- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

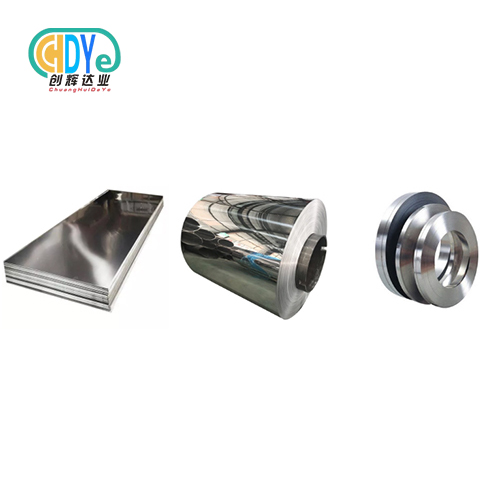

Lead Dioxide Titanium Anode Mesh

2.Support sample order

Product Introduction

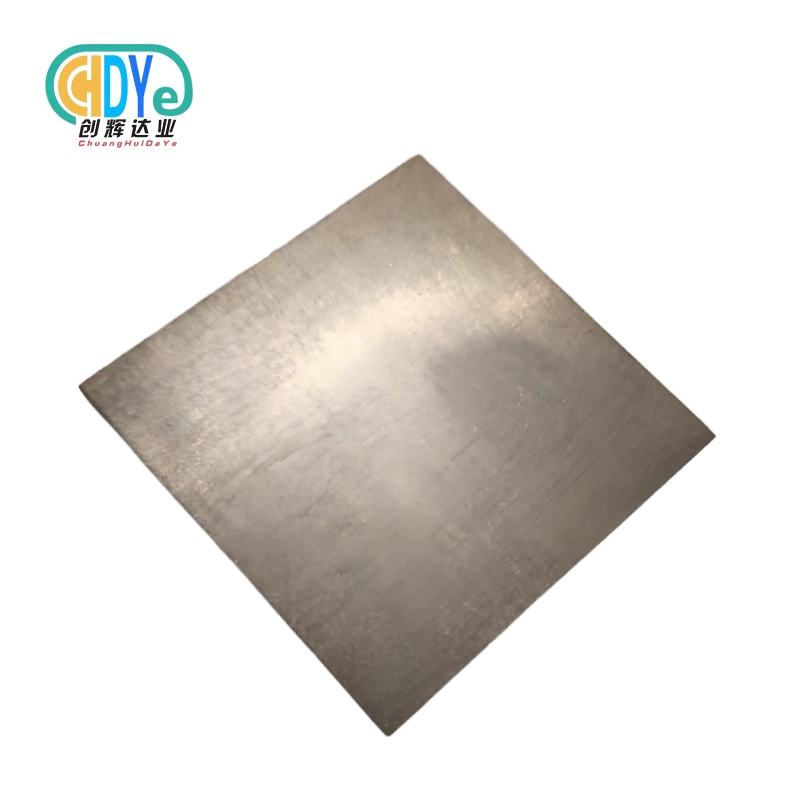

Lead Dioxide Coated Titanium Anode use pure titanium mesh as substrate, has Long life span, reusability of substrate , reduce your cost .

|

Substrate: pure titanium Gr1 |

Coating: MMO+interlayer+Ta2O5+α-PbO2+β- PbO2 |

|

Current density:≤2000 A/m² |

Coating content ≥8g |

|

Coating thickness 0.6-0.8mm |

Oxygen evolution potential ≥1.70v relative to calomel electrode |

Lead dioxide titanium anode mesh Features

1. Oxygen evolution potential≥1.70v with strong oxidizing ability.

2.High current efficiency,has similar energy consumption of iridium titanium anode at low current density.

3.Duplex coating stereo structure ,excellent binding of substrate and coating.

4.Insoluble anode ,good corrosion resistance.

5.After the coating damaged,the substrate can be reused.

6.Low-cost,long working life, high performance ,competitive price.

Application Advantages

* Electrolytic recovery and extraction of non-ferrous metal in strongly acidic water solutions;

* Chromium plating in chromic acid solution and other strongly acidic water solutions;

* Hard chromium plating, production of tin-free steel in the steel industry;

* Electrowinning of Copper,Nickel,Zinc with Sulfate, nitrate system;

* Sodium perchlorate manufacture;

* Chromate treatment;

* Production of oxidizing inorganic compounds by electrolytic oxidation;

* To make chromic acid; perchlorate, periodate, persulfate;

* Electrochemical oxidation of synthetic organic compounds in acid solution;

* Sewage Treatment: domestic sewage treatment, fading treatment of phenol wastewater, oil field wastewater, printing and dyeing wastewater, ammonia nitrogen wastewater, etc.

