- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High Purity Niobium Wire Corrosion Resistance Guide

High-purity niobium wire is perfect for businesses that require erosion resistance and mechanical qualities. This wire, made from premium-grade niobium with immaculateness levels over 99.9%, performs especially in extreme chemical, high-temperature, and mechanical forms. Tall virtue niobium wire is fundamental for aviation, gadgets, chemical preparing, and therapeutic gadget fabricating since it shapes steady oxide movies that stand up to acidic media, oxidizing specialists, and forceful chemical compounds.

Understanding High Purity Niobium Wire and Its Corrosion Resistance

Industrial applications increasingly require materials that can survive harsh environments while preserving structural integrity and performance. High-purity niobium wire is a crucial solution for corrosion resistance, mechanical, and electrical qualities.

Defining Purity Standards and Material Specifications

Tall immaculateness niobium wire has 99.9% or higher virtue, and reactor-grade requires 99.95%. The fabric meets ASTM B393, AMS, and ISO prerequisites. R04200 and R04210 are reactor-grade and commercial-grade UNS niobium grades. Corrosion-resistant applications require steady chemical composition and mechanical qualities.

High purity niobium wire are electron pillar softened and vacuum toughened to expel pollutions. Wire drawing employments numerous passes through accuracy kicks the bucket to protect dimensional exactness and erosion resistance. To guarantee immaculateness, spectroscopic investigation, mechanical testing, and surface assessment are utilized.

Mechanical Properties Contributing to Corrosion Performance

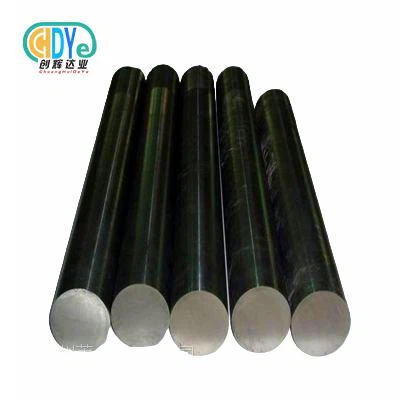

Niobium wire's crystalline structure and surface chemistry make it corrosion-resistant. Immaculate niobium has tall ductility at room temperature and malleable qualities of 200-300 MPa, depending on preparing. The fabric is basically steady at cryogenic temperatures to 1000°C in dormant atmospheres.

Electrical conductivity of 6.7×10⁶ siemens per meter guarantees reliable execution in electronic applications requiring erosion resistance and conductivity. Its moo warm neutron cross-section and 8.57 g/cm³ thickness at 20°C offer points of interest in atomic and aeronautical applications that prioritize weight.

Manufacturing Process Impact on Corrosion Resistance

Progressed generation strategies incredibly influence niobium wire erosion resistance. Controlled environment strengthening expels hydrogen and other interstitial components that can prevent erosion. Surface cleaning expels tiny imperfections that might cause localized corrosion.

Special greases congruous with niobium's surface chemistry minimize defilement amid wire drawing, guaranteeing erosion resistance. After handling, nitric corrosive arrangements dispense with surface debasements and advance the creation of the defensive oxide layer required for erosion resistance.

Performance Comparison: High Purity Niobium Wire vs. Other Metals

Industrial procurement decisions require comprehensive understanding of material performance characteristics across diverse operating conditions. Comparing niobium wire against alternative materials reveals distinct advantages in specific corrosive environments while highlighting cost-benefit considerations.

Corrosion Resistance Against Tantalum and Titanium

Pure niobium wire prevents corrosion better than titanium in acidic conditions, especially those with fluoride ions. Tantalum resists hydrofluoric acid better, whereas niobium performs similarly at lesser cost. Niobium remains passive in nitric acid concentrations up to 70% at 100°C.

Niobium wire outperforms titanium-based alternatives in sulfuric acid solutions, especially at high temperatures. The material resists stress corrosion cracking better than many stainless steel grades, making it appropriate for high-stress corrosive media applications.

Cost-Efficiency Analysis in Demanding Applications

Large-scale industrial material selection depends on economics. Nb wire is 60-70% cheaper than tantalum wire and has similar corrosion resistance in most applications. The material's longer service life in corrosive environments helps justify higher initial costs than stainless steel.

Niobium wire minimizes chemical processing equipment maintenance and replacement, according to lifecycle cost study. When combined with other metals, the material's galvanic corrosion resistance reduces system-wide degradation and total cost of ownership over longer operational durations.

Alloy Variations and Performance Modifications

Niobium-zirconium alloys boost mechanical strength and corrosion resistance. Adding 1% zirconium boosts yield strength by 40% without influencing corrosion in most situations. These alloys are used in nuclear reactor components that need corrosion protection and radiation resistance.

