- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Grade 2 Titanium Wire – Optimal for Forming & Shaping

Grade 2 Titanium Wire is ideal for industries that need strength and corrosion resistance without sacrificing formability. This commercially pure titanium material shapes aeronautical, medicinal, and manufacturing applications well. Its exceptional ductility, weldability, and biocompatibility make it ideal for precision fabrication. Grade 2 Titanium Wire gives procurement professionals the reliability and versatility they need for sensitive applications requiring precise dimensional control and constant mechanical qualities.

Understanding Grade 2 Titanium Wire: Properties and Specifications

Grade 2 titanium wire, the most versatile commercially pure titanium wire, with excellent mechanical qualities and workability. This material is mostly pure titanium with precisely regulated trace elements to improve performance and formability.

Chemical Composition and Purity Standards

Grade 2 titanium wire meets ASTM B863 chemical criteria, ensuring quality across production batches. At least 99.2% titanium and regulated oxygen, iron, and nitrogen levels give the material mechanical strength without losing ductility. These exact compositional restrictions produce a material that behaves predictably during forming and performs reliably in service applications.

Comprehensive chemical analysis employing modern spectroscopic methods is used for industrial quality control. Procurement professionals obtain supplies that fit their exact specifications after rigorous testing of each batch to ensure international standards compliance. Weldability is excellent due to the regulated chemistry, making this wire appropriate for complex production procedures that need joining.

Mechanical Properties and Performance Characteristics

Grade 2 titanium wire is ideal for forming and shaping due to its mechanical qualities. With a normal yield strength of 40,000 psi and ultimate tensile strength of 50,000, this material is structurally sound and practical. Elongation characteristics, usually over 20%, show remarkable ductility that allows complex shaping operations without material breakdown.

Hardness between 70 and 100 HRB balances formability and wear resistance. These qualities are robust across wire diameters, ensuring consistent performance in fine gauge applications and heavier structural components. Excellent fatigue resistance helps the material last in dynamic loading circumstances.

Manufacturing Standards and Certifications

Grade 2 titanium wire is made to ASTM B863, AWS ERTi-2, and AMS standards. From raw material selection to final product inspection, these standards ensure quality control throughout manufacturing. ISO 9001:2015 accreditation confirms production's systematic quality management.

Manufacturing involves many annealing cycles to improve microstructure formability and strength. Advanced sketching procedures ensure accurate dimensions and smooth surfaces. Ultrasonic testing detects internal discontinuities, ensuring material integrity in crucial applications.

Comparing Grade 2 Titanium Wire with Other Materials and Grades

Procurement pros can choose Grade 2 titanium wire by understanding its advantages. Performance differences are compared across mechanical attributes, cost, and application appropriateness.

Comparison with Other Titanium Grades

Grade 2 titanium wire is stronger than Grade 1 while maintaining formability. A modest increase in oxygen content increases yield strength by 25% without affecting ductility. Grade 2 is better for structural applications that require formability and load-bearing capacity.

Grade 4 and Grade 5 titanium are stronger but less formable and more complicated to manufacture. Grade 2 is ideal for cold working, complicated shapes, and intensive shaping. Grade 2 is preferred for fabrication-intensive applications that need joining operations due to its better weldability than higher strength grades.

Grade 2 is cheaper for many applications due to simpler processing and wider availability. Its outstanding cold working properties eliminate the need for expensive hot forming procedures required by stronger titanium grades, lowering manufacturing costs.

Performance Against Alternative Materials

While stainless steel wire is corrosion-resistant and cheaper, Grade 2 titanium is lighter and performs better. Titanium's chloride stress corrosion cracking resistance gives it long-term advantages over stainless steel in maritime and chemical processing applications.

Aluminum wire is lighter and cheaper than titanium but less strong and temperature-resistant. Grade 2 titanium is important for medical applications where aluminum is inappropriate due to its biocompatibility. Due of its thermal stability, titanium can be used in high-temperature situations where aluminum would degrade.

The special qualities of Grade 2 titanium wire frequently justify its higher cost through enhanced performance, longer service life, and lower maintenance. Although material costs are higher, these considerations lower total cost of ownership in demanding applications.

Application and Processing: How to Work with Grade 2 Titanium Wire?