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

The manufacturing of Lead Dioxide Titanium Anode Mesh involves a multi-step process that combines advanced surface treatment and electrode coating technologies to achieve high density, uniform adhesion, and strong corrosion resistance.

Production Workflow:

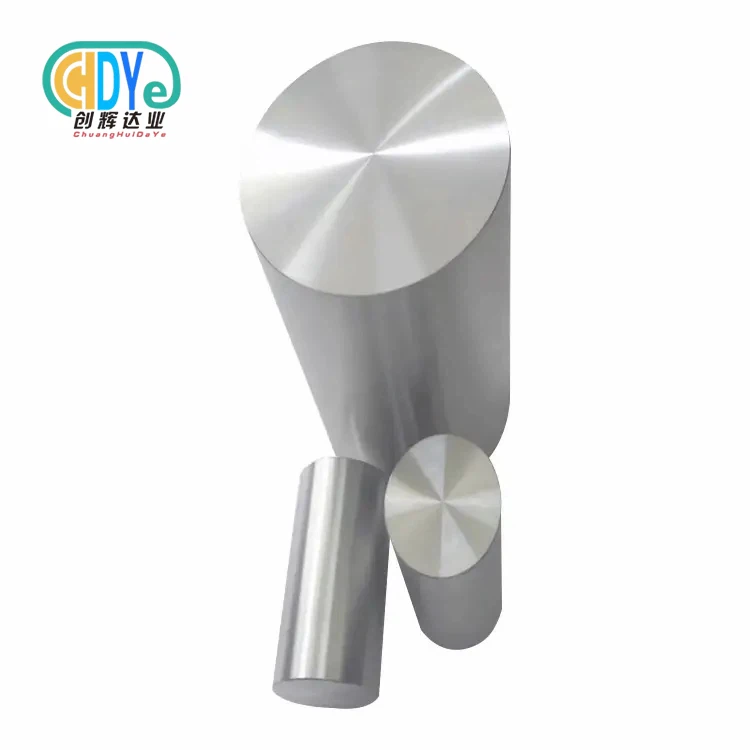

- Titanium Mesh Selection: Use of high-purity Grade 1 or Grade 2 titanium as the substrate.

- Surface Pretreatment: Acid etching, degreasing, and roughening to enhance coating adhesion.

- Intermediate Layer Application: Deposition of a conductive intermediate coating (e.g., Sn–Sb or Pt) to improve PbO₂ bonding.

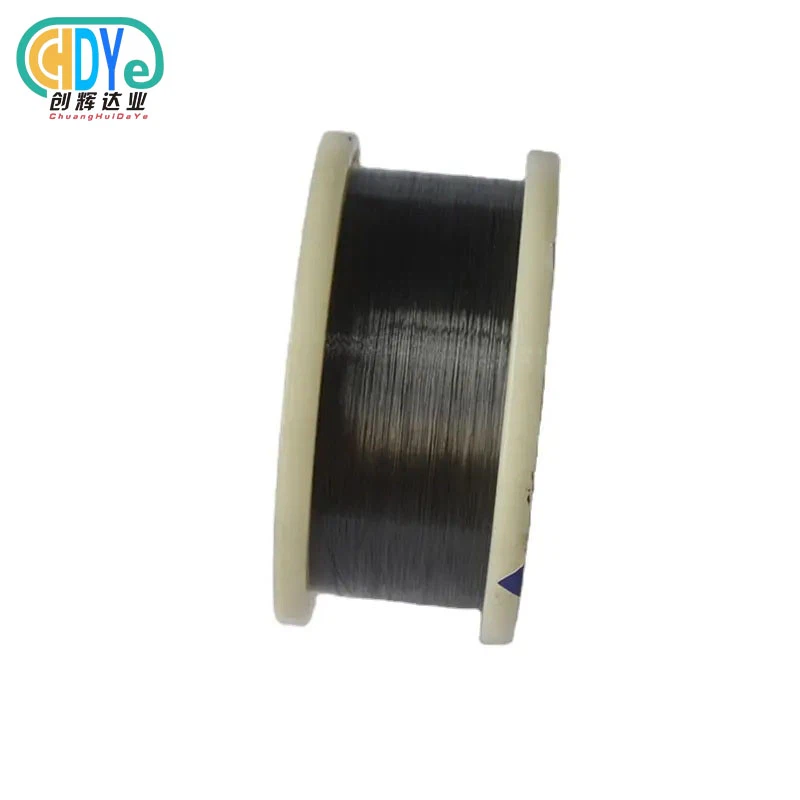

- PbO₂ Coating Formation: Electrochemical deposition of β-PbO₂ with uniform thickness and fine crystal structure.

- Heat Treatment: Stabilizes the coating and enhances oxidation resistance.

- Quality Inspection: Testing for coating density, adhesion, and electrochemical performance.

