- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

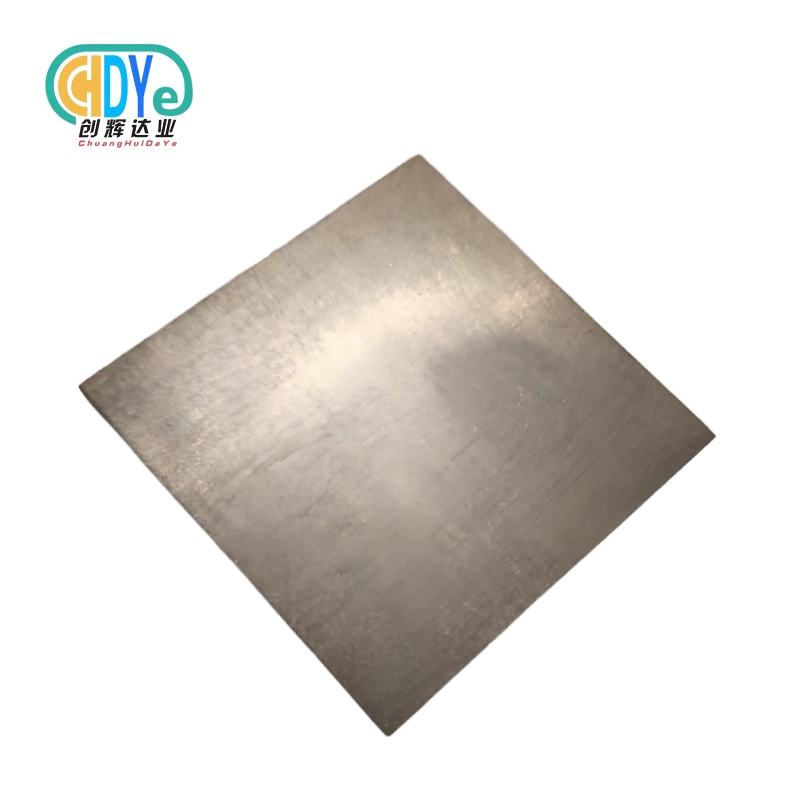

Tantalum Alloy Plate

2.Size: Thickness 0.5-20mm*width50-1200*Length30-2500mm

3.Standard: ASTM B708

4.Delivery: stock size will arrange within 1-3 days, normal production time about 15 working day.

Product Introduction

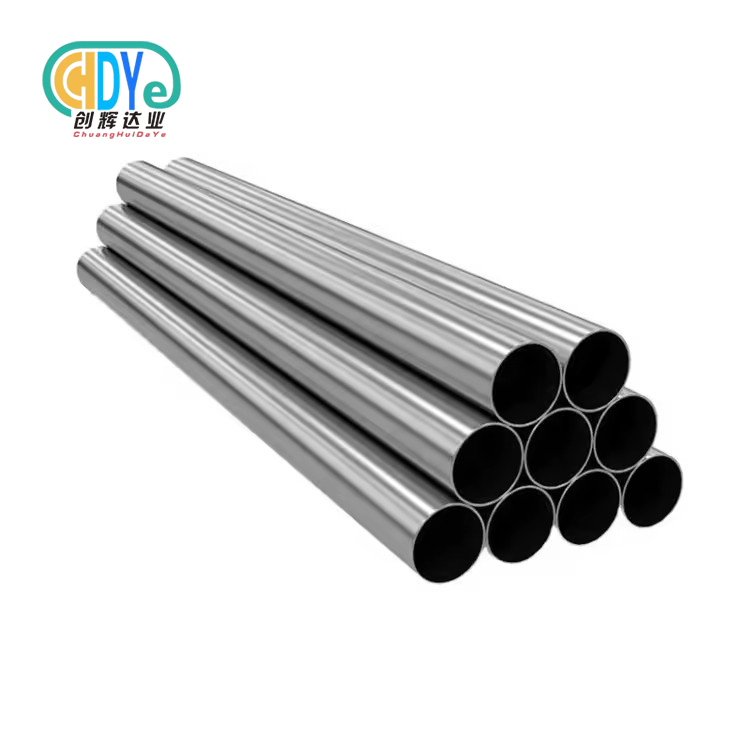

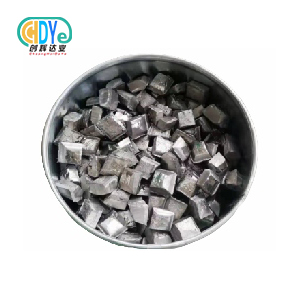

The Tantalum Alloy Plate is a high-performance refractory metal material renowned for its exceptional resistance to corrosion, oxidation, and high temperatures. Produced with advanced melting and rolling technology, it maintains excellent ductility, thermal conductivity, and stability even under extreme conditions. With outstanding chemical inertness, this plate is widely used in aerospace components, chemical process equipment, electronic devices, and vacuum coating systems. Shaanxi Chuanghui Daye Metal Material Co., Ltd. manufactures Tantalum Alloy Plate according to ASTM and ISO standards, ensuring precise dimensions, uniform microstructure, and superior mechanical properties. It is an ideal choice for industries that demand long-lasting reliability and performance in aggressive environments.

