Importing Grade 2 titanium round bar from China involves strategy and commercial knowledge. This thorough book covers finding trusted suppliers, confirming certifications, comprehending trade terms, organizing documents, and meeting international standards. Your manufacturing processes will benefit from proven ways to source high-quality titanium materials while avoiding risks and optimizing costs from supplier evaluation to delivery.

Why Source Grade 2 Titanium Round Bar from China?

Cost Advantages and Market Position

Over 57% of titanium manufacturing comes from China. Grade 2 titanium consumers benefit from this manufacturing scale's economic advantages. Chinese vendors offer affordable prices without compromising quality due to integrated supply chains, lower raw material costs, and superior processing technology.

Manufacturing Capabilities and Infrastructure

Advanced electron beam melting furnaces, vacuum arc remelting systems, and precision forging machines are used by Chinese titanium manufacturers. These modern facilities produce ASTM B348-compliant titanium round bars. Baoji, China's "Titanium Capital," offers specialist knowledge and technological support.

Quality Control and Certification Standards

Leading Chinese firms have ISO 9001:2015 certifications and sophisticated quality management systems. These facilities evaluate titanium bars for international standards using chemical composition analysis, mechanical property verification, and ultrasonic inspection.

Understanding Grade 2 Titanium Specifications

Technical Properties and Chemical Composition

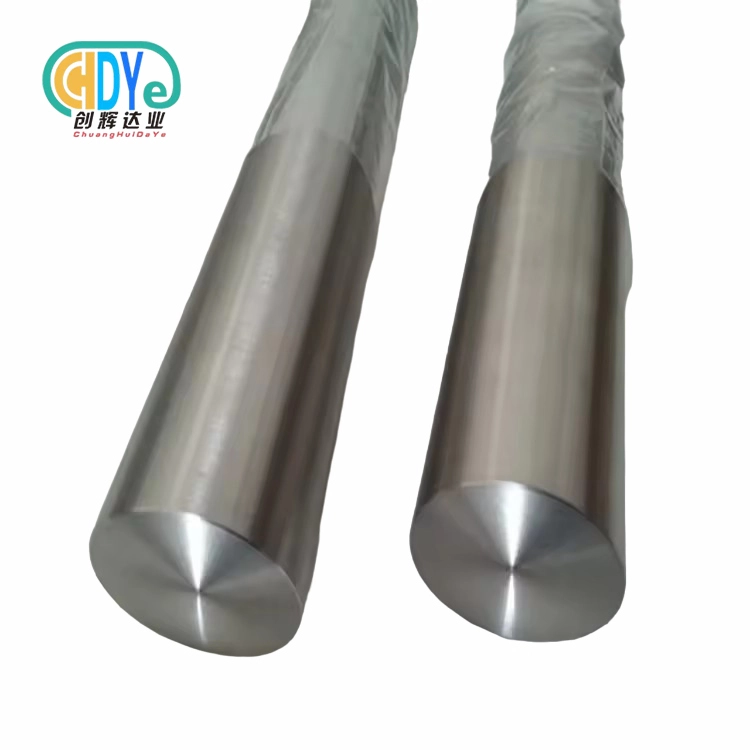

Grade 2 titanium round bar is commercially pure and has good corrosion resistance and moderate strength. Minimum 99.2% titanium with regulated oxygen, nitrogen, carbon, and iron impurities. This material has 345-485 MPa tensile strength and excellent ductility and formability.

Industry Standards and Compliance Requirements

Titanium round bars must meet ASTM B348, ASME SB348, and AMS 4921. These specs specify mechanical qualities, surface finish, and dimensional tolerances. AMS 4921 certification may be needed for aircraft components and ASTM F67 conformity for medical purposes.

Dimensional Specifications and Processing Options

Standard titanium round bar diameters are 6mm to 350mm, with bespoke dimensions possible through processing. For surface finishes and dimensional accuracy, hot rolling, forging, and precise grinding are used. Transport restrictions and client needs determine length specifications.

Step-by-Step Import Process

Supplier Identification and Evaluation

Research qualified titanium suppliers via industry directories, trade associations, and B2B platforms. Production capacity, certification, and customer references should be considered while choosing partners. To evaluate manufacturing, request firm biographies, facility photos, and quality data.

Check supplier business licenses, export permits, and quality certifications. Ask past customers about product quality, delivery, and technical support. Communicate directly with salespeople, quality managers, and technical experts.

