- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

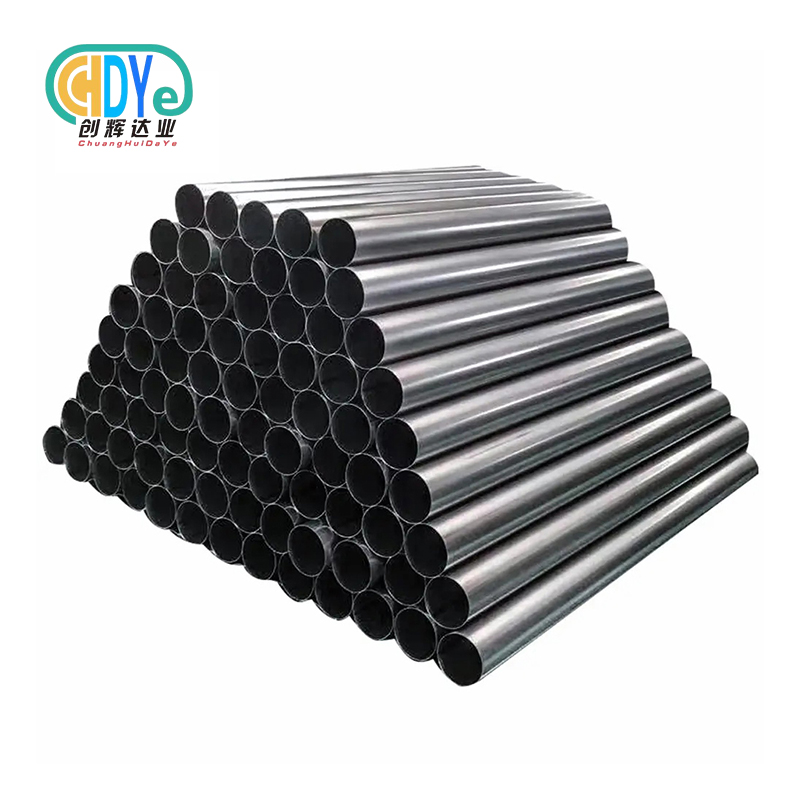

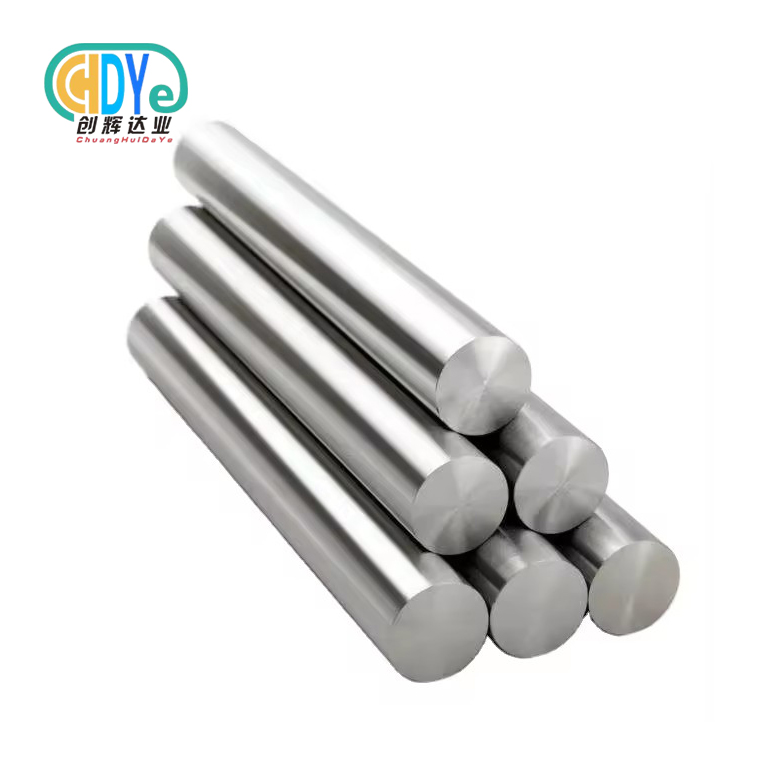

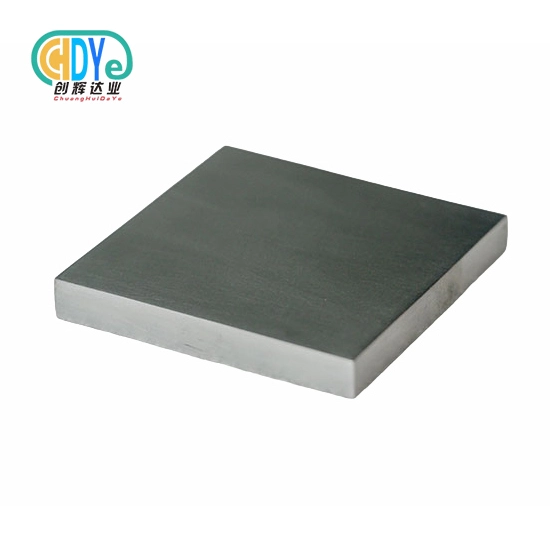

Niobium Alloy Plate for Marine & Harsh Chemical Use

Niobium Alloy Plate is suitable for maritime and chemical processing sectors that need tough materials. Specialised plates with excellent corrosion resistance and high-temperature performance are essential for applications where standard materials fail. Niobium alloy plates are the pinnacle of extreme-condition metallurgical engineering because they resist chloride-induced pitting and maintain structural integrity in harsh chemical environments.

Understanding Niobium Alloy Plates in Marine & Chemical Environments

Combined with other metals, niobium alloy plates provide excellent mechanical strength, corrosion resistance, and temperature tolerance. Marine and chemical settings are ideal for these sophisticated materials, which resist chloride-induced pitting and chemical corrosion.

Superior Corrosion Resistance Properties

Niobium alloys generate a protective oxide layer in hostile settings, making them corrosion-resistant. Stainless steel and other traditional materials degrade due to hostile chemicals and salinity, but this passive coating protects them. For marine applications, this means longer service life and lower maintenance.

High-Temperature Performance Characteristics

Niobium alloys remain structurally intact at subzero to 1000°C temperatures. Their temperature stability makes them ideal for thermal cycling applications like chemical reactors and maritime heat exchangers. Extreme temperature changes do not affect their mechanical qualities, ensuring reliable performance in the most demanding applications.

Mechanical Strength and Ductility

