The biocompatibility, erosion resistance, and hardness of pure titanium wire have changed the way therapeutic and surgical methods are done. Specialists and companies that make restorative gadgets can utilize this astounding fabric to make inserts, surgical devices, and other restorative devices that need to be consistent with human tissue for a long time. Due to its extraordinary qualities, immaculate titanium wire is an imperative portion of present-day healthcare. It makes therapeutic arrangements more secure and tougher for patients and makes a difference in that specialists donate way better care.

Understanding Key Parameters and Medical-Grade Specifications

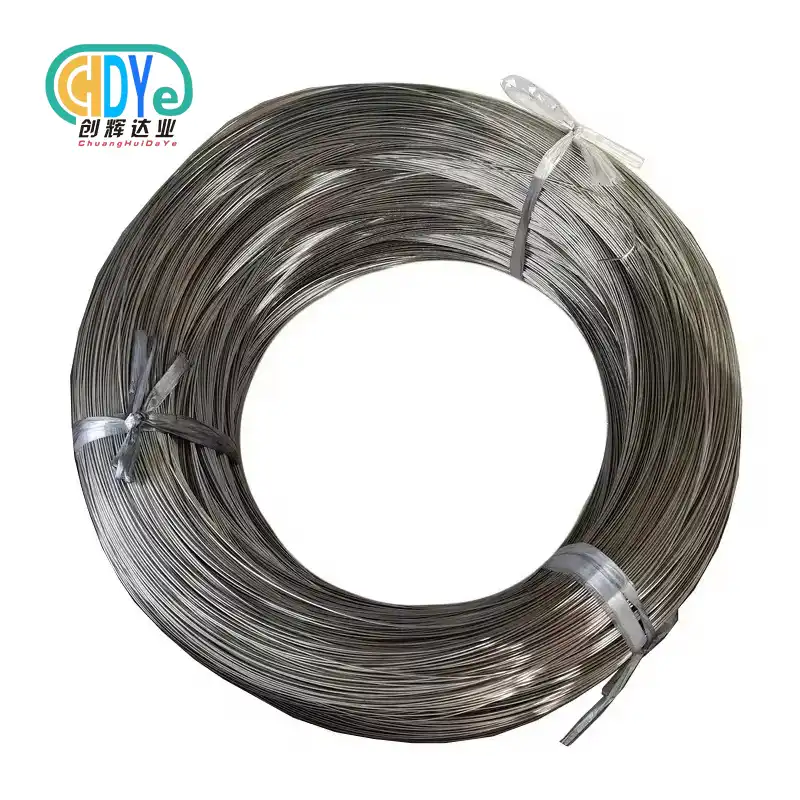

Pure titanium wire used in medicine has to meet certain standards that keep the patient safe and make sure the device works right. Grades 1 and 2 titanium wires are the best you can get because they have at least 99.6% titanium in them. It's easy to bend and shape these grades, which makes them great for high-tech medical uses.

Teflon wire made for medical use generally has a tensile strength of 240 to 550 MPa, but this can vary by grade and how it was made. Better than many normal materials, this one has a good strength-to-weight ratio, so it works well and keeps the patient's weight down. The wire's diameter can be anywhere from 0.1 mm (very small) for delicate tasks to 6 mm (very big) for building purposes.

Biocompatibility testing based on ISO 10993 standards makes sure that the titanium wire meets strict medical needs. This material is very resistant to body fluids and has stayed stable in physiological settings for decades. The quality of the surface finish is very important. Medical-grade wire has smooth, oxide-free areas that help the tissue stick to the wire.

Core Medical Benefits That Transform Healthcare Applications

The best thing about titanium wire for medical uses is that it doesn't harm living things. Titanium, unlike many other metals, makes a stable oxide layer that stops harmful ions from entering surrounding tissues. Because of this, there is no chance of allergic or toxic reactions, which can happen with other metal devices.

Long-term stability of implants is ensured by their resistance to corrosion in biological settings. With its changing pH levels and electrolyte ratios, the human body is a tough place to live. Titanium wire doesn't lose its shape or surface qualities even after being in body fluids for decades, which makes it perfect for permanent implants.

