- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

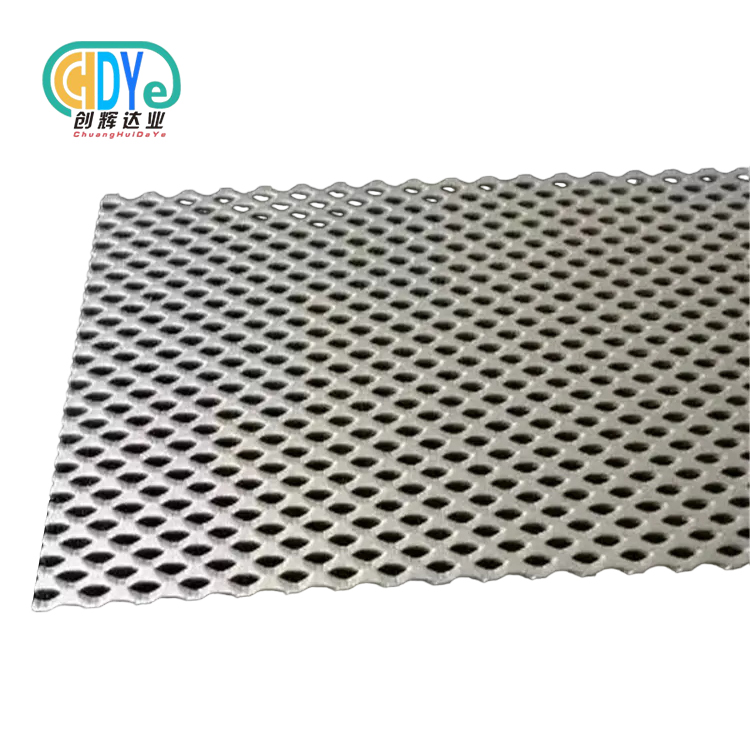

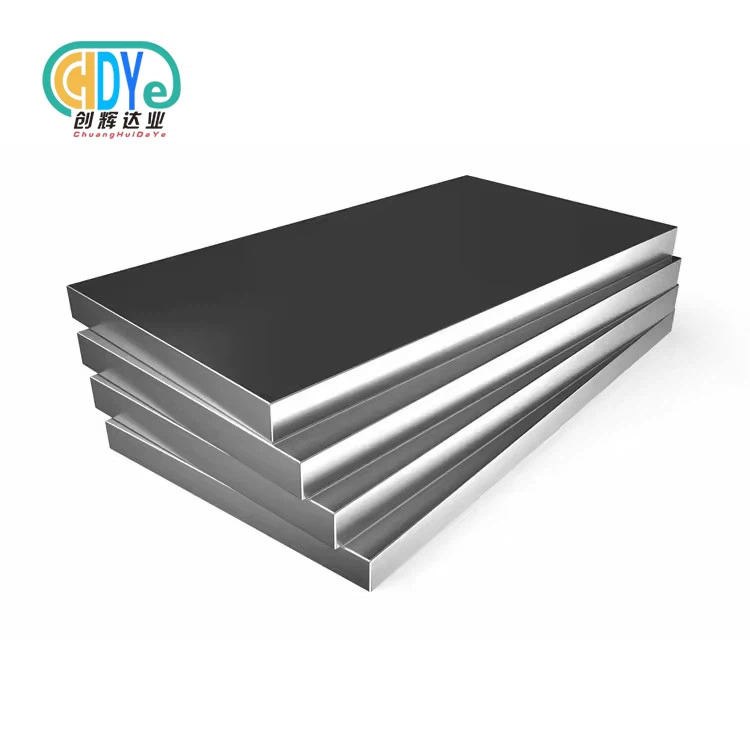

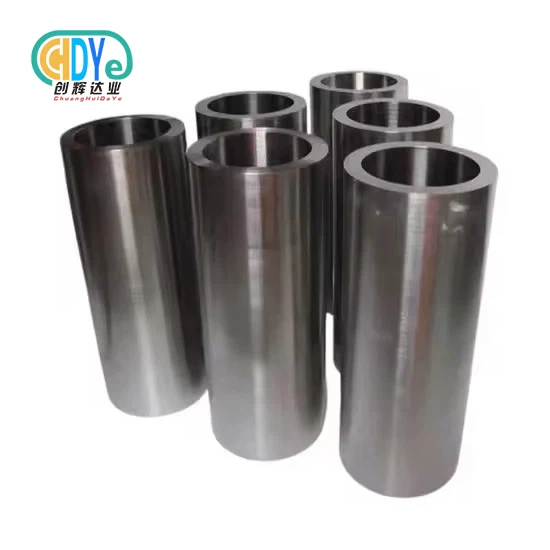

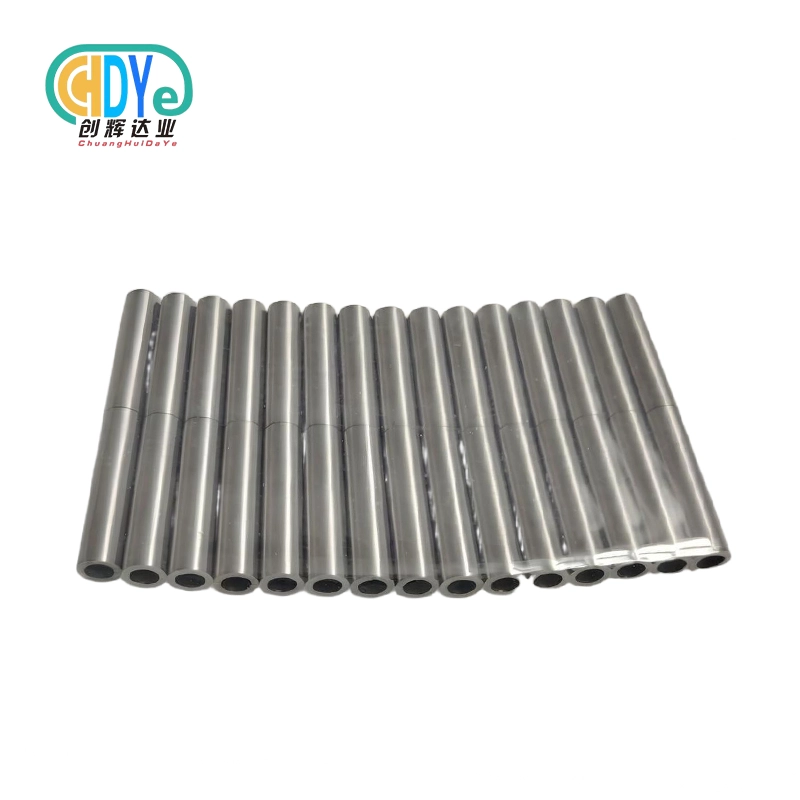

Tantalum Alloy Bar

if you need customized service just contact us.

Product Introduction

Chdymetal can offer tantalum alloy bar with various purities and sizes. It is made according to ASTM B365 ,Tantalum Alloy rod Ta10W and Ta2.5W bars are part of our main product range. if you need customized service just contact us.More details information as below :

|

Product Name |

Tantalum alloy bar |

|

Material |

Tantalum Niobium Rod / Bar R05240 (Ta-40Nb) Pure tantalum: R05200, R05400; TantalumTungsten Rod / Bar R05252 (Ta-2.5W), R05255 (Ta-10W). |

|

Surface treatment |

Polishing,Sandblast,anodizing |

|

Features |

Good ductility, good machinability Good plasticity |

|

Service |

Customized OEM, OEM/ODM/Customized, ODM Available |

|

Packing |

Wooden box |

Performance of tantalum alloy bar

|

Grade(UNS) |

Annealed |

||

|

Tensile strength min,psi (MPa) |

Yield strength min,psi (MPa)(2%) |

Elongation min,% (1 inch gage length) |

|

|

Pure Ta (RO5200,RO5400) |

30000 (207) |

20000 (138) |

20 |

|

Ta-10W (RO5255) |

70000 (482) |

60000 (414) |

15 |

|

Ta-2.5W (RO5252) |

40000 (276) |

30000 (207) |

20 |

|

Ta-40Nb (RO5240) |

35000 (241) |

20000 (138) |

25 |

Tantalum alloy bar Application

1. Solid electrolytic capacitor

2. aerospace, medical, biomedical, electronic,

3. Aircraft

4. Electronic computer

5. Heat ex changer, Heater, Evaporator

6. Part of reactive tank

7. Electronic transmitting tube

8. Part of high temperature electronic tube

