- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

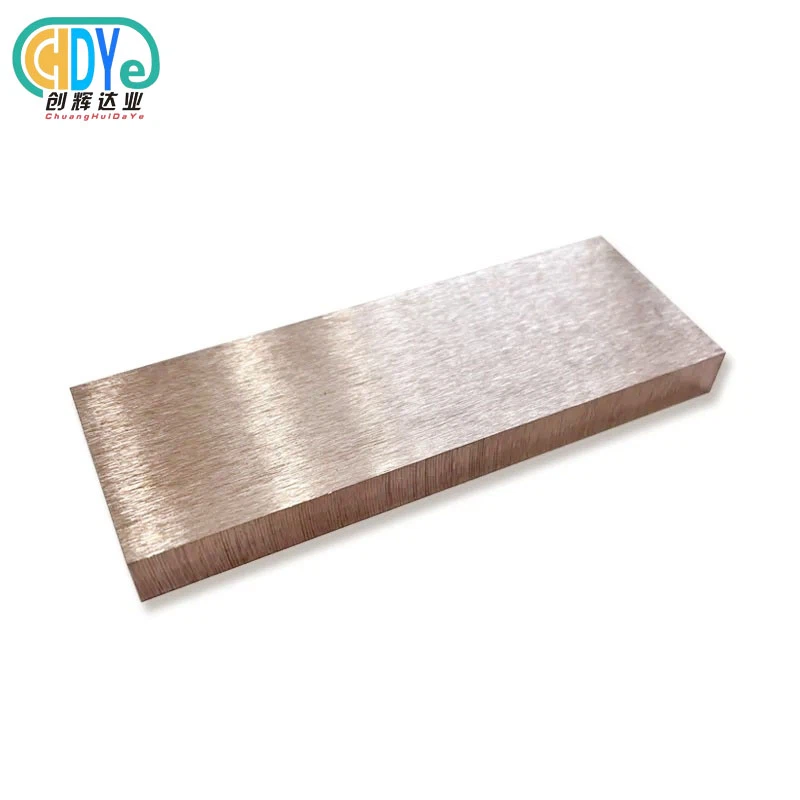

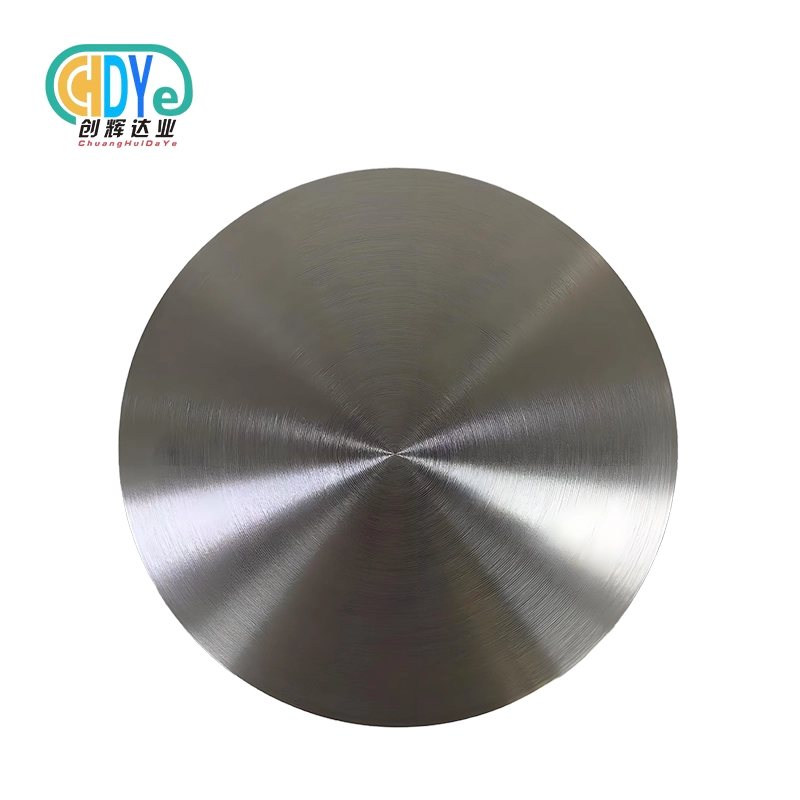

Tungsten Alloy Sheet

Thickness:0.2-5.0mm sheet type

Surface:sintering, polishing, lathing,

Product Introduction

The Tungsten Alloy Sheet manufactured by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a high-density and precision-engineered material designed for applications requiring exceptional strength, durability, and heat resistance. Produced from advanced tungsten-based alloys, this sheet combines excellent mechanical properties with superior thermal conductivity and corrosion resistance.

With tungsten’s melting point of approximately 3422°C and its outstanding density (19.0–19.3 g/cm³), the product performs reliably under extreme temperature and pressure conditions. It offers stable physical characteristics, minimal thermal expansion, and exceptional wear resistance, making it a preferred choice in industries such as aerospace, electronics, medical, and defense. Each sheet is manufactured according to ASTM, AMS, and GB standards, ensuring global compatibility and consistent quality.

