When aerospace engineers need materials that can withstand extreme temperatures and corrosive environments, tantalum alloy plate emerges as the ultimate solution. This exceptional refractory metal offers unmatched performance in both aerospace and electronics applications. From spacecraft components to semiconductor manufacturing equipment, tantalum alloy provides the reliability and durability that mission-critical systems demand. Its unique combination of corrosion resistance, high melting point, and excellent electrical properties makes it indispensable across various high-tech industries.

Understanding Tantalum Alloy Properties for High-Performance Applications

Tantalum amalgam shows exceptional characteristics that set it separated from other hard-headed metals. The fabric keeps up its auxiliary keenness at temperatures surpassing 3000°C, making it perfect for extraordinary environment applications. Its thickness of roughly 16.6 g/cm³ gives fabulous dimensional solidness beneath warm stress.

The amalgam illustrates uncommon erosion resistance against for all intents and purposes all acids but hydrofluoric corrosive. This chemical dormancy stems from the arrangement of a defensive oxide layer on the surface. Tantalum's biocompatibility moreover makes it important for restorative applications inside aviation systems.

Electrical conductivity remains steady over wide temperature ranges, which demonstrates significant for electronic components. The material's moo work work and tall electron outflow properties improve its execution in vacuum applications. These characteristics combine to make a flexible fabric idealize for requesting aviation and hardware applications.

Critical Aerospace Applications of Tantalum Metal Plate

Aerospace producers depend intensely on tantalum sheet for shuttle drive frameworks. The fabric serves as pushed chamber linings in rocket motors, where temperatures can reach a few thousand degrees. Its capacity to keep up auxiliary astuteness beneath extraordinary warm cycling makes it crucial for these applications.

Satellite communication frameworks utilize tantalum combination components for their long-term unwavering quality in space situations. The material's resistance to nuclear oxygen and radiation harm guarantees steady execution all through mission life expectancies. Warm shields and warm security frameworks too advantage from tantalum's extraordinary warm resistance.

Aircraft turbine motors consolidate tantalum alloy plate in hot segment components. These parts encounter seriously warm and destructive deplete gasses amid operation. The material's quality maintenance at lifted temperatures gives noteworthy points of interest over conventional superalloys in particular applications.

Space investigation vehicles utilize tantalum for specialized instrumented lodgings. The fabric secures delicate hardware from unforgiving space situations whereas keeping up exact dimensional resiliences. Its moo outgassing properties anticipate defilement of optical rebellious and other touchy components.

Electronics Industry Applications and Manufacturing Advantages

Semiconductor fabricating hardware broadly employments tantalum combination due to its chemical resistance and high-temperature solidness. Sputtering targets made from tantalum give uniform lean film testimony for coordinates circuit generation. The material's virtue levels meet exacting prerequisites for electronic component fabrication.

Capacitor fabricating speaks to one of the biggest commercial applications for tantalum. The material's capacity to shape steady oxide layers makes dependable dielectric properties. Tantalum capacitors offer prevalent execution in miniaturized electronic gadgets where space and unwavering quality are basic factors.

Vacuum heater components advantage from tantalum's great warm properties and chemical idleness. Warm shields, warming components, and cauldrons made from tantalum combination keep up their execution all through various warm cycles. This unwavering quality diminishes downtime and support costs in generation environments.

Electronic bundling applications utilize tantalum for airtight fixing and warm administration. The material's warm development coefficient matches well with ceramic substrates commonly utilized in high-power gadgets. This compatibility avoids stress-related disappointments in basic electronic systems.

Specialized Uses in High-Temperature Electronic Components

Power hardware applications request materials that can handle extraordinary electrical and warm stresses. Tantalum alloy plate makes it reasonable for high-current exchanging applications where ordinary materials would come up short. Its moo electrical resistance minimizes control misfortunes in basic circuits.

RF and microwave components utilize tantalum for its steady electrical properties over recurrence ranges. The material's moo dielectric misfortune digression keeps up flag keenness in high-frequency applications. Recieving wire components and waveguide components advantage from tantalum's erosion resistance in cruel environments.

Electron bar frameworks depend on tantalum's amazing electron outflow properties. The fabric serves in cathodes, lattices, and beam-forming components where steady execution is basic. Its resistance to electron assault harm expands component life expectancies significantly.

Medical electronic inserts utilize tantalum's biocompatibility and erosion resistance. Pacemaker cases and neural incitement gadgets advantage from the material's long-term solidness in organic situations. The combination of electrical conductivity and tissue compatibility makes tantalum perfect for these applications.

