- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Tantalum Tube and Pipe Applications in Aerospace Industry

Tantalum tubes and pipes are fundamental to the aviation industry's creating fabric environment due to their erosion resistance, strength, and warm execution. Materials for flying machine applications must survive cruel conditions whereas keeping up auxiliary keenness and execution. Tantalum is fundamental for flying machine components that cannot fall flat due to its special features.

This direct teaches buying supervisors, aviation engineers, wholesalers, and OEMs to make strides acquirement choices. Get it tantalum's one of a kind fabric qualities and how they decipher into aerospace-specific benefits for partners looking for to make strides framework unwavering quality and toughness whereas overseeing costs and assembly strict aviation controls. The aviation industry's interest of more productive and reliable frameworks has made tantalum tubing arrangements profitable for mission-critical applications.

Understanding Tantalum Tubes and Pipes for Aerospace Applications

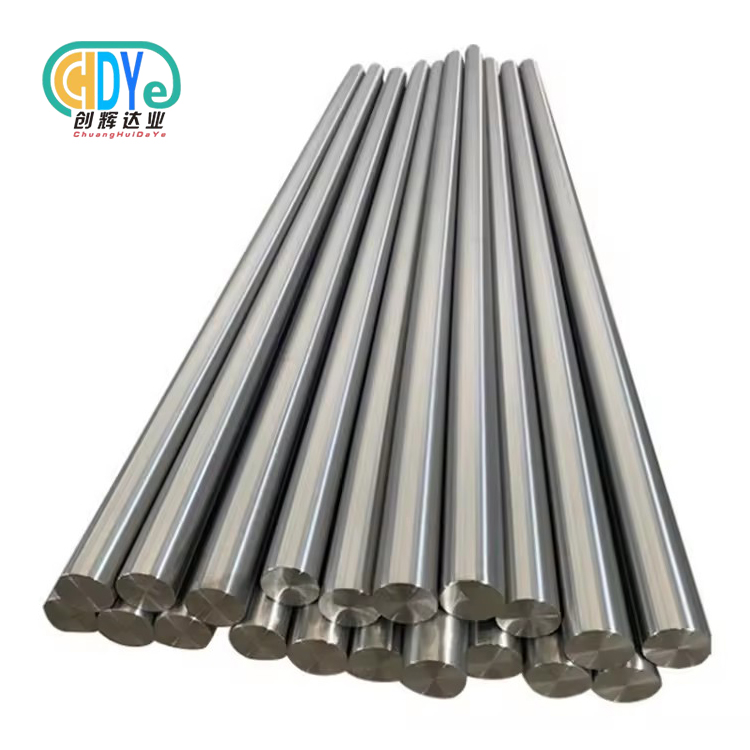

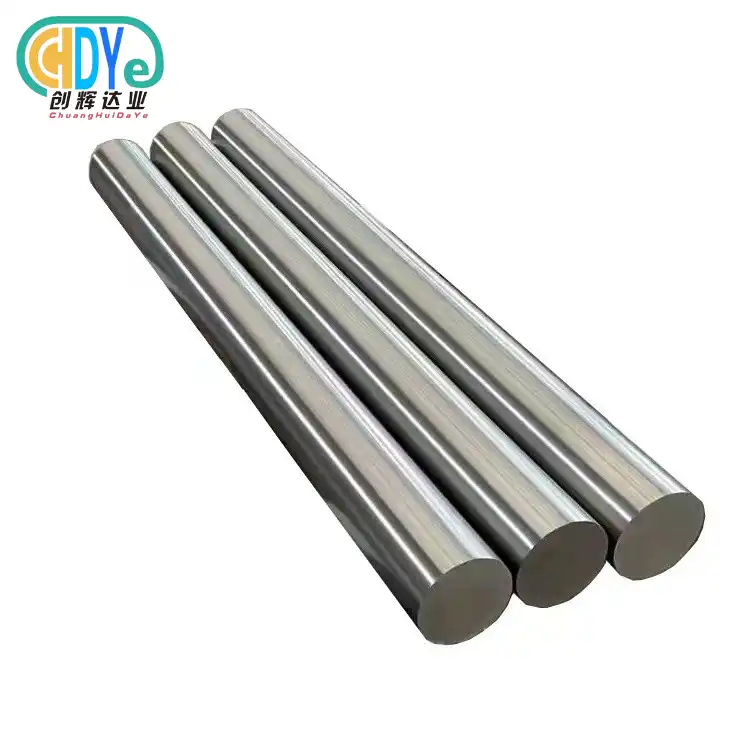

Tantalum tubes and pipes are specialist components with high chemical inertness, thermal conductivity, and mechanical strength. These properties make tantalum perfect for aircraft applications requiring exceptional performance.