The tungsten plate is made of high-quality tungsten powder, and processed into slabs with excellent performance. Special rolling process technology is used to produce tungsten plates and sheets, which have the advantages of good processing performance and low impurity content. Chdy metals offers top-quality Tungsten plates at competitive prices, with customized options to meet needs.

Specification and shape

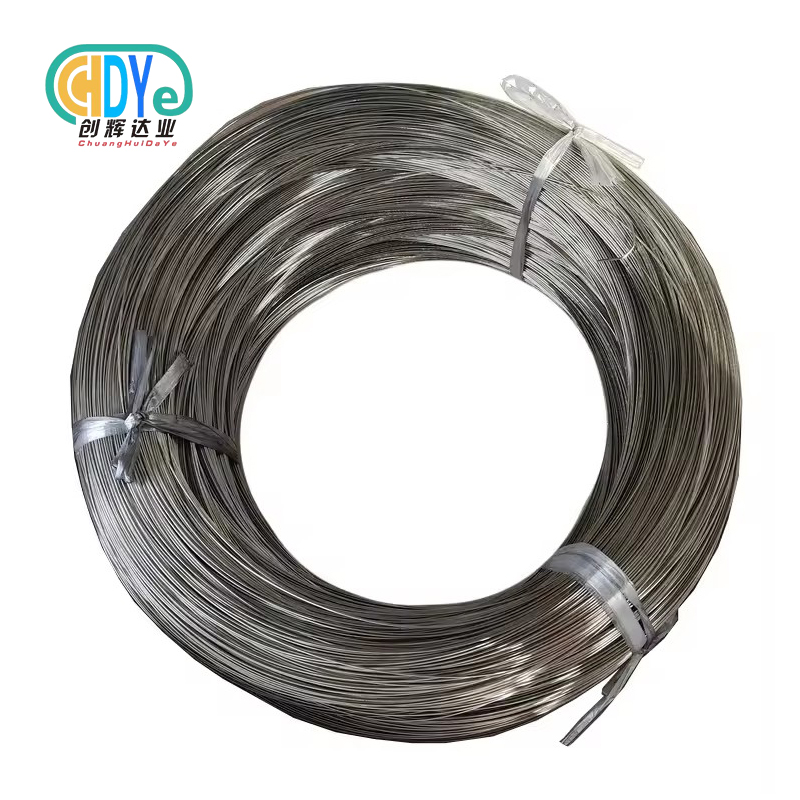

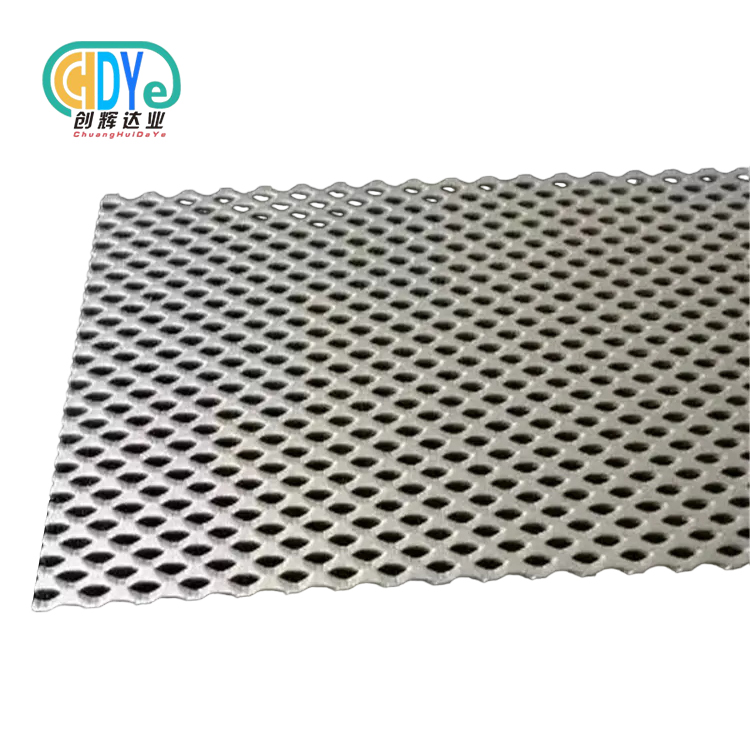

Shape:plate, sheet, strip, foil

Foil - less than 0.005 inches (0.13 mm) thick.

Strip - greater than or equal to 0.188 inches (4.75 mm) thick.

Sheet - less than or equal to 0.005 inches (0.13 mm) or less than or equal to 0.187 inches (4.75 mm) thick.

Width × length: (2.0-500.0 mm) × (2.0-500.0 mm)

Thickness: 0.2mm-5.0mm;

Density: 15.8-18.75g/cm^3

Composition: W content 90-97%, tungsten nickel iron, tungsten nickel copper

Surface treatment: surface sintering, polishing, lathing, milling.

