- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Product Introduction

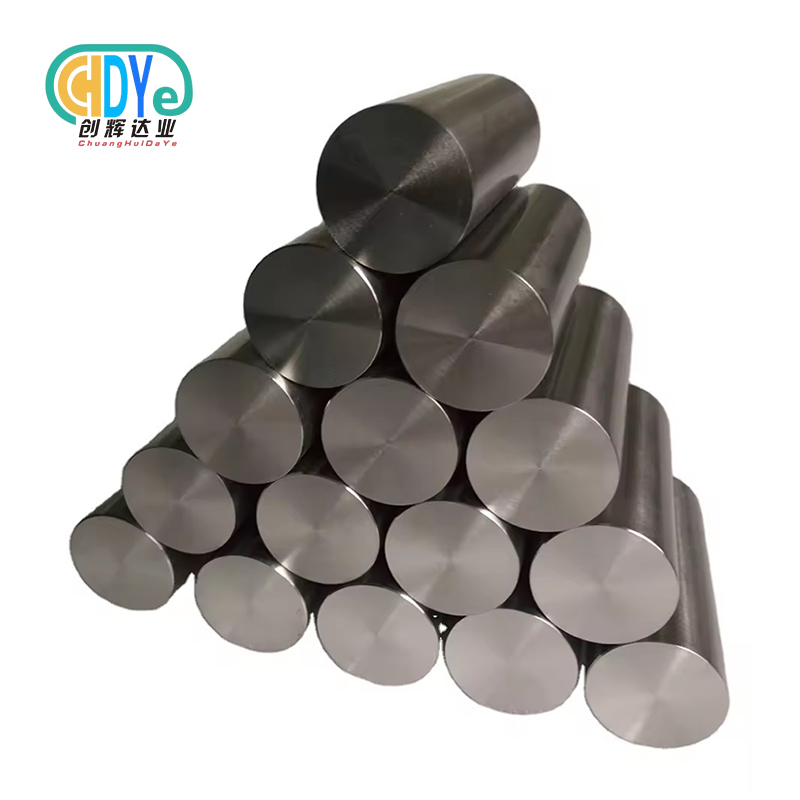

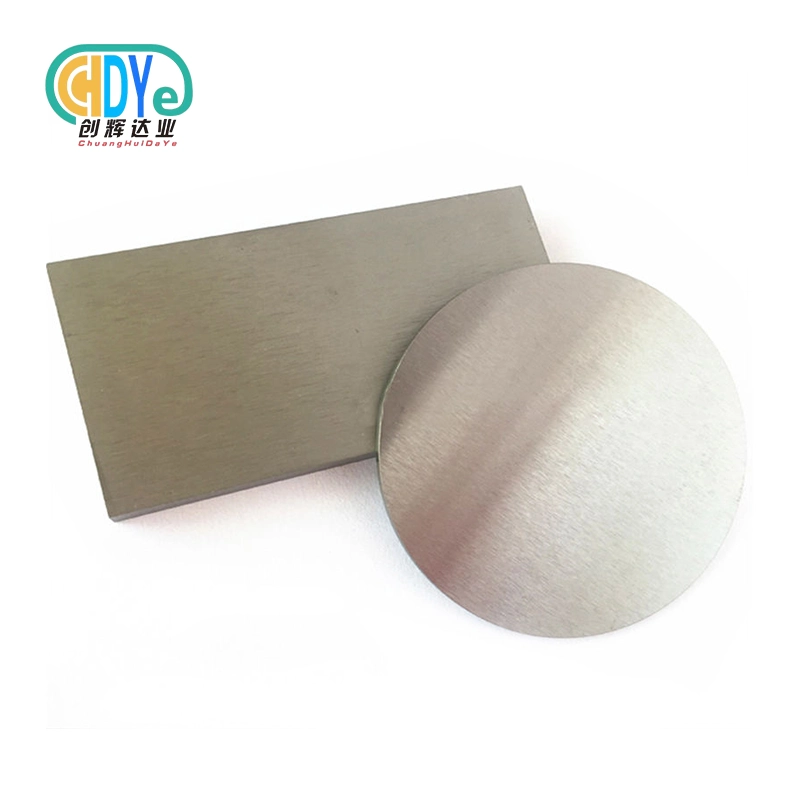

Looking for premium tantalum sputtering target materials for your thin film applications?Tantalum targets share the same properties as their raw materials. Tantalum is a rare, hard, bluish-gray, and highly corrosion-resistant refractory metal. Its melting point is 2980°C and its density is 16.68 g/cm³. Tantalum boasts a range of excellent properties, including a high melting point, low vapor pressure, good cold working properties, high chemical stability, strong resistance to liquid metal corrosion, and a high dielectric constant of its surface oxide film. Tantalum has important applications in high-tech fields such as electronics, metallurgy, steel, chemicals, cemented carbide, atomic energy, superconducting technology, automotive electronics, aerospace, healthcare, and scientific research.