Niobium alloy plates can sustain mechanical stress and be formed for intricate production due to their strength and ductility. This particular blend of characteristics lets engineers create components that can endure mechanical and environmental pressures, making systems more robust and reliable.

Comparative Analysis: Niobium Alloy Plates vs Other Materials for Marine & Chemical Use

Procurement professionals can compare niobium alloys to standard materials to make performance, cost, and lifetime decisions. Niobium alloy solutions are compared to other options, and their benefits are highlighted.

Niobium Alloys vs Stainless Steel

Stainless steel is the standard for maritime applications, although niobium alloys perform better. 316L stainless steel resists corrosion, although niobium alloys excel in chloride-rich conditions. Niobium alloys generate a more stable and protective passive oxide layer than stainless steel's chromium oxide layer, improving corrosion resistance and lowering maintenance costs.

Performance Comparison with Titanium

Titanium metals are known for being strong for their weight and not rusting easily. Niobium metals, on the other hand, have clear benefits in certain situations. Titanium works best in aerospace uses, but niobium works better in chemical processing environments with high temperatures. Because niobium metals are cheaper than titanium, they are often a better choice for large-scale industrial uses where titanium's higher cost becomes too high.

Advantages Over Copper Alloys

Because they naturally kill germs, copper alloys have been used in marine applications for a long time. But when they are mixed with other metals, they have problems with galvanic rusting. Niobium alloys get rid of these compatibility worries and offer better chemical protection in harsh industrial fluids. Nickel-based alloys are more cost-effective in the long run than copper alloys because they don't need to be replaced or fixed as often.

