- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Analysis of the Corrosion Resistance of Titanium Alloys in Multi-Media Environments

Titanium and its alloys exhibit excellent corrosion resistance in chemical engineering, environmental protection, marine engineering, and other fields due to their unique physical and chemical properties. However, their corrosion resistance is significantly affected by the composition of the medium, temperature, and alloying elements. This article systematically examines the corrosion behavior and mechanisms of titanium alloys in various media environments, providing a theoretical basis for engineering applications.

Corrosion Resistance in Chlorine-Containing Media

1. Stability in Wet Chlorine Systems

Titanium exhibits excellent corrosion resistance in wet chlorine gas and non-high-temperature, high-concentration chloride solutions (except ZnCl₂, AlCl₃, and CaCl₂). The dense oxide film (TiO₂) formed on its surface effectively blocks chloride ion penetration, making it widely used in bleaching plants, electrolytic chlorine plants, and wastewater treatment plants. However, in high-temperature (>100°C) and high-concentration chloride solutions, titanium is susceptible to crevice corrosion. This is especially true when in contact with organic materials such as polytetrafluoroethylene. The localized oxygen deficiency accelerates the breakdown of the oxide film, significantly increasing the corrosion rate.

2. Hazardous Reactions in Dry Chlorine Systems

Dry chlorine gas reacts violently with titanium in an exothermic reaction The heat released can cause spontaneous combustion or even explosion. The reaction product, titanium tetrachloride (TiCl₄), continues to volatilize in low humidity conditions, exacerbating the combustion process. Research has shown that industrially pure titanium requires a moisture content of at least 1.5% to remain passive in chlorine at 200°C; at room temperature, the moisture content must be ≥0.3%-0.4%. By optimizing the alloy composition, titanium-palladium alloys and titanium-nickel-molybdenum alloys can reduce the critical moisture content to below 0.1%, significantly improving safety.

3. Compatibility with Chlorine-Containing Solutions

Titanium exhibits excellent corrosion resistance to chlorine-containing solutions such as chlorates, chlorites, hypochlorites, and perchlorates, but high temperatures and high concentrations must be avoided. For example, in the electrolytic production of sodium hypochlorite, titanium-based anodes, due to their corrosion resistance and electrical conductivity, are an ideal alternative to graphite.

Differential Performance in Halogen Media

1. Stability of Bromine and Iodine Systems

The corrosion resistance mechanism of titanium in bromine and iodine environments is similar to that of chlorine: maintaining a trace amount of moisture in the medium (typically ≥0.5%) promotes the regeneration of the surface oxide film. In seawater desalination plants, titanium tube heat exchangers have been exposed to bromide ion-containing environments for long periods without showing any obvious signs of corrosion.

2. Achilles' Weakness of Fluorine Systems

Titanium's corrosion resistance decreases dramatically in fluorine, hydrofluoric acid, and acidic fluoride solutions. Even extremely low concentrations (e.g., 0.1% HF) can destroy the oxide film. Its corrosion rate can be over 10 times that of chlorine systems, and effective corrosion inhibitors are lacking. Exceptions include fluorides (e.g., Na₃AlF₆) or fluorocarbons (e.g., PTFE), which form stable complexes with metal ions. Fluoride ions inhibit their activity and have little corrosive effect on titanium. III. Synergistic Effects of Alloying Modification

The addition of elements such as palladium, nickel, and molybdenum can significantly increase the corrosion resistance threshold of titanium alloys:

Titanium-palladium alloy: Palladium promotes the repair of oxygen vacancies in the oxide film, reducing the critical moisture content to 0.05%.

Titanium-nickel-molybdenum alloy: Nickel and molybdenum form a solid solution, enhancing the stability of the oxide film in reducing media, making it suitable for mixed acid environments containing Cl⁻ and SO₄²⁻.

Titanium-zirconium alloy: The addition of zirconium refines the grain structure, improving resistance to crevice corrosion and demonstrating outstanding performance in marine engineering applications.

Engineering Application Recommendations

1. Medium Composition Control: In chlorine-containing processes, moisture content and temperature must be strictly monitored to avoid high-temperature, high-concentration corrosion zones.

2. Material Selection Principles:

In wet chlorine environments, commercially pure titanium (TA1/TA2) is preferred.

Dry chlorine operations require nitrogen isolation or titanium-palladium alloys.

In fluorine-containing systems, titanium should be avoided; Hastelloy or Monel should be used instead.

3. Structural Design Optimization: Avoid direct contact between titanium and organic materials. Use coatings or electrochemical protection to reduce the risk of crevice corrosion.

The corrosion resistance of titanium alloys is distinctly medium-dependent, and their "oxide film" nature-its success or failure-requires precise engineering control. Through alloying modification and process optimization, the application of titanium alloys in harsh corrosive environments is continuously expanding, providing key material support for the long-life operation of chemical equipment. Future research is needed to further elucidate the dynamic repair mechanism of oxide films and develop fourth-generation titanium alloys suitable for supercritical chlorine systems.

