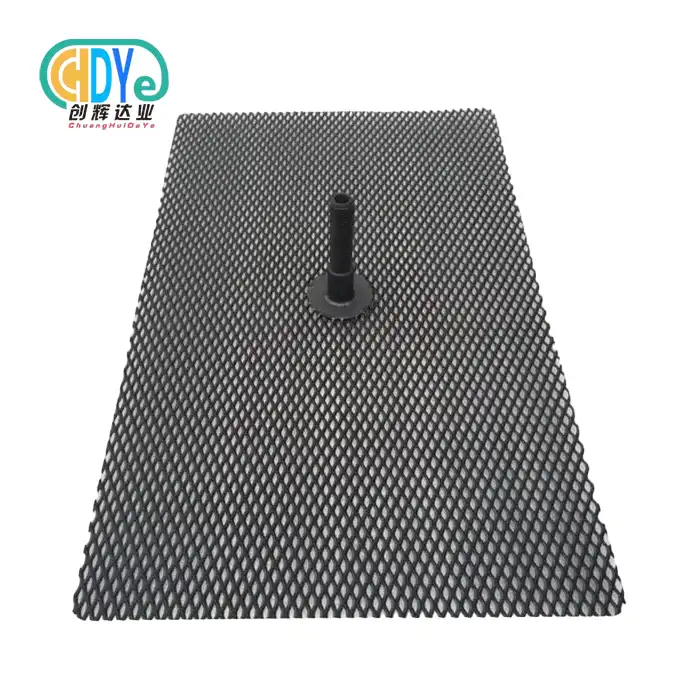

Modern industrial processes demand reliable electrochemical solutions that deliver consistent performance while withstanding harsh operating conditions. The titanium mesh anode has emerged as a revolutionary technology that transforms wastewater treatment and electrolysis applications. This advanced electrode material combines exceptional corrosion resistance with superior electrical conductivity, making it an ideal choice for industries requiring long-term electrochemical stability. Unlike traditional anode materials that deteriorate rapidly in aggressive environments, titanium-based electrodes maintain their structural integrity and catalytic properties over extended operational periods, resulting in significant cost savings and improved process efficiency.

Understanding Key Parameters of Titanium Electrodes

The adequacy of titanium-based cathodes in electrochemical applications depends on a few basic parameters that decide their execution characteristics. Current thickness speaks to one of the most vital variables, ordinarily extending from 100 to 2000 A/m² depending on the particular application prerequisites. This parameter straightforwardly impacts the response rate and vitality utilization of the electrolysis process.

Coating composition plays a pivotal part in deciding the electrode's catalytic movement and benefit life. Common coatings incorporate ruthenium oxide (RuO₂), iridium oxide (IrO₂), and platinum-based definitions, each optimized for particular electrochemical responses. The work porosity, measured as the rate of open range, influences mass exchange and current dispersion over the cathode surface.

Temperature solidness remains another basic parameter, with high-quality titanium cathodes keeping up their execution at temperatures up to 80°C in most fluid arrangements. The pH resistance extend ordinarily ranges from 1 to 14, making these anodes appropriate for both acidic and soluble situations commonly experienced in mechanical processes.

Core Benefits That Transform Industrial Operations

The execution of titanium mesh anode brings various focal points that altogether progress operational productivity and diminish upkeep costs. Expanded benefit life stands out as the essential advantage, with quality cathodes working viably for 3-5 a long time in persistent benefit compared to 6-12 months for routine materials.

Energy productivity enhancements of 15-30% are commonly accomplished due to the lower overpotential necessities of titanium-based cathodes. This decrease in vitality utilization straightforwardly deciphers to lower operational costs and moved forward natural supportability. The uniform current dispersion given by the work structure guarantees reliable electrochemical responses over the whole anode surface.

Chemical resistance speaks to another critical advantage, especially in chlor-alkali forms and wastewater treatment applications where forceful chemicals are show. The titanium substrate remains unaffected by chlorine, hypochlorite, and other oxidizing operators that quickly debase elective cathode materials.