Quotation and Negotiation Process

Grade, dimensions, quantity, delivery timeline, and packing choices must be specified. Get quotes for materials, processing, packaging, and shipping. Compare prices from multiple providers to set market standards.

Negotiate pricing changes, payment arrangements, delivery timelines, and quality guarantees. Discuss bulk order discounts and supply relationship frameworks. Define inspection, testing, and documentation duties.

Contract Formation and Purchase Order

Sign purchase agreements or proforma invoices with all business clauses. Provide product details, quality standards, delivery needs, and payment terms. Clarify quality issues, supply delays, and force majeure procedures.

Establish witness testing, third-party verification, and certificate requirements for inspections. Set packaging, branding, and shipping standards. For buyer protection, include penalties for non-conforming products and delivery delays.

Trade Terms and Payment Methods

Understanding International Trade Terms

Buyers must organize and pay for ocean freight, insurance, and destination handling under FOB terms. When products are loaded onto the vessel at the departure port, the supplier's responsibility ceases. Buyers have more control over delivery costs and arrangements.

Supplier quotes include ocean freight and basic insurance under CIF. The provider handles shipping and minimal insurance, while purchasers handle customs clearance and internal transportation. Buyer logistics are simplified by this option.

EXW (Ex Works) customers are responsible for collection, export clearance, and transportation. This term is the cheapest but requires extensive logistics management. In contrast, DDP (Delivered Duty Paid) suppliers handle all logistics, including customs clearance and delivery.

Payment Security and Risk Management

Letters of Credit give buyers and sellers secure payment methods. Documentary credits from banks guarantee payment with supporting documents. This strategy eliminates financial risk and ensures providers meet contractual commitments before payment.

T/T arrangements usually require 30% advance payment and 70% before shipment. This structure balances cash flow with party security. For further payment safety, bank guarantees might enhance T/T.

Currency Considerations and Hedging

Currency changes can considerably affect project costs, especially for large purchases with long delivery times. Forward contracts or currency hedging can lock in exchange rates. To reduce currency risk, negotiate price adjustments for orders over certain durations.

Documentation and Compliance Requirements

Essential Import Documentation

Commercial invoices must provide precise product, quantity, value, and selling terms. These documents underpin customs value and duty calculations. Maintain detailed product descriptions, harmonized tariff codes, and country of origin statements on invoices.

Cargo dimensions, weights, and packaging specifications are listed in packing lists. Bills of lading allow cargo release at destination ports as title documents and shipping receipts. Certificates of origin prove goods nationality for trade agreement benefits.

Quality Certificates and Technical Documentation

Material test certificates (MTCs) record manufacturing lot chemical composition, mechanical qualities, and heat treatment parameters. These certificates guarantee end-use application quality and traceability. Products are further verified by third-party inspection certificates.

Compliance certificates prove compliance with ASTM B348, ISO, and industry standards. Testing equipment calibration certificates guarantee measurement accuracy and dependability. Materials are tracked throughout the supply chain with chain of custody documents.

Customs and Regulatory Compliance

Some nations require titanium import licenses due to dual-use technology. Check destination country restrictions and get permits before shipping. Customs declarations must match product descriptions, values, and uses.

Titanium imports from certain nations may be subject to anti-dumping and countervailing tariffs. Track duty rates and trade policy changes to compute landing costs. To optimize costs, consider duty drawback programs for re-exports.

Quality Assurance and Inspection

Pre-Shipment Inspection Protocols

Verify dimensions, surface quality, and mechanical properties via extensive inspection methods. Monitor melting, forging, and heat treatment to assure process compliance. Record inspections with photos, test findings, and conformance statements.

Hire qualified third-party inspection firms to verify product quality and standards. These organizations offer impartial evaluation and global certification. To avoid production delays and ensure comprehensive inspection, schedule inspections.

Testing and Certification Requirements

Chemical analysis confirms Grade 2 titanium elemental composition. Yield, ultimate, and elongation values are confirmed by tensile testing. Ultrasonic inspection finds interior faults that could affect key applications.

Surface finish measurements assure roughness and aesthetic conformity. Dimensional inspection checks straightness, length, and diameter tolerances. Hardness testing verifies material properties for quality assurance.

Corrective Action and Non-Conformance Management

Supplier notification, root cause analysis, and remedial action implementation should be standard for non-conforming items. Determine product acceptability, rework, or rejection based on application and quality standards.

