- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

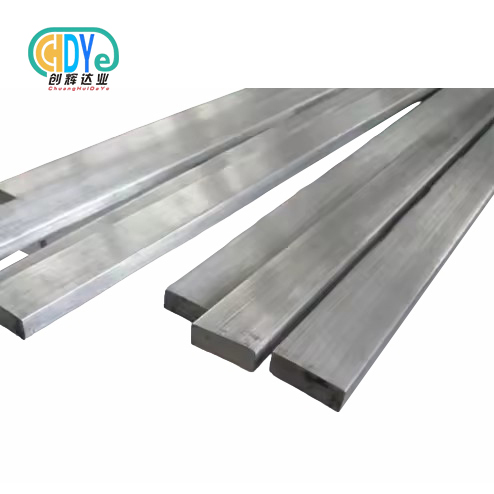

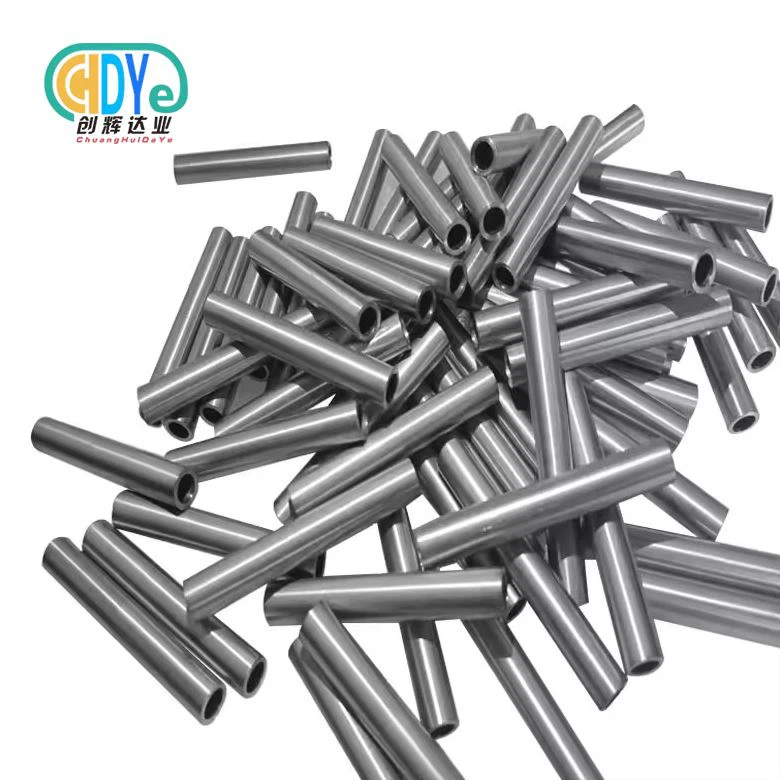

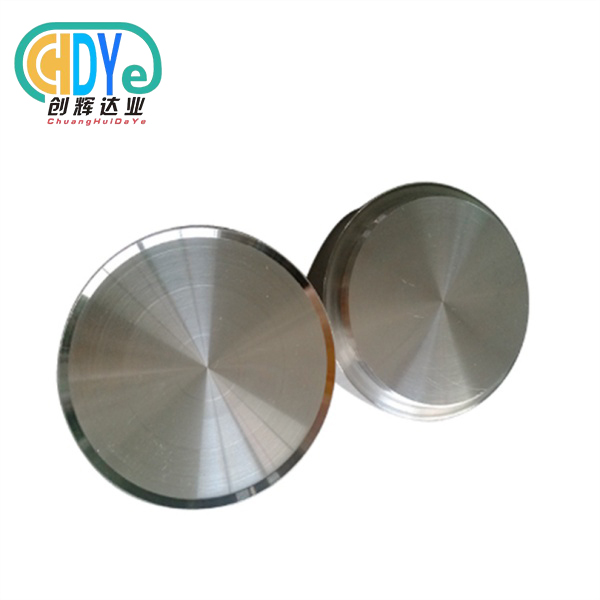

Titanium Anode For Chlor-alkali

2.Coating type: Mixed oxides of ruthenium

3.Shape: customized

Product Overview

The Titanium Anode for Chlor-Alkali industry is a high-performance electrochemical component designed to withstand the harsh and corrosive environments typical of chlorine and caustic soda production. During the chlor-alkali process, strong corrosive agents such as chlorine gas, hydrochloric acid, and hypochlorite ions (ClO⁻) are continuously present. Therefore, selecting durable, corrosion-resistant anode materials is crucial to maintaining stable operation and extending the service life of electrolytic equipment.

