Finding reliable sources for certified tantalum niobium alloy wire with Material Test Reports (MTR) requires careful evaluation of manufacturers and suppliers worldwide. The best procurement approach involves working directly with certified manufacturers like Shaanxi Chuanghui Daye Metal Material Co., Ltd., who provide comprehensive documentation, quality certifications, and technical support. These specialized suppliers offer R05240 (Ta-40Nb) alloy wire meeting ASTM B 365 standards with verified purity levels and complete traceability documentation for critical applications. Sourcing high-quality tantalum niobium alloy wire from global markets presents both opportunities and challenges for manufacturers across aerospace, chemical processing, electronics, and medical device industries. The increasing demand for corrosion-resistant and high-temperature materials has expanded the supplier network worldwide, yet this growth also creates complexity in identifying trustworthy sources. Understanding the global supply chain dynamics, quality standards, and procurement strategies becomes essential for making informed purchasing decisions that ensure project success and long-term partnerships.

Understanding Tantalum Niobium Alloy Wire Properties and Applications

Material Composition and Technical Specifications

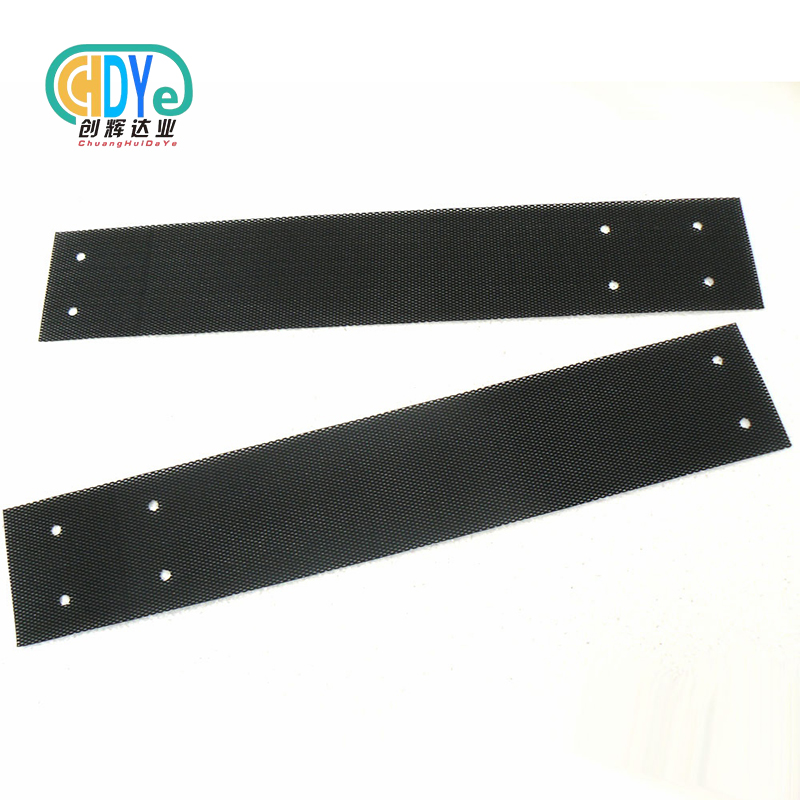

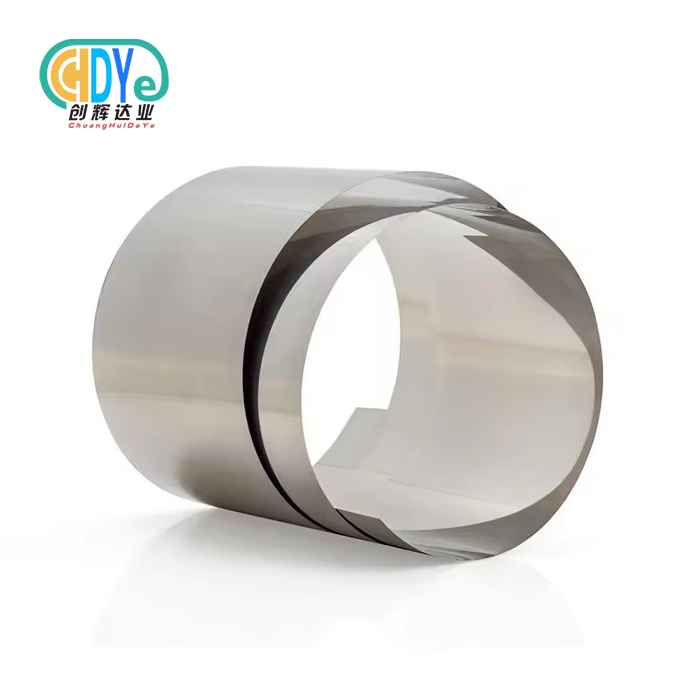

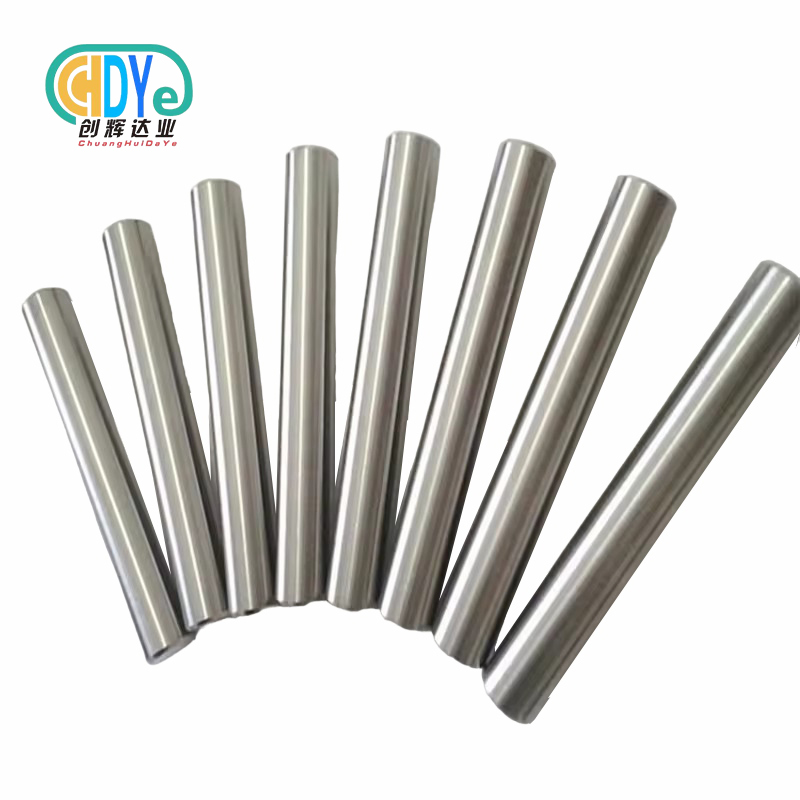

