- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

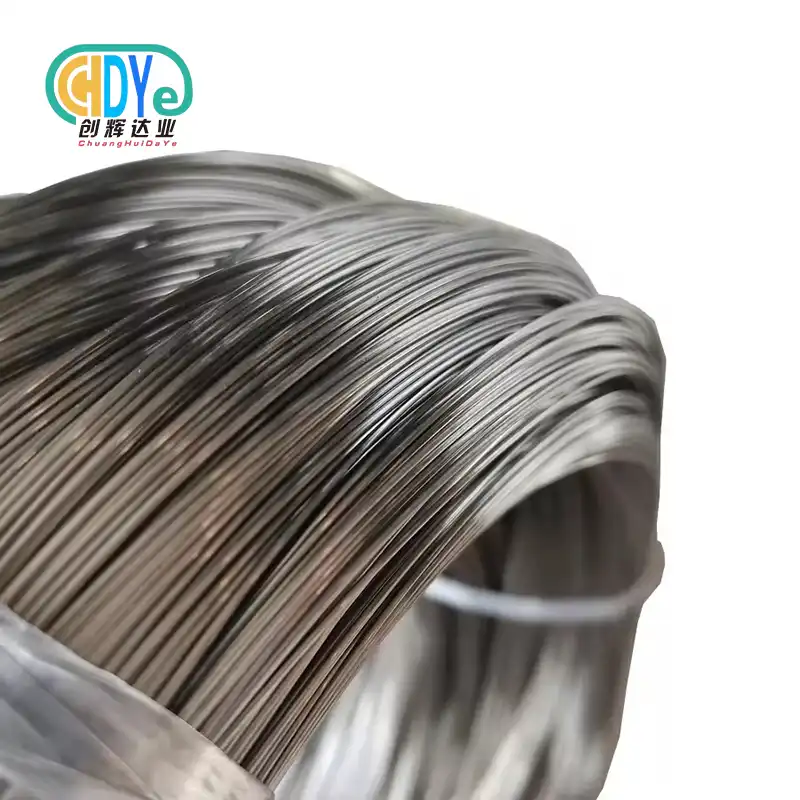

Advanced Gr5 Titanium Wire for Chemical & Petrochemical Industry

Within the realm of metallurgical engineering, Gr5 Titanium Wire is considered to be the pinnacle of excellence for chemical and petrochemical applications. Because of its extraordinary resistance to corrosion and its superior mechanical qualities, this Ti-6Al-4V alloy is a vital material for use in tough industrial environments. With this cutting-edge material, chemical processing plants all over the world are able to guarantee the durability of their equipment and the safety of their operations even under the most rigorous conditions.

Understanding Gr5 Titanium Wire and Its Superior Properties

The alloy composition of Ti-6Al-4V wire has been meticulously designed, which is the source of its remarkable performance. The remaining 6% of this premium titanium grade is composed of pure titanium, while the remaining 4% is composed of vanadium, and around 6% is aluminum. Because of this particular formulation, a one-of-a-kind equilibrium of qualities is produced, which is superior to that of other grades of titanium and alternative materials.

Alloy Composition and Mechanical Excellence

The presence of vanadium in Gr5 titanium alloy improves both its hardenability and its strength at elevated temperatures, whereas the presence of aluminum in the alloy increases its strength and decreases its density. With a tensile strength that is greater than 925 MPa and a yield strength that is greater than 870 MPa, this combination greatly outperforms pure titanium grades such as Gr2 and Gr4. It is normal for the elongation to be greater than 10%, which guarantees sufficient ductility for the forming operations.

Manufacturing Process and Quality Control

Precision melting in electron beam furnaces is the first step in our manufacturing process, which is then followed by controlled forging and rolling operations. A multi-pass drawing process and a vacuum annealing process are both performed on the wire in order to obtain exact tolerance control. In order to guarantee consistent mechanical qualities and surface quality, which are required for applications in the chemical industry, this process is quite stringent.

Thermal and Chemical Stability

Gr5 titanium wire is appropriate for use in high-temperature chemical processes because it can keep its structural integrity even when subjected to temperatures as high as 400 degrees Celsius. The alloy demonstrates remarkable resistance to neutral and oxidizing environments, which includes the majority of organic acids and chloride solutions. On the other hand, procurement experts should be aware that this material is not advised for use in applications that involve boiling sodium hydroxide solutions.