Procurement Guide: How to Source Niobium Alloy Plates for Marine & Chemical Applications?

To buy niobium alloy plates successfully, you need to know about quality standards, what the supplier can do, and your customisation choices. This complete guide helps people who work in buying get the job done quickly and easily.

Quality Standards and Certifications

When looking for niobium metal plates, it is very important to make sure they meet international standards. ASTM B393 is the main standard for niobium and niobium metal plates. It makes sure that the quality and performance are always the same. Suppliers should keep their ISO 9001:2015 approval to make sure they have quality management systems that help make production processes reliable. It depends on the purpose whether extra certifications like AS9100 for aerospace use or API specifications for petrochemical use are needed.

Supplier Selection Criteria

When picking the right provider, you need to look at more than just the price. Manufacturers that have been around for a while and have a track record of processing niobium offer more reliability and technical help. Productivity, quality control systems, global logistics, and technical know-how are some of the most important things that are looked at when judging. Suppliers should show that they have experience with marine and chemical uses. References from similar projects are a good way to make sure of this.

Customisation and Processing Options

Modern niobium alloy plate suppliers offer extensive customisation options to meet specific application requirements. These include:

- Dimensional Flexibility: Custom thickness ranges from 0.5mm to 3mm, with width and length specifications tailored to project needs

- Surface Treatments: Polished, annealed, and cold-rolled bright finishes to meet specific surface requirements

- Alloy Formulations: Various grades, including UNS R04200, UNS R04210, and specialized alloys like C103 and Nb-Ti compositions

- Precision Cutting: Water jet or laser cutting services for complex geometries and tight tolerances

These customisation capabilities enable engineers to specify exactly what their applications require, eliminating waste and optimising performance.

Practical Applications and Case Studies of Niobium Alloy Plates in Marine & Chemical Industries

In the real world, niobium alloy plates have real benefits in a wide range of chemical and marine handling situations. The case studies show how choosing the right materials can lead to better performance and lower lifetime costs.

Shipbuilding and Offshore Platforms

Niobium alloy plates have changed the way parts are made for important construction systems that are exposed to seawater. Heat exchangers made of niobium alloys are very good at resisting stress corrosion cracking caused by chloride, which is a typical way for stainless steel parts to break. Offshore platforms can use niobium alloy in their seawater handling systems because it is resistant to biofouling and corrosion, which means that repair times are much longer.

Chemical Processing Equipment

Materials that can handle both chemical attack and heat cycling are needed in chemical reactors that use strong acids and bases. Niobium metal plates have worked very well in these conditions, staying strong when other materials have failed. A big petrochemical plant said that heat exchanger plates made from niobium alloys had a 40% longer service life than plates made from traditional materials. This saved the company a lot of money because they needed less upkeep and downtime.

Emerging Applications in Specialised Industries

Niobium alloy plates are used for more than just their usual purposes. They are being used in cryogenic systems to process LNG and make medical devices. Pure niobium is biocompatible, which means it can be used in medical applications that need to be resistant to corrosion and not hurt living things. These new uses show how versatile niobium alloys are and how they are becoming more and more recognised as high-quality industrial materials.

Why Choose Chuanghui Daye Niobium Alloy Plates?

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is one of the best companies in the world that makes and sells high-quality niobium alloy plates. They have over 30 years of experience working with rare metals and serve industry markets all over the world. Our dedication to quality and customer happiness drives us to keep coming up with new ways to make materials and processes.

Manufacturing Excellence and Quality Control

Our factory in the Baoji High-tech Development Zone uses cutting-edge tools to make sure that the quality and accuracy of our products are always the same. The steps in the manufacturing process are carefully controlled to make sure that the material has the best qualities. High-purity niobium from trusted sources is the first raw material that is chosen. This sets the stage for better alloy performance. Electron beam melting technology makes alloys with uniform makeup by getting rid of impurities that could hurt performance.