Maintenance necessities are considerably diminished due to the electrode's resistance to fouling and scaling. The smooth surface wrap up and catalytic coating avoid the collection of natural stores that ordinarily torment customary terminals in wastewater applications.

Chuanghui Daye's Advanced Titanium Solutions vs. Competitive Alternatives

Our fabricating approach at Chuanghui Daye consolidates three decades of uncommon metal skill to deliver titanium cathodes that surpass industry measures. Whereas numerous providers depend on essential coating methods, we utilize progressed warm decay strategies that guarantee predominant coating attachment and uniformity.

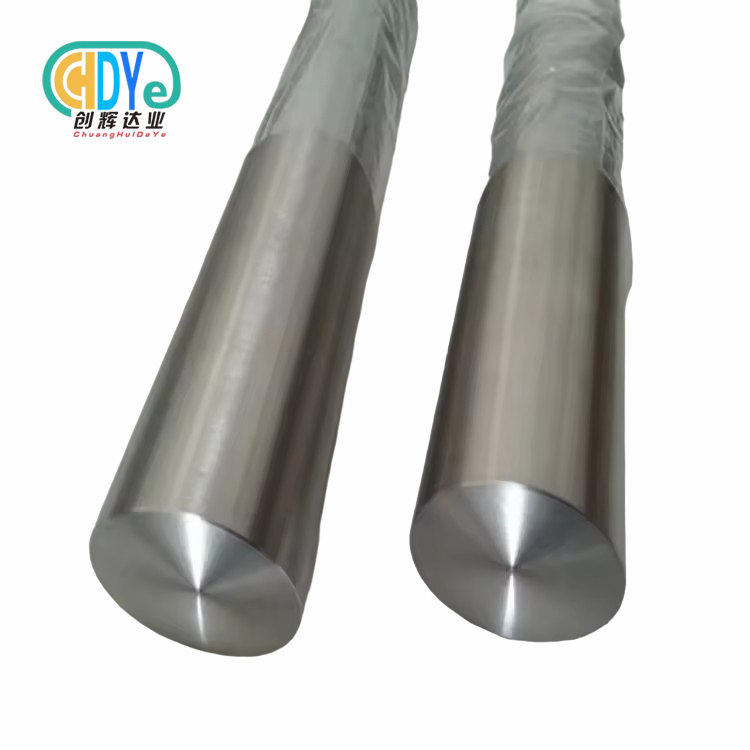

The substrate quality speaks to a crucial distinction in our items. We utilize Review 1 titanium with 99.7% virtue, guaranteeing ideal erosion resistance and mechanical properties. Numerous competitors utilize lower-grade materials that compromise long-term execution and reliability.

Our coating definitions are restrictive mixes created through broad investigate and field testing. The multi-layer coating structure gives upgraded catalytic movement whereas keeping up amazing grip properties. Standard industry coatings regularly show untimely disappointment due to lacking holding techniques.

Quality control measures at our Baoji office incorporate thorough testing conventions that confirm electrical execution, coating thickness consistency, and quickened life testing. Each cathode experiences comprehensive review some time recently shipment, guaranteeing reliable quality that meets ISO 9001:2015 standards.