Titanium is radiolucent, which means it doesn't get in the way of medical images. When used in X-rays, CT scans, or MRIs, titanium wire doesn't show up as clearly as steel or other thick metals. Because the implant is clear, doctors can see how the healing is going and spot any problems that might happen without having to take it out.

Because it can fuse with bone, titanium wire is very useful in orthopedic and dentistry settings. The surface of the material makes direct bone attachment easier, which forms a strong biological link that gets stronger over time. This combination lowers the chance of the implant coming loose and makes the device last longer.

Chuanghui Daye's Medical-Grade Titanium Wire Excellence

Our method for making titanium wire meets the strictest medical standards. We use cutting-edge quality control systems to make sure that the purity and performance of the wire are always the same. Based in Baoji, China, which is known as the "Titanium Capital," we use our more than 30 years of experience with rare metals to make medical-grade materials that go above and beyond what the industry expects.

Our thorough testing process is what makes our pure titanium wire stand out. Spectrochemical analysis is used to check the purity levels of each batch, mechanical testing is used to check the strength properties, and the surface quality is checked to make sure it is biocompatible. Our ISO 9001:2015 certification shows that we are dedicated to managing quality at all stages of the production process.

We keep a large stock of common medical grades and sizes, so we can send quickly—within one to three days—for urgent surgical needs. Our production methods are flexible enough to handle both large-scale orders and small research amounts. This means that they can be used in a wide range of medical settings, from big hospitals to cutting-edge research centers.

We give you full batch records, material certificates, and test reports that meet FDA and CE marking requirements for traceability. This detailed information helps companies that make medical devices with their regulatory filings and quality control methods.

Optimizing Medical Applications Through Proper Selection and Usage

Choosing the right grade of titanium wire relies on the needs of the medical application. Grade 1 titanium is the most flexible and can be used to make complicated shapes and delicate instruments. Grade 2 titanium is stronger and can be used for load-bearing purposes. When choosing a wire, think about what it will be used for, what mechanical qualities it needs, and whether it needs to be biocompatible.

The material's medical-grade qualities are kept when it is handled properly. Keep the titanium wire in a clean, dry place to keep it from getting dirty. To keep the material from getting contaminated with other materials during preparation, only use the right tools and equipment. Surface processes should follow standard procedures for making medical devices.

By annealing, the qualities of the wire can be made better for certain uses. Controlled heat treatment makes the material more flexible for shaping while keeping its ability to fight corrosion and be biocompatible. Our expert team gives advice on the best annealing conditions for a range of medical uses.

At every step of the process, quality checks are done to make sure that the finished goods meet medical standards. To keep quality consistent, check incoming materials, keep an eye on work-in-progress, and test the finished product. Keep track of all the steps in the processes to meet traceability standards and legal requirements.

Applications Across Modern Medical and Surgical Fields

Titanium wire is used in many ways in orthopedic surgery, from bone fixation devices to joint replacement parts. It is strong and biocompatible, which makes it perfect for bone fracture repair systems, spine fusion hardware, and custom orthopedic implants. Surgeons like that the wire is flexible enough to make changes during surgery and stays stable over time.

The osseointegration properties of titanium wire are used in dental applications for implant systems and orthodontic devices. For abutments, screws, and framework parts, dental implant makers depend on our high-purity wire. Because the material doesn't corrode, it will work well in the harsh conditions of the mouth environment.

Titanium wire is useful in cardiovascular uses because it is radiolucent and doesn't react with blood. Heart pacemaker leads, stent parts, and surgery clips are all made of titanium, which is strong and biocompatible at the same time. Because the material isn't magnetic, it can be used with MRI machines for heart patients.

Titanium wire is used in neurosurgery for cranial reconstruction, spine instrumentation, and deep brain stimulation. Because the material is stable and biocompatible, it gives surgeons reliable options for difficult neurological treatments that need to be implanted permanently.