Performance Benefits of Gr5 Titanium Wire in Chemical & Petrochemical Applications

Facilities in the chemical and petrochemical industries operate in some of the most difficult circumstances that are encountered in the creation of industrial goods. In order to retain both safety and operating efficiency, the equipment must be able to tolerate harsh chemicals, severe temperatures, and mechanical stress.

Corrosion Resistance in Aggressive Environments

Because of its remarkable corrosion resistance, Ti-6Al-4V wire is a very important component for utilization in chemical processing equipment. When exposed to chloride conditions, titanium creates a persistent oxide layer that offers better protection. This is in contrast to stainless steel, which might experience pitting and crevice corrosion. As a result of this quality, the costs of maintenance are greatly reduced, and the service life of equipment in chemical plants and refineries is significantly extended.

Mechanical Performance Under Stress

Static and cyclic loading circumstances are situations that are frequently encountered by equipment used in chemical processing. The fatigue resistance of Gr5 titanium wire is greater than that of conventional materials, which ensures that it will continue to work reliably even when subjected to repeated mechanical stress. Because of the high strength-to-weight ratio, it is possible to design lighter components without sacrificing their structural integrity. This is especially advantageous for large-scale installations, where a reduction in weight results in cost savings.

Industry Compliance and Safety Standards

Chemical facilities in the modern era are required to comply with severe laws on safety and the environment. The creation of our Gr5 titanium wire adheres to the quality management standards established by ISO 9001:2015. This ensures that the wire is of uniform quality and can be traced throughout the whole manufacturing process. The procurement teams are able to have faith in the reliability of the materials and the compliance with the regulations, thanks to this certification.

Comparative Analysis for Informed Procurement Decisions

It is necessary to conduct a thorough analysis of performance features, financial considerations, and long-term operational benefits in order to select the most suitable material for chemical and petrochemical applications.

Performance Comparison with Alternative Materials

The corrosion resistance and strength-to-weight ratio of Gr5 titanium wire are better than those of stainless steel grades that are typically utilized in the chemical processing industry. There is a possibility that the initial material cost will be higher; however, the longer service life and decreased maintenance requirements typically result in a cheaper total cost of ownership. Despite the fact that nickel-based alloys are resistant to corrosion, they are often unable to match the strength and lightweight qualities of titanium sixth alloy four-volt.

Form Factor Considerations

The needs of a particular application should be taken into consideration while selecting between wire, rod, or cable configurations. Wire forms offer a degree of flexibility that allows for sophisticated routing and vibration isolation, all while preserving the intrinsic qualities of the base alloy. In order to cater to a wide variety of application requirements, our manufacturing capabilities encompass both straight wire and coil wire types, with diameters ranging from 0.5mm to 6.0mm.

Supplier Evaluation Criteria

For procurement to be successful, it is necessary to do a comprehensive examination of the capabilities of the supplier, which should include the manufacturing facilities, quality certificates, and technical assistance. The ability of the supplier to provide material certifications, maintain consistent delivery dates, and offer technical competence for application-specific requirements are all important considerations to consider.

Strategic Guide for Procuring Gr5 Titanium Wire

A grasp of the dynamics of the market, the capabilities of the suppliers, and the quality assurance procedures is necessary for effective procurement of titanium alloy materials. This is necessary to ensure that the project will be successful.

Minimum Order Quantities and Pricing Structures

The titanium adhesive works with particular, least arranged amounts that reflect the specialized nature of generation forms. Our adaptable approach suits both large-scale mechanical ventures and littler investigate applications. Estimating structures ordinarily reflect fabric virtue, dimensional resistances, and conveyance requirements, with volume rebates available for built-up organizations.

Quality Verification and Documentation

Comprehensive fabric documentation is fundamental for chemical industry applications. Our quality affirmation handle incorporates crude fabric assessment, prepare checking during softening and shaping, and last assessment some time recently bundling. Each shipment incorporates nitty-gritty process test certificates recording chemical composition, mechanical properties, and dimensional details.

Global Supply Chain Considerations

Due to the fact that chemical and petrochemical projects are conducted on a global scale, it is necessary for suppliers to possess solid logistics skills and a grasp of the needs needed for global trade. The fact that we are located in Baoji, which is known as China's "Titanium Capital," gives us access to raw materials and specialized manufacturing facilities, and our extensive experience in exporting ensures that our customers receive their orders without any problems.