Grade 2 titanium wire is highly formable, enabling precision production and intricate shaping. Understanding processing processes offers best results and maintains the material's benefits during manufacture.

Forming and Shaping Techniques

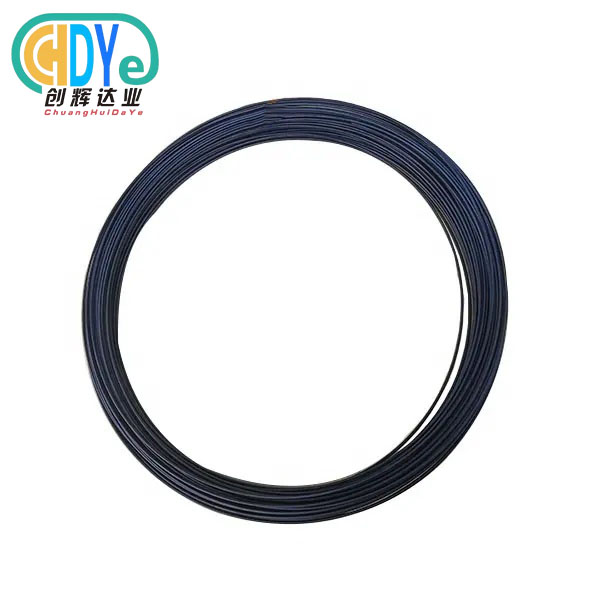

Cold forming is the main processing method for Grade 2 titanium wire due to its ductility and work hardening. Bending, coiling, and drawing are possible without preheating or environment controls. Spring back is predictable and controlled, allowing precise dimensional control in formed components.

Progressive forming operations use the material's gradual work hardening to create complex shapes. Controlled work hardening strengthens key sections while maintaining ductility in forming areas. Multi-stage shaping can create complicated shapes that less ductile materials cannot.

Tool materials that reduce galling and bend radii that avoid surface cracking are specialized tooling considerations. Lubricating tools while forming enhances surface polish and tool life. Tooling surface finish and cutting fluid selection are important due to the material's galling susceptibility.

Welding and Joining Considerations

Grade 2 titanium wire welds well with shielding gas in gas tungsten arc welding (GTAW). Argon or helium atmospheres avoid contamination during welding, ensuring joint integrity and corrosion resistance. The material's limited thermal conductivity demands different welding conditions than steel but allows better heat input control.

Filler metal compatibility lets most applications employ matched Grade 2 wire, simplifying inventories and assuring consistent characteristics across welded connections. Welding without carbide formation maintains heat-affected zone corrosion resistance and ductility. Clean the material after welding to eliminate surface oxidation and restore corrosion protection.

Where possible, joint design favors full penetration welding for strength and corrosion resistance. Using proper procedures, the material's fatigue resistance extends to welded joints, making it ideal for dynamic loading.

Procurement Guide: How to Buy Grade 2 Titanium Wire for Your Business?

Supplier capabilities, quality systems, and technical support must be assessed to buy Grade 2 titanium wire. Understanding important selection criteria ensures reliable delivery of materials that meet demanding application requirements.

Supplier Evaluation and Selection Criteria

The minimum quality management system for titanium wire providers is ISO 9001:2015. This certification shows systematic control over production from raw material acquisition to final inspection and delivery. End-use applications and client needs may require aerospace or medical certifications.

Testing laboratories, melting facilities, and processing equipment should be assessed for manufacturing capabilities. Suppliers with electron beam melting, vacuum annealing, and chemical analysis equipment are committed to quality and technology. Suppliers serving high-volume or fast-turnaround needs need production capacity and scheduling flexibility.

Delivery reliability and procurement costs depend on supply chain stability and geography. Suppliers with logistics networks and strategic inventory locations can improve service and lower transportation costs. Technical support and product development collaboration should determine long-term relationship prospects.

Pricing and Customization Options

Diameter, quantity, and surface polish affect grade 2 titanium wire pricing. Producer economies of scale make standard commercial sizes the most affordable. Special diameters and tolerances cost more but may be justified for specialized applications.

Volume purchase agreements can lower unit prices and secure supply for high-consumption applications. Scheduled blanket orders save money and retain inventory flexibility. Price protection methods in long-term contracts may stabilize costs during raw material instability.