Addressing Critical Considerations and Safety Requirements

When using surgical titanium wire, the ability to withstand sterilization is very important. The substance can be sterilized in a steam autoclave, with gamma radiation, or by being exposed to ethylene oxide without losing any of its qualities. Understanding the effects of sterilization helps improve the way things are processed and keep the integrity of the materials.

Surface preparation needs change based on what the surface is going to be used for. For some processes, certain surface treatments are needed to make the device more biocompatible or help the tissue stick together. Based on the needs of your unique medical application, our technical team can suggest the right surface treatments.

Material selection and paperwork needs are affected by regulatory compliance. Manufacturers of medical devices must make sure that the titanium wire they use meets all FDA, CE, and other government standards. We give you a lot of paperwork to back up your regulatory filings and quality system standards.

Protocols for storage and handling keep materials in good shape until they are used. Set up the right inventory management tools to make sure that items are rotated from first-in, first-out, and that records of traceability are kept. Set up ways to keep the material from getting contaminated so that its medical-grade status is maintained throughout the supply chain.

Conclusion

Through its unique mix of biocompatibility, hardness, and corrosion resistance, pure titanium wire continues to make medical and surgical procedures better. As medical technology improves, there is a greater need for high-quality titanium products. This leads to new ways of caring for patients and improving the results of treatments. Healthcare providers and companies that make medical devices can work together better with suppliers who have been in the business for a while and know what medical uses need. Spending money on high-quality titanium wire materials directly leads to safer patients, better gadget performance, and long-term clinical success. Doctors and nurses can keep pushing the limits of what's possible in modern healthcare by picking the right titanium wire provider and sticking to strict quality standards.

FAQ

Q: What makes titanium wire superior to stainless steel for medical applications?

A: Titanium wire offers superior biocompatibility, eliminating the risk of nickel allergies common with stainless steel. It also provides better corrosion resistance in biological environments and doesn't interfere with medical imaging procedures like MRI or CT scans.

Q: How long can titanium wire implants remain in the human body?

A: High-quality pure titanium wire implants can remain functional for several decades. The material's excellent corrosion resistance and biocompatibility ensure long-term stability, with many orthopedic and dental implants lasting 20-30 years or longer with proper care.

Q: Are there any contraindications for titanium wire in medical procedures?

A: Titanium allergies are extremely rare, affecting less than 1% of the population. However, patients with known titanium sensitivity should avoid titanium implants. Additionally, some specific medical conditions may affect osseointegration, requiring careful evaluation by healthcare providers.

Partner with Chuanghui Daye for Premium Medical Titanium Solutions

Shaanxi Chuanghui Daye delivers exceptional pure titanium wire solutions tailored for demanding medical applications. Our manufacturing excellence, combined with rapid delivery capabilities and comprehensive technical support, makes us the preferred pure titanium wire supplier for medical device manufacturers worldwide. Experience the difference that three decades of rare metal expertise brings to your medical projects. Contact us at info@chdymetal.com to discuss your specific requirements and receive free samples for evaluation.

References

1. Steinemann, S.G. "Titanium - the material of choice for medical implants." Materials Science and Engineering, Medical Applications of Titanium and Its Alloys (1998): 123-145.

2. Niinomi, M. "Mechanical biocompatibility of titanium alloys for biomedical applications." Journal of the Mechanical Behavior of Biomedical Materials 1, no. 1 (2008): 30-42.

3. Liu, X., Chu, P.K., Ding, C. "Surface modification of titanium, titanium alloys, and related materials for biomedical applications." Materials Science and Engineering Reports 47, no. 3-4 (2004): 49-121.

4. Geetha, M., Singh, A.K., Asokamani, R., Gogia, A.K. "Ti-based biomaterials, the ultimate choice for orthopaedic implants - A review." Progress in Materials Science 54, no. 3 (2009): 397-425.

5. Rack, H.J., Qazi, J.I. "Titanium alloys for biomedical applications." Materials Science and Engineering C 26, no. 8 (2006): 1269-1277.

6. Elias, C.N., Lima, J.H.C., Valiev, R., Meyers, M.A. "Biomedical applications of titanium and its alloys." JOM 60, no. 3 (2008): 46-49.