- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

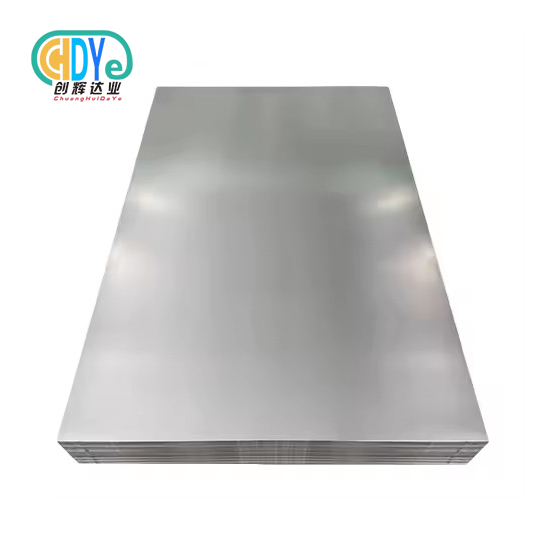

niobium tube and pipe

2. OD: 5–200 mm

3. Wall thickness: 0.2–10 mm

4. Length: up to 3000 mm

5. Density: 8.57 g/cm³

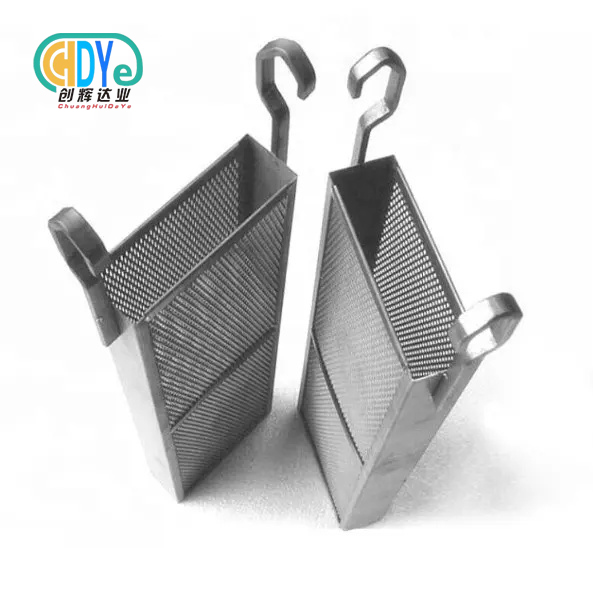

6. Applications: Chemical, electronics

7. Seamless or welded

Niobium has a density of 8.57g/cm³, a melting point of 2477°C, and a boiling point of 4744°C. Niobium is a silver-gray, soft and ductile rare high melting point metal. Because niobium has good superconductivity, high melting point, corrosion resistance, wear resistance and other characteristics, it is widely used in steel, superconducting materials, aerospace, atomic energy and other fields.

Looking for reliable niobium tube and pipe products for your industrial applications? Shaanxi Chuanghui Daye Metal Material Co., Ltd. delivers premium-grade niobium tubing solutions engineered to meet your exact specifications. Our niobium tube and pipe products feature exceptional purity levels exceeding 99.9%, ensuring superior performance in demanding environments. With over 30 years of industry expertise, we provide comprehensive tubular solutions that serve chemical processing, electronics, and specialized industrial applications worldwide.

Key Features and Benefits

Our niobium tubing offers remarkable advantages for critical applications:

- Exceptional corrosion resistance - Perfect for aggressive chemical environments