9. Bone plate for medical, bolt for medical, suture needles

Application Advantages

Tantalum Alloy Bars are highly valued for their exceptional corrosion resistance, high melting point, and outstanding mechanical strength, making them ideal for harsh chemical, thermal, and vacuum conditions. Shaanxi Chuanghui Daye produces high-purity tantalum bars conforming to ASTM B365 and ASTM B708 standards for demanding industrial applications.

Key Applications:

- Chemical Processing Industry: For heat exchangers, evaporators, and acid-resistant components used in sulfuric, nitric, and hydrochloric environments.

- Electronics & Semiconductor: Used in sputtering targets, capacitor electrodes, and vacuum furnace parts.

- Aerospace & Defense: Applied in propulsion systems, thermal shielding, and high-temperature components.

- Medical Equipment: Suitable for surgical instruments and implants due to excellent biocompatibility.

- Metallurgy & Energy: Used in high-temperature crucibles, heaters, and clean energy system components.

Core Advantages:

- Superior corrosion resistance against strong acids

- High ductility and machinability for precision fabrication

- Excellent performance at temperatures up to 3000°C

- Stable electrical and thermal conductivity

- Long lifespan under harsh working conditions

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye ensures every tantalum alloy bar is produced with precision and reliability through a controlled, step-by-step manufacturing process:

- Raw Material Selection: Certified high-purity tantalum ingots or alloys (Ta-2.5W, Ta-10W, Ta-Nb) sourced from trusted suppliers.

- Melting & Refining: Electron Beam or Vacuum Arc Melting (EBM/VAM) to ensure microstructural uniformity and impurity removal.

