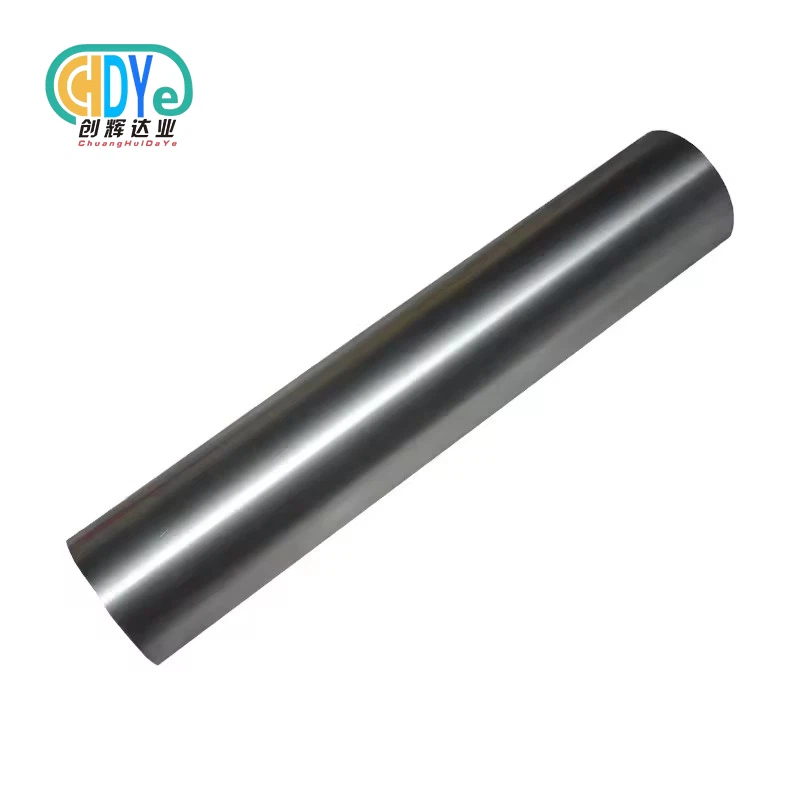

Grade 2 titanium round bar stands as one of the most versatile and reliable materials in modern medical and engineering applications. Known for its exceptional corrosion resistance, biocompatibility, and excellent strength-to-weight ratio, this commercially pure titanium material serves critical functions across multiple industries. From life-saving medical implants to aerospace components, Grade 2 titanium round bar delivers unmatched performance where reliability matters most.