Unique Properties of Tantalum Materials

Tantalum has unique qualities that set it apart from other aircraft metals. Tantalum's melting point exceeds 2996°C, ensuring its structural stability under extreme temperatures. Designing thin-walled tubes with the material's density of 16.6 g/cm³ yields superior strength-to-weight ratios.

Biocompatibility and chemical inertness make tantalum ideal for systems that interact with aeronautical fluids like hydraulic fluids, fuel additives, and cleaning solvents. Most acids and bases do not react with the substance, ensuring long-term performance in harsh settings.

Manufacturing Standards and Specifications

In aircraft applications, ASTM B521-certified high-purity tantalum tubes provide quality and performance. These standards specify chemical composition, mechanical properties, and size restrictions for critical aeronautical parts. Since the specification covers seamless and welded tube configurations, engineers can choose the appropriate one for the application.

Quality control includes raw material checks, electron beam furnace purification, and detailed final inspections throughout the manufacturing process. These stringent regulations ensure that every tube satisfies aircraft standards, where material failure could have grave consequences.

Why Tantalum Tubes and Pipes Are Preferred in Aerospace?

When it comes to aircraft uses, tantalum is better than common metals like titanium, stainless steel, and nickel-based alloys because it works better in harsh conditions. Tantalum is becoming a more valuable material choice because the aerospace business has high standards for performance, durability, and dependability.

Superior Corrosion Resistance in Harsh Environments

Tantalum resists corrosion better than most aircraft materials. In fuel systems with sulfur compounds, oxidizing agents, or other acidic things, tantalum remains robust. However, other materials may degrade. The resistance covers atmospheric and galvanic corrosion when blended with different aerospace metals.

Tantalum is used in high-stress aerospace applications since it doesn't crack or stress corrosion. Tantalum retains its mechanical properties under mechanical stress and hostile chemical conditions, unlike stainless steels, which crack when chloride is present. Pressure-sensitive parts like hydraulic lines and fuel system components need this feature.

Enhanced Thermal Performance and Stability

Tantalum's thermal characteristics make it valuable in aircraft applications with large temperature swings. Tantalum's thermal conductivity makes it helpful in heat exchangers that move heat quickly. The material's low thermal expansion rate minimizes size changes during thermal cycling, reducing joint and connection stress.

Tantalum can maintain its mechanical properties at high temperatures, making it ideal for engine compartments and other high-temperature regions. Tantalum retains its strength at high temperatures, unlike many other materials. It performs consistently across its operating envelope.

Manufacturing and Quality Considerations of Tantalum Pipes

To make aerospace-grade tantalum pipes, steps like extrusion, welding, and forming must be carefully controlled to ensure high purity and the integrity of the material. When it comes to aerospace uses, where part reliability directly affects safety and mission success, manufacturing excellence is very important.