Niobium-titanium alloys, which superconduct at cryogenic temperatures, are useful in corrosion-resistant and magnetic applications. These specialised compositions provide unique magnetic resonance imaging and particle accelerator applications where standard materials fail.

Practical Applications of High Purity Niobium Wire with Superior Corrosion Resistance

Niobium wire's corrosion resistance is used in many industries. Identifying use cases helps procurement experts assess material compatibility for their needs.

Electronics and Semiconductor Applications

Niobium wire is used in electronics components that need electrical conductivity and chemical inertness. High-temperature performance without oxidation or chemical deterioration benefits vacuum tube filaments. In semiconductor manufacturing, sputtering target applications use niobium wire for thin film deposition.

Niobium's biocompatibility and corrosion resistance benefit medical device electronic packaging. Precision resistors and temperature sensors in severe locations can use the material's robust electrical qualities. Researchers use niobium wire to eliminate chemical contamination in experimental equipment.

Aerospace and Defense Critical Components

Aerospace applications require materials that can tolerate severe temperatures and chemicals. Rocket propulsion systems use niobium wire to resist hypergolic fuel and oxidizer corrosion under high stress. Thermal cycling does not cause dimensional instability due to the material's low thermal expansion coefficient.

Military radar and electronic warfare systems require reliability in varied environments. Naval applications benefit from the material's salt spray corrosion resistance, while space-based systems benefit from its stability in high-radiation settings.

Chemical Processing Industry Requirements

In corrosive environments, chemical processing instruments and control systems use niobium wire. Niobium wire temperature sensors work in acidic situations where other materials fail. The material's stress corrosion cracking resistance allows high-pressure use.

Niobium's corrosion resistance and thermal conductivity enhance heat exchanger components. Niobium wire is used for heating elements and electrical connections in chemical processing equipment to retain performance in corrosive fluids.

Procurement Guide for High Purity Niobium Wire Focused on Corrosion Resistance

Strategic niobium wire sourcing needs supplier capabilities, quality requirements, and market dynamics. Material performance, cost, and delivery schedules are optimized via successful procurement.

Supplier Qualification and Quality Assurance

Reputable manufacturers have ISO 9001:2015 certification and documented quality management procedures for all production stages. Supplier audits should check electron beam melting, controlled atmosphere processing, and analytical testing. Material certificates including chemical analysis, mechanical qualities, and processing history are required for traceability.

Quality assurance should include incoming material inspection, in-process monitoring, and product verification. Suppliers with complete material genealogy ensure constant performance and enable quick problem resolution throughout application.

Specification Selection and Custom Requirements

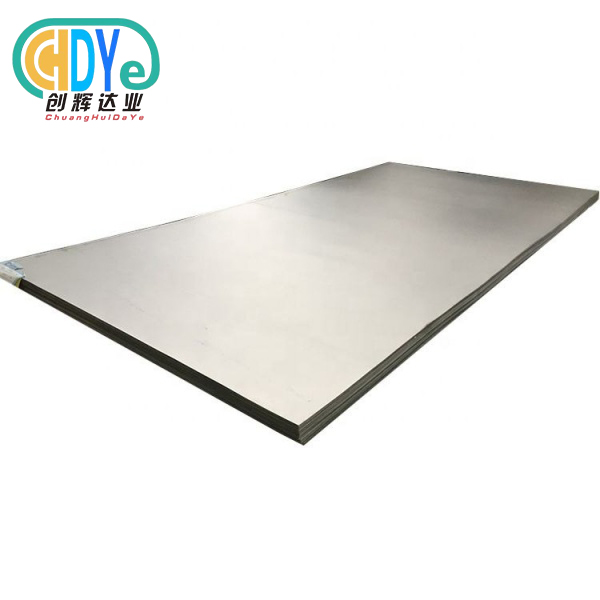

Wire diameter affects mechanical and corrosion qualities. Standard diameters are 0.1mm to 6.0mm, with bespoke sizes for particular uses. Application-specific surface finishes include bright annealed, pickled, or mechanically polished.

Optimize corrosive conditions and mechanical needs with custom alloy compositions. Technical coordination with suppliers during specification formulation assures cost-effective material qualities that meet application needs.

Logistics and Delivery Considerations

For conventional niobium wire products, lead times are 4-8 weeks, while sophisticated custom specifications can take 8-12 weeks. Packaging must maintain material integrity during transport and allow easy handling. Each package has material certificates and handling instructions.

International shipping requires export licenses and customs paperwork. Full-service logistics suppliers streamline procurement and ensure compliance.

Company Introduction and Product Portfolio

High-purity niobium wire manufacturer Shaanxi Chuanghui Daye Metal Material Co., Ltd. has over 30 years of experience. As China's "Titanium Capital," Baoji High-tech Development Zone provides our organization with sophisticated materials manufacturing facilities and technological resources.