Track performance trends and improvement initiatives by documenting quality issues and supplier replies. Address quality issues and improve performance via supplier development programs. Keep quality records for traceability and development.

Why Chuanghui Daye is Your Ideal Import Partner?

Expertise and Manufacturing Excellence

Strategically located in China's best titanium manufacturing location, Baoji High-tech Development Zone houses Shaanxi Chuanghui Daye Metal Material Co., Ltd. Our founder contributes technical and market expertise to every customer interaction with over 30 years of rare metal industry experience.

Electron beam furnaces, precision forging, and extensive machining are available at our modern manufacturing facilities. Product quality is controlled and lead times are competitive with this integrated strategy. We are ISO 9001:2015 certified for systematic quality management and continuous development.

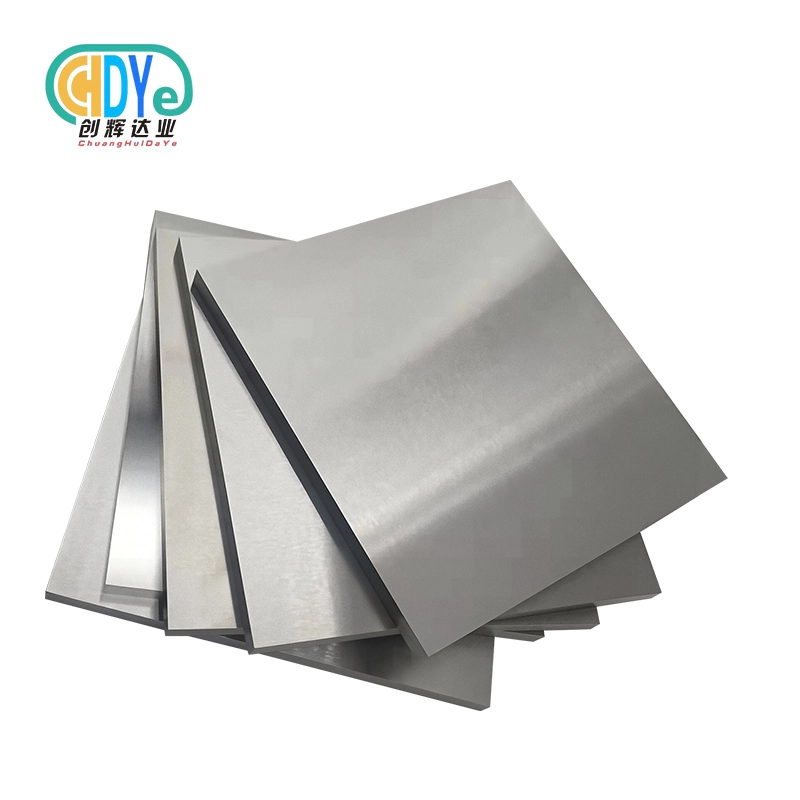

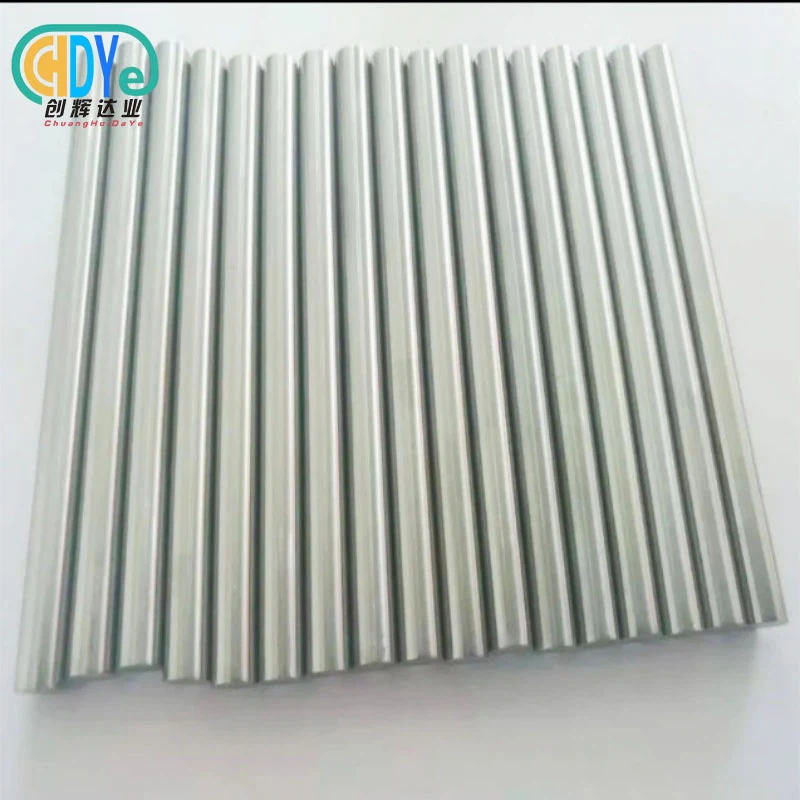

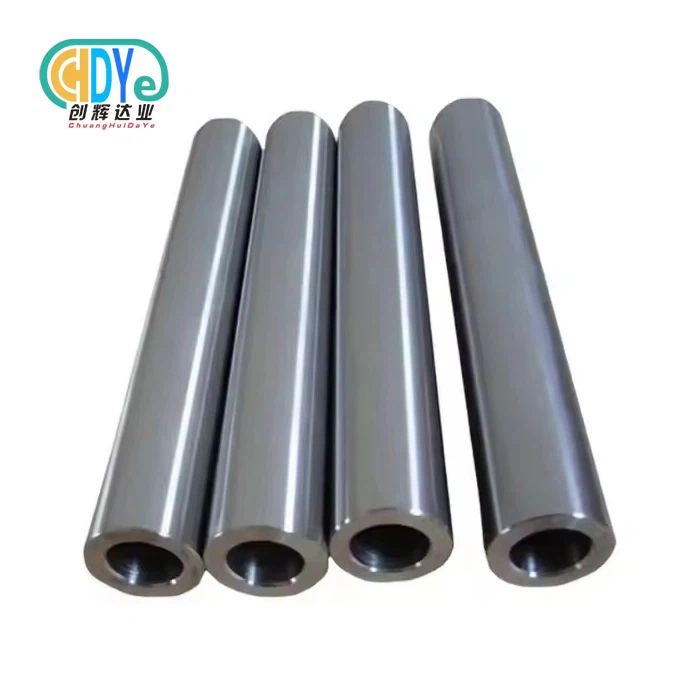

Comprehensive Product Range and Customization

We make 6mm to 350mm titanium round bars in round, square, and hexagonal cross-sections. To fulfill application needs, hot-rolled, forged, and precision-ground finishes are available. Specialized processing and dimensions meet project needs.

Grade 5 (Ti-6Al-4V), Grade 7, Grade 9, and Grade 12 titanium alloys are available for high-performance applications. This extensive selection lets consumers buy numerous materials from one reputable supplier.

Technical Support and Customer Service

Our technical team offers material selection, processing, and performance optimization advice. We work closely with customers to understand their needs and create customized solutions that improve product performance and lower expenses.