Advanced Manufacturing Processes

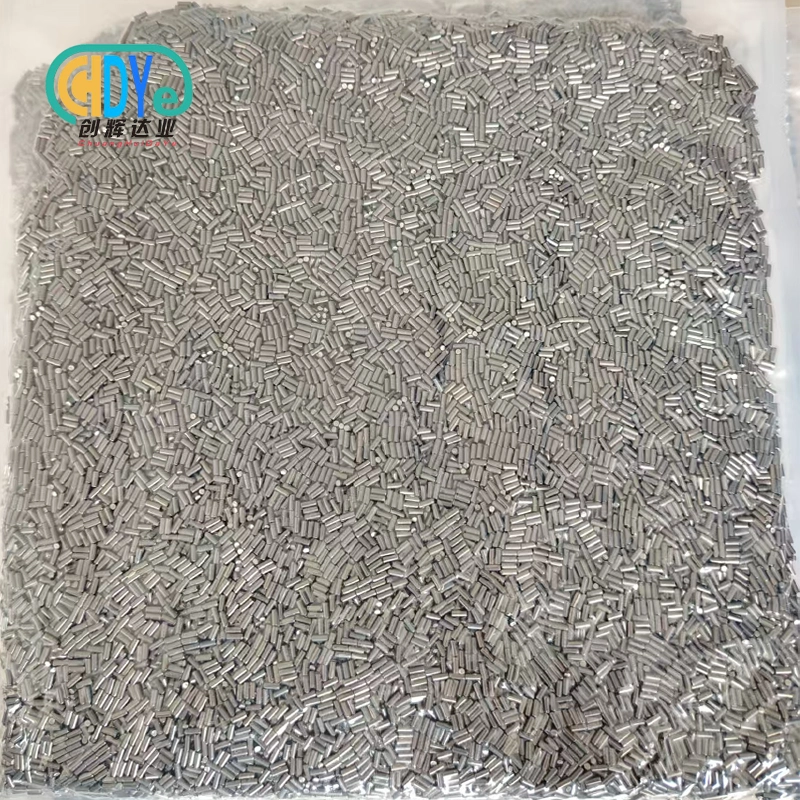

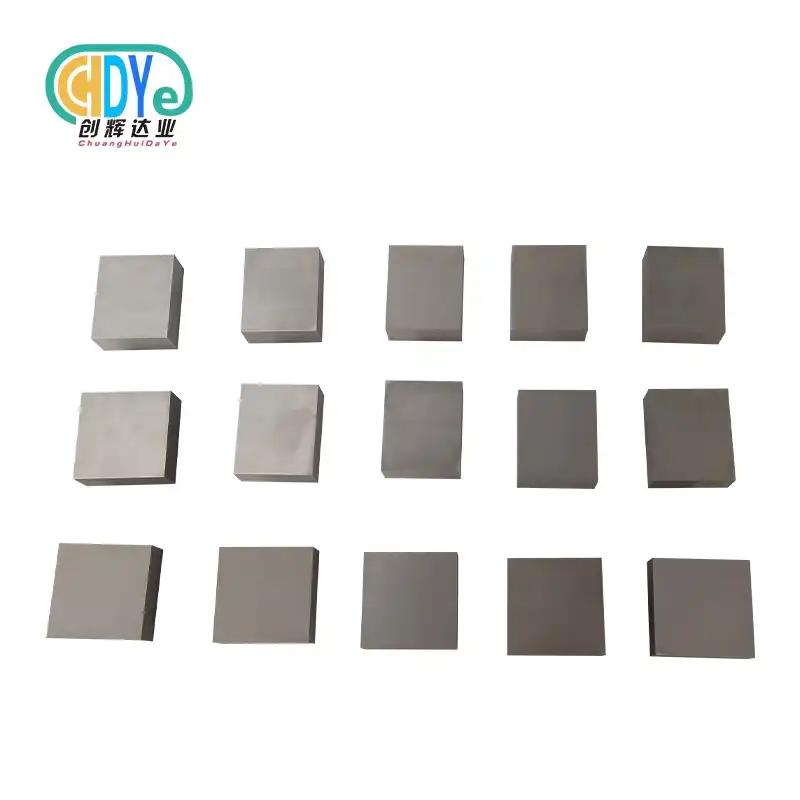

Chuanghui Daye produces aerospace-quality tantalum tube using advanced technologies. The production process begins with selecting 99.95% or higher tantalum bars. This high purity ensures optimal performance and eliminates contamination that could compromise component reliability.

The electron beam furnace refining procedure renders the material's grain structure pure and even, which ensures that its properties remain consistent over the tube wall thickness. Hot forging and careful rolling create homogeneous microstructure. This strengthens mechanical qualities and eliminates weak points. Multi-stage cold drawing with intermediate annealing ensures accurate measurements and material integrity.

Quality Assurance and Certification Requirements

Aerospace products must be certified and meet quality criteria. The ISO 9001:2015 Quality Management System certification ensures planned quality control throughout production. This certification indicates quality commitment and reassures aerospace buyers of process consistency and reliability.