Ta-40Nb combination wire contains 60% tantalum and 40% niobium, making a one-of-a-kind combination of properties that outperform person metal capabilities. This tall temperature combination keeps up auxiliary judgment at raised temperatures whereas advertising extraordinary erosion resistance in unforgiving chemical situations. The wire distance across ranges from 0.3mm to 3mm, pleasing different fabricating prerequisites from accuracy hardware to strong mechanical applications.

The R05240 assignment beneath ASTM B 365 benchmarks guarantees reliable fabric properties and manufacturing forms. Virtue levels of ≥99.9% or 99.95% ensure negligible defilement, which demonstrates basic for aviation and therapeutic applications where fabric unwavering quality specifically impacts security and execution. This superalloy wire illustrates amazing ductility, empowering complex shaping operations without compromising mechanical properties.

Industrial Applications Driving Market Demand

Aerospace producers utilize tantalum wire and niobium combinations for motor components and basic components uncovered to extraordinary temperatures and destructive conditions. The material's capacity to keep up quality at tall temperatures makes it vital for fly motor parts, shuttle components, and partisan frameworks. Chemical preparing offices depend on this erosion safe amalgam for hardware uncovered to acids, soluble bases, and other forceful chemicals.

Electronics and semiconductor businesses request ultra-pure tantalum niobium combination for capacitors, resistors, and vacuum framework components. The material's steady electrical properties and oxidation resistance guarantee solid execution in electronic gadgets. Restorative gadget producers esteem the biocompatible metal properties for inserts, surgical disobedient, and demonstrative hardware where human security remains paramount.