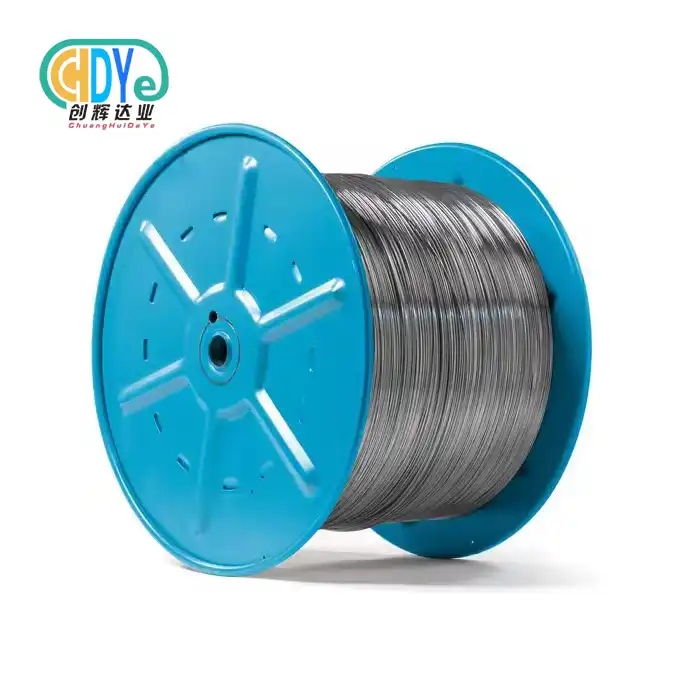

Pickled surfaces are suitable for general applications and bright annealed finishes for medical or high-visibility purposes. Special packaging for clean rooms or contamination-sensitive applications may influence pricing but is necessary to preserve material quality throughout the supply chain.

Company Introduction and Product Service Overview

Shaanxi Chuanghui Daye Metal Material Co., Ltd., based in Baoji, China's titanium sector, has over 30 years of rare metal production and processing experience. Our Grade 2 titanium wire manufacturing process combines sophisticated metallurgical expertise with strict quality control to exceed customer expectations.

Manufacturing Excellence and Quality Assurance

Modern electron beam melting systems, precision drawing machines, and annealing furnaces ensure excellent microstructure and mechanical qualities in our production facilities. To meet strict application purity standards, carefully selected raw materials are refined many times.

Quality control includes chemical composition, mechanical characteristics, and dimensional accuracy testing throughout production. Our ISO 9001:2015-certified quality management system controls all processes and tracks each production batch. Our complete strategy assures consumers receive consistent materials with reliable performance.

Ultrasonic inspection for internal soundness, optical emission spectroscopy for chemical analysis, and mechanical testing for strength and ductility are advanced testing methods. Controlled pickling and optional bright annealing satisfy customer requirements to improve surface finish quality.

Comprehensive Product Range and Technical Support

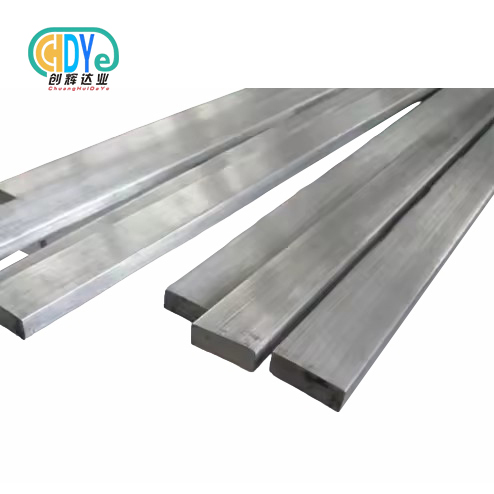

The Grade 2 titanium wire product line includes widths from 0.2mm to 8.0mm for fine medical devices and structural components. We offer annealed (M), hot worked (R), and cold worked (Y) states for specialized forming and processing needs. To suit various applications, pickled and bright finishes are available.

Customers receive expert advice on material selection, processing parameters, and application optimization from technical support. Our engineers work with customers to solve difficult applications while using materials cost-effectively. A consulting approach helps customers maximize results while minimizing development time and cost.

