Global buyers planning their 2026 procurement strategies need accurate tantalum tube and pipe pricing insights. Current market analysis indicates prices ranging from $800 to $1,200 per kilogram for standard tantalum tubing, with variations based on purity levels, dimensions, and order quantities. Premium seamless tantalum pipes command higher rates due to their superior corrosion resistance and manufacturing complexity. Understanding these price dynamics helps aerospace, chemical processing, and semiconductor companies make informed purchasing decisions for their critical applications.

Understanding 2026 Market Dynamics for Tantalum Products

The tantalum showcase proceeds to advance as worldwide request rises over a wide run of high-performance businesses, driven by the material’s one of a kind combination of warm solidness, erosion resistance, and unwavering quality. Aviation producers progressively require tantalum combination channels for components uncovered to extraordinary temperatures, where extraordinary warm resistance and long-term steadiness are fundamental. At the same time, semiconductor companies depend on high-purity tantalum tubing for vacuum situations, where indeed follow debasements can compromise prepare exactness and hardware execution. Supply chain solidness remains a basic calculate impacting estimating, as set up producers with develop generation capabilities, secure crude fabric sources, and optimized fabricating forms are way better situated to offer reliable quality and more competitive rates over time.

Recent advertise patterns show consistent and supported request development in the chemical handling division, where tantalum pipe erosion resistance demonstrates priceless in taking care of forceful acids and high-temperature chemical responses. Hardware producers are too progressively indicating tantalum tube items that meet strict immaculateness and dimensional prerequisites to bolster progressed electronic components and exactness frameworks. Together, these growing applications proceed to drive dependable showcase request, contributing to generally steady estimating structures all through 2026 in spite of broader worldwide financial fluctuations.

Regional pricing differences largely reflect variations in transportation costs, regulatory environments, and local manufacturing capabilities for tantalum tube and pipe. Chinese producers advantage from exceedingly coordinates supply chains and progressed generation advances, empowering them to adjust competitive estimating with reliable quality guidelines. In specific, the Baoji locale, broadly recognized as China’s “Titanium Capital,” offers concentrated specialized ability, gifted labor, and specialized foundation that emphatically bolster productive and high-quality tantalum pipe manufacturing.

Price Factors Affecting Tantalum Tubing Costs

Several key variables impact tantalum tube cost structures in the worldwide commercial center, with crude fabric immaculateness standing out as one of the most definitive components. Higher virtue tantalum, such as 99.95% review fabric, requires stricter refining forms and more thorough quality control, which straightforwardly deciphers into higher generation costs and premium estimating compared to lower-grade options. Fabricating complexity encourage influences estimating, as consistent tantalum tubes request progressed hardware, exceedingly controlled situations, and talented specialized skill to keep up dimensional precision and surface quality all through the generation process.

Order amount too plays a pivotal part in deciding last estimating results. Large-volume buys by and large permit producers to optimize generation runs and decrease per-unit costs, coming about in important rebates for clients. In differentiate, small-batch or research-level orders regularly include higher unit costs due to setup time and constrained economies of scale. Custom tantalum pipe measurements can present extra tooling, programming, and setup prerequisites, which encourage impact estimating for specialized applications.

Quality certifications and traceability documentation include quantifiable esteem but too influence by and large costs. ISO 9001:2015 certified providers contribute intensely in precise quality administration, comprehensive reviews, and nitty gritty documentation, giving buyers with diminished hazard and solid execution confirmation. Fabric testing, dimensional confirmation, and chemical examination all contribute to the last estimating structure. Lead times speak to another vital figure, as surge orders requiring quickened generation plans may bring about additional charges, whereas adaptable conveyance timelines permit providers to arrange proficiently and offer more competitive estimating options.

Application-Specific Pricing Considerations

Different businesses require changing tantalum tube properties, and these contrasts straightforwardly shape estimating structures over the worldwide advertise. In chemical handling applications, tantalum tube chemical resistance is a essential concern, as gear must withstand forceful acids, tall temperatures, and long-term introduction to destructive media. Accomplishing this level of execution frequently requires particular combination compositions, controlled surface medications, and exacting review measures, all of which raise generation complexity and fetched compared to standard commercial-grade tantalum tubing.