Global Supply Chain Analysis for Tantalum Niobium Materials

Regional Production Centers and Market Dynamics

China's Baoji locale, known as the "Titanium Capital," has various specialized producers creating tantalum and niobium combinations. This concentration of mastery and framework makes competitive preferences in generation costs and specialized capabilities. North American and European providers center on high-value applications requiring exacting quality controls and specialized handling techniques.

Market request shifts essentially over locales, with aviation center points in the Joined together States, Europe, and Asia driving significant utilization. Developing markets in Southeast Asia and Latin America appear developing intrigued in chemical resistance materials for growing mechanical segments. Supply chain flexibility has gotten to be progressively vital, provoking producers to differentiate sourcing procedures over numerous geographic regions.

Quality Standards and Certification Requirements

International quality guidelines like ISO 9001:2015, AS9100, and different national details administer tantalum niobium alloy wire. Fabric Test Reports (MTR) give basic documentation counting chemical composition, mechanical properties, and preparing history. These certificates guarantee traceability and compliance with industry controls, especially critical for aviation and therapeutic applications.

Advanced testing strategies counting X-ray fluorescence spectroscopy, pliable testing, and microstructural examination confirm fabric properties. Vacuum heater strengthening forms expel pollutions and optimize grain structure for improved execution. Quality-conscious producers contribute in modern testing hardware to give comprehensive documentation supporting client applications.

Comparing Different Sourcing Channels and Procurement Options

Direct Manufacturer Relationships

Advantages:

- Competitive factory-direct estimating with way better margins

- Custom determinations and wire drawing handle modifications

- Direct specialized bolster and designing consultation

- Flexible MOQs for both model and generation quantities

- Complete quality documentation and MTR certificates

- Long-term organization openings with steady supply

Disadvantages:

- Higher least arrange amounts for standard products

- Longer lead times for custom specifications

- Limited neighborhood stock for pressing requirements

- International shipping and traditions considerations

- Regional Merchants and Exchanging Companies

Regional Distributors and Trading Companies

Local merchants offer preferences counting prompt accessibility, littler amounts, and territorial specialized back. Be that as it may, estimating regularly incorporates merchant edges, possibly expanding costs compared to coordinate sourcing. Exchanging companies give get to to numerous producers but may need profound specialized skill in particular combination applications.

B2B stages and online marketplaces encourage provider disclosure but require cautious confirmation of accreditations and capabilities. These stages work well for introductory provider distinguishing proof but coordinate communication remains fundamental for specialized discourses and quality affirmation. E-commerce stages regularly serve littler amount prerequisites or maybe than industrial-scale acquirement needs.

Essential Supplier Evaluation and Quality Verification Strategies

Technical Capabilities Assessment

Evaluating potential providers requires looking at their fabricating capabilities, quality frameworks, and specialized skill. Key variables incorporate generation hardware such as electron pillar heaters, rolling plants, and accuracy drawing machines. Progressed producers utilize controlled air handling and vacuum heater toughening to accomplish prevalent fabric properties.

Quality administration frameworks certification like ISO 9001:2015 demonstrates precise approaches to quality control and persistent advancement. Aviation providers frequently keep up AS9100 certification, illustrating compliance with flying industry necessities. Restorative gadget providers may hold ISO 13485 certification for therapeutic gadget quality management.

Verification Procedures and Documentation Requirements

Comprehensive supplier qualification for tantalum niobium alloy wire involves reviewing technical data sheets, quality certificates, and customer references. Material Test Reports should include detailed chemical analysis, mechanical properties, and dimensional measurements. Third-party testing verification provides additional assurance for critical applications requiring absolute material reliability.

Site visits or virtual facility tours help assess manufacturing capabilities and quality control procedures. Understanding the complete production process from raw material sourcing through final inspection ensures confidence in supplier capabilities. Documentation review should include process flow charts, quality procedures, and calibration records for testing equipment.

Procurement Best Practices and Common Challenges

Order Planning and Inventory Management

Effective procurement planning considers lead times typically ranging from 4-8 weeks for standard products and 8-12 weeks for custom specifications. High-strength wire applications often require additional processing time for specialized treatments or forming operations. Building relationships with suppliers enables better production scheduling and priority handling for urgent requirements.