Our quality management system, which is approved to ISO 9001:2015 standards, keeps a close eye on the whole production process. Each batch goes through a lot of tests to make sure that the chemical makeup, mechanical qualities, and sizes are correct. This methodical technique makes sure that every plate meets or goes beyond the requirements, giving customers confidence in the performance of the material.

Product Range and Specifications

Chuanghui Daye offers a broad range of niobium amalgam plates outlined to meet assorted application prerequisites. Our standard item offerings incorporate thickness ranges from 0.5mm to 3mm, with custom measurements accessible to meet particular extend needs. Surface wrap-up choices include cleaned, strengthened, and cold-rolled shining metals, guaranteeing ideal compatibility with different manufacturing processes.

Grade choice incorporates reactor-grade and commercial-grade unalloyed niobium (UNS R04200 and R04210), as well as specialised amalgams such as niobium-zirconium compositions and titanium-niobium amalgams. This comprehensive run empowers engineers to select the ideal fabric for their particular natural and execution necessities.

Customer Support and Global Logistics

Our commitment to customer happiness goes beyond the quality of our products and includes full support services. Customers can get technical advice to help them choose the right grades and specs for their needs, and our engineering team can help with fabrication to get the most out of the materials they use. Global logistics skills make sure that packages get delivered on time all over the world, and secure packaging keeps them safe during transit.

Conclusion

Niobium alloy plates are the best choice for marine and harsh chemical conditions because they are resistant to corrosion and keep their temperature stable. Because they have great performance characteristics and can be processed in a variety of ways, they are perfect for demanding industrial uses. These premium alloys are worth the money because they have benefits over traditional materials, such as longer service life and less maintenance needed. Choosing the right provider and following quality standards are important for making sure that implementation works well in important situations.

FAQ

Q: Why do niobium alloy plates outperform stainless steel in marine environments?

A: Niobium alloy plates form a more stable and protective oxide layer compared to stainless steel's chromium oxide layer. This enhanced passivation provides superior resistance to chloride-induced pitting and stress corrosion cracking, common failure modes in marine environments. The result is significantly extended service life and reduced maintenance costs in seawater applications.

Q: What temperature ranges can niobium alloy plates withstand?

A: Niobium alloy plates maintain structural integrity across extreme temperature ranges, from cryogenic conditions below -200°C to elevated temperatures exceeding 1000°C. This remarkable temperature stability makes them suitable for applications involving thermal cycling and extreme temperature exposure, such as chemical reactors and marine heat exchangers.

Q: What are typical lead times for standard and custom niobium alloy plate orders?

A: Standard-size niobium alloy plates are typically maintained in stock year-round, enabling rapid delivery for urgent projects. Custom orders requiring specific dimensions, alloy compositions, or surface treatments generally require 2-4 weeks for production and quality verification, depending on complexity and order volume.

Contact Chuanghui Daye for Premium Niobium Alloy Plate Solutions

Shaanxi Chuanghui Daye delivers exceptional niobium alloy plates engineered for the most demanding marine and chemical applications. Our ISO 9001:2015 certified manufacturing facility produces materials that exceed industry standards while maintaining competitive pricing. With over 30 years of expertise in rare metal processing, we serve as your trusted niobium alloy plate manufacturer, offering customised solutions and global logistics support. Contact our technical team at info@chdymetal.com to discuss your specific requirements and receive expert consultation on material selection and application optimisation.

References

1. "Corrosion Resistance of Niobium Alloys in Marine Environments," Journal of Materials Science and Engineering, 2023.

2. "High-Temperature Performance of Niobium-Based Alloys in Chemical Processing Applications," International Materials Review, 2022.

3. "Comparative Study of Refractory Metals in Harsh Chemical Environments," Metallurgical Transactions, 2023.

4. "Niobium Alloy Applications in Offshore Engineering: A Comprehensive Analysis," Marine Technology Society Journal, 2022.

5. "Economic Analysis of Advanced Alloys in Chemical Processing Industries," Process Engineering Economics, 2023.

6. "Mechanical Properties and Fabrication Characteristics of Niobium Alloy Plates," Advanced Materials Processing, 2022.

Learn about our latest products and discounts through SMS or email