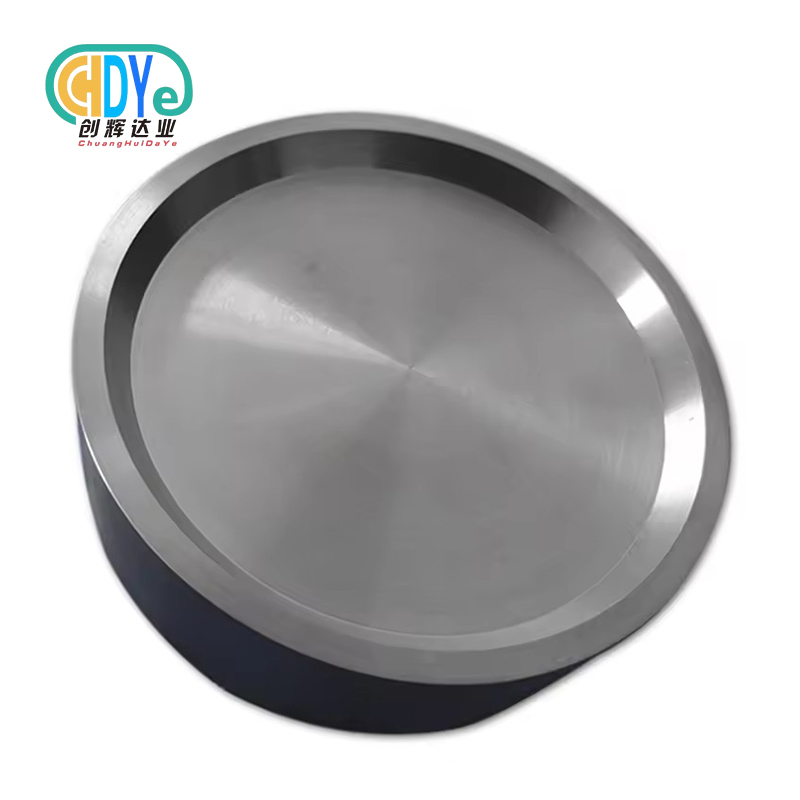

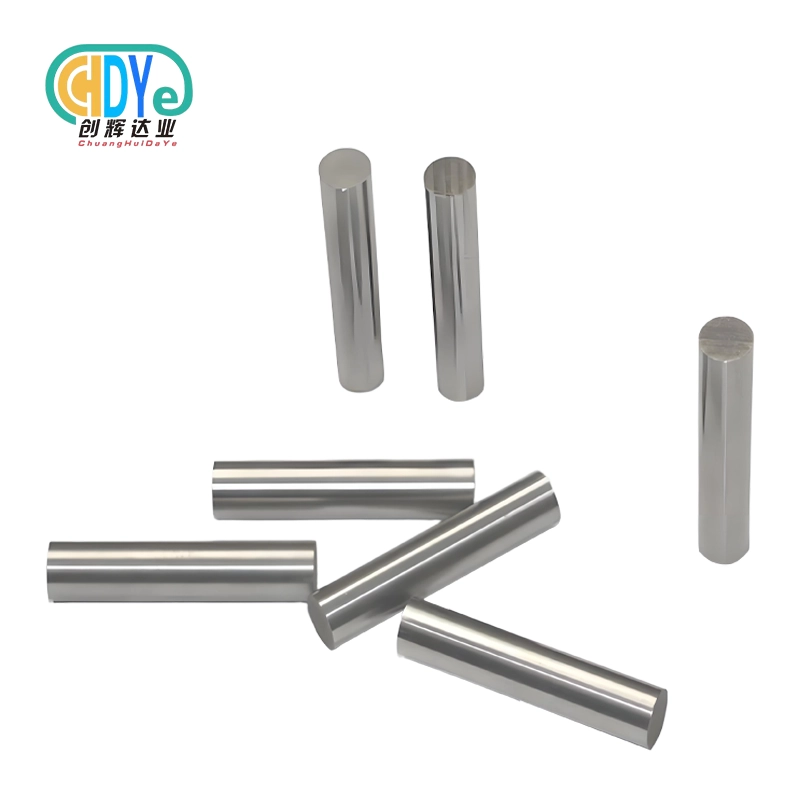

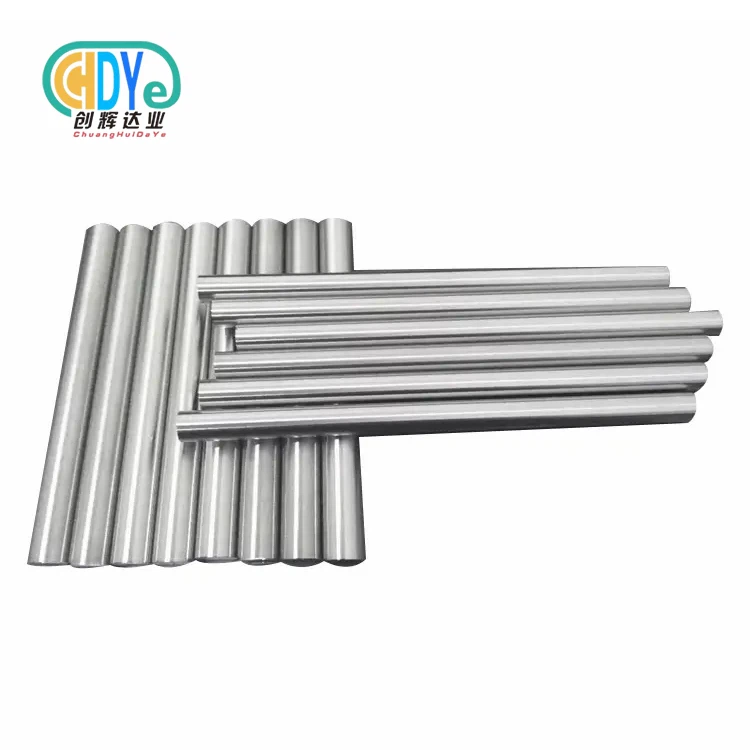

Shaanxi Chuanghui Daye Metal Material CO.,Ltd provide titanium, tantalum, niobium bar, plate, wire, tube and machined products, if you have any requirements pls feel free to contact us.

E-mail: info@chdymetal.com

Mobile.: 86-18049386902

Learn about our latest products and discounts through SMS or email