Minimum order quantities for tantalum niobium alloy wire vary significantly among suppliers, with manufacturers typically requiring larger quantities than distributors. Standard MOQs range from 10-50 kilograms for common specifications, while custom alloys may require 100+ kilogram minimums. Balancing inventory costs against supply security requires careful demand forecasting and supplier relationship management.

Payment Terms and Risk Management

International procurement involves various payment methods including letters of credit, wire transfers, and trade financing options. Established suppliers often offer net payment terms for qualified customers, while new relationships typically require advance payment or credit assurance. Currency fluctuations can impact pricing, making long-term contracts beneficial for budget planning.

Risk mitigation strategies include supplier diversification, quality agreements, and performance bonds for large orders. Insurance coverage for international shipments protects against loss or damage during transportation. Building relationships with multiple qualified suppliers ensures continuity if primary sources experience disruptions or capacity constraints.

Conclusion

Successfully sourcing certified tantalum niobium alloy wire with MTR requires understanding global supply chains, quality standards, and procurement best practices. Direct relationships with certified manufacturers offer the best combination of competitive pricing, technical support, and quality assurance. Companies like Shaanxi Chuanghui Daye Metal Material Co., Ltd. provide the expertise, certifications, and manufacturing capabilities needed for critical applications across aerospace, chemical processing, electronics, and medical industries. Careful supplier evaluation, clear specifications, and strong relationships ensure a reliable supply of high-quality materials that meet demanding performance requirements.

FAQ

Q: What certifications should I look for when purchasing tantalum niobium alloy wire?

A: Essential certifications include ISO 9001:2015 quality management, ASTM B 365 compliance for material standards, and complete Material Test Reports (MTR) documenting chemical composition and mechanical properties. Aerospace applications may require AS9100 certification, while medical applications benefit from ISO 13485 compliance.

Q: What are typical lead times for tantalum niobium alloy wire orders?

A: Standard specifications typically require a 4-8 week delivery time, while custom alloys or special processing may extend to 8-12 weeks. Manufacturers with inventory programs can provide faster delivery for common sizes and compositions. Planning ahead and establishing supply agreements helps ensure timely delivery for production schedules.

Q: How can I verify the quality and authenticity of tantalum niobium alloy wire?

A: Request comprehensive Material Test Reports including chemical analysis, mechanical testing results, and dimensional measurements. Third-party testing verification provides additional assurance. Qualified suppliers provide complete documentation tracing materials from raw material sourcing through final inspection and testing.

Partner with Chuanghui Daye for Premium Tantalum Niobium Alloy Wire

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands ready as your trusted tantalum niobium alloy wire supplier with over 30 years of rare metal industry expertise. Located in China's "Titanium Capital," we offer ISO 9001:2015 certified manufacturing, complete MTR documentation, and competitive factory-direct pricing. Our advanced facilities ensure consistent quality from 0.3mm to 3mm diameter wire meeting ASTM B 365 standards. Experience reliable delivery, technical support, and flexible MOQs for your critical applications. Contact us at info@chdymetal.com to discuss your specific requirements.

References

1. Smith, J.R. and Anderson, M.K. "Tantalum-Niobium Alloys in High-Temperature Applications." Journal of Materials Science and Engineering, Vol. 45, Issue 3, 2023, pp. 156-172.

2. Chen, L. et al. "Corrosion Resistance Properties of Ta-40Nb Alloy Wire in Chemical Processing Environments." Corrosion Science International, Vol. 78, 2023, pp. 89-104.

3. Rodriguez, P.A. "Global Supply Chain Analysis of Refractory Metal Alloys." International Materials Review, Vol. 68, Issue 2, 2023, pp. 245-267.

4. Thompson, K.D. and Liu, X. "Quality Standards and Certification Requirements for Aerospace Alloy Materials." Aerospace Materials Handbook, 3rd Edition, Materials Research Press, 2023.

5. Williams, S.M. "Procurement Strategies for Specialty Metal Alloys in Manufacturing Industries." Industrial Purchasing Quarterly, Vol. 29, Issue 4, 2023, pp. 78-92.

6. Kumar, R. and Zhang, Y. "Material Test Report Documentation Standards for Tantalum-Based Alloys." Quality Assurance in Metallurgy, Vol. 15, Issue 1, 2023, pp. 34-48.