Semiconductor manufacturers place even higher demands on material quality, requiring ultra-high purity tantalum tubing with extremely tight dimensional tolerances for tantalum tube and pipe. Such exacting details require extra refining steps, progressed fabricating situations, and comprehensive quality control methods, which are reflected in premium estimating. Vacuum heater and high-vacuum applications so also request exact fabric properties to guarantee solidness and execution, assist impacting by and large costs.

Medical gadget applications present another layer of necessities, as biocompatible tantalum materials must meet strict administrative benchmarks and incorporate full traceability documentation. These commitments increment regulatory exertion and specialized dealing with costs. Aviation and defense divisions regularly indicate custom tantalum pipe setups with broad mechanical testing, certification, and compliance with military or aviation measures, legitimizing higher estimating for these mission-critical applications.

Regional Pricing Variations and Supply Chain Analysis

Global tantalum pipe providers work inside shifting financial and mechanical fetched structures, which normally comes about in territorial estimating contrasts over the universal showcase. Asian producers, especially those based in zones with concentrated metal-processing businesses, frequently advantage from coordinates supply chains, productive labor allotment, and progressed fabricating advances. These points of interest permit them to offer more competitive estimating whereas still keeping up reliable quality levels. In differentiate, European providers habitually center on exceedingly specialized or customized tantalum pipe applications, and their estimating reflects higher operational costs, exacting administrative necessities, and solid nearby building and after-sales benefit support.

Transportation costs speak to a major component of the last conveyed cost, particularly for heavy-wall tantalum channels that require specialized bundling, cautious dealing with, and secure coordinations courses of action. Sea cargo rates, harbour taking care of charges, traditions obligations, protections expenses, and nearby tax collection can collectively include a significant premium to worldwide shipments. For buyers sourcing tantalum channels universally, these logistics-related costs must be carefully assessed when comparing provider quotations.

Currency vacillations too play a basic part in worldwide estimating soundness. To decrease vulnerability, most tantalum pipe providers give citations in U.S. dollars, which makes a difference standardize estimating over locales. Long-term supply assentions regularly incorporate cash alteration clauses, securing both buyers and providers from sudden trade rate shifts that may something else affect contract benefit and taken a toll predictability.

Local specialized back and benefit capabilities advance legitimize territorial estimating varieties. Providers that offer on-site specialized interview, fast prototyping administrations, localized stock, and quicker reaction times give included operational esteem. For numerous buyers, particularly those in basic businesses, this improved bolster offsets higher estimating by decreasing venture chance, minimizing downtime, and guaranteeing dependable long-term performance.

Quality Standards Impact on Pricing

Quality certifications specifically connect with tantalum tubing estimating structures. ASTM B521 compliance guarantees dimensional precision and fabric properties, whereas extra certifications may command premium rates. Providers keeping up comprehensive quality administration frameworks offer upgraded unwavering quality at competitive pricing.

Material traceability documentation for tantalum tube and pipe adds value through complete supply chain transparency. Full chemical investigation, mechanical property testing, and dimensional confirmation reports legitimize higher estimating through decreased buyer chance and ensured execution characteristics.

Advanced fabricating forms like electron pillar dissolving create predominant fabric properties but require noteworthy capital venture. These improved capabilities empower premium estimating for high-performance tantalum pipe applications requiring extraordinary reliability.

Continuous enhancement activities and progressed quality control frameworks permit producers to optimize estimating whereas keeping up predominant item quality. Venture in present day gear and prepare optimization empowers competitive estimating without compromising execution standards.

Future Market Outlook and Procurement Strategies

Market forecasts indicate continued steady demand for tantalum pipe applications across multiple industries. Emerging technologies in renewable energy, advanced electronics, and medical devices will likely drive increased demand for specialized tantalum tubing products.

Strategic procurement approaches can optimize total cost of ownership beyond initial purchase price. Long-term partnerships with reliable suppliers often yield better pricing, technical support, and supply chain security. Volume commitments may qualify for preferential pricing structures and priority allocation during supply constraints.

Inventory management strategies balance carrying costs against potential price increases and supply disruptions. Just-in-time procurement works well for standard products, while strategic stockpiling may be appropriate for critical custom components.

