- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

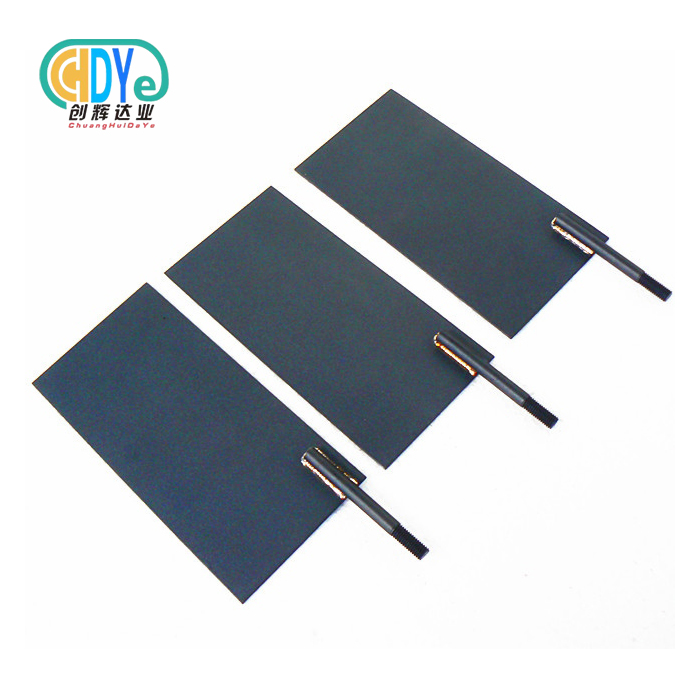

5mm titanium rod

2. Density 4.43g/cm³, strength ≥895MPa.

3. Precision-machined surface finish.

4. Used in aerospace and medical fields.

5. Length 1000–2000mm.

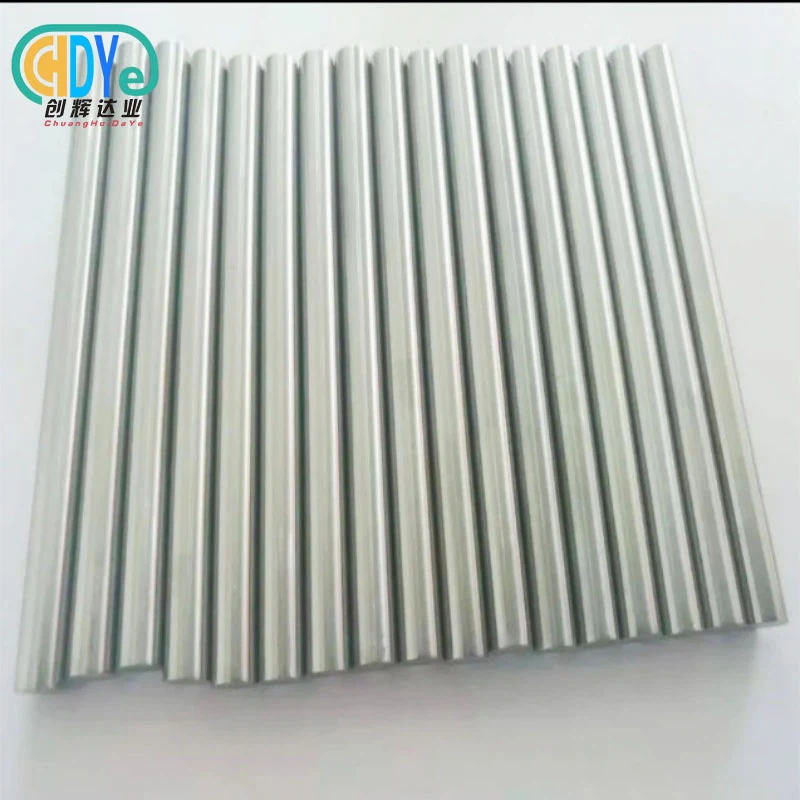

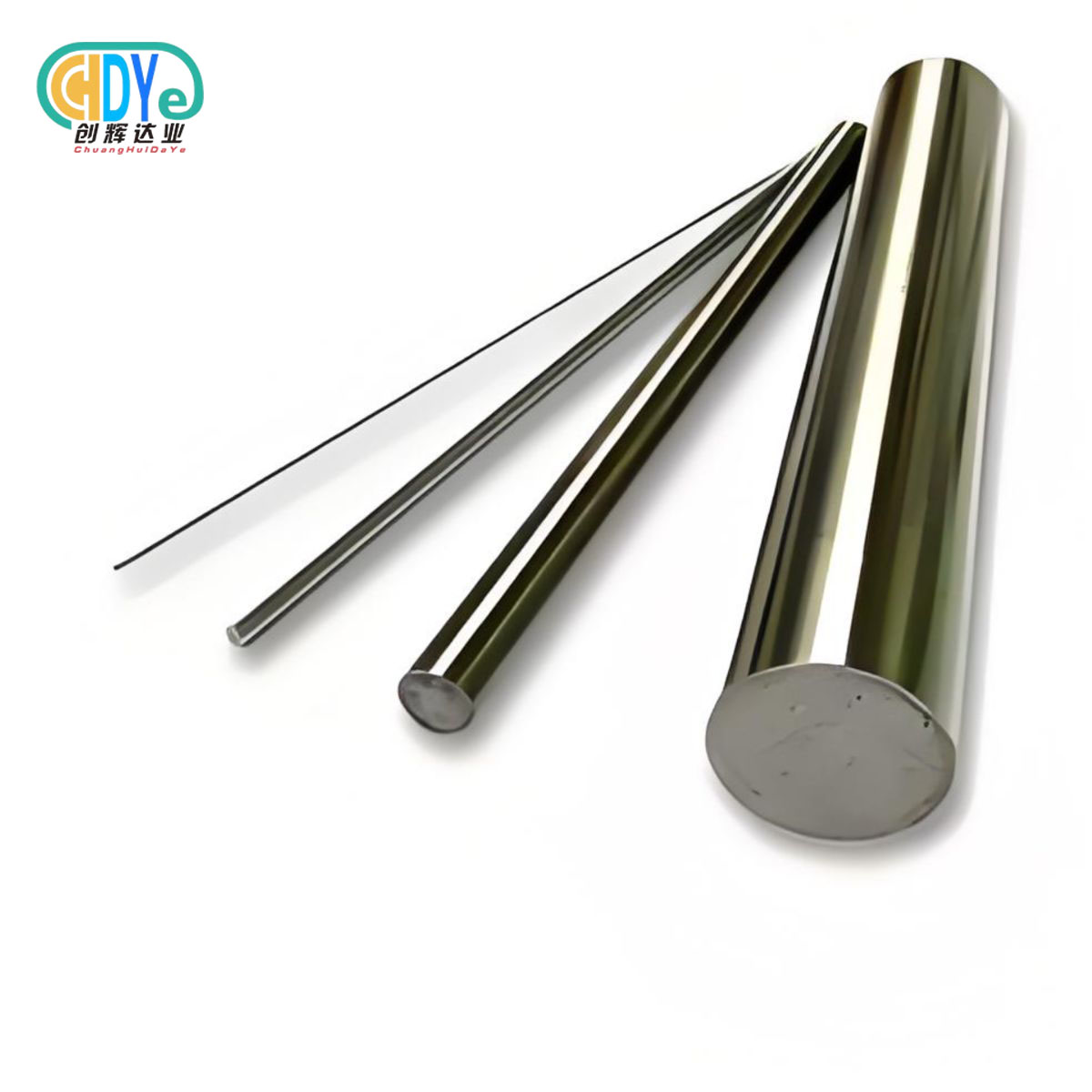

5mm Titanium Rod

Looking for high-quality 5mm titanium rod for your precision applications? Our Grade 5 titanium rods deliver exceptional strength, corrosion resistance, and reliability for demanding projects. Manufactured to ASTM B348 standards, these precision-engineered rods offer superior performance in aerospace, medical, and industrial applications. With over 30 years of expertise in rare metal manufacturing, we provide you with titanium products that meet the highest quality standards. Each rod features precision-machined surfaces and consistent dimensional accuracy for your critical applications.

Key Features and Benefits

Your projects deserve materials that won't let you down. Our titanium rods offer remarkable corrosion resistance in harsh environments. You'll appreciate the excellent strength-to-weight ratio that reduces overall component weight without sacrificing performance.

The biocompatibility makes these rods perfect for medical applications. You get consistent mechanical properties throughout each rod. The material maintains stability across wide temperature ranges. Non-magnetic properties ensure compatibility with sensitive equipment.