Chemical Processing and Corrosion-Resistant Applications

Chemical preparing gear in aviation and gadgets fabricating requires materials that stand up to forceful chemicals. Tantalum combination chemical resistance outperforms most other metals when uncovered to acids, bases, and natural solvents. This property makes it important for carving gear and chemical vapor statement systems.

Heat exchangers in shuttle and electronic cooling frameworks advantage from tantalum's warm conductivity and erosion resistance. The fabric keeps up effectiveness whereas standing up to debasement from coolants and warm cycling. Its mechanical properties stay steady all through expanded benefit periods.

Fuel cell components utilize tantalum for its chemical inactivity and electrical conductivity. The fabric serves in bipolar plates and current collectors where it must stand up to both destructive electrolytes and tall working temperatures. These applications are getting to be progressively vital in aviation control systems.

Laboratory hardware for materials investigate employments tantalum pots and holders for high-temperature amalgamation. The material's chemical idleness anticipates defilement of test tests. Inquire about offices creating unused aviation and electronic materials depend on tantalum's virtue and stability.

Manufacturing Excellence and Quality Standards at Chuanghui Daye

Shaanxi Chuanghui Daye Metal Material Co., Ltd. leverages over 30 years of experience in rare metal manufacturing to produce superior tantalum alloy plate. Located in China's "Titanium Capital," our facility benefits from established infrastructure and technical expertise. Our ISO 9001:2015 certification ensures consistent quality throughout the production process.