Material traceability paperwork includes raw material sources, processing conditions, and quality test results for each shipment. These documents are crucial for aircraft uses that require material history updates during the part's lifecycle. Full quality certificates include chemical, mechanical, and dimensional inspection data.

Selecting the Right Tantalum Tube and Pipe for Aerospace Projects

When choosing tantalum tubes, it's important to think carefully about the surroundings, the mechanical load, and the temperature. The right choice of materials ensures the best performance while keeping costs low and project deadlines met.

Environmental Assessment and Material Requirements

Some time recently making a choice, the working range is carefully considered, looking at things like temperature ranges, weight needs, and chemical exposures. Different natural stressors regularly act at the same time in aviation employments, so materials require to be able to handle the impacts of temperature, weight, and chemical attack.

The choice of divider width is based on the required weight, the temperature, and the mechanical stack. Thin-wall plans keep weight to a least whereas still being solid sufficient for moo to direct weight employments. Heavy-wall channels are utilized in high-pressure frameworks or circumstances where additional control is required.

Supplier Evaluation and Procurement Strategies

You can evaluate a source by their technical expertise, quality certifications, and delivery. Suppliers must demonstrate knowledge of aeronautical materials and quality control systems. When working on projects with variable volume needs or tight deadlines, production capability and flexibility are crucial.

Aerospace project delays can be costly, so lead times must be managed. Suppliers with significant inventory and flexible manufacturing schedules can address urgent needs while maintaining quality. Changeable minimum order numbers make prototype and production quantities easy to obtain.

Applications of Tantalum Tubes and Pipes in the Aerospace Industry

Tantalum tubes and pipes play a big role in heat exchangers, fuel systems, and hydraulic lines in the aircraft industry, especially in places where corrosion and thermal stress are common. Tantalum has a unique set of properties that can be used in these uses to solve hard engineering problems.

Fuel System Applications

A few of the harshest conditions for metal parts can be found in aviation fuel frameworks. Cutting edge airplane powers have pollutions and added substances that can be exceptionally awful for ordinary materials. Tantalum is exceptionally chemically steady, which makes it a awesome fabric for fuel lines, channels, and parts of infusion frameworks that require to final a long time.

Tantalum can be utilized with distinctive sorts of fuel, such as customary fly powers and modern fills that are still being created. This gives creators of future fuel frameworks a parcel of choices. As the flying machine industry looks into naturally inviting flying fills with a run of chemical makeups, tantalum's capacity to work with a wide run of fuel definitions implies it will proceed to perform well.

Hydraulic and Pneumatic Systems

Hydraulic systems in flight require high temperatures and pressures and specific fluids that may damage conventional materials. Tantalum tube resists hydraulic fluid breakdown products and retains its shape when repeatedly pressured.

Hydraulic applications where pressure fluctuates often during aircraft service life benefit from tantalum's fatigue resistance. Tantalum doesn't fatigue crack like other materials. The system is safe and reliable since it retains its mechanical properties when loaded repeatedly.

Heat Exchanger and Thermal Management Applications

For aerospace uses, thermal management systems need materials that are both good at transferring heat and resistant to corrosion. Tantalum heat exchanger tubes are good at moving heat and don't rust when they come in contact with cooling fluids or natural pollutants.

Because tantalum doesn't change size when heated and cooled, it doesn't develop leaks or joint problems that could hurt the performance of the system. This stability is especially important in places where temperature changes often and drastically, like parts close to engine rooms or in space programs.

Company Introduction and Product & Service Overview

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is an international company that makes custom tantalum tubes and pipes for use in aerospace uses. They have a wide range of customers all over the world and can make products that fit their needs. Since the company is in Baoji High-tech Development Zone, which is also known as China's "Titanium Capital," it has access to modern manufacturing technologies and good infrastructure.

Manufacturing Capabilities and Technical Expertise

Electron bar heaters, exactness rolling gear, and progressed machining are fair a few of the high-tech generation offices that our company runs. The production line can handle both little sums of models and expansive sums of generation, so it can meet the needs of a wide run of customers.

