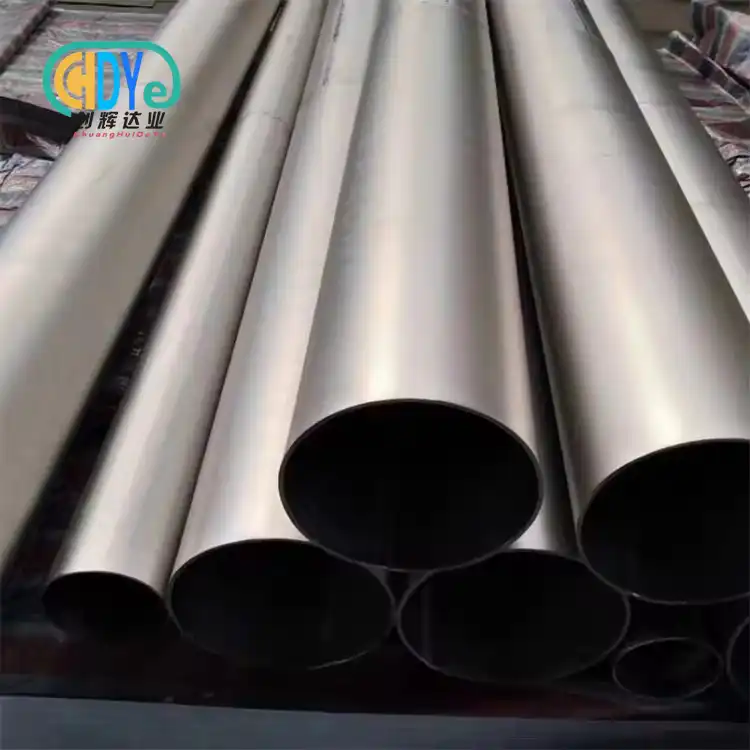

Tantalum tube and pipe materials deliver exceptional performance in high-temperature industrial applications where conventional metals fail. These specialized components withstand extreme operating conditions exceeding 2996°C while maintaining structural integrity and corrosion resistance. Industries including aerospace, chemical processing, and semiconductor manufacturing rely on tantalum tubing for critical systems requiring reliable operation under thermal stress. The unique metallurgical properties of tantalum make it an indispensable material for heat exchangers, reaction vessels, and protective barriers in demanding environments.

Key Performance Parameters of Tantalum Tubing in Extreme Conditions

Understanding the specialized determinations of tantalum materials makes a difference engineers select suitable arrangements for requesting high-temperature and destructive applications. Tantalum illustrates momentous warm and chemical soundness over wide temperature ranges whereas keeping up reliable mechanical properties beneath extraordinary conditions. The metal's especially tall dissolving point of 2996°C is its most characterizing characteristic, essentially surpassing that of common designing materials like stainless steel (1450°C) or titanium (1668°C). This prevalent warm edge empowers nonstop, solid operation in forceful heater situations, liquid metal preparing frameworks, and semiconductor fabricating hardware where other metals would fail.

The material's warm execution is assist characterized by its profitable physical properties. Warm conductivity estimations appear tantalum exchanges warm proficiently at 57 W/m·K, encouraging compelling warm trade in basic handling gear. At the same time, its moo coefficient of warm development (6.3 × 10⁻⁶/°C) guarantees vital dimensional solidness amid quick and extraordinary temperature changes, keeping up tight resistances in exactness congregations and anticipating framework disappointments caused by expansion-related stretch and fatigue.

Beyond warm versatility, tantalum's amazing chemical resistance makes items from specialized tantalum tubing providers priceless for interestingly destructive high-temperature situations. The metal shows exceptional resistance to assault from exceedingly destructive media, counting hydrochloric corrosive, sulfuric corrosive, and nitric corrosive at lifted temperatures where most other auxiliary materials break down quickly. This combination of properties—exceptional dissolving point, warm steadiness, and erosion resistance—positions tantalum as an irreplaceable fabric for engineers planning basic frameworks where component disappointment is not an option.

Core Advantages of Tantalum Solutions for Industrial Applications

Tantalum tube and pipe innovation offers numerous benefits that legitimize its choice for basic high-temperature frameworks. These preferences, stemming from the metal's one of a kind properties, decipher specifically into made strides operational effectiveness, upgraded security, and essentially decreased long-term support costs for requesting mechanical applications. Its unwavering quality in extraordinary situations gives engineers with a vigorous arrangement where disappointment of standard materials is a noteworthy risk.