Understanding Grade 2 Titanium Properties

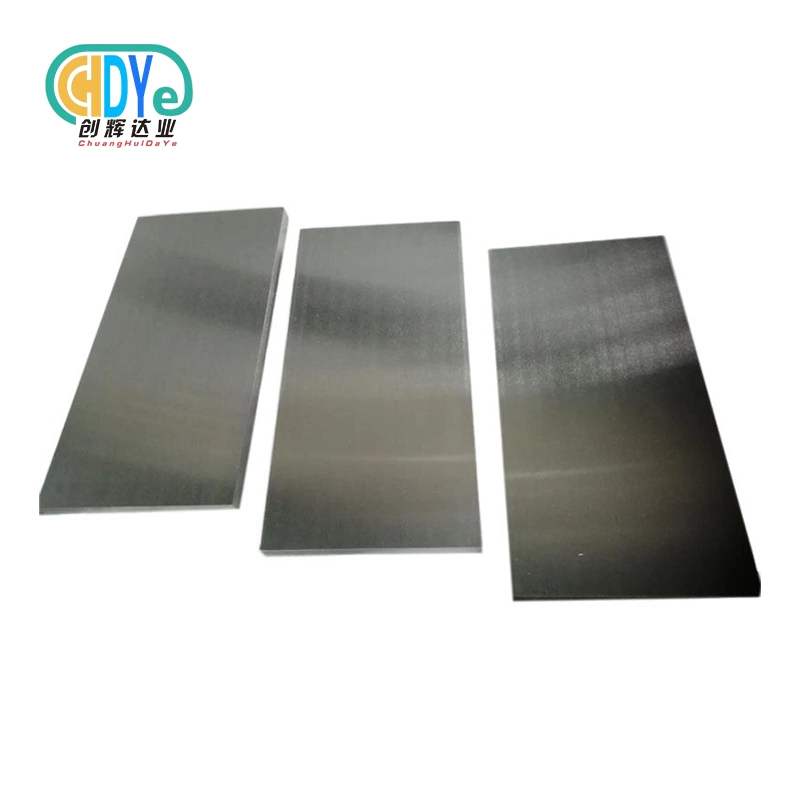

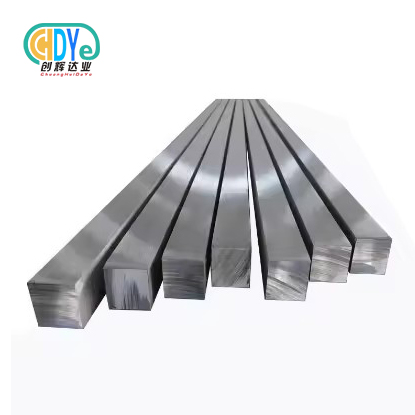

Grade 2 titanium speaks to the most commonly utilized frame of commercially unadulterated titanium in mechanical applications. This fabric contains 99.2% immaculate titanium with negligible alloying components, making it perfect for applications requiring fabulous formability and erosion resistance. The one of a kind properties of this titanium amalgam bar make it especially important in requesting environments.

The fabric shows momentous resistance to chloride situations, seawater, and most natural acids. With a ductile quality extending from 345 to 483 MPa and amazing ductility, Review 2 Ti bar gives engineers with solid execution over temperature ranges from cryogenic to 300°C. These characteristics clarify why producers reliably select this immaculate titanium bar for basic applications.

Chuanghui Daye produces Grade 2 titanium round bar that meets worldwide benchmarks counting ASTM B348, ASTM F67, and ASTM F136. Our fabricating handle guarantees steady quality and traceability for each titanium circular bar we provide to worldwide customers.

Medical Applications of Titanium Round Bars

The medical industry relies heavily on Grade 2 titanium metal rod for various life-critical applications. Biocompatibility remains the primary reason medical device manufacturers choose this material over alternatives. The human body accepts titanium exceptionally well, with minimal risk of rejection or adverse reactions.

Orthopedic Implants and Prosthetics

Surgeons around the world depend on titanium circular bar measurements for making custom orthopedic inserts. Hip substitutions, knee joints, and spinal combination bars all advantage from titanium's one of a kind combination of quality and lightweight properties. The material's moo modulus of versatility closely matches human bone, decreasing push protecting impacts that can lead to embed failure.

Dental inserts speak to another vital application where Review 2 titanium bar applications sparkle. The material's osseointegration properties permit bone tissue to develop specifically onto the embed surface, making a changeless, steady establishment for manufactured teeth. This prepare regularly takes 3-6 months and gives patients with long-lasting solutions.

Surgical Instruments and Tools

Medical experts lean toward titanium bar providers who can give precision-machined surgical rebellious. Surgical blade handles, forceps, and specialized surgical instruments made from Review 2 titanium offer prevalent execution compared to stainless steel options. These disobedient stand up to erosion from sterilization forms and keep up sharp edges longer.

The non-magnetic properties of titanium bar for aviation applications moreover advantage restorative situations. MRI-compatible surgical disobedient permit specialists to perform methods without evacuating inserts or apparatuses amid attractive reverberation imaging. This capability demonstrates fundamental for complex surgeries requiring real-time imaging guidance.

Engineering Applications Across Industries

Engineering applications for Grade 2 titanium round bar span multiple industries, each leveraging the material's unique properties to solve specific challenges. The aerospace, chemical processing, and marine industries represent the largest consumers of titanium round stock outside medical applications.

Aerospace and Defense Components

Aerospace engineers indicate Review 2 titanium mechanical properties for components requiring extraordinary strength-to-weight proportions. Flying machine motor components, landing adapt parts, and basic components advantage from titanium's capacity to keep up quality at lifted temperatures. The fabric weighs roughly 45% less than steel whereas giving comparable quality characteristics.

Military applications request materials that perform dependably beneath extraordinary conditions. Titanium circular bar producers like Chuanghui Daye supply materials for rocket components, armor plating, and maritime vessel parts. The material's resistance to saltwater erosion makes it perfect for marine applications where conventional metals would fall flat rapidly.

Chemical Processing Equipment

Chemical engineers select titanium bar erosion resistance for hardware uncovered to forceful chemicals. Warm exchangers, weight vessels, and channeling frameworks made from Review 2 titanium circular bars work securely in situations containing chlorine, acids, and high-temperature gasses. This strength decreases support costs and makes strides plant safety.