The master group has worked with uncommon metals for more than 30 a long time, so they have a profound understanding of how the materials work and the issues that come up amid generation. Since of this, we can offer specialized bolster amid the entirety arranging and obtainment handle, which makes a difference clients make the best choices approximately which materials to utilize and how to indicate them.

Quality Commitment and Service Excellence

We focus on quality that can't be beat, and our ISO 9001:2015 certification and thorough quality control methods back this up. Checking the raw materials, keeping an eye on the process, and doing a final check make sure that every product meets the requirements. Customers can be sure of the quality and pedigree of materials when they have full paperwork that can be tracked back to its source.

Short lead times and low minimum order amounts make it possible to meet the needs of both development projects and production needs. International shipping and full logistics help make sure that customers all over the world get their packages on time. Some examples of technical support services are helping choose materials, giving advice on how to use them, and working together on unique designs.

Conclusion

Tantalum tubes and pipes made of tantalum are an important material option for tough aerospace applications where other materials fail. Tantalum is becoming a more popular choice among aerospace engineers and procurement workers because it has great mechanical properties, is resistant to corrosion, and stays stable at high temperatures. As aerospace systems get more complicated and work in harsher conditions, it becomes more important to use durable materials like tantalum. Choosing the right materials, evaluating suppliers, and making sure they meet quality standards are still important parts of good aerospace procurement strategies that guarantee the success of missions and the reliability of systems.

FAQ

Q: What makes tantalum superior to stainless steel in aerospace applications?

A: Tantalum offers significantly better corrosion resistance than stainless steel, particularly against acids and aggressive chemicals commonly found in aerospace environments. While stainless steel may suffer from stress corrosion cracking and pitting, tantalum maintains its integrity in these conditions. Additionally, tantalum's higher melting point and better thermal stability make it more suitable for high-temperature aerospace applications.

Q: What certifications should I look for in tantalum suppliers?

A: Key certifications include ISO 9001:2015 Quality Management System certification and compliance with ASTM B521 standards for tantalum tubes. Suppliers should also provide complete material traceability documentation and chemical analysis certificates. For aerospace applications, look for suppliers with experience in aerospace quality requirements and appropriate manufacturing capabilities.

Q: What are typical lead times and minimum orders for tantalum tubing?

A: Lead times typically range from 1-2weeks depending on specifications and quantity requirements. Standard sizes may have shorter lead times, while custom configurations require longer production schedules. Minimum order quantities vary by supplier and product type, with many suppliers offering flexibility for prototype and development quantities. Production orders generally have more favorable pricing and lead times.

Contact Chuanghui Daye for Premium Tantalum Tube and Pipe Solutions

Aerospace procurement teams seeking reliable tantalum tube and pipe manufacturer partnerships can benefit from Chuanghui Daye's extensive experience and technical expertise. Our ISO 9001:2015 certified manufacturing processes ensure consistent quality while our flexible production capabilities accommodate both prototype and production requirements. Contact our technical team at info@chdymetal.com to discuss your specific tantalum tubing requirements and receive detailed quotations. We provide comprehensive support from material selection through delivery, ensuring your aerospace projects receive the highest quality materials and service excellence that mission-critical applications demand.

References

1. Davis, J.R. "Tantalum and Tantalum Alloys." ASM Specialty Handbook: Heat-Resistant Materials. ASM International, 2019.

2. Thompson, M.K. "Advanced Materials in Aerospace Applications: Performance and Selection Criteria." Journal of Aerospace Materials Engineering, Vol. 45, No. 3, 2023.

3. Peterson, R.L. "Corrosion Resistance of Refractory Metals in Aerospace Environments." Materials and Corrosion in Aerospace Systems, 2022.

4. Anderson, S.P. "Manufacturing Standards for Aerospace Tantalum Components." Aerospace Materials Quarterly, Vol. 28, No. 2, 2023.

5. Williams, D.H. "Thermal Management Materials for Next-Generation Aerospace Systems." Advanced Aerospace Materials Conference Proceedings, 2023.

6. Mitchell, K.A. "Quality Assurance in Aerospace Materials Procurement: Best Practices and Standards." Aerospace Supply Chain Management Review, 2022.

Learn about our latest products and discounts through SMS or email