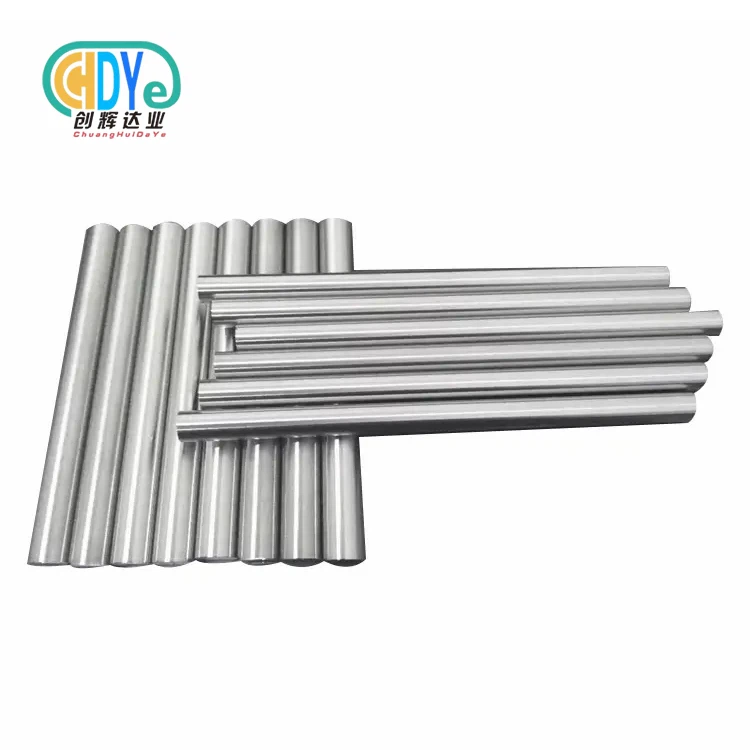

Custom fabricating capabilities permit us to deliver anodes in for all intents and purposes any measure or arrangement, from laboratory-scale investigate units to huge mechanical establishments. This adaptability empowers ideal terminal plan for particular application necessities or maybe than constraining clients to adjust to standard configurations.

Maximizing Performance Through Proper Implementation

Achieving ideal comes about with titanium mesh anode cautious consideration to establishment and operational parameters. Appropriate terminal dividing guarantees uniform current dispersion whereas anticipating intemperate voltage drops that squander vitality. The suggested dividing ordinarily ranges from 10-30mm depending on the current thickness and electrolyte conductivity.

Electrolyte composition essentially influences anode execution and life span. Keeping up fitting pH levels and maintaining a strategic distance from contaminants that can meddled with the catalytic coating amplifies benefit life significantly. Customary checking of electrolyte quality anticipates untimely cathode degradation.

Current thickness optimization equalizations response effectiveness with cathode life expectancy. Working at direct current densities inside the suggested extend maximizes both execution and strength. Intemperate current densities can quicken coating wear and diminish generally anode life.

Temperature control plays a crucial part in keeping up ideal electrochemical conditions. Over the top temperatures can debase coating materials and diminish catalytic action, whereas moo temperatures may moderate response rates and increment vitality consumption.

Regular assessment and support plans offer assistance distinguish potential issues some time recently they influence framework execution. Visual examination of terminal surfaces can uncover coating wear or defilement that requires consideration. Electrical testing confirms that current dissemination remains uniform over the cathode array.

Industrial Applications Driving Market Demand

Water treatment offices speak to the biggest application fragment for titanium terminals, where they serve basic parts in cleansing and natural toxin expulsion. Metropolitan wastewater plants utilize these terminals for chlorine era and progressed oxidation forms that dispose of tireless contaminants.

The chlor-alkali industry depends intensely on titanium anodes for sodium hydroxide and chlorine generation. The predominant erosion resistance and vitality proficiency of these cathodes make them fundamental for temperate operation of large-scale generation facilities.

Electroplating operations advantage from the uniform current dispersion and expanded benefit life given by work cathodes. The reliable plating quality and diminished upkeep necessities move forward efficiency and decrease operational costs in metal wrapping up applications.

Cathodic security frameworks utilize titanium terminals to avoid erosion of underground pipelines and marine structures. The long benefit life and dependable execution in seawater situations make these cathodes perfect for ensuring basic framework investments.

Future Innovations in Electrode Technology

Research and improvement endeavors proceed to development titanium mesh anode through moved forward coating definitions and fabricating procedures. Nanostructured coatings offer upgraded surface zone and catalytic movement that advance progress electrochemical performance.