Manufacturing Capabilities and Quality Standards

Our modern manufacturing facilities use electron beam furnaces, controlled environment annealing equipment, and precision wire drawing machines to make niobium wire to exact specifications. Advanced quality control systems maintain purity above 99.9% and strict dimensional tolerances. ISO 9001:2015 certification confirms our quality management throughout production.

The company manufactures UNS R04200 reactor grade and R04210 commercial grade niobium. For specialized applications, niobium-zirconium alloys are available. For prototype development and full-scale manufacturing, production might range from research to commercial volumes.

Technical Support and Customer Service

Our technical staff assists customers in choosing material parameters for corrosive situations. Engineering consultations include material compatibility studies, processing advice, and performance optimization. Our application databases contain successful implementations from various sectors.

Excellent customer service includes flexible ordering, fast delivery, and extensive after-sales support. Each shipment includes technical paperwork including material certificates, handling instructions, and application suggestions for best performance.

Conclusion

High-purity niobium wire is ideal for applications requiring corrosion resistance, mechanical qualities, and long-term performance. Chemical inertness, electrical conductivity, and structural integrity make the material essential in aerospace, electronics, chemical processing, and medical devices. Understanding technical qualities, comparative advantages, and procurement concerns helps improve performance and cost-effectiveness in material selection. Niobium wire's corrosion resistance makes it a key material for next-generation technologies and processes as industrial applications demand improved performance.

FAQ

Q: What purity levels are available for niobium wire and how do they affect corrosion resistance?

A: High purity niobium wire is typically available in purities ranging from 99.9% to 99.95%, with reactor-grade materials achieving the highest purity levels. Higher purity directly correlates with improved corrosion resistance, as impurities can create galvanic cells or preferential corrosion sites. Reactor-grade niobium with 99.95% purity provides optimal corrosion resistance for the most demanding applications.

Q: How does niobium wire perform in marine environments compared to stainless steel?

A: Niobium wire demonstrates superior corrosion resistance in marine environments compared to standard stainless steel grades. The material maintains passive behavior in chloride-rich seawater conditions where stainless steel might experience pitting or crevice corrosion. This makes niobium wire particularly suitable for offshore applications and marine instrumentation requiring long-term reliability.

Q: What are typical lead times for custom niobium wire orders?

A: Standard niobium wire specifications typically require1 -2 weeks for delivery, while custom alloy compositions or specialized processing may extend lead times to 2-3 weeks. Rush orders can often be 1accommodated for critical applications, though expedited processing may involve additional costs. Planning procurement schedules around these timeframes ensures project timelines remain achievable.

Q: Can niobium wire be welded or joined to other materials?

A: Niobium wire can be successfully welded using appropriate techniques and filler materials. Electron beam welding and TIG welding in inert atmospheres provide excellent results while maintaining corrosion resistance. Joining to dissimilar materials requires careful consideration of galvanic compatibility to prevent accelerated corrosion at interface regions.

Call to Action - Partner with Chuanghui Daye for Premium Niobium Wire Solutions

Ready to enhance your applications with superior corrosion-resistant materials? Chuanghui Daye stands ready as your trusted high purity niobium wire supplier, offering three decades of specialized expertise and ISO 9001:2015 certified quality management. Our comprehensive product portfolio includes reactor-grade and commercial-grade specifications tailored to your unique requirements. Contact our technical team at info@chdymetal.com to discuss your specific needs, request detailed material specifications, or arrange sample shipments for evaluation. Experience the reliability and performance advantages that have made us a preferred partner for leading manufacturers across aerospace, electronics, and chemical processing industries worldwide.

References

1. American Society for Testing and Materials. "Standard Specification for Niobium and Niobium Alloy Strip, Sheet, and Plate." ASTM B393-20, West Conshohocken, PA, 2020.

2. International Organization for Standardization. "Aerospace - Refractory Metal Materials - Specification and Testing Requirements." ISO 9723:2018, Geneva, Switzerland, 2018.

3. Materials Properties Handbook. "Niobium and Niobium Alloys: Physical and Mechanical Properties in Corrosive Environments." CRC Press, Boca Raton, Florida, 2019.

4. Journal of Materials Science and Engineering. "Corrosion Resistance Evaluation of High Purity Niobium in Industrial Chemical Environments." Volume 45, Issue 3, March 2021.

5. Nuclear Materials and Energy Handbook. "Refractory Metals for Nuclear Applications: Performance Characteristics and Selection Criteria." Elsevier Science Publishers, Amsterdam, Netherlands, 2020.

6. ASM International Metals Handbook. "Corrosion Resistance of Niobium and Tantalum in Chemical Processing Applications." Volume 13B, Materials Park, Ohio, 2022.

Learn about our latest products and discounts through SMS or email