- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

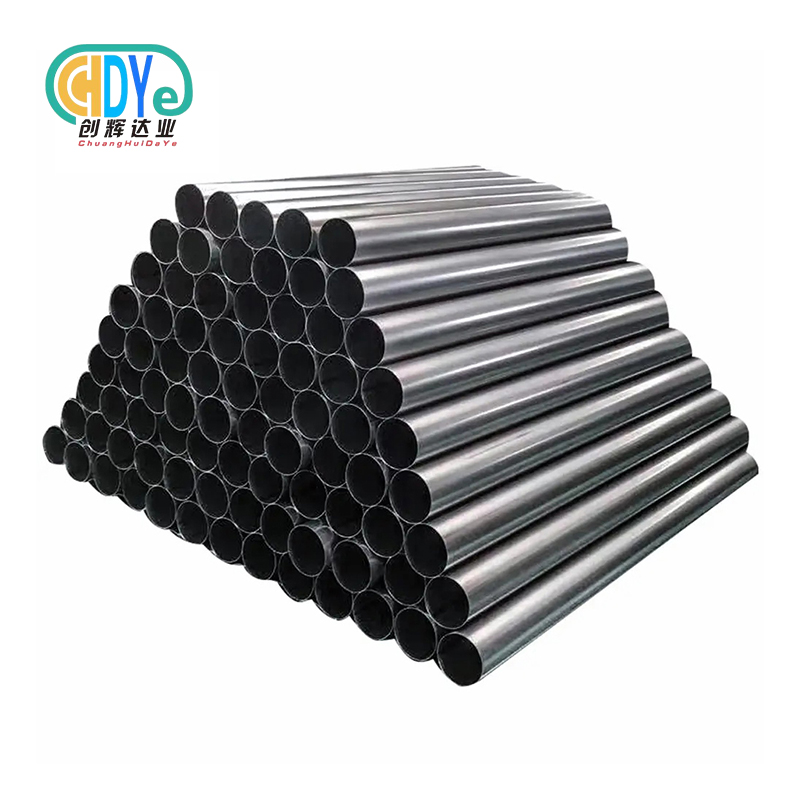

niobium bars

2. Diameter/width: 1–50 mm

3. Length: up to 1000 mm

4. Density: 8.57 g/cm³

5. Tensile strength: 200–350 MPa

6. Applications: Chemical, medical

7. Surface: Polished/as-rolled

Looking for reliable niobium bars for your industrial applications? Our high-purity niobium bars deliver exceptional performance across chemical processing, medical devices, and advanced manufacturing sectors. With over 99.9% purity and precise dimensional control, these bars meet the most demanding specifications. Our experienced team understands your requirements for consistent quality and reliable supply. We manufacture niobium bars using advanced metallurgical processes to ensure superior mechanical properties and surface finish.

Key Features and Benefits

Our niobium bars offer outstanding corrosion resistance and biocompatibility. The material maintains excellent ductility and workability for complex fabrication processes. You'll appreciate the consistent chemical composition and reliable mechanical properties across every batch. These bars provide superior performance in high-temperature applications and aggressive chemical environments.

The lightweight yet durable nature makes them ideal for aerospace and medical applications. Your projects benefit from reduced weight without compromising structural integrity. The excellent thermal and electrical conductivity opens possibilities for specialized electronic applications.

Technical Specifications

| Property | Specification |

|---|---|

| Purity | Nb ≥99.9% |

| Density | 8.57 g/cm³ |

| Tensile Strength | 200-350 MPa |

| Diameter Range | 1-50 mm |

| Length | Up to 1000 mm |

| Melting Point | 2,477°C |

| Surface Finish | Polished/As-rolled |

| Packing | Wooden box |

| Payment terms | 30%TT in advance, 70% balance before shipment |

Chemcial Composition

|

Niobium and Niobium Alloys Sheet Chemical Composition |

||||

|

Element |

Type1 (Reactor Grade Unalloyed Nb) R04200 |

Type2 (Commercial Grade Unalloyed Nb) R04210 |

Type3 (Reactor Grade Nb-1%Zr) R04251 |

Type4 (Commercial Grade Nb-1%Zr) R04261 |

|

Max Weight % (Except Where Otherwise Specified) |

||||

|

C |

0.01 |

0.01 |

0.01 |

0.01 |

|

N |

0.01 |

0.01 |

0.01 |

0.01 |

|

O |

0.015 |

0.025 |

0.015 |

0.025 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Zr |

0.02 |

0.02 |

0.8-1.2 |

0.8-1.2 |

|

Ta |

0.1 |

0.3 |

0.1 |

0.5 |

|

Fe |

0.005 |

0.01 |

0.005 |

0.01 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

W |

0.03 |

0.05 |

0.03 |

0.05 |

|

Ni |

0.005 |

0.005 |

0.005 |

0.005 |

|

Mo |

0.01 |

0.02 |

0.01 |

0.05 |

|

Hf |

0.02 |

0.02 |

0.02 |

0.02 |

|

Ti |

0.02 |

0.03 |

0.02 |

0.03 |

Available Grades and Materials

We supply commercial grade and high-purity grades to match your specific requirements. Our standard offering includes RO4200-1 and RO4210-2 grades conforming to international standards. Custom alloy compositions are available for specialized applications requiring modified properties.