Traditional graphite anodes used in early chlor-alkali systems were prone to rapid wear and caused environmental pollution. With technological advancements, titanium-based ruthenium–iridium coated electrodes have become the preferred solution due to their excellent corrosion resistance, long lifespan, and superior electrochemical performance.

The following are general parameters, other specifications can be designed and customized

|

Substrate |

GR1/GR2 |

|

Coating type |

Mixed oxides of ruthenium |

|

chlorine evolution potential |

≤1.13V |

|

polarizability |

≤30mv |

|

Enhanced life test |

≥3000h |

|

Shape |

Commonly used shape cage type, single pole multiple plate anode group or other forms, can also be designed and customized |

|

Cathode |

Same specification with anode |

Advantages of Titanium Anode for Chlor-Alkali

-

Exceptional Corrosion Resistance

The Titanium Anode for Chlor-Alkali is coated with a ruthenium–iridium oxide layer, providing outstanding resistance to corrosion in high-concentration chloride environments. This ensures stable, long-term operation even under strong chemical exposure. -

Superior Electrochemical Efficiency

The advanced coating lowers both the discharge overpotential and oxygen evolution potential, resulting in more efficient chlorine generation and reduced oxygen formation at the same current density—improving overall electrolysis performance. -

Extended Service Life

Compared to graphite anodes, which typically last less than a year, the Titanium Anode for Chlor-Alkali can operate efficiently for 8 years or more, offering significant cost and maintenance savings over time. -

High Current Density Capability

This anode can sustain higher current densities, allowing production capacity to double under the same electrolytic conditions, thereby enhancing productivity without compromising stability. -

Improved Product Purity

The use of titanium-coated ruthenium–iridium anodes leads to higher purity levels of chlorine gas and other products by minimizing contamination and impurity formation, thus improving end-product quality.

Precautions for Using Titanium Anode for Chlor-Alkali

-

Recommended Working Current Density:

For most industrial operations, maintain a current density below 2000 A/m² for optimal performance and longevity. -

Electrolyte Composition:

The electrolyte must not contain cyanide or fluoride ions, as these substances severely corrode the titanium substrate. -

Anode–Cathode Distance:

Adjust spacing based on system conditions, typically between 5–25 mm. -

Polarity Reversal:

Avoid polarity reversal; for cleaning and descaling, acid pickling is the preferred method. -

Operating Temperature:

Maintain electrolyte temperature between 25–40°C to ensure stable electrochemical behavior.

Application Advantages

The Titanium Anode for Chlor-Alkali Industry is a key electrochemical component used in the electrolysis of sodium chloride (NaCl) to produce chlorine (Cl₂), hydrogen (H₂), and sodium hydroxide (NaOH). Manufactured from high-purity titanium substrates and coated with mixed metal oxides (MMO) such as Ru-IrO₂, Ru-TiO₂, or Ir-TaO₂, these anodes deliver exceptional conductivity, corrosion resistance, and long-term stability in harsh chloride environments.

Main Advantages:

- High Electrochemical Efficiency: Optimized coating composition ensures high current efficiency for chlorine and caustic soda production.

- Superior Corrosion Resistance: Stable under high chlorine concentrations and alkaline conditions.

- Energy Saving: Reduced cell voltage leads to lower power consumption and higher output efficiency.

- Long Service Life: Multi-layer oxide coating provides extended durability and consistent performance.

- Stable Operation: Maintains uniform current distribution and consistent product purity.

- Environmental Safety: Non-toxic and maintenance-free, contributing to greener production.

Typical Applications:

- Chlor-alkali membrane cells

- Diaphragm electrolyzers

- Brine electrolysis systems

- Electrolytic sodium hypochlorite generation units

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

Shaanxi Chuanghui Daye uses precision-controlled processes to produce each Titanium Anode for Chlor-Alkali applications. From substrate preparation to coating deposition, every step ensures high adhesion, uniform coating, and consistent performance.

Production Process:

- Raw Material Selection – Choose ASTM B265 Grade 1 or Grade 2 titanium plates or meshes for high corrosion resistance.

- Surface Preparation – Degreasing, acid pickling, and mechanical polishing to ensure coating adhesion.

- Coating Preparation – Formulation of ruthenium, iridium, or tantalum-based oxide coatings.

- Thermal Decomposition Coating – Multiple layers of MMO coating applied by brush or spray, followed by sintering at 400–600°C.

- Sintering & Stabilization – Layer-by-layer heating for strong bonding and uniform catalytic performance.

- Final Inspection & Testing – Electrical conductivity, adhesion, and electrochemical tests before shipment.