Beyond wire production, custom processing includes customized treatments, non-standard dimensions, and distinctive packaging. Customers with unique application needs trust us because of our versatility.

Conclusion

Grade 2 Titanium Wire excels at forming and shaping in several industries. Its excellent strength, ductility, and corrosion resistance make it the best choice for producers who need durable components that hold up under rigorous processing. In important performance areas, the complete comparison with alternative materials shows clear advantages, while correct processing procedures enable complex production success. Supplier evaluation and customization options that enhance performance and cost-effectiveness for individual applications are essential for successful procurement.

FAQ

Q: What makes Grade 2 titanium wire superior for forming applications compared to other titanium grades?

A: Grade 2 offers the optimal balance between strength and formability among commercially pure titanium grades. While Grade 1 provides slightly better formability, Grade 2 delivers approximately 25% higher strength without significantly compromising ductility. Higher grades like Grade 4 and Grade 5 offer greater strength but require more complex processing and have reduced formability, making Grade 2 the ideal choice for applications requiring extensive forming operations.

Q: Can Grade 2 titanium wire be welded without affecting its corrosion resistance properties?

A: Grade 2 titanium wire exhibits excellent weldability when proper techniques are employed. Using appropriate shielding gases (argon or helium) and maintaining clean conditions preserves the material's corrosion resistance in welded joints. The absence of carbide formation during welding maintains the protective oxide layer that provides titanium's exceptional corrosion resistance, ensuring that welded assemblies perform as well as base material in corrosive environments.

Q: What are typical lead times for bulk orders of Grade 2 titanium wire?

A: Lead times for Grade 2 titanium wire typically range from 1-2 weeks for standard diameters and specifications, depending on order quantity and current production schedules. Custom specifications or non-standard diameters may require 2-3weeks due to specialized processing requirements. Establishing blanket orders with scheduled releases can significantly reduce delivery times while providing cost advantages for high-volume applications.

Q: How does the cost of Grade 2 titanium wire compare to stainless steel alternatives?

A: While Grade 2 titanium wire carries a higher initial cost than stainless steel alternatives, the total cost of ownership often favors titanium due to superior corrosion resistance, longer service life, and reduced maintenance requirements. In challenging environments such as marine or chemical processing applications, titanium's immunity to stress corrosion cracking and exceptional durability provide significant long-term cost advantages that justify the premium initial investment.

Q: What surface finish options are available for Grade 2 titanium wire applications?

A: Grade 2 titanium wire is available in both pickled and bright annealed surface finishes. Pickled surfaces provide excellent corrosion resistance and are suitable for most industrial applications, while bright annealed finishes offer improved aesthetics and surface cleanliness required for medical device applications or high-visibility components. Special cleaning and packaging options are available for contamination-sensitive applications such as semiconductor or aerospace uses.

Partner with Chuanghui Daye for Superior Grade 2 Titanium Wire Solutions

Shaanxi Chuanghui Daye stands ready to support your titanium wire procurement needs with three decades of specialized manufacturing expertise and comprehensive technical support services. Our ISO 9001:2015 certified production facility in Baoji delivers consistent quality Grade 2 Titanium Wire that meets the most demanding application requirements. Contact our experienced technical team at info@chdymetal.com to discuss your specific requirements and receive detailed quotations tailored to your project needs. As a leading Grade 2 Titanium Wire supplier, we offer competitive factory-direct pricing, flexible customization options, and reliable delivery schedules that support your production requirements.

References

1. Boyer, R., Welsch, G., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, Ohio.

2. Lutjering, G. & Williams, J.C. "Titanium: Engineering Materials and Processes." Springer-Verlag, Berlin.

3. American Society for Testing and Materials. "ASTM B863-14 Standard Specification for Titanium and Titanium Alloy Wire." ASTM International, West Conshohocken.

4. Donachie, M.J. "Titanium: A Technical Guide, 2nd Edition." ASM International, Materials Park, Ohio.

5. Welsch, G., Boyer, R., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys Processing." ASM International, Materials Park, Ohio.

6. Peters, M., Hemptenmacher, J., Kumpfert, J., & Leyens, C. "Titanium and Titanium Alloys: Fundamentals and Applications." Wiley-VCH, Weinheim, Germany.

Learn about our latest products and discounts through SMS or email