Handling high purity niobium wire safely requires following specific protocols to prevent contamination, ensure worker safety, and maintain material integrity. Key practices include using clean handling environments, wearing appropriate protective equipment, storing the wire in controlled atmospheric conditions, and avoiding contact with reactive chemicals. Proper handling techniques protect both the valuable niobium material properties and personnel working with these specialized superconducting materials. Safety contemplations amplify past securing the fabric itself. Laborers taking care of niobium metal must take appropriate defensive measures to anticipate respiratory protection and skin contact. The fabricating environment essentially impacts both laborer welfare and item quality outcomes.

Essential Safety Equipment for Niobium Wire Handling

Proper defensive hardware shapes the establishment of secure niobium wire, taking care of methods. Laborers must wear nitrile or vinyl gloves to prevent skin oils from sullying the wire surface. Cotton gloves give an extra layer underneath chemical-resistant external gloves, retaining dampness while keeping up dexterity.

Respiratory security gets to be vital when cutting, pounding, or machining niobium materials. N95 respirators offer the least security, whereas fueled air-purifying respirators give prevalent security edges for amplified introduction periods. Eye security, utilizing security glasses with side shields, avoids metal particles from causing harm during wire manipulation.

Workspace Preparation Standards

Clean room situations or controlled climate workspaces minimize defilement dangers. HEPA filtration frameworks evacuate airborne particles that might compromise wire integrity. Stainless steel work surfaces stand up to erosion and clean effortlessly with suitable solvents.

Anti-static measures avoid electrostatic release that might harm delicate electronic applications of high purity niobium wire. Grounded work mats and wrist straps scatter inactive power securely. Mugginess control between 30-50% decreases inactive buildup, while avoiding moisture-related oxidation.

Temperature and Environmental Controls

Room temperature capacity keeps up niobium wire steadiness without warm stretch. Maintaining a strategic distance from temperature changes avoids extension and withdrawal cycles that might present micro-cracks. Climate-controlled capacity zones secure against moisture varieties that advance surface oxidation.

Inert gas situations offer prevalent assurance for long-term capacity. Argon or nitrogen environments anticipate oxygen presentation that may degrade surface properties. Vacuum capacity gives the extreme assurance for ultra-high virtue applications requiring flawless surface conditions.

Material Handling Techniques and Best Practices

Gently taking care of jam niobium wire mechanical properties and anticipates work solidifying. Dodging sharp twists or wrinkles keeps up the wire's superconducting characteristics fundamental for hardware applications. Specialized taking care of devices with smooth, clean surfaces anticipate scratching or gouging the wire surface.

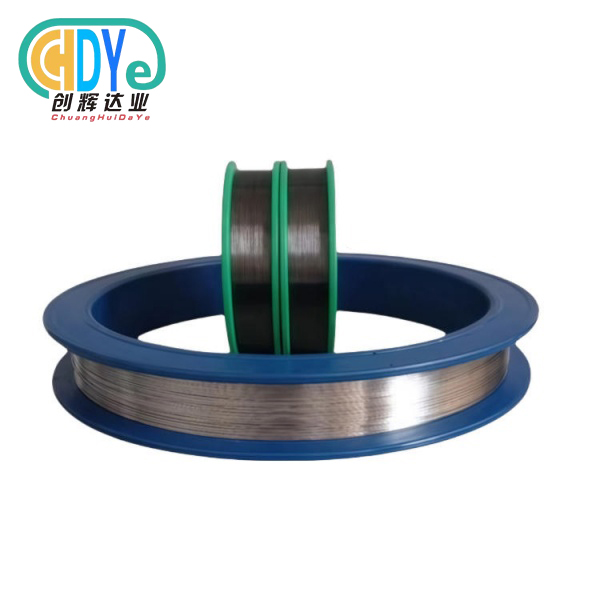

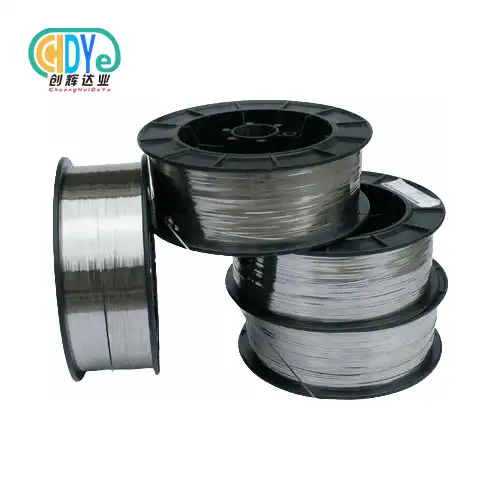

Proper coiling procedures disseminate stretch equitably over the wire length. Expansive sweep coils minimize push concentration focuses that may lead to untimely disappointment. Supporting the wire weight amid dealing with anticipates extending that might modify the wire distance across or present remaining stresses.

Documentation necessities guarantee full traceability from crude fabric through last application. Recording dealing with conditions, presentation times, and natural parameters keeps up quality control guidelines. ISO 9001:2015 certified offices like Chuanghui Daye execute comprehensive following frameworks that screen each handling step.

Contamination Prevention Strategies

Chemical compatibility contemplations avoid receptive defilement that seem compromise niobium wire execution. Maintaining a strategic distance from contact with chlorinated solvents, which can cause stretch erosion splitting, ensures fabric judgment. Utilizing as it were affirmed cleaning operators keeps up surface virtue without presenting destructive residues.

