- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

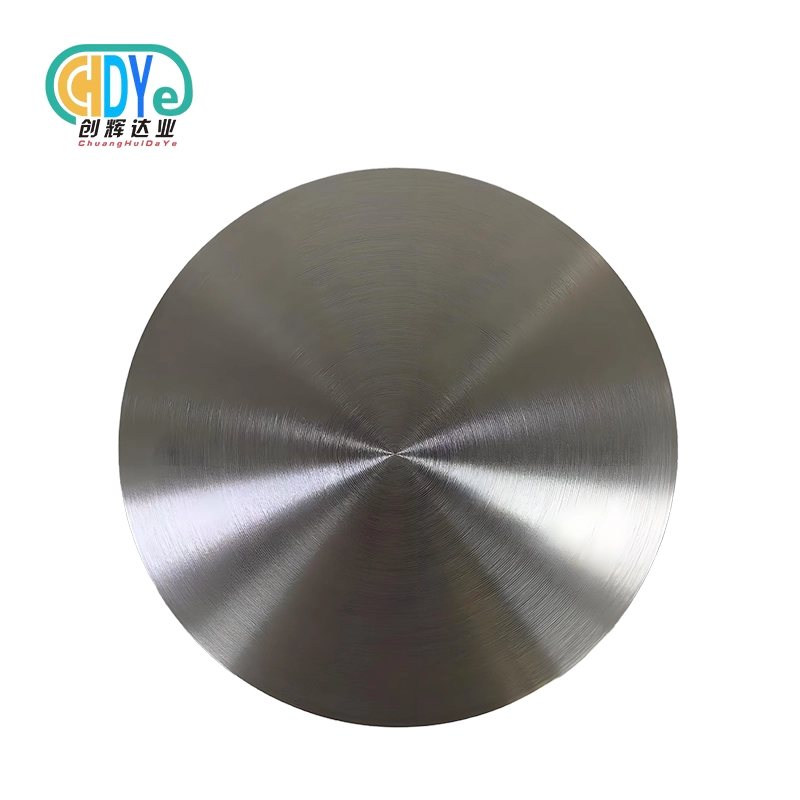

Gr5 Titanium Bar

Chdymetal have gr5 titanium bar common sizes in stock all year round. Please contact us to confirm the specific delivery time.

Product Details

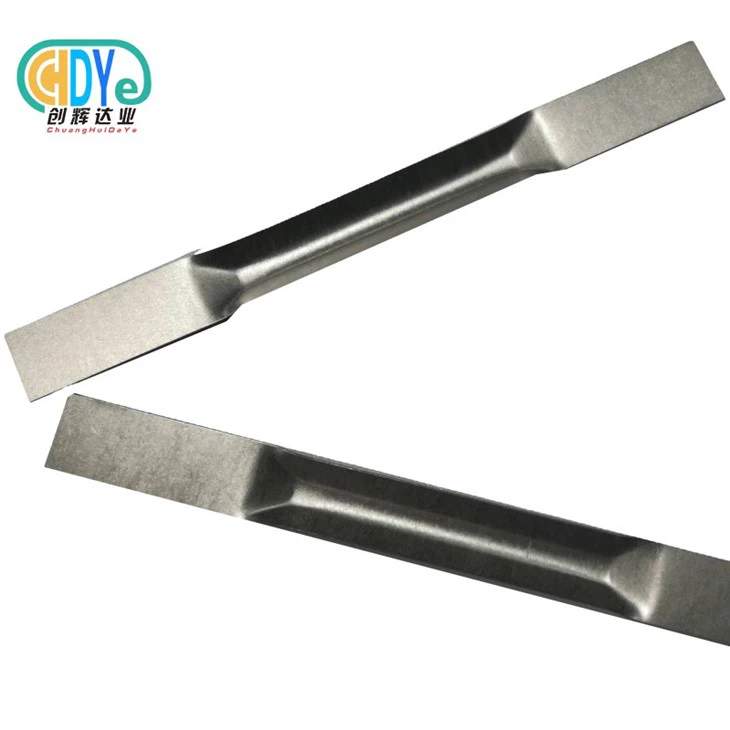

Gr5 Titanium Bar, also known as Ti-6Al-4V, is a high-performance titanium alloy renowned for its outstanding balance of strength, low density, corrosion resistance, and durability. Containing approximately 6% aluminum and 4% vanadium, this alloy delivers superior mechanical properties suitable for aerospace, medical, chemical, and industrial sectors.

Produced in a wide range of diameters, lengths, and surface finishes, our bars comply with ASTM B348, AMS 4928, and ISO 5832-3 standards. The material is extensively applied in fields such as metallurgy, electronics, medical equipment, petrochemical processing, salt production, pharmaceuticals, and aerospace engineering.