Small-batch research and large-scale manufacturing are accommodated by flexible production. Fast prototyping services provide speedy product development while retaining supply chain traceability and quality documentation.

Cost Analysis and Budgeting

Material Cost Components

Titanium sponge costs, processing complexity, and market demand affect base material pricing. Specialized processing, bespoke dimensions, and expedited delivery cost extra. Volume discounts apply to orders over minimum quantities.

Forged bars cost more to process than hot-rolled ones. Precision grinding and specialist surface treatments cost more but provide better dimensional accuracy and surface quality for important applications.

Logistics and Transportation Expenses

Shipping volume, route choice, and seasonal demand affect ocean freight rates. Smaller orders might save on shipping via container consolidation. Express delivery costs more for urgent needs.

Countries and product classifications affect import levies, taxes, and customs clearing fees. Include these costs in total landing cost calculations for appropriate budgeting. Duty drawback programs for exporting items can lower import expenses.

Hidden Costs and Risk Mitigation

Project budgets can include large quality inspection, third-party testing, and certification expenditures. Insurance covers shipping damage, supplier default, and currency fluctuations. Complex transactions or disputes may require legal and documentation fees.

Inventory carrying, storage, and handling costs add up, especially for large purchases or irregular consumption. Just-in-time delivery reduces these costs while maintaining productivity.

Supply Chain Management and Logistics

Production Planning and Lead Times

Order confirmation to completion takes 15-25 days for standard Grade 2 titanium round bar manufacture. Large volumes, custom specifications, or specialty processing might increase wait times to 30-45 days. Production schedules and delivery times are optimized by advanced planning and demand forecasts.