Our Service Processes

Application Advantages

The Tungsten Alloy Sheet is widely utilized across industries that demand high performance in harsh environments. Key applications include:

- Aerospace and Defense: Used for radiation shielding, balance weights, and kinetic energy penetrators.

- Electronics and Semiconductors: Ideal for sputtering targets, heat spreaders, and high-current electrodes.

- Medical Equipment: Applied in radiotherapy shielding, collimators, and imaging device components.

- Metallurgical and Vacuum Technology: Used for furnace parts, hot zone components, and thermal shields.

- Energy and Nuclear Engineering: Serves as a reliable material for control rods and protective barriers.

Its combination of density, strength, and corrosion resistance makes it indispensable for precision engineering and advanced manufacturing.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

1. Mixed powder( Mixed powder machine)

2. Pressing( isostatic press)

3 .Sintering ( Medium frequency sintering furnace)

4. Rolling (hot rolling, warm rolling, cold rolling)

5. Alkali washing (centrifugal extractor)

6. Polishing (grinder)

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is at the core of our production philosophy. Every Tungsten Alloy Sheet undergoes comprehensive testing and inspection in accordance with ISO 9001:2015 standards.

Inspection Procedures Include:

- Chemical Composition Analysis: Verified by XRF and ICP testing to ensure proper alloy ratios.

- Density and Porosity Testing: Ensures the material achieves required compactness.

- Tensile Strength & Hardness Testing: Measures performance under mechanical stress.

- Ultrasonic Flaw Detection: Identifies any internal defects or microcracks.

- Dimensional & Surface Inspection: Conducted using precision metrology instruments.

All test results are documented with material certificates for traceability and client assurance.

R&D and Customization

With over 30 years of experience in the rare metal industry, Shaanxi Chuanghui Daye has built a strong research and development foundation. Our technical team continuously explores new tungsten-based materials and improves processing methods to enhance product reliability.

Customization Capabilities Include:

- Tailored alloy compositions (W-Ni-Fe, W-Ni-Cu, or other blends).

- Custom sheet thicknesses and widths according to application.

- Polished, rolled, or machined surface finishes.

- Prototype and small-batch production for experimental use.

We work closely with clients to provide solutions optimized for mechanical, thermal, and radiation performance needs.

Packaging & Global Logistics

Each product is packaged and shipped following international export standards to ensure protection during transportation.

Packaging Details:

- Anti-rust film or vacuum-sealed wrapping.

- Foam or shock-resistant padding for mechanical safety.

- Export-standard wooden boxes with clear product labeling.

Logistics Services:

- Global air, sea, and land transport options.

- Tracking support and full export documentation.

- 7-day fast delivery for standard specifications.

Our logistics network covers more than 50 countries, ensuring safe and timely delivery of products worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

Shaanxi Chuanghui Daye provides complete OEM and ODM manufacturing support for global clients.

Service Features:

- Custom dimensions and alloy grades based on design drawings.

- Private labeling and specialized packaging.

- Technical consultation for material selection and performance optimization.

- Flexible production from prototypes to large-scale batches.

We aim to deliver reliable, cost-effective solutions while maintaining the highest levels of precision and consistency.

Inspection Process

Every order follows a strict inspection routine before delivery:

- Raw Material Verification: Ensures tungsten purity and alloy accuracy.

- In-Process Monitoring: Parameters controlled during pressing, sintering, and rolling.

- Dimensional Testing: Accuracy checked with calibrated instruments.

- Surface Examination: Detects scratches, pits, or inclusions.

- Final Quality Audit: All certifications and test results are reviewed before packaging.

This multi-level system guarantees the consistency and integrity of all outgoing products.

Why Choose Us

- 30+ Years of Rare Metal Expertise: Decades of professional manufacturing experience.

- Advanced Equipment: Electron beam furnaces, rolling mills, and precision machining systems.

- ISO 9001:2015 Certification: Comprehensive quality management across all stages.

- Global Export Reputation: Clients in over 50 countries and regions.

- R&D Capability: Continuous improvement and innovation in tungsten alloy materials.

- OEM & ODM Support: Full customization from concept to final delivery.

- Fast Delivery & Reliable Logistics: 7-day standard order fulfillment.

|

|

|

|

|

|

FAQs

Q1: What is the typical composition of your tungsten alloy sheets?

A1: Our common compositions include W-Ni-Fe and W-Ni-Cu systems, customizable based on specific applications.

Q2: Can you provide small samples for testing?

A2: Yes, we offer small samples and prototype production for research and validation.

Q3: What surface finishes are available?

A3: Sheets can be supplied polished, ground, or machined to meet precision requirements.

Q4: How do you ensure consistent quality across batches?

A4: Each batch is tested for density, chemical composition, and dimensional accuracy under ISO-certified procedures.

Q5: What industries use your tungsten alloy sheets most frequently?

A5: They are widely used in aerospace, medical, electronics, and nuclear applications for heat and radiation shielding.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email