- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Buy Forged Titanium Square Bars – Superior Structural Quality

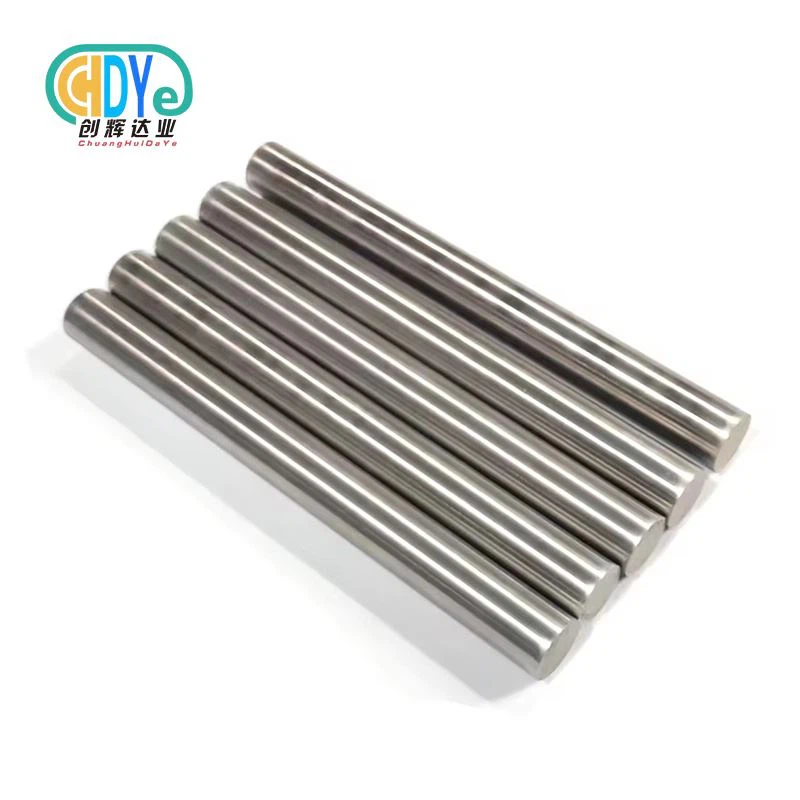

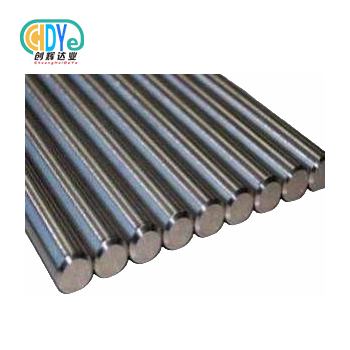

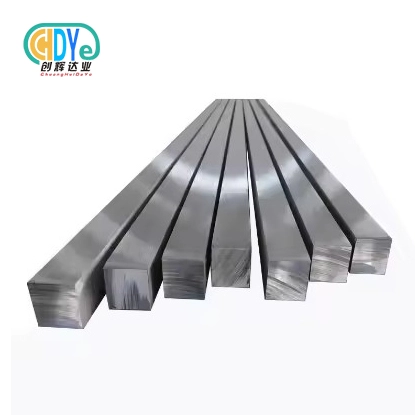

For those seeking high-quality titanium square bars with outstanding structural performance, forged choices are the pinnacle of material engineering excellence. Forged titanium square bars from our company use advanced metalworking methods and careful production to make goods that are stronger, more resistant to corrosion, and more accurately sized than those made by other companies. These special bars are forged under high pressure, which improves the grain structure and gets rid of any internal flaws. This gives them better mechanical qualities that are needed for important uses in the medical, aerospace, and industrial sectors.

Understanding Forged Titanium Square Bars: Properties and Specifications

To get better mechanical properties, forged titanium square bars are made using special production techniques. They are a high-tech type of structural material. Forging is the process of applying controlled high-pressure forces to titanium billets. This smooths out the grain structure and gets rid of any weak spots that could be present in cast or extruded options.

Superior Mechanical Properties Through Advanced Processing

The process of forging changes the structure of the material on the inside, making the grain pattern more uniform and thick. Significant increases in tensile strength happen as a result of this change. Many grades achieve values above 900 MPa while still being very flexible. The better grain flow properties also help make these bars more resistant to wear, which makes them perfect for uses that will be loaded and unloaded many times.

We have different grades of titanium square bars, from Grade 1 and Grade 2 (which are practically pure) to Grade 5 (Ti-6Al-4V) and Grade 23 (which are high-strength alloys). Each grade has its own benefits. For example, commercially pure grades are the most resistant to corrosion and biocompatibility, while alloy grades have better strength-to-weight ratios that are needed for aerospace uses.

Precision Specifications and Manufacturing Standards

For structural uses, manufacturing accuracy is still very important, and our forged titanium square bars meet very strict dimensional standards. Standard measurements for the sides range from 8x8mm to 200x200mm, and the lengths can go up to 6000mm. Because we can do so much complex processing, we can easily make custom dimensions.

