircraft components and structures due to its high strength, low weight, and excellent corrosion resistance.

- Chemical processing: Titanium is used in pipes, tanks, and valves in chemical processing plants due to its excellent corrosion resistance.

- Biomedical: Titanium is biocompatible, making it ideal for medical implants and devices such as orthopedic implants, dental implants, and surgical tools.

- Marine: Titanium is used in shipbuilding and offshore structures due to its excellent corrosion resistance in saltwater environments.

The combination of durability and performance makes pure titanium tube a preferred choice across demanding industrial sectors.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye employs a complete in-house production line for titanium pipe manufacturing, ensuring high precision and reliability:

- Vacuum Arc Remelting (VAR): Guarantees high purity and consistent microstructure.

- Hot and Cold Rolling: Provides uniform wall thickness and dimensional accuracy.

- Welding & Annealing: Utilizes automatic TIG welding for welded pipes and controlled heat treatment to enhance ductility.

- Precision Machining: CNC cutting, beveling, threading, and surface polishing as per client specifications.

- Comprehensive Inspection: Hydrostatic, ultrasonic, and eddy current testing on each pipe section.

Our advanced facilities allow both seamless and welded production routes, ensuring flexibility for customized orders.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is integrated into every stage of our production process.

All pure titanium tube are produced under the ISO 9001:2015 quality management system, ensuring full traceability and consistent reliability.

Inspection and Testing Procedures:

- Raw material chemical composition verification

- Mechanical property and hardness testing

- Non-destructive testing (UT, RT, and PT)

- Hydrostatic pressure and leakage testing

- Dimensional and surface finish examination

Each product is accompanied by complete inspection certificates, ensuring our clients receive fully compliant and dependable products.

Packaging & Global Logistics

We use export-grade packaging and safe logistics to ensure products arrive in perfect condition:

- Inner Packaging: Anti-corrosion film or vacuum-sealed plastic wrapping

- Outer Packaging: Plywood boxes or steel-framed cases with foam inserts

- Marking: Detailed identification including grade, size, standard, and batch number

- Shipping Options: Air freight for urgent orders; sea shipment for bulk export

All packaging adheres to international transport regulations, ensuring safe and moisture-free delivery worldwide.

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Our OEM/ODM capabilities allow us to design and manufacture pure titanium tube tailored to your specific project:

- Custom diameter, wall thickness, and length options

- Special tolerance and surface finishing requirements

- Welding, threading, and flange connection designs

- Prototype development and mass production services

- Technical advice on corrosion resistance and alloy selection

Our engineers work closely with clients to develop the most cost-effective and application-specific titanium piping solutions.

Titanium tube for sale testing

Appearance inspection: Check the outer diameter, wall thickness, and surface quality of the titanium tube.

Mechanical performance testing: including tensile strength, yield strength, elongation, and other indicators to ensure that the titanium tube has sufficient mechanical strength.

Chemical composition analysis: Detect the content of chemical elements in titanium tubes to ensure that they meet the corresponding standards and specifications.

Non destructive testing, such as eddy current testing and ultrasonic testing, is used to check for defects inside titanium tubes.

Corrosion resistance testing: Although this testing may not be conducted in all cases, it may be necessary to evaluate the corrosion resistance of titanium tubes for specific applications in specific environments.

The specific content and requirements of the above testing items may vary depending on different standards and customer needs. In practical operation, testing should be conducted in accordance with relevant national or industry standards.

Why Choose Us

- Over 30 years of titanium industry expertise and technical know-how

- Comprehensive quality system certified to ISO 9001:2015

- Global supply to 50+ countries across North America, Europe, and Asia

- Custom fabrication with advanced CNC and welding technology

- Competitive pricing with stable production capacity

- Quick delivery—standard pipes ready to ship within 7 days

- Dedicated technical team for design consultation and after-sales support

We are dedicated to long-term cooperation and providing reliable titanium solutions that help our partners succeed.

|

|

|

|

|

|

FAQs

Q1: What are the advantages of pure titanium tube compared to stainless steel?

A1: Gr2 titanium offers superior corrosion resistance, lighter weight, and longer service life in aggressive environments.

Q2: Do you provide both seamless and welded types?

A2: Yes, we produce both seamless and welded pure titanium tube according to customer preference and application needs.

Q3: Can I request special dimensions or customized ends?

A3: Absolutely. We provide customized OD, wall thickness, and end finishing such as threaded or beveled ends.

Q4: What testing methods are applied before shipment?

A4: Every pipe undergoes hydrostatic, ultrasonic, and visual testing to guarantee quality and performance.

Q5: What is your minimum order quantity (MOQ)?

A5: We accept flexible MOQs depending on product size and specifications, including sample orders for initial evaluation.

Contact Us

Are you still browsing? Pls contact us if you have any requirements for titanium tube.

Email: info@chdymetal.com

WhatsApp: +86-18049386902

Learn about our latest products and discounts through SMS or email