The atomic industry depends on titanium's steadiness and erosion resistance for reactor components. Cooling framework channels and warm exchangers advantage from the material's capacity to stand up to radiation harm whereas keeping up auxiliary astuteness. These applications require strict fabric certification and traceability documentation.

Marine and Offshore Applications

Seawater speaks to one of the most destructive situations for metals, however Review 2 titanium circular bar performs uncommonly well in marine conditions. Propeller shafts, submerged vehicle components, and seaward penetrating gear utilize titanium's seawater resistance. The fabric shapes a defensive oxide layer that anticipates advance erosion, guaranteeing long benefit life.

Desalination plants around the world depend on titanium bar warm treatment forms to make components that stand up to brine erosion. Warm exchanger tubes and pump components made from Review 2 titanium work productively for decades with negligible upkeep. This unwavering quality demonstrates fundamental for offices giving new water to coastal communities.

Manufacturing and Processing Considerations

Titanium bar machining requires specialized information and hardware to accomplish ideal comes about. The material's moo warm conductivity and work-hardening characteristics request particular cutting speeds and apparatus geometries. Legitimate machining strategies guarantee dimensional exactness whereas keeping up surface wrap up quality.

Manufacturers must consider titanium bar surface wrap up necessities when arranging generation forms. Restorative applications regularly require cleaned surfaces to minimize bacterial development, whereas aviation components may require particular surface surfaces for ideal execution. Chuanghui Daye keeps up progressed machining capabilities to meet different client requirements.

Quality control amid titanium circular bar weight confirmation guarantees client details are met reliably. Our ISO 9001:2015 certified forms incorporate dimensional assessment, chemical investigation, and mechanical property testing. This comprehensive approach ensures that each Review 2 titanium metal pole meets or surpasses universal standards.

Economic and Performance Benefits

While Grade 2 titanium rod price may appear higher than alternative materials initially, the total cost of ownership often favors titanium solutions. Extended service life, reduced maintenance requirements, and improved performance characteristics provide substantial long-term value for end users.

Industries benefit from titanium's lightweight properties through reduced transportation costs and improved fuel efficiency. Aerospace applications particularly value weight savings that translate directly into operational cost reductions. A 10% weight reduction in aircraft components can result in significant fuel savings over the vehicle's operational life.

The biocompatibility of Grade 2 titanium eliminates the need for protective coatings in medical applications, reducing manufacturing complexity and potential failure points. This simplification improves reliability while reducing production costs for medical device manufacturers.

Future Developments and Innovations

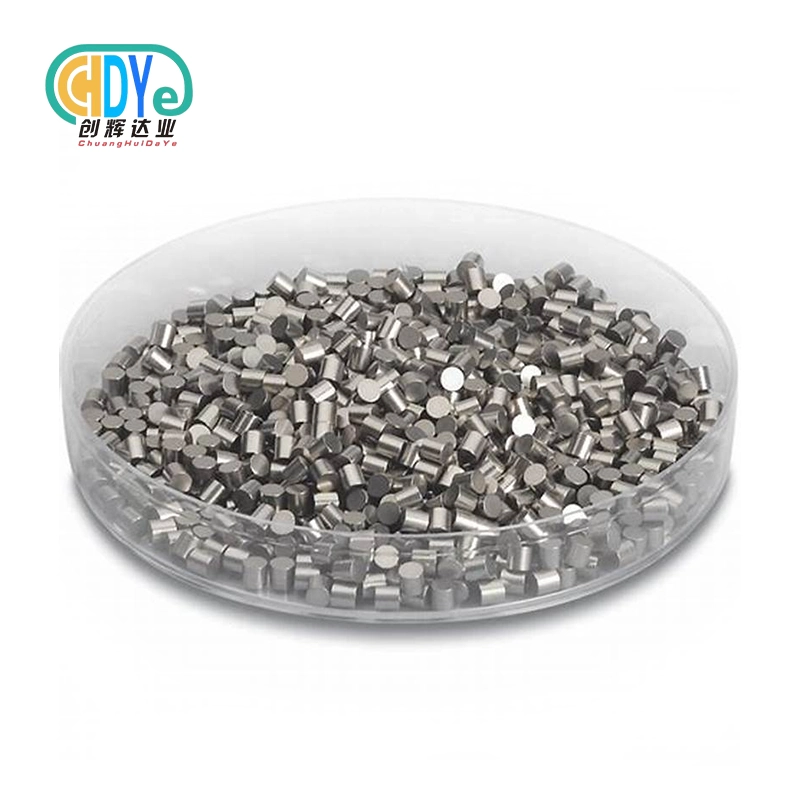

Additive manufacturing technologies are expanding the possibilities for titanium applications. 3D printing of titanium components allows for complex geometries previously impossible with traditional manufacturing methods. This capability opens new opportunities for customized medical implants and optimized aerospace components.

