- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the fatigue strength of a niobium round bar?

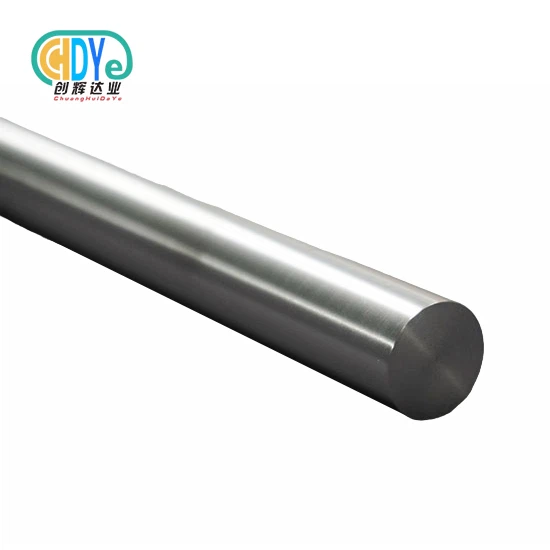

Fatigue strength is a critical mechanical property, especially when it comes to materials used in demanding applications. As a supplier of Niobium Round Bars, I often encounter questions about the fatigue strength of these products. In this blog, I will delve into what fatigue strength means for a niobium round bar, factors affecting it, and why it matters in various industries.

Understanding Fatigue Strength

Fatigue strength refers to the maximum stress that a material can withstand for a specified number of cycles without failing. Unlike static strength, which deals with a single - time load, fatigue strength is concerned with repeated or cyclic loading. When a niobium round bar is subjected to cyclic loads, such as vibrations, alternating stresses, or repeated impacts, its internal structure gradually weakens over time. Micro - cracks may initiate and propagate, eventually leading to failure.

The fatigue strength of a niobium round bar is typically determined through fatigue testing. In a fatigue test, a specimen of the niobium round bar is loaded cyclically at a specific stress level. The number of cycles until failure is recorded. This process is repeated at different stress levels, and the results are plotted on an S - N curve (stress - number of cycles curve). The S - N curve shows the relationship between the applied stress and the number of cycles to failure. From this curve, the fatigue strength at a given number of cycles can be determined.

Factors Affecting the Fatigue Strength of Niobium Round Bars

Material Purity

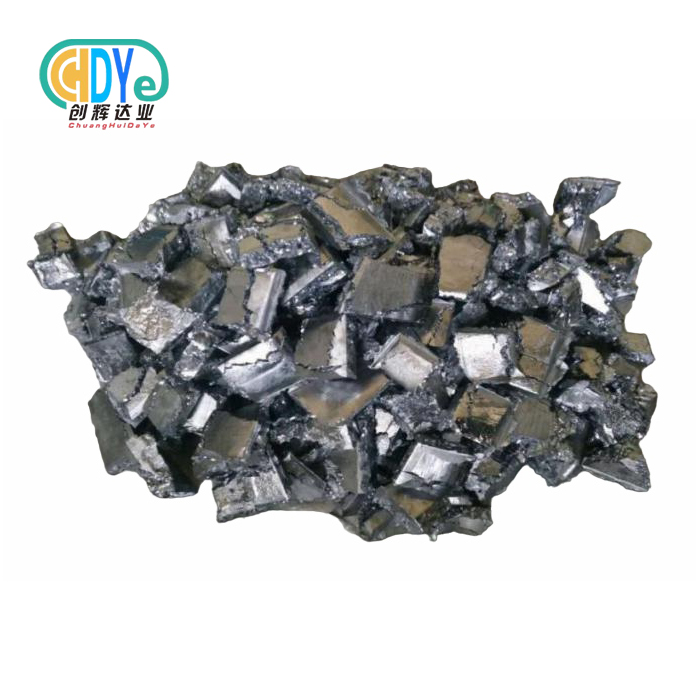

The purity of niobium in the round bar has a significant impact on its fatigue strength. Higher purity niobium generally has fewer impurities and inclusions, which can act as stress concentrators. Stress concentrators are points in the material where the stress is higher than the average stress, making it easier for micro - cracks to initiate. Our Pure Niobium Rod is produced with high - grade niobium, ensuring a low impurity content and better fatigue resistance.

Grain Structure

The grain structure of the niobium round bar also affects its fatigue strength. Fine - grained niobium has more grain boundaries, which can impede the propagation of micro - cracks. During cyclic loading, the grain boundaries act as barriers, forcing the cracks to change direction and dissipating the energy of the crack. On the other hand, coarse - grained niobium may have fewer barriers to crack propagation, resulting in lower fatigue strength. Through proper heat treatment and processing techniques, we can control the grain structure of our niobium round bars to optimize their fatigue performance.