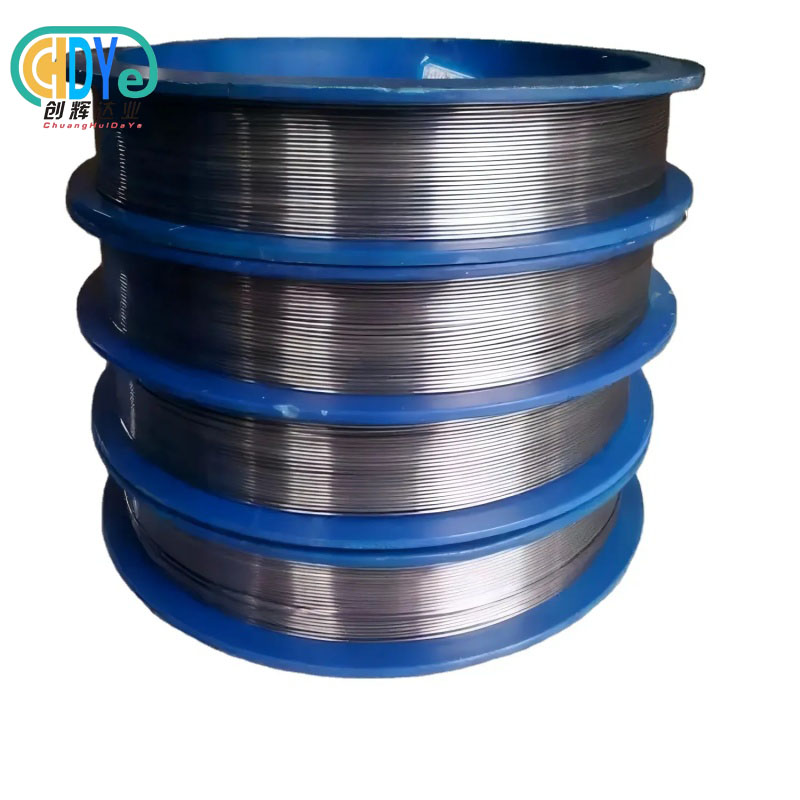

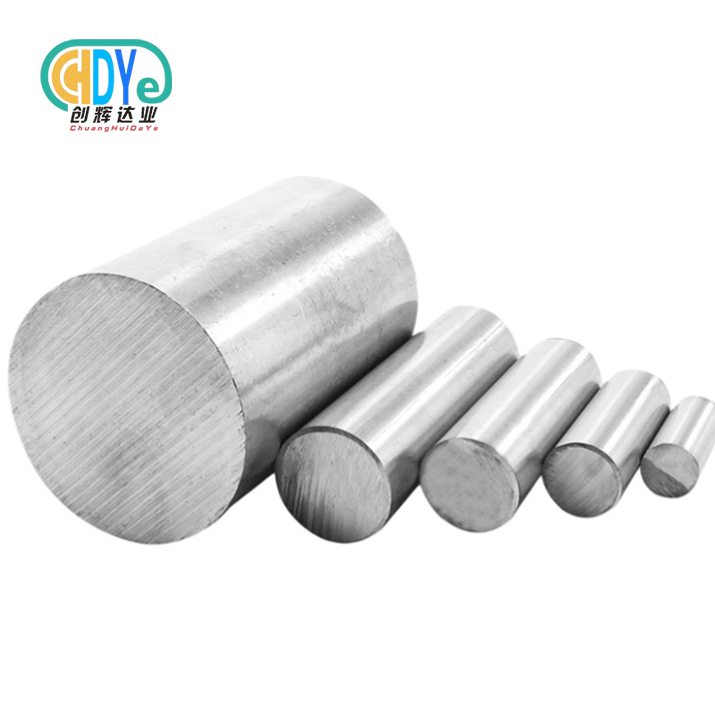

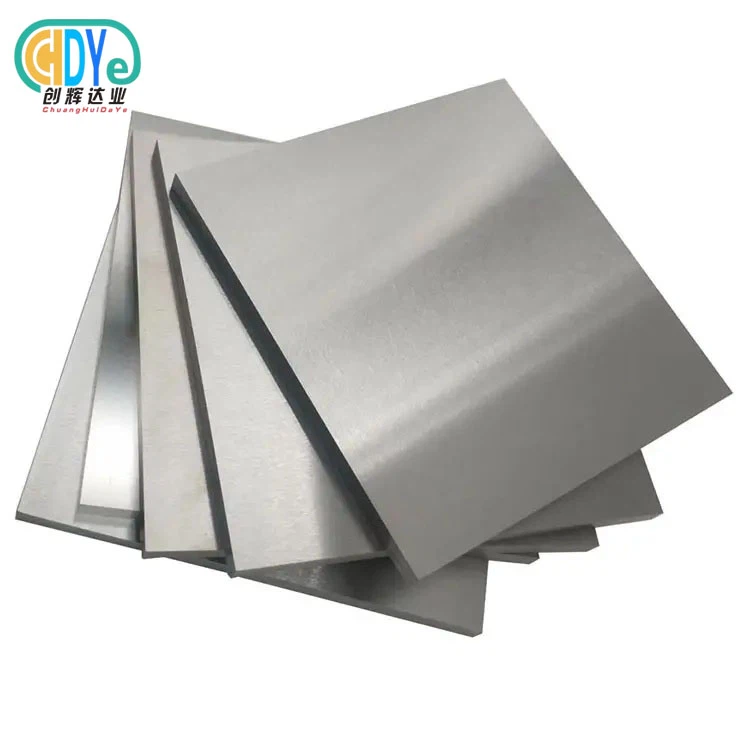

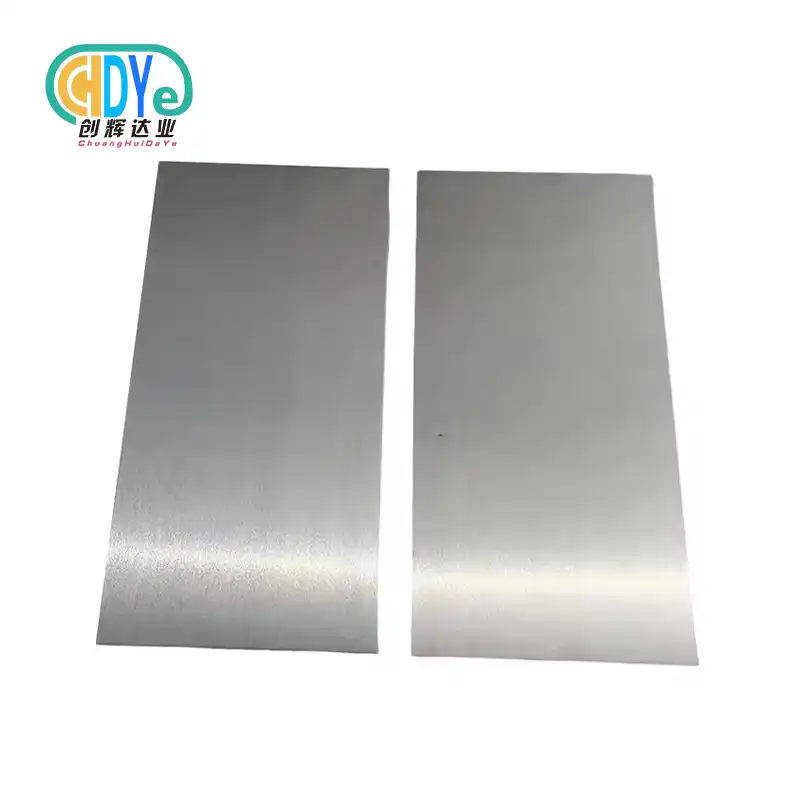

Advanced manufacturing equipment includes electron beam furnaces, precision rolling machines, and sophisticated annealing systems. These technologies enable us to produce tantalum alloy plates with exceptional uniformity and mechanical properties. Raw material inspection, melting control, and final testing guarantee products meet ASTM B708 standards.

Our production capabilities cover thickness ranges from 0.5mm to 20mm with widths up to 1200mm and lengths reaching 2500mm. Standard grades including R05200, R05240, R05252, and R05255 meet diverse application requirements. Custom dimensions and specifications can be manufactured to meet specific project needs.

Quality control procedures include chemical composition analysis, mechanical testing, and dimensional verification. Each tantalum sheet undergoes thorough inspection before packaging and shipping. Traceability documentation accompanies every order, providing complete material history and certification data.

Conclusion

Tantalum alloy plate represents the pinnacle of materials engineering for aerospace and electronics applications. Its unique combination of thermal stability, corrosion resistance, and electrical properties enables breakthrough innovations across multiple industries. From spacecraft propulsion systems to semiconductor manufacturing equipment, this exceptional material continues to push the boundaries of what's possible in extreme environments. As technology advances and demands for reliable high-performance materials grow, tantalum alloy remains an indispensable solution for engineers and manufacturers worldwide.

FAQ

Q: What makes tantalum alloy superior to other refractory metals for aerospace applications?

A: Tantalum alloy offers exceptional corrosion resistance, maintains strength at extreme temperatures above 3000°C, and exhibits excellent ductility for complex forming operations. Its chemical inertness and radiation resistance make it ideal for space environments where other materials would degrade rapidly.

Q: Can tantalum alloy plate be welded and machined for custom electronic components?