Surface modification techniques continue advancing, enabling enhanced performance characteristics for specific applications. Treatments that improve wear resistance, reduce friction, or enhance biological integration expand the utility of Grade 2 titanium round bars across diverse industries.

Research into titanium recycling methods addresses sustainability concerns while reducing material costs. Closed-loop recycling systems allow manufacturers to reprocess titanium waste into new products, supporting environmental goals while maintaining material quality standards.

Quality Assurance and Standards Compliance

International standards govern the production and testing of titanium materials to ensure consistent quality and safety. ASTM B348 specifies requirements for unalloyed titanium bars, while ASTM F67 covers materials intended for surgical implant applications. These standards define chemical composition, mechanical properties, and testing procedures.

Chuanghui Daye maintains rigorous quality control processes throughout production. Raw material verification, process monitoring, and final inspection ensure every titanium round bar meets applicable standards. Our traceability systems track materials from source through delivery, providing customers with complete documentation for critical applications.

Third-party testing and certification provide additional assurance for customers requiring independent verification of material properties. Our laboratory capabilities include chemical analysis, mechanical testing, and metallographic examination to support customer requirements and regulatory compliance.

Conclusion

Grade 2 titanium round bar continues proving its value across medical and engineering applications through unmatched performance characteristics and reliability. From life-saving medical implants to critical aerospace components, this versatile material enables innovations that improve human life and advance technology. The combination of biocompatibility, corrosion resistance, and strength-to-weight ratio makes Grade 2 titanium the material of choice for demanding applications where failure is not an option. As manufacturing technologies advance and new applications emerge, titanium round bars will undoubtedly play an increasingly important role in shaping our technological future.

FAQ

Q: What makes Grade 2 titanium suitable for medical implants?

A: Grade 2 titanium offers exceptional biocompatibility, meaning the human body accepts it without adverse reactions. Its corrosion resistance prevents degradation in body fluids, while its strength-to-weight ratio and elastic modulus closely match human bone properties, reducing stress shielding effects.

Q: How does Grade 2 titanium compare to other grades for engineering applications?

A: Grade 2 titanium provides the best combination of formability, weldability, and corrosion resistance among commercially pure titanium grades. While higher grades offer greater strength, Grade 2 delivers sufficient mechanical properties for most applications while being easier to machine and form.

Q: What are the typical lead times for custom titanium round bar orders?

A: Lead times vary based on size, quantity, and processing requirements. Standard sizes typically ship within 2-4 weeks, while custom dimensions may require 6-8 weeks. Rush orders can often be accommodated with expedited processing for urgent project requirements.

Partner with Chuanghui Daye for Premium Grade 2 Titanium Round Bar Supply

Shaanxi Chuanghui Daye stands ready to meet your titanium material requirements with our comprehensive Grade 2 titanium round bar manufacturing capabilities. Located in China's Titanium Capital, we combine three decades of industry expertise with ISO 9001:2015 certified quality systems to deliver reliable materials for your critical applications. Our factory-direct pricing and global shipping capabilities ensure you receive premium titanium round bar products on schedule and within budget. Contact us at info@chdymetal.com to discuss your specific requirements with our technical team.

References

1. Boyer, R.R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering A, vol. 213, no. 1-2, 1996, pp. 103-114.

2. Geetha, M., et al. "Ti Based Biomaterials, the Ultimate Choice for Orthopaedic Implants – A Review." Progress in Materials Science, vol. 54, no. 3, 2009, pp. 397-425.

3. Donachie, Matthew J. "Titanium: A Technical Guide." ASM International, 2nd edition, 2000.

4. Liu, X., et al. "Surface Modification of Titanium, Titanium Alloys, and Related Materials for Biomedical Applications." Materials Science and Engineering Reports, vol. 47, no. 3-4, 2004, pp. 49-121.

5. Peters, M., et al. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, vol. 5, no. 6, 2003, pp. 419-427.

6. Lutjering, Gerd, and James C. Williams. "Titanium: Engineering Materials and Processes." Springer Science & Business Media, 2nd edition, 2007.