About Our Company and How We Support Your Chemical & Petrochemical Projects?

As a leading manufacturer of high-performance titanium alloys, Shaanxi Chuanghui Daye Metal Material Co., Ltd. is committed to providing the chemical and petrochemical industries across the world with products that are of the highest quality and reliability.

Manufacturing Capabilities and Expertise

Our facility, which is situated in the Baoji High-tech Development Zone, is able to take advantage of more than thirty years of experience in the rare metal business. Our complete production capabilities include cutting-edge facilities for melting, forging, rolling, and machining. These facilities are outfitted with electron beam furnaces, annealing systems, and precision machining equipment. With this integrated method, total control over product quality is ensured, beginning with the raw materials and ending with the final wire.

Quality Assurance and Certifications

Our commitment to quality control throughout the production process is demonstrated by our ISO 9001:2015 certification at every stage of the process. Each and every batch of Gr5 titanium wire is subjected to stringent testing in order to validate its chemical composition, mechanical qualities, and correctness in terms of dimensions. The use of this methodical approach guarantees quality that is constant and satisfies both international standards and the requirements of the customer.

Technical Support and Customization

The fact that chemical and petrochemical applications frequently call for specific solutions is something that we are aware of. Our team of technical experts offers comprehensive support for the selection of materials, application engineering, and the development of individualized specifications. Whether you require certain diameter tolerances, surface treatments, or packaging requirements, we collaborate closely with our clients to produce individualized solutions that are designed to fit the requirements of that particular project.

Conclusion

Advanced Gr5 Titanium Wire is an essential material option for the chemical and petrochemical industries, which are looking for dependable performance in settings that are demanding. Because of its outstanding resistance to corrosion, superior mechanical qualities, and demonstrated reliability, Ti-6Al-4V wire is an intelligent choice for professionals who are responsible for the design of equipment and procurement. Because of our extensive manufacturing capabilities, quality assurance procedures, and technical assistance, we guarantee that our clients will obtain materials that are up to the highest industry standards while also contributing to the success of our operations over the long term.

FAQ

Q: Why does Gr5 Titanium Wire offer superior chemical resistance compared to stainless steel?

A: The exceptional chemical resistance of Ti-6Al-4V stems from its ability to form a stable, self-healing oxide layer when exposed to oxidizing environments. Unlike stainless steel, which relies on chromium content for corrosion protection, titanium's oxide layer provides superior protection against a broader range of chemicals, including chlorides and organic acids commonly found in petrochemical processes.

Q: How do you handle customization requirements for wire diameter and length?

A: Our manufacturing capabilities accommodate wire diameters from 0.5mm to 6.0mm, with length specifications tailored to customer requirements. We utilize precision drawing processes and can provide both straight wire and coil configurations. Custom lengths are available based on application needs, with appropriate packaging to ensure material protection during transport and storage.

Q: What documentation is provided to verify product certification and quality?

A: Every shipment includes comprehensive mill test certificates documenting chemical composition analysis, mechanical property testing results, and dimensional inspection data. Our ISO 9001:2015 certification ensures traceability throughout the manufacturing process, and additional testing or certifications can be arranged to meet specific project requirements or industry standards.

Partner with Chuanghui Daye for Superior Gr5 Titanium Wire Solutions

Enhance your chemical processing operations with our premium-grade Ti-6Al-4V wire manufactured to exacting standards. Chuanghui Daye combines decades of metallurgical expertise with state-of-the-art production facilities to deliver consistent quality and reliable performance. Contact our technical team at info@chdymetal.com to discuss your specific requirements and discover why leading companies choose us as their trusted Gr5 Titanium Wire supplier for critical applications worldwide.

References

1. Boyer, R., Welsch, G., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, OH.

2. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International.

3. Schutz, R.W. & Thomas, D.E. "Corrosion of Titanium and Titanium Alloys in Chemical Process Industries." Materials Performance, NACE International.

4. Peters, M., Kumpfert, J., Ward, C.H., & Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Wiley-VCH.

5. Rack, H.J. & Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering: C, Elsevier.

6. Froes, F.H. "Titanium: Physical Metallurgy, Processing, and Applications." ASM International Handbook Committee.

Learn about our latest products and discounts through SMS or email