All of our products meet widely recognized standards like ASTM B348, AMS 4928, and ISO 5832, which means they can be used with any engineering software around the world. The annealed state makes it easy to shape while keeping the structure strong. Different surface finishes, such as bright, polished, and machined, can be used for different purposes.

Titanium Square Bar vs Alternatives: How to Make the Right Choice?

Choosing the right materials has a big effect on the success of a project, especially when long-term dependability and structural performance are very important. The benefits of titanium square bars make them stand out from common options like stainless steel and aluminum alloys.

Strength-to-Weight Advantage in Critical Applications

The extraordinary strength-to-weight proportion of titanium makes openings for weight lessening without compromising basic keenness. Titanium combinations regularly weigh 45% less than comparable steel components whereas keeping up identical or predominant quality characteristics. This advantage demonstrates especially profitable in aviation applications where each gram things for fuel effectiveness and payload capacity.

Marine situations exhibit another range where titanium exceeds expectations compared to options. The material's remarkable resistance to chloride-induced erosion outperforms that of most stainless steel grades, indeed in forceful seawater conditions. This erosion resistance deciphers to diminished upkeep necessities and amplified benefit life, frequently defending higher introductory fabric costs through lifecycle investment funds.

Square vs Round Bar Configuration Benefits

There are clear benefits to using square bars instead of round bars in some situations. When you weld or place something on a square bar, the surface area is bigger, which makes the connection stronger in structural assemblies. The flat surfaces also make it easier to place and line up parts during assembly, which lowers the complexity of the manufacturing process.

When it comes to uses that involve twisting forces, square cross-sections are better than round bars with the same cross-sectional area at resisting torsional loads. This geometric advantage is especially useful for aircraft structural parts and high-precision machinery where stable dimensions are still very important.

Procuring Forged Titanium Square Bars: A Practical Buying Guide

Fruitful acquirement of produced titanium square bars requires understanding key variables that impact item quality, conveyance execution, and generally esteem. Exploring these contemplations guarantees ideal results for requesting applications.

Supplier Evaluation and Certification Requirements

Quality approval is the basis for buying titanium with confidence. A supplier's ISO 9001:2015 approval shows that they are dedicated to quality management systems and process control. Depending on how the product will be used, it may need extra certifications like AS9100 for aircraft uses or ISO 13485 for medical devices.

Material traceability is becoming very important for important uses, especially in the medical and aircraft industries. Material test certificates (MTC), chemical composition analyses, mechanical property verifications, and ultrasonic inspection reports are just a few of the documents that reliable providers provide. This paperwork makes sure that everything can be tracked from the sources of the raw materials to the end stages of processing.

Inventory Management and Custom Processing Capabilities

Many procurement pros find it hard to balance the costs of inventory with the need for availability. Working with suppliers who keep strategic stock levels of popular grades and sizes cuts down on lead times and gives you access to materials right away for projects that need to be done quickly. We keep a large stock of standard square shapes in many popular titanium types, such as Grade 2 and Grade 5.

We can do more than just basic cuts for custom processing. We can also do precision machining, surface treatments, and specialized forming. Advanced suppliers give services that add value, like precisely cutting to length, edge conditioning, and surface finishing, which cut down on the need for further processing and the costs that come with it.

International Logistics and Delivery Considerations

To get titanium materials from around the world, you need to carefully plan your logistics and follow the rules for foreign trade. Titanium surfaces are kept safe during shipping with the right packaging, and full paperwork makes the customs clearance and material certification processes easier.

When it comes to project-critical products, coordinating delivery schedules becomes even more important. Reliable suppliers give accurate estimates of lead times and let you know ahead of time about any changes that might affect your plan. Our strategic position in China's "Titanium Capital" gives us easy access to transportation for quick shipping around the world.

Why Choose Our Forged Titanium Square Bars?

Shaanxi Chuanghui Daye Metal Material Co., Ltd. has been working with rare metals for more than 30 years and knows how to make titanium square bars. We are right in the middle of China's titanium industry because we are in the Baoji High-tech Development Zone, which gives us access to high-quality raw materials and specialized manufacturing facilities.

Advanced Manufacturing Capabilities and Quality Control

Our way of making things uses cutting-edge tools and strict process control to make sure that the standard of our products is always the same. At the start of the production process, vacuum melting ovens make titanium ingots that are all the same and free of any contamination. The ingots are then shaped in hot forging tools, where the temperature and pressure are carefully controlled to make the grain structure work best.

Precision rolling mills keep the material's properties while making sure that the dimensions are accurate, and CNC lathes make exact finishing operations possible. At every step of the production process, our skilled workers keep an eye on important factors like temperature profiles, deformation rates, and microstructural development to make sure the quality is always high and consistent.

Quality assurance includes more than just the making process. It also includes strict rules for testing and inspection. Each batch goes through ultrasonic testing to find flaws inside, chemical makeup analysis to make sure it meets grade standards, and mechanical property testing to make sure it works as expected. This multi-layered method makes sure that the quality of delivery is never compromised.