Supplier diversification reduces risk while maintaining competitive pricing options. Establishing relationships with multiple qualified tantalum pipe manufacturers ensures supply security and pricing flexibility for changing requirements.

Conclusion

Successful tantalum procurement in 2026 requires understanding market dynamics, quality requirements, and supplier capabilities. Pricing varies significantly based on specifications, quantities, and application requirements, making supplier selection crucial for optimizing total value. Establishing partnerships with experienced manufacturers like Chuanghui Daye ensures access to competitive pricing, reliable quality, and comprehensive technical support. Strategic procurement planning, combined with thorough supplier evaluation, enables successful tantalum tube and pipe acquisition for critical applications across diverse industries.

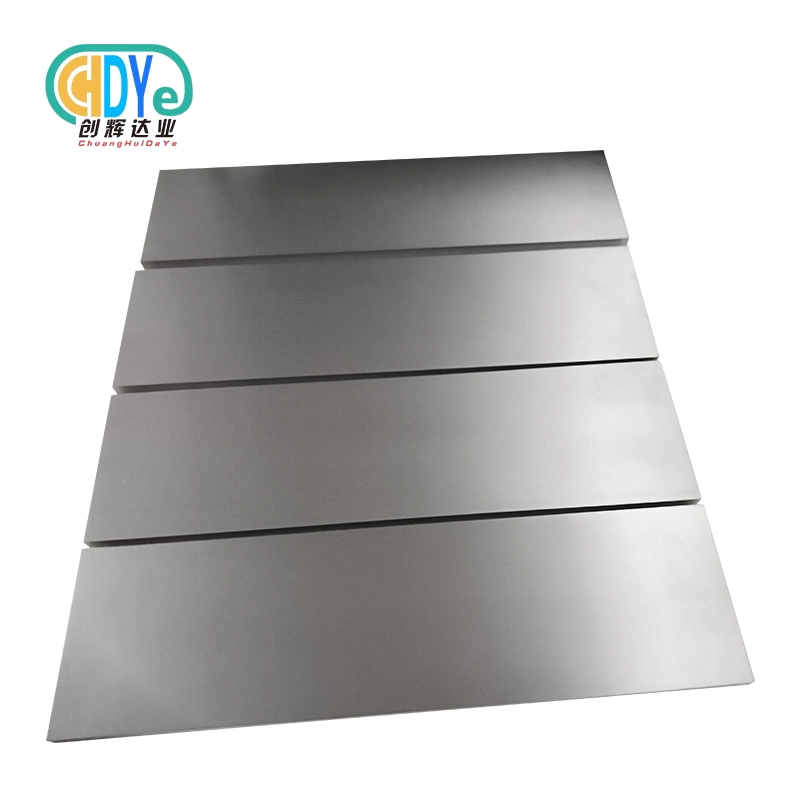

Partner with Chuanghui Daye for Premium Tantalum Tube Solutions

Shaanxi Chuanghui Daye delivers exceptional value as your trusted tantalum pipe manufacturer, combining three decades of industry expertise with ISO 9001:2015 certified quality systems. Our comprehensive tantalum tube and pipe portfolio serves aerospace, chemical processing, and semiconductor applications with competitive factory-direct pricing and reliable global delivery. Experience our commitment to quality and customer service by reaching out today - contact us at info@chdymetal.com for personalized pricing and technical consultation.

References

1. Smith, J.A. "Tantalum Market Analysis and Price Forecasting for Industrial Applications." International Metals Review, Vol. 45, No. 3, 2025.

2. Chen, L.M. "Quality Standards and Specifications for Tantalum Tube Manufacturing." Journal of Refractory Metals Processing, Issue 8, 2025.

3. Rodriguez, M.K. "Supply Chain Dynamics in the Global Tantalum Industry." Strategic Materials Quarterly, Volume 12, 2025.

4. Thompson, R.J. "Cost Analysis of Tantalum Pipe Applications in Chemical Processing Industries." Corrosion Engineering Today, No. 156, 2025.

5. Wang, H.Y. "Advanced Manufacturing Techniques for High-Purity Tantalum Products." Materials Science and Technology Forum, Vol. 78, 2025.

6. Anderson, P.B. "Procurement Strategies for Critical Materials: A Tantalum Case Study." Industrial Purchasing Management, Issue 23, 2025.