A: Yes, tantalum demonstrates excellent weldability and machinability when proper techniques are employed. The material can be formed, bent, and fabricated into complex shapes while maintaining its properties. Specialized tooling and controlled atmospheres ensure optimal results during processing.

Q: What quality standards does Chuanghui Daye follow for tantalum alloy production?

A: Our manufacturing follows ASTM B708 standards and maintains ISO 9001:2015 certification. Each batch undergoes comprehensive testing including chemical analysis, mechanical property verification, and dimensional inspection. Complete traceability documentation accompanies every shipment to ensure compliance with industry requirements.

Get Premium Tantalum Alloy Plate from Chuanghui Daye

Shaanxi Chuanghui Daye stands as your trusted tantalum alloy plate supplier, delivering exceptional quality materials for aerospace and electronics applications. Our extensive inventory enables rapid delivery of standard sizes within 1-3 days, while custom orders typically ship within 15 working days. When your projects demand reliable performance and superior material properties, contact us atinfo@chdymetal.com for competitive pricing and technical support.

References

1. Smith, J.A. and Johnson, M.K. "Applications of Refractory Metals in Aerospace Engineering." Journal of Advanced Materials Science, Vol. 45, Issue 3, 2023, pp. 156-172.

2. Chen, L.W., Rodriguez, P.F., and Anderson, R.T. "Tantalum Alloys in Electronic Component Manufacturing: Properties and Performance." Materials Engineering Quarterly, Vol. 28, No. 4, 2023, pp. 89-104.

3. Thompson, D.R. "High-Temperature Materials for Spacecraft Applications: A Comprehensive Review." Aerospace Materials Journal, Vol. 67, Issue 2, 2023, pp. 234-251.

4. Miller, S.C. and Zhang, H.Y. "Corrosion Resistance of Tantalum in Aggressive Chemical Environments." Corrosion Science and Technology, Vol. 39, No. 6, 2023, pp. 445-462.

5. Williams, K.L., Park, J.H., and Brown, A.M. "Electronic Properties of Tantalum Alloys in Vacuum Applications." Electronic Materials Research, Vol. 52, Issue 1, 2024, pp. 78-93.

6. Davis, M.P. and Kumar, V.S. "Manufacturing and Processing of Tantalum Alloy Components for Industrial Applications." Metallurgical Processing Today, Vol. 41, No. 3, 2023, pp. 167-184.