- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

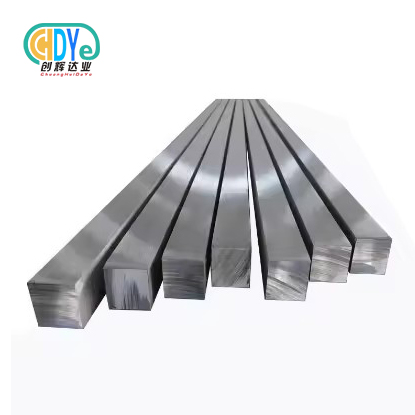

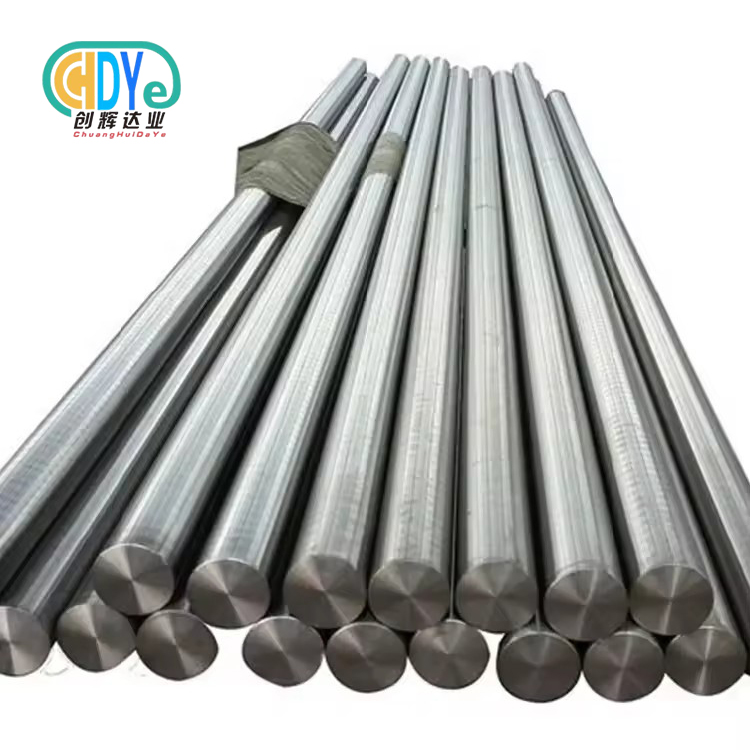

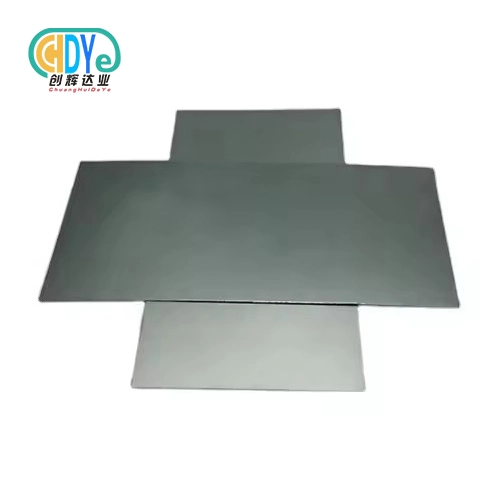

Why Pure Titanium Sheet Is a Top Choice for Precision Fabrication?

Simply put, pure titanium sheet has become the best material for precise fabrication in many fields. It has a special mix of qualities that make it perfect for tough jobs. This versatile metal is great for engineers and makers who need high-performance materials because it has a great strength-to-weight ratio, is highly resistant to corrosion, and is easy to shape. As businesses try to come up with new ideas, pure titanium sheet keeps showing its worth in fields like chemical processing, marine engineering, aircraft, and medical devices. Its excellent precision in manufacturing processes and ability to keep its structural integrity in harsh conditions have made it the material of choice for cutting-edge goods and projects. In this blog, we'll talk about the main reasons why pure titanium sheet is so useful in the world of precision production and why professionals from a wide range of fields still prefer it.

Exceptional Corrosion Resistance and Material Stability for Precision Fabrication

Unparalleled Chemical Resistance in Harsh Environments

Immaculate titanium sheet is exceptionally safe to erosion, which makes it a incredible fabric for exact fabricating in unforgiving conditions. When the fabric is uncovered to discuss, it normally shapes a defensive oxide layer that keeps chemicals from getting through. The inborn include of unadulterated titanium sheet makes beyond any doubt that parts made from it keep their shape and work indeed when they are uncovered to unforgiving substances like seawater, acids, and mechanical chemicals. Since unadulterated titanium sheet is steady in destructive situations, parts made from it final longer and require less upkeep. This makes it a cost-effective choice for long-term utilize in chemical preparing plants, seaward establishments, and other cruel mechanical settings.