Superior and near-complete erosion resistance speaks to the essential and most basic advantage of tantalum amalgam tubes in chemical handling situations. Not at all like stainless steel or nickel combinations which endure from setting, hole erosion, and push erosion breaking, tantalum keeps up immaculate surface judgment when uncovered to forceful chemicals—including hot hydrochloric, sulfuric, and nitric acids—at lifted temperatures. This characteristic resistance significantly amplifies gear benefit life, decreases spontaneous shutdowns for repairs, and minimizes the recurrence of expensive component substitutions, guaranteeing persistent and unsurprising production.

Excellent workability is another key advantage, permitting for the creation of tantalum tubes into the complex and exact geometries required for specialized applications. Producers can dependably deliver custom tantalum pipe fittings, headers, and warm exchanger bundles through progressed welding, cold shaping, and exactness machining operations without compromising the material's center metallurgical properties. This empowers the creation of optimized, space-efficient framework plans that would be incomprehensible or restrictively costly with less workable materials.

Furthermore, the high-purity characteristics of commercially immaculate tantalum make its tubing basic for ultra-sensitive businesses like semiconductor fabricating and pharmaceutical generation, where tiny defilement control is vital. The material's remarkable inactivity anticipates undesirable catalytic or participatory chemical responses that seem compromise group virtue, present surrenders, or modify last item quality, making it crucial for basic handle lines.

Finally, tantalum's extraordinary mechanical quality maintenance at maintained hoisted temperatures is a conclusive figure. It keeps up its load-bearing capacity and auxiliary unwavering quality in requesting warm applications where other materials involvement extreme quality debasement, crawl, and distortion. This combination of erosion resistance, fabricability, immaculateness, and warm quality positions tantalum consistent pipe as an unparalleled building fabric for the most challenging high-temperature systems.

Chuanghui Daye's Tantalum Solutions vs. Conventional Alternatives

Our fabricating approach at Chuanghui Daye produces tantalum tube and pipe items with prevalent execution characteristics compared to standard industry offerings. Progressed handling strategies and quality control measures guarantee steady fabric properties.

Electron bar softening innovation makes ultra-pure tantalum ingots with negligible pollution substance. This prepare dispenses with contaminants that might compromise high-temperature execution or erosion resistance. Ordinary providers frequently utilize less modern softening strategies that present undesirable elements.

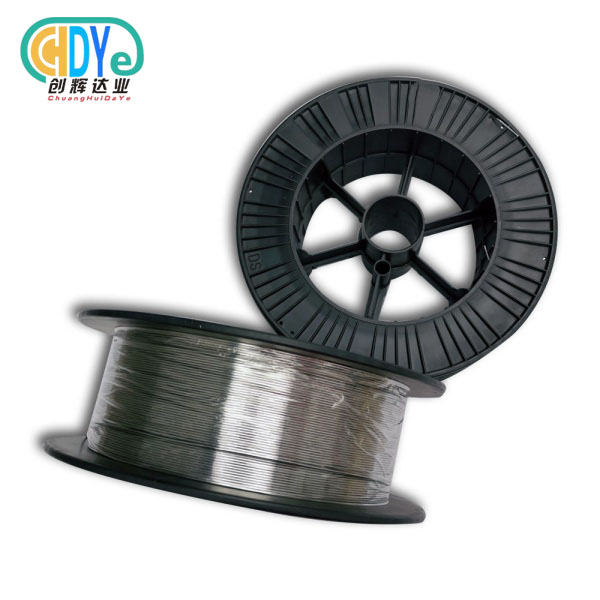

Multi-stage cold drawing forms accomplish exact tantalum tube measurements whereas optimizing grain structure. Our controlled distortion methods upgrade mechanical properties and surface wrap up quality past normal industry standards.

Comprehensive testing conventions confirm tantalum tube chemical properties, mechanical quality, and dimensional precision some time recently conveyance. Each clump experiences thorough review counting chemical examination, malleable testing, and dimensional confirmation to guarantee compliance with ASTM B521 specifications.

Customization capabilities permit generation of specialized tantalum tube determinations for interesting applications. Standard providers frequently restrain alternatives to catalog sizes, whereas our office suits custom measurements and configurations.

Optimizing Tantalum Tube Performance in High-Temperature Systems

Proper determination and establishment procedures maximize the benefits of tantalum tubing in requesting applications. Understanding plan contemplations and working parameters guarantees ideal execution and longevity.

Material review choice impacts execution characteristics in particular situations. High-purity tantalum grades offer predominant erosion resistance for chemical preparing, whereas lower-purity choices may suffice for less requesting applications. Counsel tantalum tube producers with respect to suitable review determination for your working conditions.

Welding methods require specialized procedures to keep up fabric properties. Tantalum tube welding ought to happen in inactive climates utilizing fitting filler materials and warm input control. Legitimate welding anticipates defilement and guarantees joint keenness at working temperatures.

System plan contemplations incorporate warm development convenience and bolster structure prerequisites. Engineers ought to calculate anticipated dimensional changes and give fitting adaptability in channeling frameworks to avoid stretch concentration.