Key Features and Benefits

Our tantalum targets offer superior performance characteristics that set them apart in the market. The fine grain structure ensures uniform coating distribution across your substrate. High electrical conductivity with RRR values exceeding 40 guarantees stable sputtering performance. Low oxygen content keeps your thin films clean and pure. The corrosion-resistant properties of tantalum make these targets perfect for demanding environments.

Technical Specifications

|

Application |

Electronic Light Source Part;Implantation Parts.etc |

|

Purity |

99.95% Min |

|

Density |

16.65g/cm3 |

|

Surface |

Polished and Black |

|

Size |

Φ50-400m,customized |

|

Chemical Composition |

Pure Tantalum targets, bars |

|

Melting point |

3400℃ |

|

Packing |

Wooden box |

|

Production process |

Tantalum raw material - electron beam vacuum melting - forging - polishing - inspection - delivery |

Chemical composition

|

Grade |

Chemical composition%, no more than |

|||||||||||

|

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

Ta |

|

|

Ta1 |

0.005 |

0.005 |

0.005 |

0.005 |

0.002 |

0.002 |

0.005 |

0.02 |

0.004 |

0.002 |

0.005 |

Balance |

|

Ta2 |

0.005 |

0.005 |

0.005 |

0.005 |

0.002 |

0.002 |

0.1 |

0.03 |

0.1 |

0.002 |

0.01 |

Balance |

Available Grades and Materials

We offer two primary grades to meet your specific requirements:

- Ta 1: Ultra-high purity grade for semiconductor applications

- Ta 2: High purity grade for general sputtering applications

Both grades undergo vacuum annealing for optimal microstructure. Surface treatments include alkaline wash and precision machining options.

Manufacturing Process

Our advanced production process ensures consistent quality. We start with high-purity tantalum powder processed through sodium thermal reduction. Cold isostatic pressing at pressures exceeding 200 MPa creates dense ingots. Vacuum sintering at temperatures above 2400°C develops the final microstructure. Rolling and heat treatment optimize the mechanical properties for sputtering applications.

|

|

|

|

|

|

|

|

Applications and Industries

Electronic Chip Manufacturing: Essential for semiconductor integrated circuit production. Creates tantalum thin films for capacitors and resistors in electronic devices.

Display Technology: Critical component in LCD and OLED manufacturing. Forms electrode structures and barrier layers that improve display performance and longevity.

Optical Coating: Enhances transmittance and reduces reflection in optical products. Used in camera lenses, eyeglass lenses, and architectural glass applications.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

| Specification | Range |

|---|---|

| Diameter | 50-400 mm |

| Thickness | Custom sizes available |

| Tolerance | ±0.02 mm |

| Surface Condition | Vacuum annealed |

| Processing Method | CNC milling machinery |

Product Features in Detail

Your tantalum sputtering target benefits from our precision manufacturing approach. The uniform grain structure prevents defects during deposition. Superior surface finish ensures excellent adhesion between target and backing plate. Our processing eliminates internal stress that could cause cracking during use. Every target undergoes strict dimensional control for consistent performance.

Quality Assurance and Testing

We maintain rigorous quality standards throughout production. Each target undergoes comprehensive testing including purity analysis, density measurement, and dimensional inspection. Our quality management system ensures every product meets your specifications. Traceability documentation accompanies each shipment for complete quality assurance.

|

|

|

OEM & Customization Services

Need specific dimensions or configurations? Our experienced team provides complete customization services. We work with your exact specifications to deliver targets that perfectly fit your equipment. Custom backing plate bonding services are available. Our engineering team supports your unique application requirements.

Packaging and Shipping

Protective packaging ensures your targets arrive in perfect condition. Each piece receives individual protection against contamination and damage.

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we bring over 30 years of rare metal expertise to every project. Our founder's extensive industry experience ensures you receive knowledgeable support. We serve customers in more than 50 countries worldwide. Competitive pricing combined with reliable delivery makes us your ideal partner. Customer satisfaction drives everything we do.

FAQs

Q: What purity levels do you offer?

A: Our standard purity is 99.95% minimum, with higher purities available upon request.

Q: Can you provide custom dimensions?

A: Yes, we specialize in custom sizes to match your specific equipment requirements.

Q: What's your typical delivery time?

A: Standard delivery is 1-2 weeks for stock sizes, custom orders may require 2-3 weeks.

Q: Do you provide backing plate bonding?

A: Yes, we offer professional backing plate bonding services for complete target assemblies.

When you choose our tantalum sputtering target products, you're investing in proven performance and reliable partnership for your critical applications.

|

|

|

|

|

|

Contact Us

Ready to discuss your tantalum target requirements? Our technical team stands ready to support your project success. Contact us today at info@chdymetal.com for detailed specifications, pricing, and delivery information.

Learn about our latest products and discounts through SMS or email

_1760924769851.jpg)

_1760924447399.jpg)