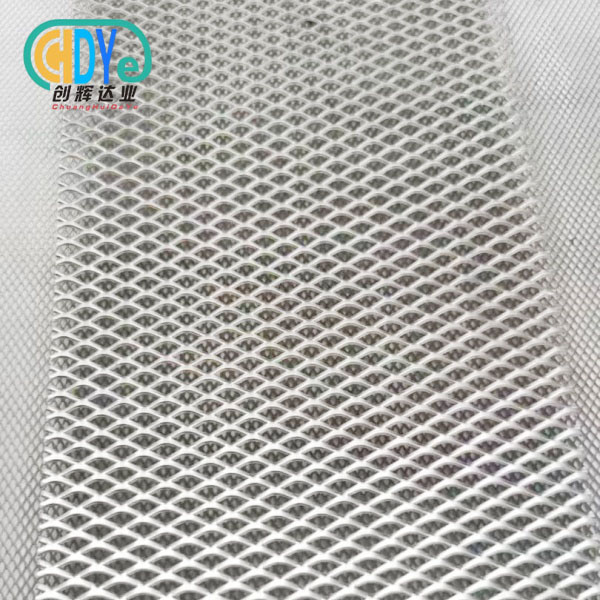

Surface Finish

The surface finish of the niobium round bar plays a crucial role in its fatigue strength. A rough surface can have microscopic defects, such as scratches and pits, which act as stress concentrators. These stress concentrators can initiate micro - cracks under cyclic loading. In contrast, a smooth surface finish reduces the likelihood of crack initiation. We take great care in the manufacturing process to ensure that our niobium round bars have a high - quality surface finish, thereby enhancing their fatigue resistance.

Loading Conditions

The type, magnitude, and frequency of the cyclic loading also affect the fatigue strength of niobium round bars. For example, a high - frequency cyclic load may cause more rapid crack propagation compared to a low - frequency load. Similarly, a load with a large stress amplitude will generally lead to a shorter fatigue life than a load with a small stress amplitude. Understanding the specific loading conditions of the application is essential for selecting the appropriate niobium round bar with the required fatigue strength.

Importance of Fatigue Strength in Different Industries

Aerospace Industry

In the aerospace industry, niobium round bars are used in various components, such as engine parts and structural elements. These components are subjected to severe cyclic loads during flight, including vibrations, thermal cycling, and aerodynamic forces. A failure due to fatigue can have catastrophic consequences. Therefore, high fatigue strength is crucial to ensure the reliability and safety of aerospace systems. Our Niobium Alloy Rod is designed to meet the stringent requirements of the aerospace industry, providing excellent fatigue resistance under extreme conditions.

Energy Industry

The energy industry, particularly in nuclear power plants and oil and gas extraction, also relies on niobium round bars. In nuclear reactors, niobium is used in components that are exposed to high - temperature and high - radiation environments, as well as cyclic thermal stresses. In oil and gas extraction, niobium round bars may be used in drilling equipment, which is subjected to repeated impacts and vibrations. The fatigue strength of these components is vital to prevent failures that could lead to costly downtime and environmental hazards.

Medical Industry

In the medical industry, niobium round bars are used in the manufacturing of surgical instruments and implants. These devices are often subjected to repeated use and cyclic loading. For example, a surgical clamp may be opened and closed numerous times during a surgical procedure. High fatigue strength ensures that these medical devices can withstand the repeated loading without failure, providing reliable performance and patient safety.

Our Offerings

As a leading supplier of Niobium Bar and Rod, we are committed to providing high - quality products with excellent fatigue strength. We use advanced manufacturing processes and strict quality control measures to ensure that our niobium round bars meet or exceed industry standards. Our team of experts can also provide technical support and guidance to help you select the right niobium round bar for your specific application.

If you are in need of niobium round bars with reliable fatigue strength, we encourage you to contact us for further discussion. Whether you are in the aerospace, energy, medical, or any other industry, we can work with you to find the best solution for your needs. Our products are designed to offer long - term performance and durability, ensuring that your applications run smoothly and efficiently.

Conclusion

The fatigue strength of a niobium round bar is a complex property that is influenced by multiple factors, including material purity, grain structure, surface finish, and loading conditions. Understanding these factors is essential for selecting the appropriate niobium round bar for a specific application. In industries such as aerospace, energy, and medical, high fatigue strength is crucial for ensuring the reliability and safety of components. As a trusted supplier of niobium round bars, we are dedicated to providing products that meet the highest standards of fatigue performance. Contact us today to discuss your requirements and explore how our niobium round bars can benefit your projects.

Shaanxi Chuanghui Daye Metal Material CO.,Ltd is a ISO9001:2015 certified company can produce niobium round bar, niobium alloy bar ,if you have any requirements about niobium round bar, pls feel free to contact us.

E-mail: info@chdymetal.com

Mob./what's app: 86-18049386902

References

-ASM Handbook Volume 19: Fatigue and Fracture. ASM International.

"Niobium: Properties, Processing, and Applications" by various authors in the Journal of Metals.

"Mechanical Behavior of Materials" by Donald R. Askeland and Pradeep P. Phule.

Learn about our latest products and discounts through SMS or email