Specification

Grade: R05200, R05240, R0525, R05255

Size: Thickness 0.5-20mm*width50-1200*Length30-2500mm

Standard: ASTM B708

Delivery: stock size will arrange within 1-3 days, normal production time about 15 working day.

Tantalum alloy plate Chemical composition

|

Content, Max, Weight % |

||||

|

Element |

R05200 Uanlloyed Tantalum |

R05255 90% Tantalum 10% Tungsten |

R05252 97.5% Tantalum 2.5% Tungsten |

R05240 60% Tantalum 40% Niobium |

|

C |

0.010 |

0.010 |

0.010 |

0.010 |

|

O |

0.015 |

0.015 |

0.015 |

0.020 |

|

N |

0.010 |

0.010 |

0.010 |

0.010 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Fe |

0.010 |

0.010 |

0.010 |

0.010 |

|

Mo |

0.020 |

0.020 |

0.020 |

0.020 |

|

Nb |

0.100 |

0.100 |

0.50 |

35.0~42.0 |

|

Ni |

0.010 |

0.010 |

0.010 |

0.010 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

Ti |

0.010 |

0.010 |

0.010 |

0.010 |

|

W |

0.05 |

9.1~11.0 |

2.0~3.5 |

0.050 |

|

Ta |

Remainder |

Remainder |

Remainder |

Remainder |

Application Advantages

The Tantalum Alloy Plate provides a combination of unique physical and chemical properties that make it highly suitable for various industrial applications:

Excellent corrosion resistance to strong acids, including hydrochloric and sulfuric acids.

High melting point (over 3000°C) suitable for high-temperature environments.

Outstanding biocompatibility, ideal for medical and laboratory applications.

Excellent formability and weldability for customized fabrication.

Stable electrical and thermal conductivity for electronic components.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of Tantalum Alloy Plate at Shaanxi Chuanghui Daye Metal Material Co., Ltd. follows a carefully controlled process to ensure superior quality:

Raw Material Selection – High-purity tantalum alloy ingots are used as feedstock.

Melting & Casting – Vacuum electron beam melting ensures material purity and uniform composition.

Hot Rolling & Forging – Increases density and mechanical strength.

Cold Rolling – Achieves precise thickness and smooth surface finish.

Annealing Treatment – Enhances ductility and structural stability.

Precision Machining & Finishing – Meets dimensional accuracy and surface quality requirements.

Final Inspection & Packaging – Ensures product integrity and compliance with standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is at the heart of our operations. Each Tantalum Alloy Plate undergoes multiple inspection stages, including:

Chemical Composition Analysis using spectrometers to confirm alloy purity.

Mechanical Property Testing (tensile strength, elongation, hardness).

Ultrasonic and Visual Inspections to detect internal or surface defects.

Dimensional and Surface Checks according to ASTM and ISO standards.

Final Certification – Each plate is delivered with a detailed quality report and traceable batch number.

R&D and Customization

Our professional R&D team continuously works on improving material properties and production efficiency. We offer tailored solutions for clients with unique design or performance needs, including:

Custom alloy compositions and thicknesses.

Precision machining for vacuum, electronic, or chemical use.

Prototype and small-batch development for experimental or pilot projects.

Technical consultation and performance optimization support.

Packaging & Global Logistics

Each Tantalum Alloy Plate is securely packed to ensure safety and integrity during transportation:

Vacuum-sealed or anti-rust film wrapping.

Foam cushioning for shock absorption.

Export-standard wooden crates for international shipping.

We partner with reliable global logistics providers to guarantee fast and efficient delivery by air, sea, or land, ensuring products arrive on time and in perfect condition.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers comprehensive OEM and ODM support, enabling clients to receive fully customized Tantalum Alloy Plate products. Services include:

Custom dimensions, shapes, and surface treatments.

Private labeling and special packaging.

Engineering consultation for performance design.

Dedicated after-sales and technical support.

Inspection Process

Raw Material Verification

Melting and Refining Inspection

Rolling and Annealing Checks

Mechanical and Dimensional Testing

Surface Quality and Ultrasonic Inspection

Final Certification and Documentation

This systematic inspection process ensures every Tantalum Alloy Plate meets international quality benchmarks and customer specifications.

Why Choose Us

Over 30 years of rare metal manufacturing experience.

ISO 9001:2015 certified production system.

Advanced equipment: electron beam furnaces, rolling mills, and annealing lines.

Global export to 50+ countries with excellent customer feedback.

100% quality guarantee and 7-day fast delivery for standard sizes.

|

|

|

|

|

|

FAQs

Q1: What grades are available for your Tantalum Alloy Plate?

A1: We supply grades such as Ta-2.5W, Ta-10W, and TaNb alloys, depending on application requirements.

Q2: Can you produce custom dimensions and surface finishes?

A2: Yes, both standard and customized sizes, as well as surface treatments, can be produced according to drawings.

Q3: What industries typically use Tantalum Alloy Plate?

A3: It is commonly used in aerospace, electronics, medical equipment, vacuum furnaces, and chemical processing industries.

Q4: What is your minimum order quantity (MOQ)?

A4: We accept small orders for R&D and prototype use, as well as bulk production for industrial applications.

Q5: How do you ensure stable quality for every order?

A5: All products are manufactured under strict ISO 9001 quality control procedures with full traceability and test reports.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email