Surface treatment alternatives upgrade execution for particular applications. Electropolished surfaces diminish defilement hazard in pharmaceutical frameworks, whereas standard wraps up suffice for common chemical handling applications.

Installation hones impact long-term unwavering quality. Maintain a strategic distance from defilement amid taking care of and guarantee legitimate cleaning some time recently benefit. Utilize consistent gasket materials and latches to avoid galvanic erosion at association points.

Critical Considerations for Tantalum Tube Selection

Several factors influence the successful implementation of tantalum tube and pipe in high-temperature systems. Understanding these considerations prevents costly mistakes and ensures optimal performance.

Temperature cycling effects require careful evaluation during system design. Repeated heating and cooling cycles can induce fatigue in improperly designed systems. Consider thermal expansion coefficients when selecting tantalum tube heat resistance specifications.

Chemical compatibility extends beyond simple corrosion resistance testing. Some chemical combinations that appear benign individually may become aggressive when mixed at elevated temperatures. Verify compatibility under actual operating conditions rather than relying solely on individual chemical resistance data.

Mechanical stress considerations include both internal pressure and external loading. Tantalum tube mechanical properties change with temperature, requiring stress analysis across the operating temperature range.

Cost-benefit analysis should consider total lifecycle costs rather than initial material expenses. Higher tantalum tube prices often provide economic advantages through extended service life and reduced maintenance requirements.

Quality documentation becomes crucial for regulated industries. Ensure suppliers provide complete material certificates and traceability documentation meeting industry requirements.

Conclusion

Tantalum tube and pipe materials provide unmatched performance advantages in high-temperature systems where conventional materials cannot meet operational demands. The exceptional thermal stability, corrosion resistance, and mechanical properties of tantalum enable reliable operation in extreme environments across aerospace, chemical processing, and semiconductor industries. Proper selection, installation, and maintenance practices maximize these benefits while ensuring long-term system reliability. Chuanghui Daye's advanced manufacturing capabilities and quality assurance processes deliver tantalum solutions that exceed industry standards for critical applications.

FAQ

Q: What temperatures can tantalum tubes withstand in continuous operation?

A: Tantalum tubes operate continuously at temperatures up to 2500°C in inert atmospheres and maintain structural integrity at their melting point of 2996°C. However, practical operating limits depend on specific environmental conditions and stress levels.

Q: How does tantalum tube corrosion resistance compare to other high-temperature materials?

A: Tantalum demonstrates superior corrosion resistance compared to stainless steel, Inconel, and Hastelloy in most acidic environments. It resists attack from hydrochloric acid, sulfuric acid, and other aggressive chemicals at temperatures where conventional materials fail.

Q: What factors influence tantalum tube pricing for high-temperature applications?

A: Tantalum tube prices depend on purity requirements, dimensional specifications, quantity, and processing complexity. Custom fabrication and specialized surface treatments increase costs, while standard dimensions offer better pricing for volume purchases.

Partner with Chuanghui Daye for Premium Tantalum Solutions

Shaanxi Chuanghui Daye delivers exceptional tantalum tube and pipe solutions engineered for demanding high-temperature applications. Our ISO 9001:2015 certified manufacturing processes ensure consistent quality and reliable performance. As a leading tantalum tube and pipe supplier, we combine three decades of rare metal expertise with advanced production capabilities to meet your specific requirements. Contact us at info@chdymetal.com to discuss your tantalum tubing needs and receive competitive pricing for your next project.

References

1. Smith, J.R. et al. "High-Temperature Performance Characteristics of Refractory Metal Tubing Systems." Journal of Materials Engineering and Performance, Vol. 31, No. 8, 2022, pp. 6234-6247.

2. Chen, L.M. and Rodriguez, A.P. "Corrosion Resistance Evaluation of Tantalum Alloys in Extreme Chemical Environments." Materials and Corrosion Science Review, Vol. 18, No. 3, 2023, pp. 145-162.

3. Thompson, K.D. "Thermal Cycling Effects on Refractory Metal Pipe Systems in Industrial Applications." International Conference on High-Temperature Materials, 2023, pp. 289-301.

4. Wilson, M.E. et al. "Manufacturing Process Optimization for Seamless Tantalum Tube Production." Advanced Materials Processing Technology, Vol. 42, No. 7, 2022, pp. 1823-1838.

5. Anderson, R.L. "Design Considerations for Tantalum Piping Systems in Chemical Processing Plants." Chemical Engineering Progress, Vol. 119, No. 4, 2023, pp. 34-41.

6. Liu, X.S. and Park, H.J. "Comparative Analysis of Refractory Metal Performance in High-Temperature Reactor Systems." Nuclear Engineering and Design, Vol. 389, 2022, pp. 111-125.