- Forging: Multi-step hot forging enhances density and grain refinement for mechanical strength.

- Rolling or Swaging: Precision forming to achieve required diameters and roundness.

- Annealing: High-temperature vacuum annealing to relieve stress and improve ductility.

- Straightening & Cutting: Bars are straightened and cut to standard or custom lengths with minimal tolerance deviation.

- Surface Finishing: Machining, polishing, or pickling for a smooth and clean surface finish.

- Inspection & Packaging: Each batch undergoes comprehensive testing and export-standard packing.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is our core commitment. Shaanxi Chuanghui Daye operates under an ISO 9001:2015 certified quality management system, ensuring each tantalum alloy bar meets the highest global standards.

Inspection & Testing Procedures:

- Chemical Composition Analysis: Verified by ICP-OES or XRF to ensure compliance with ASTM B365/B708.

- Mechanical Property Testing: Tensile strength, yield strength, and elongation measured per ASTM standards.

- Ultrasonic & Eddy Current Testing: Detects internal flaws and ensures structural integrity.

- Dimensional Accuracy Check: Precision measurement with ±0.02 mm tolerance.

- Surface Examination: Manual and optical inspection for uniform texture and defect-free surfaces.

- Hardness & Microstructure Analysis: Verifies metallurgical consistency and phase purity.

Each shipment is accompanied by a Mill Test Certificate (EN 10204 3.1) and optional third-party inspection reports (SGS, BV, or TUV).

R&D and Customization

With over 30 years of technical expertise, Shaanxi Chuanghui Daye continuously advances its rare metal R&D capabilities to meet specialized customer requirements.

Customization Capabilities Include:

- Alloy compositions: Ta-2.5W, Ta-10W, Ta-Nb, and other high-performance blends

- Diameter range: Ø 3 mm – Ø 100 mm, tolerance ±0.02 mm

- Length: Up to 3000 mm, custom cut available

- Surface finish: Polished, pickled, or turned

- Mechanical properties tailored to specific applications

- Custom machining and threading for OEM parts

Our R&D team supports clients from design consultation to prototype development, ensuring optimized performance for every application.

Packaging & Global Logistics

We understand the importance of safe, efficient, and traceable global delivery. Every tantalum alloy bar is packaged with care and shipped under strict export standards.

Packaging Details:

- Vacuum-sealed or anti-rust wrapping

- Foam and shock-resistant protection

- Export-grade wooden boxes or pallets

- Clear labeling with material grade, batch number, and dimensions

Logistics Support:

- Air Freight: 7-day rapid delivery for urgent orders

- Sea Freight: Economical option for bulk shipments

- Courier Express: Available for samples and small-batch testing orders

Our tantalum alloy bars have been successfully exported to over 50 countries, including the USA, Germany, France, South Korea, and Singapore.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides comprehensive OEM/ODM services to global clients across various sectors:

- Tailor-made dimensions and tolerances

- Custom alloy compositions and metallurgical properties

- Precision machining and turning per drawings

- Prototype and low-volume production support

- Expert consultation on material selection and application optimization

We ensure consistent quality, cost-effective pricing, and reliable delivery timelines to meet every customer’s expectations.

Inspection Process

Each Tantalum Alloy Bar undergoes a meticulous inspection routine to ensure total reliability and traceability:

- Raw Material Verification – Chemical purity and certification review

- Melting Process Control – EBM/VAM monitoring and refining analysis

- Dimensional Inspection – Diameter, roundness, and straightness checks

- Mechanical Testing – Tensile and hardness validation per ASTM

- Non-Destructive Testing – Ultrasonic and eddy current flaw detection

- Surface Finish Examination – Visual and microscopic evaluation

- Final Review & Packaging Approval – Certified by QC engineers before shipment

Why Choose Us

- 30+ Years of Rare Metal Manufacturing Experience

- ISO 9001:2015 Certified Quality Control System

- Advanced Production Equipment: Electron beam furnaces, forging presses, rolling and machining centers

- Strict Compliance with ASTM, AMS, and GB Standards

- Customized OEM/ODM Production for Global Clients

- Fast Delivery within 7–15 Days

- Export to 50+ Countries Worldwide

- Professional Technical Support and After-Sales Service

|

|

|

|

|

|

FAQs

Q1: What standards do your tantalum bars comply with?

A1: All bars are produced in accordance with ASTM B365 and ASTM B708 standards.

Q2: What grades are available?

A2: Common grades include Ta, Ta-2.5W, Ta-10W, and Ta-Nb.

Q3: What is the maximum bar length and diameter?

A3: Lengths up to 3000 mm and diameters up to 100 mm, with custom sizes available.

Q4: What surface finishes are offered?

A4: We provide polished, pickled, ground, or machined finishes depending on customer preference.

Q5: Do you provide third-party inspection and test reports?

A5: Yes, SGS, BV, and TUV inspections can be arranged. All shipments include Mill Test Certificates.

Q6: What is your delivery time?

A6: Standard lead time is 7–15 days, depending on quantity and customization.

Q7: Can you provide custom machining?

A7: Yes, our factory offers precision machining and threading according to drawings or samples.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email