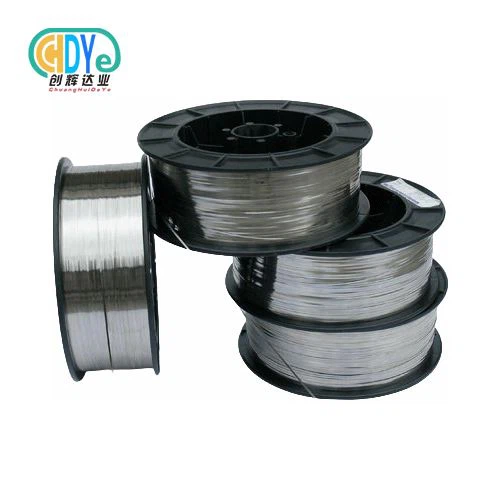

Manufacturing Process

Our manufacturing begins with high-quality raw materials sourced from trusted suppliers. The vacuum melting process ensures minimal contamination and consistent purity levels. Precision rolling and drawing operations create the exact dimensions you need. Heat treatment processes optimize mechanical properties for your specific application.

Quality control measures monitor every production step. We maintain strict temperature and atmosphere controls throughout processing. Final inspection ensures dimensional accuracy and surface quality meet your specifications.

|

|

|

|

|

|

|

|

Applications and Industries

Chemical processing industries rely on our products for reactor components and heat exchangers. The excellent corrosion resistance handles aggressive acids and alkaline solutions effectively. Medical device manufacturers choose our materials for implants and surgical instruments due to exceptional biocompatibility.

Aerospace applications benefit from the high strength-to-weight ratio and temperature resistance. Electronics manufacturers use these materials for specialized components requiring precise electrical properties. Research institutions depend on our consistent quality for experimental applications.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

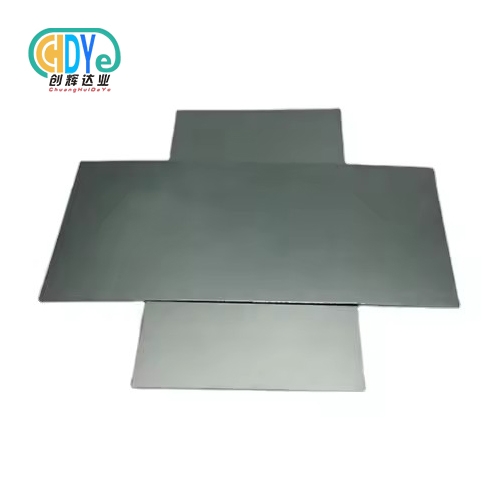

Product Dimensions and Tolerances

Standard diameter tolerances range from ±0.1mm for smaller sizes to ±0.2mm for larger diameters. Length tolerances maintain ±2mm accuracy for standard cuts. Custom tolerances are available to meet your specific machining requirements.

Surface finish options include mill finish, polished, and precision ground surfaces. Straightness tolerances ensure easy handling and processing in your facility.

Product Features in Detail

The fine grain structure provides excellent mechanical properties and consistent performance. Superior surface quality reduces preparation time for your manufacturing processes. Excellent weldability allows for complex fabrication without compromising joint integrity.

Low outgassing properties make these materials suitable for vacuum applications. The stable oxide layer provides natural corrosion protection in many environments. Consistent electrical and thermal properties ensure predictable performance in electronic applications.

Quality Assurance and Testing

Every batch undergoes comprehensive chemical analysis using advanced spectroscopic methods. Mechanical testing verifies tensile strength, yield strength, and elongation properties. Dimensional inspection ensures conformance to your specifications.

We maintain ISO quality management systems for consistent production standards. Certificate of analysis accompanies every shipment with complete test results. Traceability records track material from raw material to final product.

|

|

|

OEM & Customization Services

Our engineering team works with you to develop custom solutions for unique applications. We offer precision cutting, machining, and surface treatment services. Custom packaging options protect your materials during shipping and storage.

Flexible minimum order quantities accommodate both prototype and production requirements. Technical support helps optimize material selection for your specific application needs.

Packaging and Shipping

Protective packaging prevents contamination and damage during transit. Moisture barrier materials maintain product quality in various climates. Clear labeling ensures proper identification and handling at your facility.

Multiple shipping options provide flexible delivery schedules. Express shipping available for urgent requirements. International shipping expertise ensures smooth customs clearance.

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of rare metal industry experience, we understand your quality requirements. Our location in China's "Titanium Capital" provides access to advanced metallurgical expertise and infrastructure. We serve customers in over 50 countries with consistent quality and reliable delivery.

Our customer-focused approach ensures responsive service and technical support. Competitive pricing helps optimize your material costs without compromising quality. Long-term partnerships built on trust and reliability drive our business philosophy.

|

|

|

|

|

|

FAQs

Q: What minimum order quantities do you require?

A: We accommodate orders from small quantities for research to large production volumes.

Q: Can you provide custom dimensions?

A: Yes, we offer precision cutting and custom sizing to meet your specifications.

Q: What certifications do you provide?

A: Complete certificates of analysis with chemical and mechanical test results accompany every shipment.

Q: How do you ensure consistent quality?

A: Rigorous quality control at every production stage and comprehensive testing ensure consistent properties.

Contact Us

Ready to discuss your niobium bar requirements? Our technical team is available to help select the right material for your application. Contact us at for quotes, technical specifications, or application guidance. We're committed to providing the high-quality materials and service you need for project success.

E-mail: info@chdymetal.com

Mob./what'sapp: 86-18049386902

Learn about our latest products and discounts through SMS or email