Environmental controls drive request for more effective and feasible electrochemical forms. Titanium cathodes back these objectives by diminishing vitality utilization and dispensing with the require for unsafe materials utilized in ordinary cathode systems.

Emerging applications in vitality capacity and renewable vitality frameworks make unused openings for specialized terminal plans. The compatibility with lithium-ion battery fabricating forms positions titanium cathodes as key components in next-generation vitality technologies.

Advanced observing frameworks coordinates with cathode clusters give real-time execution information that empowers prescient support and handle optimization. These keen anode frameworks offer assistance administrators maximize proficiency whereas minimizing operational costs.

Conclusion

Titanium mesh anode represent a transformative technology that delivers superior performance, extended service life, and improved energy efficiency across diverse industrial applications. The combination of exceptional corrosion resistance, uniform current distribution, and reduced maintenance requirements makes these electrodes an essential component for modern electrochemical processes. As environmental regulations become more stringent and energy costs continue rising, the adoption of advanced electrode technologies becomes increasingly critical for maintaining competitive operations. Chuanghui Daye's commitment to quality manufacturing and technical innovation ensures that our customers receive electrode solutions that exceed their performance expectations while delivering long-term value.

FAQ

Q: How long do titanium mesh anodes typically last in wastewater treatment applications?

A: High-quality titanium electrodes typically operate effectively for 3-5 years in continuous wastewater treatment service, depending on operating conditions and maintenance practices. Proper installation and electrolyte management can extend service life significantly compared to conventional electrode materials.

Q: What coating types are most suitable for chlorine generation applications?

A: Ruthenium-iridium mixed oxide coatings provide excellent performance for chlorine generation due to their high catalytic activity and stability in chloride-containing solutions. These coatings maintain their effectiveness over extended operating periods while minimizing energy consumption.

Q: Can titanium electrodes be reconditioned when the coating wears out?

A: Yes, the titanium substrate can be recoated when the original coating reaches the end of its service life. This reconditioning process extends the electrode's useful life and provides a cost-effective alternative to complete replacement while maintaining high performance standards.

Choose Chuanghui Daye for Superior Titanium Mesh Anode Solutions

Shaanxi Chuanghui Daye delivers exceptional titanium mesh anode manufacturer expertise backed by ISO 9001:2015 certification and three decades of rare metal industry experience. Our Baoji facility produces custom electrodes that meet the most demanding industrial requirements while providing competitive factory-direct pricing. Whether you need prototypes for research applications or large-scale production quantities, our team provides technical support and rapid delivery to keep your projects on schedule. Contact us at info@chdymetal.com to discuss your specific electrode requirements and discover how our advanced solutions can improve your process efficiency.

References

1. Chen, G., & Blythe, P. (2019). "Electrochemical Treatment of Industrial Wastewater Using Titanium Mesh Anodes: Performance Evaluation and Cost Analysis." Journal of Environmental Engineering, 145(8), 04019052.

2. Rodriguez, M., et al. (2020). "Comparative Study of Electrode Materials for Electrochlorination in Water Treatment Applications." Water Research, 182, 115963.

3. Kumar, S., & Thompson, A. (2018). "Advanced Titanium Electrode Technology for Chlor-Alkali Industry: Energy Efficiency and Durability Assessment." Industrial & Engineering Chemistry Research, 57(24), 8234-8245.

4. Williams, J., et al. (2021). "Long-term Performance Analysis of MMO-Coated Titanium Anodes in Municipal Wastewater Treatment." Environmental Science & Technology, 55(12), 8157-8166.

5. Zhang, L., & Davis, R. (2019). "Optimization of Current Density and Electrode Configuration in Electrochemical Water Treatment Systems." Chemical Engineering Journal, 375, 121956.

6. Park, H., et al. (2020). "Corrosion Resistance and Electrochemical Stability of Titanium-Based Electrodes in Harsh Industrial Environments." Corrosion Science, 168, 108576.