Supplier collaboration improves capacity allocation and urgent scheduling. Framework agreements with delivery schedules ensure dependable supply and volume flexibility.

Inventory Management Strategies

Customers can hold local inventory on consignment without immediate payment. Supplier-managed inventory strategies optimize stock and save customer paperwork. Orders with regular releases ensure supply security and reduce inventory investment.

Strategic safety stock levels prevent supply disruptions, demand spikes, and transportation delays. Establish buffer inventories at critical locations with suppliers to improve urgent response.

Transportation and Packaging

Proper packing protects titanium products from contamination, mechanical damage, and environmental exposure during shipping. Valued cargo is protected by moisture-proof wrapping, foam padding, and timber crating. Labelling and marking ensure logistics chain accuracy.

Shipping route optimization balances cost, reliability, and transit time. Direct shipping routes reduce handling and damage risk but may increase expenses. Consolidated shipments cut unit costs but delay delivery.

Conclusion

China Grade 2 titanium round bar imports demand careful preparation, supplier selection, and trade procedures knowledge. China is an interesting titanium material supplier due to its cost, manufacturing, and quality advantages.

Maintaining clear communication, working with certified suppliers, and having strong quality assurance systems are key to import success. Effective paperwork, compliance management, and risk minimization enable seamless transactions and satisfaction.

This guide's organized strategy helps your firm navigate international titanium procurement's complexities while minimizing risks and optimizing value.

FAQ

Q: What is the minimum order quantity for Grade 2 titanium round bar imports?

A: Minimum order quantities typically range from 100 to 500 kg, depending on the supplier and specifications. Smaller quantities are possible but may incur premium pricing due to setup costs and shipping inefficiencies. Discuss specific requirements with suppliers to determine optimal order sizes for your applications.

Q: How long does the complete import process take from order to delivery?

A: Total import timeline ranges from 6-10 weeks, including production (15-25 days), shipping (10-20 days), and customs clearance (3-7 days). Expedited options can reduce this timeframe but increase costs. Plan accordingly and consider buffer time for potential delays or complications.

Q: What certifications should I require from Chinese titanium suppliers?

A: Essential certifications include ISO 9001:2015 quality management, ASTM B348 material compliance, and material test certificates for each production lot. Additional certifications like AS9100 for aerospace applications or ISO 13485 for medical devices may be required based on your specific industry requirements.

Q: Can I visit the supplier's facility before placing a large order?

A: Reputable suppliers welcome facility visits and quality audits from potential customers. Schedule visits during production periods to observe manufacturing processes, quality control procedures, and testing capabilities. Virtual tours and video conferences can provide initial assessments before physical visits.

Q: What happens if the delivered products don't meet specifications?

A: Establish clear quality agreements and inspection procedures before shipment to prevent non-conformance issues. Include warranty clauses covering replacement, rework, or refund options for defective materials. Third-party inspection services provide independent verification and dispute resolution support.

Partner with Chuanghui Daye for Premium Grade 2 Titanium Round Bar Supply

Shaanxi Chuanghui Daye stands ready to become your trusted Grade 2 titanium round bar supplier, combining three decades of metallurgical expertise with state-of-the-art manufacturing capabilities. Our Baoji-based facility produces precision titanium products meeting the most demanding specifications while maintaining competitive pricing and reliable delivery schedules.

Whether you require standard dimensions or custom specifications, our technical team provides comprehensive support throughout the procurement process. Ready to experience the Chuanghui Daye advantage? Contact us at info@chdymetal.com to discuss your titanium requirements and receive detailed quotations tailored to your specific applications.

References

1. American Society for Testing and Materials. "ASTM B348/B348M - Standard Specification for Titanium and Titanium Alloy Bars and Billets." ASTM International, West Conshohocken, PA, 2019.

2. Boyer, Rodney, Gerhard Welsch, and E.W. Collings. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, OH, 1994.

3. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, Materials Park, OH, 2000.

4. International Organization for Standardization. "ISO 5832-2:2018 - Implants for surgery — Metallic materials — Part 2: Unalloyed titanium." Geneva, Switzerland, 2018.

5. Lutjering, Gerd and James C. Williams. "Titanium, 2nd Edition." Springer-Verlag, Berlin Heidelberg, 2007.

6. Peters, Manfred, et al. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Vol. 5, No. 6, 2003.