Comprehensive Product Range and Customization Services

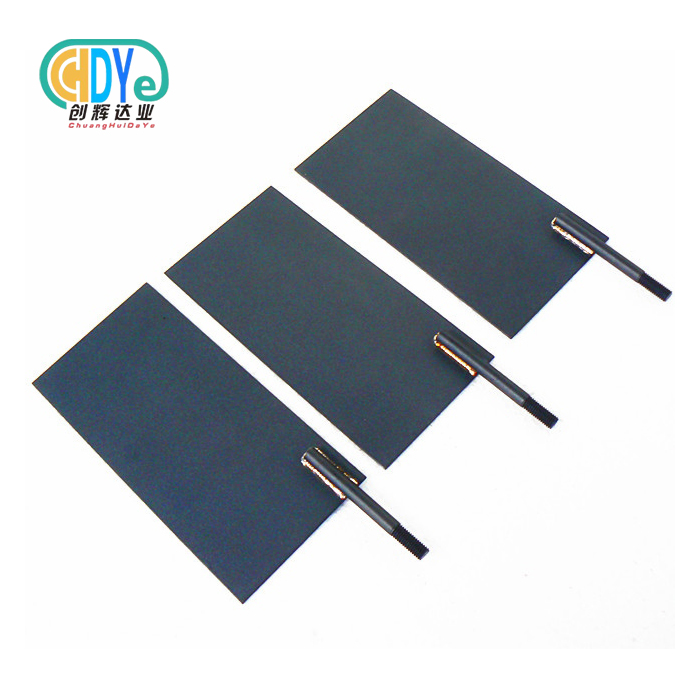

Our product line includes all of the grades of titanium that are usually used in structural uses. For chemical processes and medical uses, commercially pure grades like Gr1, Gr2, and Gr4 are very good at resisting corrosion and being biocompatible. High-strength alloys like Gr5, Gr9, and Gr23 have better mechanical properties that are needed in aircraft and other demanding structural uses.

Customization is possible at every step of the making process, from choosing the alloy to treating the surface in the end. Custom sizes can be made to fit the needs of each project, and different surface styles, such as bright, polished, and machined, can be used for a variety of purposes. Our engineering team works with customers to make sure that the specifications of the materials are the best they can be for the working conditions and performance needs.

Conclusion

Forged titanium square bars are the best choice for uses that need high-quality structure, resistance to rust, and long-term dependability. Advanced forging techniques, precise manufacturing, and strict quality control all work together to make goods that always go above and beyond what the industry requires. With thirty years of experience working with rare metals, cutting-edge manufacturing tools, and strict quality control systems, we are a reliable partner for important titanium uses in the medical, aerospace, and industry fields.

FAQ

Q: What makes forged titanium superior to other manufacturing methods?

A: Forged titanium offers enhanced grain structure through controlled deformation processes that eliminate internal defects and improve mechanical properties. The forging process creates superior strength, fatigue resistance, and dimensional stability compared to cast or extruded alternatives.

Q: Which titanium grade should I select for my application?

A: Grade selection depends on specific requirements including strength, corrosion resistance, and operating environment. Commercially pure grades (Gr1, Gr2) provide maximum corrosion resistance, while alloys like Gr5 (Ti-6Al-4V) offer higher strength for structural applications.

Q:What lead times should I expect for custom orders?

A: Standard grades typically ship within 1-2 weeks from stock, while custom specifications require 2-3 weeks depending on complexity. We maintain strategic inventory to minimize lead times for common configurations.

Q: How do you ensure material quality and traceability?

A: Our ISO 9001:2015 certified quality system includes comprehensive testing, ultrasonic inspection, and documentation for full traceability. Material test certificates, chemical analysis reports, and dimensional inspection records accompany every shipment.

Partner with Chuanghui Daye for Premium Titanium Square Bar Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands ready to support your titanium procurement needs with industry-leading expertise and comprehensive service capabilities. Our extensive inventory, advanced manufacturing capabilities, and commitment to quality excellence ensure reliable supply chain solutions for your most demanding applications. Whether you require standard configurations or custom-engineered titanium square bars, our technical team provides personalized consultation to optimize material selection and specifications. Contact our experienced titanium square bar supplier team at info@chdymetal.com to discuss your requirements and discover how our three decades of rare metal expertise can enhance your project success.

References

1. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International Materials Park, 2000.

2. Peters, Manfred, et al. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Vol. 5, No. 6, 2003.

3. Schutz, Robert W. "Recent Developments in Titanium Alloy Application in the Energy Industry." Materials Science and Engineering A, Vol. 243, 1998.

4. Boyer, Rodney R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering A, Vol. 213, 1996.

5. Lutjering, Gerd and James C. Williams. "Titanium Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, 2007.

6. American Society for Testing and Materials. "ASTM B348 Standard Specification for Titanium and Titanium Alloy Bars and Billets." ASTM International, 2019.

Learn about our latest products and discounts through SMS or email