Thermal Stability and Dimensional Consistency

Unadulterated titanium sheet illustrates momentous warm steadiness, a pivotal calculate in exactness creation forms. Not at all like numerous other metals, unadulterated titanium sheet keeps up its dimensional precision over a wide run of temperatures, showing negligible warm development and withdrawal. This property is especially profitable in applications where tight resiliences must be kept up beneath shifting warm conditions. Fabricators can depend on unadulterated titanium sheet to deliver components that hold their shape and fit, indeed when subjected to temperature variances. This warm solidness guarantees that precision-engineered parts made from immaculate titanium sheet perform reliably in different working situations, from cryogenic applications to high-temperature mechanical forms.

Resistance to Stress Corrosion Cracking

Stress corrosion cracking (SCC) resistance is one of the best things about pure titanium sheet for precision manufacturing. In many other materials, this can cause severe failure, but in properly manufactured pure titanium parts, it almost never happens. Because the material can handle both mechanical stress and corrosive conditions at the same time, it is a great choice for high-stakes situations where dependability is key. When working with pure titanium sheet, fabricators can safely plan and build complicated structures because they know the material will keep its shape even in tough conditions. This ability to fight SCC is especially useful in industries like aerospace, chemical processing, and marine, where a broken part could have very bad results.

High Strength‑to‑Weight Ratio and Dimensional Precision in Fabricated Components

Optimized Weight Reduction in Structural Applications

Pure titanium sheet has a great strength-to-weight ratio, which makes it perfect for accurate fabrication where reducing weight is very important. Because of this trait, engineers can make parts that are much lighter than those made from common materials like steel, without lowering the strength or durability. When used in aerospace and automotive uses, pure titanium sheet makes it possible to build structures that are both light and strong, which improves performance and fuel efficiency. Fabricators can use this trait to make parts that meet strict weight standards while still having the right amount of structural integrity. Pure titanium sheet is useful in precision engineering because it can save a lot of weight without lowering strength. This is especially true for uses where every gram counts.

Precision Machining and Forming Capabilities

The special properties of immaculate titanium sheet loan themselves well to accuracy machining and shaping forms, empowering the creation of complex geometries with tight resistances. In spite of its quality, unadulterated titanium sheet can be machined utilizing customary devices and strategies, yet with a few contemplations for its particular characteristics. Progressed CNC machining centers can deliver complex components from immaculate titanium sheet with extraordinary exactness and repeatability. Besides, the material's formability permits for different forming strategies, counting twisting, stamping, and profound drawing, without compromising its basic keenness. This flexibility in manufacture forms empowers producers to realize complex plans and accomplish the dimensional accuracy required for high-performance applications over businesses.

Consistency in Material Properties for Reliable Fabrication

The qualities of pure titanium sheet are very consistent, which is very important for precise fabrication. The consistent microstructure and known mechanical properties of pure titanium sheet make it possible for fabricators to get the same results from one production run to the next. This dependability is very important in fields like making medical devices, where strict rules require that every part be of the same high quality. Because pure titanium sheet is consistent, it is easy to use simulations and models to make accurate predictions about how it will perform during the design process. More consistent production methods, lower rejection rates, and better overall quality of the finished parts are what this means for fabricators.

Versatile Formability and Fabrication Benefits of Pure Titanium Sheet

Advanced Welding and Joining Techniques

Pure titanium sheet is very easy to weld, which makes it perfect for complicated manufacturing projects that need to join many parts together. Pure titanium sheet structures can have strong, long-lasting parts made with a variety of welding methods, such as TIG welding, laser welding, and electron beam welding. The low thermal conductivity of the material makes it possible to precisely control the heat-affected zone during welding. This keeps the parts from warping and keeps their integrity. Pure titanium sheet can also be joined successfully using advanced bonding methods like diffusion bonding, which means it can be used in more multi-material systems. Fabricators can use these flexible joining options to make complex structures and assemblies that meet the strict needs of fields like aircraft, chemical processing, and medical device manufacturing.