- Final Packaging: Each anode is securely packed in export-standard protective packaging.

|

|

|

|

|

|

|

|

Quality Control & Inspection

At Shaanxi Chuanghui Daye, every Lead Dioxide Titanium Anode Mesh undergoes comprehensive inspection under the ISO 9001:2015 Quality Management System to guarantee performance consistency and reliability.

Inspection Procedures Include:

- Material Verification: Titanium substrate grade and purity inspection.

- Coating Adhesion Test: Peel and scratch tests to ensure strong bonding between PbO₂ and titanium.

- Thickness and Uniformity Measurement: Using precision instruments to verify consistent coating layers.

- Electrochemical Performance Testing: Evaluation of potential stability and oxidation efficiency.

- Dimensional and Visual Inspection: Check for uniform mesh formation and defect-free surfaces.

Each product is delivered with complete inspection documentation and traceable production data.

R&D and Customization

With a dedicated R&D team and advanced laboratory facilities, Shaanxi Chuanghui Daye continues to innovate in electrode technology to meet specific industry needs.

R&D Focus Areas:

- Development of multilayer PbO₂ coatings with enhanced service life.

- Optimization of Sn–Sb interlayer for improved adhesion and conductivity.

- Tailored electrode design for high-voltage oxidation and specialized reactors.

- Research on composite anode structures combining PbO₂ with MMO or Pt layers.

Customization Options:

- Titanium grade (Gr1, Gr2)

- Mesh size, wire diameter, and thickness

- Coating type (α-PbO₂, β-PbO₂, or mixed layers)

- Anode geometry and mounting design according to customer drawings

Our technical experts provide one-on-one support from concept design to final production.

Packaging & Global Logistics

We take every precaution to ensure our products arrive safely and in perfect condition.

Standard Packaging:

- Anti-rust or vacuum-sealed film wrapping

- Foam-lined and reinforced wooden cases

- Clearly labeled packages with batch numbers and specifications

Logistics Solutions:

- Fast global delivery via air, sea, or land

- 7-day shipment for standard sizes

- Export documentation and logistics tracking services

All packaging materials meet international export and environmental standards.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide comprehensive OEM and ODM services for global distributors, system integrators, and end-users.

Our Services Include:

- Custom mesh size, shape, and coating specifications

- Private labeling and logo marking

- Engineering support and technical drawing assistance

- Prototype manufacturing and small-batch trial production

- On-site technical consultation and after-sales support

Our flexible production system enables efficient delivery of both standard and custom-designed PbO₂ titanium anodes.

Inspection Process

To maintain consistent quality and long-term reliability, each Lead Dioxide Titanium Anode Mesh follows a detailed inspection workflow before shipment:

- Titanium Substrate Inspection – Confirm material grade, dimensions, and surface condition.

- Intermediate Layer Verification – Measure conductivity and uniformity of the bonding layer.

- PbO₂ Coating Test – Check for adhesion strength, thickness, and surface uniformity.

- Electrochemical Testing – Verify oxidation potential and anode efficiency under controlled conditions.

- Final Visual and Dimensional Check – Ensure flawless appearance and accuracy.

- Packaging and Certification – Attach quality inspection reports and serial number traceability.

Why Choose Us

- Over 30 Years of Industry Expertise: Deep knowledge of titanium and rare metal electrode production.

- ISO 9001 Certified Manufacturer: Full process quality control and traceability.

- Advanced Coating Technology: Reliable PbO₂ deposition for superior performance.

- Global Export Experience: Products supplied to over 50 countries, including the USA, Germany, and South Korea.

- Strong R&D Support: Continuous innovation in coating and electrode structures.

- Complete OEM/ODM Solutions: Flexible customization to meet specific application needs.

- Fast Delivery and Competitive Pricing: Efficient production and global logistics network.

- Comprehensive After-Sales Service: Technical assistance and long-term cooperation commitment.

|

|

|

|

|

|

FAQs

Q1: What is the main advantage of a Lead Dioxide Titanium Anode Mesh?

A1: It combines the corrosion resistance of titanium with the strong oxidation ability of PbO₂, offering high efficiency and long service life in electrochemical oxidation processes.

Q2: What coating types are available?

A2: We provide α-PbO₂, β-PbO₂, or dual-layer PbO₂ coatings depending on the required performance and working conditions.

Q3: Can the mesh size and shape be customized?

A3: Yes. We can produce different mesh patterns, wire diameters, and geometries according to customer drawings or reactor designs.

Q4: How long does the anode last?

A4: The lifespan typically ranges from 1 to 5 years, depending on the electrolyte composition, current density, and coating structure.

Q5: Do you provide technical support?

A5: Absolutely. Our engineers offer coating selection advice, process optimization, and after-sales guidance for all projects.

Q6: What is your delivery time?

A6: Standard products can be shipped within 7 working days, while customized orders depend on specifications and quantity.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email