|

Specifications Chart |

ASTM B348/ ASTM SB348 |

|

Dimensions |

EN, DIN, JIS, ASTM, BS, ASME, AISI |

|

Diameter in mm |

3 mm to 350 mm |

|

Length in mm |

<= 3000 mm |

|

Surface Finish |

Black, Bright Polished |

|

Form |

Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

Chemical Structure of gr5 titanium bar

|

Grade |

Ti |

C |

Fe |

Al |

V |

O |

|

Grade 5 Titanium |

90 min |

– |

0.25 max |

6 min |

4 min |

0.02 max |

Mechanical properties reference standard

|

Grade |

Mechanical properties at room temperature, not less than |

|||

|

tensile strength |

Yield Strength |

Elongation |

percentage reduction of area |

|

|

GR1 |

240 MPa |

170MPa |

25% |

30% |

|

GR2 |

345MPa |

275MPa |

20% |

30% |

|

GR5 |

895MPa |

825 MPa |

10% |

20% |

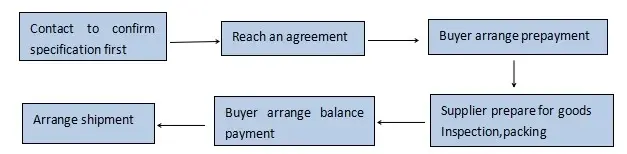

Transaction Process

First contact us to confirm the grade, size quantity and standard you need, we check the stock size if we have then will provide you formal invoice to confirm, meanwhile you should arrange 30% prepayment and we preparing for the quick delivery, then we will take a photo of the actual weight of tantalum plate, you arrange the balance payment,when we receive your full payment the good will be picked up by express After 5-7 days you will receive them. And for the important the material certificate will be provide to you.

Our Service

1.Provide mill test certificate of the material

2. Rich experience in metal industry and we can give you professional advice when you select the suitable material.

3. Chdymetal can cut to precise dimensions with very tight tolerances. Rather than ordering big titanium bar and cutting the material yourself, let us do the cutting for you and reduce your risk and scrap.

4. Stock products with various grade and size, we can arrange quick delivery on the same day.

Manufacturing & Processing Capability

At Shaanxi Chuanghui Daye Metal Material Co., Ltd., every Gr5 titanium bar is manufactured through a precisely controlled process to ensure structural integrity and consistent mechanical performance.

Our advanced facilities include:

- Vacuum melting furnaces for high-purity alloy production

- Hot forging and rolling machines for shaping and refining the microstructure

- CNC machining centers for dimensional precision

- Straightening and polishing lines for perfect surface finish

Each stage, from melting to final machining, is carefully monitored by experienced engineers to ensure the product meets or exceeds ASTM and AMS standards.

|

|

|

|

|

|

|

|

Surface & Mechanical Performance

Surface Finish Options:

- Bright Polished: For enhanced corrosion resistance and decorative appearance

- Machined Surface: Precision-turned and finished for close tolerances

- Pickled Surface: Clean and oxide-free, suitable for further processing

Mechanical Performance Highlights:

- Outstanding tensile and yield strength with excellent fatigue resistance

- High corrosion resistance in seawater, acid, and alkali environments

- Excellent heat resistance and oxidation stability up to 400°C

- Good biocompatibility suitable for medical and dental use

These properties make Gr5 titanium alloy bars ideal for structural components that require both strength and lightweight performance.

Quality Assurance

Quality is at the core of our production philosophy. Our Gr5 titanium bars are manufactured under a strict ISO 9001:2015 quality management system.

Quality Control Procedures:

- Raw Material Inspection – chemical composition analysis and ultrasonic testing

- In-Process Monitoring – temperature, deformation, and dimensional control

- Mechanical Testing – tensile, yield, elongation, and hardness verification

- Surface and Ultrasonic Inspection – ensuring defect-free finish and structure

- Final Inspection – 100% checked before packing

We provide complete Mill Test Certificates (MTC) and inspection documentation with each shipment.

Application Advantages

The Gr5 titanium bar combines mechanical strength and corrosion resistance that make it the preferred choice across multiple industries:

- Aerospace & Aviation: Airframe structures, landing gear components, turbine parts

- Medical Industry: Orthopedic implants, surgical instruments, dental implants

- Marine Engineering: Offshore structures, seawater pipelines, propeller shafts

- Automotive & Motorsport: Lightweight high-strength fasteners and engine parts

- Chemical Processing: Reactors, heat exchangers, and valves for corrosive environments

- Energy & Power Generation: Used in nuclear and renewable energy systems

Its lightweight nature and biocompatibility also make it an ideal material for high-precision and safety-critical equipment.

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

With a skilled R&D team and extensive experience in titanium metallurgy, Chuanghui Daye provides full customization services:

- Tailored bar diameters and tolerances

- Custom alloy compositions and heat treatment states

- Precision cutting, machining, and surface finishing

- OEM/ODM support for aerospace, medical, and industrial clients

Our R&D department continuously improves alloy processing techniques to enhance fatigue resistance, corrosion protection, and machinability for next-generation titanium applications.

Packaging & Logistics

Each Gr5 titanium bar is carefully packed to prevent any damage during transport:

- Packaging: Vacuum or anti-rust film with foam protection and export-grade wooden boxes

- Marking: Each bar labeled with grade, batch number, and dimensions

- Documentation: Includes packing list, inspection report, and MTC

- Shipping: Reliable logistics by air, sea, or express courier

We ensure safe and prompt global delivery to more than 50 countries, including the USA, Germany, Japan, France, and South Korea.

|

|

|

|

|

|

|

|

|

|

|

|

Global Cooperation& Certification

Shaanxi Chuanghui Daye Metal Material Co., Ltd. has established long-term cooperation with clients across Europe, North America, and Asia, serving sectors such as aerospace, medical, and chemical processing.

We are proud to hold:

- ISO 9001:2015 Quality Certification

- Full Material Traceability Certificates

- Third-Party Inspection Approvals (SGS, BV, TUV)

With more than 30 years of industry experience, a strong technical foundation, and reliable after-sales service, we aim to become your trusted partner for premium Gr5 titanium bar materials worldwide.

|

|

|

|

|

|

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email