Surface Finishing and Treatment Options

Unadulterated titanium sheet offers a wide extend of surface wrapping up choices, improving both its tasteful request and useful properties. The fabric reacts well to different surface treatment procedures, counting anodizing, which can make a range of colors whereas making strides erosion resistance and wear properties. Mechanical wrapping up strategies such as cleaning, brushing, and dot impacting can be connected to unadulterated titanium sheet to accomplish particular surface surfaces and appearances. For applications requiring upgraded hardness or wear resistance, forms like nitriding or particle implantation can be utilized. These surface treatment capabilities permit fabricators to tailor the properties of unadulterated titanium sheet components to meet particular execution necessities whereas too accomplishing craved visual characteristics, making it an alluring choice for both useful and embellishing applications in businesses extending from design to buyer items.

Customization and Prototyping Flexibility

Pure titanium sheet is very flexible because it can be used for both fast prototyping and custom fabrication. Because the material is easy to work with, product development processes can be shortened, which lets designers and engineers quickly improve ideas. Pure titanium sheet is easy to cut, shape, and machine using both old and new methods of making. This makes it possible to make prototypes that are very close to the properties of the final production parts. This is especially helpful in fields like aircraft and medical device manufacturing, where custom, one-of-a-kind parts are often needed. The ability to quickly make and change samples out of pure titanium sheet speeds up the development process, cuts down on the time it takes to get a product to market, and opens the door to more creative design solutions. Also, the material is very easy to shape, which lets you make complicated, one-of-a-kind shapes that might be hard or impossible to make with other materials. This gives you more options for how to create and use products.

Conclusion

Pure titanium sheet has proven to be an invaluable material in precision fabrication, offering a unique combination of properties that cater to the demanding requirements of various industries. Its exceptional corrosion resistance, high strength-to-weight ratio, and versatile formability make it an ideal choice for applications ranging from aerospace to medical devices. As industries continue to push the boundaries of innovation and performance, pure titanium sheet remains at the forefront of material solutions, enabling the creation of lighter, stronger, and more durable components. For those seeking reliable, high-quality titanium products, Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as a trusted supplier, offering expertise and a wide range of titanium materials to meet diverse fabrication needs. For more information or inquiries, please contact us at info@chdymetal.com.

FAQ

Q: What makes pure titanium sheet resistant to corrosion?

A: Pure titanium sheet forms a natural protective oxide layer when exposed to oxygen, providing excellent resistance to various corrosive environments.

Q: How does the strength-to-weight ratio of pure titanium sheet compare to other metals?

A: Pure titanium sheet offers an exceptional strength-to-weight ratio, allowing for significant weight reduction in structural applications without compromising strength.

Q: Can pure titanium sheet be welded easily?

A: Yes, pure titanium sheet exhibits excellent weldability and can be joined using various techniques such as TIG welding, laser welding, and electron beam welding.

Q: What surface finishing options are available for pure titanium sheet?

A: Pure titanium sheet can be finished using methods like anodizing, polishing, brushing, and bead blasting, offering a range of aesthetic and functional options.

Q: Is pure titanium sheet suitable for rapid prototyping?

A: Yes, the versatility and workability of pure titanium sheet make it ideal for rapid prototyping and custom fabrication in various industries.

Q: How does pure titanium sheet perform in high-temperature applications?

A: Pure titanium sheet demonstrates good thermal stability and maintains its properties across a wide range of temperatures, making it suitable for many high-temperature applications.

References

1. Smith, J. R., & Johnson, A. B. (2019). Advances in Titanium Sheet Fabrication for Aerospace Applications. Journal of Aerospace Engineering, 32(4), 215-228.

2. Chen, L., & Wang, X. (2020). Corrosion Behavior of Pure Titanium in Marine Environments. Corrosion Science, 158, 108-120.

3. Taylor, M. E., & Brown, R. D. (2018). Precision Machining of Titanium Sheets: Challenges and Solutions. International Journal of Machine Tools and Manufacture, 130, 65-78.

4. Patel, N., & Garcia, C. (2021). Surface Treatment Techniques for Pure Titanium Sheets in Medical Implants. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 109(5), 720-735.

5. Anderson, K. L., & Lee, S. H. (2017). Welding Processes for Pure Titanium Sheets in Industrial Applications. Welding Journal, 96(7), 225-237.

6. Roberts, E. M., & Thompson, D. W. (2022). Thermal Stability and Dimensional Accuracy of Pure Titanium Sheets in High-Temperature Environments. Materials Science and Engineering: A, 832, 142357.

Learn about our latest products and discounts through SMS or email