This multi-step production ensures superior coating durability and excellent electrolysis efficiency in long-term operation.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Our factory follows a strict ISO 9001:2015 quality management system, ensuring every titanium anode meets international chlor-alkali standards.

Inspection Highlights:

- Material Verification: Check titanium purity and thickness consistency.

- Coating Composition Analysis: Verify oxide ratios (RuO₂, IrO₂, TiO₂, Ta₂O₅) for stable catalytic performance.

- Adhesion Test: Mechanical and ultrasonic tests ensure coating integrity.

- Surface Uniformity Test: Microscopic evaluation for coating evenness.

- Electrochemical Life Test: Simulate industrial conditions to ensure long-term stability.

- Final Dimension & Marking Check: Confirm size, batch number, and labeling.

Each anode is supplied with a detailed inspection report and traceable batch certification.

R&D and Customization

With over 30 years of metallurgical expertise, Shaanxi Chuanghui Daye continually advances the coating technology for titanium anodes. Our R&D team focuses on improving anode lifespan, reducing energy consumption, and enhancing performance in harsh chemical environments.

Customizable Options:

- Substrate Type: Titanium plate, mesh, or expanded sheet

- Coating Composition: Ru-IrO₂, Ru-TiO₂, Ir-TaO₂, or Pt coating systems

- Coating Thickness: 3–10 μm depending on current density

- Operating Conditions: Custom designs for current density up to 10 kA/m²

- Anode Shape: Round, rectangular, or modular design

We can design complete electrode assemblies for chlor-alkali membrane cells, ensuring perfect fit and performance consistency.

Packaging & Global Logistics

Shaanxi Chuanghui Daye guarantees secure, export-standard packaging and fast, reliable delivery worldwide.

Packaging Details:

- Vacuum-sealed or anti-rust protective film

- Foam padding and edge protection

- Export plywood cases meeting ISPM-15 standards

- Clear labeling with batch number, coating type, and production date

Logistics:

- International shipping via air, sea, or land

- Global delivery to 50+ countries

- Standard lead time: 7–10 working days

- Express options for urgent orders

We work with global freight partners to ensure timely, damage-free delivery to our customers.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides OEM and ODM services for chlor-alkali plant manufacturers, system integrators, and chemical engineering firms.

OEM Support Includes:

- Co-design and engineering consultation

- Custom coating formulation based on operating environment

- Small batch and prototype production

- Private labeling and technical documentation

- After-sales technical assistance

Our goal is to support clients with cost-effective, durable, and energy-efficient anode solutions that fit seamlessly into their production systems.

Inspection Process

Every Titanium Anode for Chlor-Alkali undergoes a full inspection and test protocol before shipment:

- Visual & Dimensional Check – Surface condition and size precision verified.

- Coating Thickness Measurement – Confirmed via non-destructive testing.

- Adhesion Strength Evaluation – Mechanical stress test to assess coating bonding.

- Electrochemical Test – Analyze overpotential, voltage stability, and chlorine yield.

- Final Packaging Audit – Confirm labeling, traceability, and protective wrapping integrity.

Only products that pass all inspections are approved for export.

Why Choose Us

- 30+ Years of Rare Metal Expertise – Deep experience in titanium and MMO anode manufacturing.

- ISO 9001:2015 Certified Factory – Strict process and quality management.

- Advanced Facilities – Equipped with electron beam furnaces, annealing lines, and precision machining tools.

- Global Reach – Exported to 50+ countries across North America, Europe, and Asia.

- 7-Day Fast Delivery – Flexible production scheduling for quick order turnaround.

- Professional OEM Support – Tailored solutions for chlor-alkali and electrochemical industries.

Shaanxi Chuanghui Daye is your trusted partner for high-performance titanium anodes that combine stability, efficiency, and durability.

|

|

|

|

|

|

FAQs

Q1: What coating materials are used in chlor-alkali titanium anodes?

A1: We use mixed metal oxides (MMO) such as Ru-IrO₂, Ru-TiO₂, or Ir-TaO₂, optimized for chlorine generation and corrosion resistance.

Q2: What is the typical service life of the titanium anode?

A2: Service life ranges from 3 to 10 years, depending on coating type, current density, and operating environment.

Q3: Can you design anodes for specific electrolyzer systems?

A3: Yes, we provide custom shapes, mounting frames, and assembly designs according to client drawings or system parameters.

Q4: What standards do your titanium anodes comply with?

A4: All products conform to ASTM B265, ASTM B338, AMS, and ISO standards.

Q5: Do you offer sample testing before bulk orders?

A5: Absolutely. We can supply sample anodes or small-batch prototypes for performance evaluation before full-scale production.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email