Technical Specifications

Material Grade: Grade 5 (Ti-6Al-4V)

Diameter: 5mm ±0.1mm

Standard Length: 1000-3000mm

Density: 4.43 g/cm³

Tensile Strength: ≥895 MPa

Yield Strength: ≥825 MPa

Elongation: ≥10%

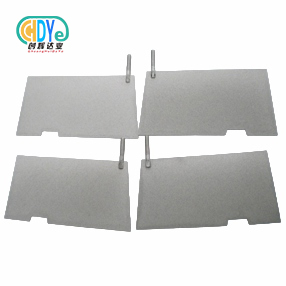

Surface Finish: Precision machined

Available Grades and Materials

We offer multiple titanium grades to meet your specific requirements. Grade 5 (Ti-6Al-4V) provides the highest strength for structural applications. Grade 2 commercially pure titanium offers excellent corrosion resistance for chemical processing.

Grade 1 delivers maximum ductility for forming operations. Grade 4 provides enhanced strength while maintaining good formability. Each grade comes with full material certification and traceability documentation.

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

|

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

|

Manufacturing Process

Our manufacturing process begins with premium titanium ingots. We use precision drawing techniques to achieve exact dimensional tolerances. Multiple quality checkpoints ensure consistent properties throughout production.

Heat treatment optimizes mechanical properties for your applications. Surface finishing removes any imperfections for smooth, clean surfaces. Final inspection verifies all specifications before packaging.

|

|

|

|

|

|

|

|

Applications and Industries

Aerospace components benefit from the lightweight, high-strength properties. Medical implants and surgical instruments rely on biocompatibility and corrosion resistance. Marine hardware withstands saltwater environments without degradation.

Chemical processing equipment handles corrosive media safely. Automotive racing parts reduce weight while maintaining strength. Sports equipment manufacturers choose our 5mm titanium rod for premium performance products.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard diameter tolerance: ±0.05mm

Length tolerance: +10mm/-0mm

Straightness: ≤1mm per meter

Surface roughness: Ra ≤1.6μm

Concentricity: ≤0.05mm TIR

Custom dimensions available upon request. We can provide shorter lengths or longer sections based on your needs. Special tolerances achievable for critical applications.

Product Features in Detail

The precision-machined surface finish eliminates the need for additional processing in many applications. You receive rods with excellent dimensional consistency from batch to batch. The material exhibits superior fatigue resistance for cyclic loading applications.

Low thermal expansion coefficients ensure dimensional stability. The passive oxide layer provides natural corrosion protection. Excellent machinability allows for easy secondary operations.

Quality Assurance and Testing

Every batch undergoes comprehensive testing including chemical analysis and mechanical property verification. We maintain full traceability from raw material to finished product. Our quality system complies with AS9100 aerospace standards.

Ultrasonic testing detects any internal defects. Dimensional inspection verifies all tolerances. Material certificates accompany each shipment with complete test results.

|

|

|

OEM & Customization Services

We understand that your projects may require specific modifications. Our engineering team works with you to develop custom solutions. We can adjust lengths, surface treatments, or mechanical properties to meet your exact requirements.

Prototype quantities available for testing and validation. Volume production capabilities ensure consistent supply for your manufacturing needs. Technical support helps optimize material selection for your applications.

Packaging and Shipping

Products ship in protective packaging to prevent damage during transit. Individual rods receive foam protection and moisture barriers. We use sturdy wooden crates for larger quantities.

International shipping available to over 50 countries worldwide. Express delivery options for urgent requirements. All shipments include proper documentation for customs clearance.

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we have direct access to premium raw materials. Our founder brings over 30 years of rare metal industry experience. This expertise ensures you receive the highest quality products.

We focus on customer satisfaction and long-term partnerships. Competitive pricing combined with reliable delivery makes us your ideal supplier. Our products successfully serve customers across the United States, Germany, South Korea, and Singapore.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate orders from single pieces to large production runs.

Q: Can you provide material certificates?

A: Yes, complete material certificates accompany every shipment.

Q: What payment terms do you accept?

A: We offer flexible payment terms including T/T, L/C, and others.

Q: How quickly can you deliver?

A: Standard items ship within 7-15 days. Custom products may require additional time.

Contact Us

Ready to discuss your requirements? Our technical team stands ready to help you select the perfect material for your application. Whether you need standard 5mm titanium rod or custom specifications, we provide expert guidance and reliable service.

Email us at info@chdymetal.com for detailed quotations and technical support. Let's work together to bring your projects to success with premium titanium materials.

Learn about our latest products and discounts through SMS or email