- Superior thermal stability - Maintains properties at elevated temperatures

- Low thermal neutron capture - Ideal for nuclear applications

- Outstanding ductility - Easy fabrication and installation

- Hypoallergenic properties - Safe for sensitive applications

- High strength-to-weight ratio - Efficient structural performance

Technical Specifications

|

Product name |

niobium tube and pipe |

|

Grade |

R04200, R04210, R04251, R04261 |

|

Standard |

ASTM B394 |

|

Size |

OD3-100*wall thickness 0.5-5mm*Length200-6000mm |

|

Melting point |

2468℃ |

|

Boiling point |

4742℃ |

|

Packing |

Foam material inside, wooden box outside. |

|

Payment terms |

30%TT in advance, 70% balance before shipment |

|

Delivery time |

Stock size will be arrange quick delivery within 1-3 days |

|

Sample |

Sample order are supported |

Chemical composition

|

Main elements(%) |

Impurities (Maximum %) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

Remainder |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.07 |

0.015 |

0.0040 |

0.0015 |

0.003 |

|

Remainder |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.10 |

0.02 |

0.01 |

0.0015 |

0.01 |

Available Grades and Materials

We supply various niobium grades to match your specific requirements:

- Pure Niobium (Nb-1) - 99.9% minimum purity

- Reactor Grade Niobium - Nuclear-qualified material

- Commercial Grade - Standard industrial applications

- High-Purity Grade - Electronics and specialized uses

Manufacturing Process

Our advanced manufacturing ensures consistent quality:

- Raw Material Selection - Premium niobium ingots

- Hot Working - Precise temperature control during forming

- Cold Drawing - Achieving exact dimensions

- Heat Treatment - Optimizing mechanical properties

- Quality Testing - Comprehensive inspection protocols

|

|

|

|

|

|

|

|

Applications and Industries

Niobium tube and pipe serves diverse sectors:

- Chemical Processing - Reactor vessels and heat exchangers

- Electronics Industry - Capacitor components and vacuum tubes

- Nuclear Technology - Reactor components and fuel assemblies

- Aerospace - High-temperature structural elements

- Medical Equipment - Biocompatible device components

- Research Facilities - Laboratory and experimental equipment

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional accuracy:

- Outer Diameter Tolerance: ±0.05mm for precision applications

- Wall Thickness Tolerance: ±10% standard, ±5% precision

- Length Tolerance: +0/-5mm

- Straightness: 0.5mm per meter maximum deviation

- Surface Finish: Ra 0.8μm standard, Ra 0.4μm available

Product Features in Detail

Our tubing delivers exceptional performance characteristics. The high-purity niobium construction provides excellent chemical inertness, making it suitable for corrosive environments. The material's unique properties include remarkable formability at room temperature, preventing oxidation concerns during fabrication.

Quality Assurance and Testing

Every niobium tube and pipe undergoes rigorous testing:

- Chemical composition analysis

- Dimensional verification

- Mechanical property testing

- Surface quality inspection

- Non-destructive testing when required

|

|

|

OEM & Customization Services

We specialize in custom solutions tailored to your needs:

- Custom dimensions and tolerances

- Special alloy compositions

- Unique surface treatments

- Application-specific designs

- Technical consultation and support

Packaging and Shipping

Your products receive careful protection:

- Individual protective wrapping

- Cushioned packaging materials

- Moisture-resistant containers

- Secure shipping arrangements

- Global delivery capabilities to 50+ countries

Why Choose Us

With three decades of rare metal expertise, we understand your challenges. Our Baoji facility in China's "Titanium Capital" provides manufacturing advantages and cost-effective solutions. We combine technical knowledge with customer-focused service, ensuring you receive exactly what your application demands.

1. Rich experience in metal industry and we can give you professional advice when you choose in your application

2. Stock products with various grade and size, we can arrange quick delivery.

3. We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

|

|

|

|

|

|

FAQs

Q: What's the difference between seamless and welded options?

A: Seamless tubes offer higher pressure ratings, while welded versions provide better dimensional accuracy and cost-effectiveness for larger sizes.

Q: Can you provide material certificates?

A: Yes, we supply complete certification documentation including chemical analysis and mechanical properties.

Q: What's your typical lead time?

A: Standard products ship within 2-3 weeks, while custom specifications may require 3-4weeks.

Contact Us

Ready to discuss your niobium tubing requirements? Our technical team is here to help you select the perfect solution for your application. Contact us today at info@chdymetal.com for detailed specifications, pricing, and technical support. Let's work together to find the ideal niobium tube and pipe solution for your project needs.

Learn about our latest products and discounts through SMS or email