Cross-contamination avoidance requires devoted devices and capacity zones for niobium materials. Isolated dealing with hardware disposes of the chance of exchanging contaminants from other metal handling operations. Color-coded apparatuses and capacity holders offer assistance keep up legitimate isolation protocols.

Quality Control During Wire Processing

Inspection methods confirm wire condition some time recently, amid, and after taking care of operations. Visual examination beneath legitimate lighting uncovers surface abandons, defilement, or mechanical harm. Amplification apparatuses offer assistance recognize unpretentious issues that might influence execution in basic applications.

Dimensional confirmation guarantees wire breadth remains inside indicated resiliences for high purity niobium wire. Accuracy measuring rebellious track any changes that might happen amid taking care of or capacity. Customary calibration of measuring gear keeps up estimation exactness and traceability.

Surface wrap up appraisal decides reasonableness for particular applications. Unpleasant or scratched surfaces may demonstrate unsatisfactory for vacuum applications requiring ultra-smooth interfacing. Documentation of surface conditions makes a difference clients select fitting materials for their particular requirements.

Chemical examination confirms immaculateness levels stay inside detail limits. Spectroscopic methods identify follow contaminants that may influence superconducting properties. Normal testing guarantees fabric quality meets rigid aviation and restorative gadget industry standards.

Storage and Transportation Guidelines

Proper packaging protects niobium wire during transportation and storage periods. Cushioned containers prevent mechanical damage from vibration or impact. Moisture barrier films exclude humidity that could promote surface oxidation or corrosion.

Transportation considerations include temperature control and shock absorption. Insulated packaging maintains stable temperatures during shipping. Fragile labeling ensures careful handling by transportation personnel unfamiliar with specialized materials.

Inventory management systems track storage duration and environmental exposure history. First-in, first-out rotation prevents extended storage that might degrade material properties. Environmental monitoring records document storage conditions throughout the supply chain.

International shipping requirements mandate proper documentation and hazardous material classifications when applicable. Customs declarations must accurately describe the material composition and intended use. Proper paperwork prevents delays that could expose materials to adverse environmental conditions.

Industry Applications and Market Considerations

The global niobium wire market serves diverse industries with varying purity and performance requirements. Superconducting magnet manufacturers demand the highest purity grades for MRI machines and particle accelerators. These applications require niobium filament with purity levels exceeding 99.95% to achieve optimal superconducting performance.

Electronics manufacturers utilize high purity niobium wire for joining components in vacuum environments. The semiconductor industry requires niobium cable assemblies for high-temperature processing equipment. These applications demand consistent wire diameter and exceptional surface quality to ensure reliable performance.

Regional market preferences influence product specifications and quality requirements. European aerospace manufacturers often specify different standards compared to North American suppliers. Asian electronics companies may require unique packaging or certification documentation.

Regulatory compliance varies significantly across global markets. Medical device applications must meet FDA requirements in the United States and CE marking standards in Europe. These regulatory frameworks mandate specific handling procedures and documentation requirements that affect the entire supply chain.

Advanced Processing and Custom Solutions

Custom wire drawing operations produce specific diameters not available in standard product lines. Precision annealing processes optimize mechanical properties for particular applications. These specialized processing steps require careful environmental control and handling procedures.

Alloy compositions containing zirconium additions improve certain performance characteristics. UNS R04251 reactor-grade niobium-zirconium alloys offer enhanced corrosion resistance for chemical processing applications. Proper handling of these alloy compositions requires understanding their unique properties and behavior.

Small batch production capabilities serve research institutions and prototype development projects. Universities conducting superconductor research often require custom wire configurations not available through standard commercial channels. Flexible manufacturing approaches accommodate these specialized requirements while maintaining quality standards.

Technical support services help customers optimize their handling procedures and application techniques. Experienced metallurgists provide guidance on material selection, processing parameters, and quality control measures. This expertise proves invaluable for customers developing new applications or improving existing processes.

Industry Trends and Summary

The niobium wire industry continues expanding as superconducting applications grow across multiple sectors. Quantum computing developments drive demand for ultra-high purity materials with exceptional consistency. Medical device innovation creates new opportunities for biocompatible niobium alloy applications. Proper handling procedures remain essential for maintaining material quality and ensuring safe working conditions throughout the supply chain.

Conclusion

Safe handling of high purity niobium wire requires a comprehensive understanding of material properties, environmental controls, and worker protection measures. Implementing proper procedures protects valuable material investments while ensuring personnel safety. Quality-focused suppliers like Chuanghui Daye provide the technical expertise and manufacturing capabilities necessary for demanding applications across aerospace, electronics, and medical device industries. Following established best practices ensures optimal material performance and project success.

FAQ

Q: What purity levels are available for niobium wire products?

A: High purity niobium wire is available in purities ranging from 99.9% to 99.99%, depending on the specific application requirements. Superconducting applications typically require the highest purity grades, while general industrial applications may use lower purity materials. Custom purity levels can be produced to meet specific customer requirements.

Q: How should niobium wire be stored to maintain its properties?

A: Niobium wire should be stored in dry, clean environments with stable temperatures. Ideally, storage occurs in inert gas atmospheres or vacuum conditions to prevent surface oxidation. Moisture-barrier packaging protects against humidity exposure during long-term storage periods.

Q: What safety precautions are necessary when machining niobium wire?

A: Machining operations require appropriate respiratory protection to prevent inhalation of metal particles. Use sharp, clean cutting tools to minimize work hardening effects. Proper ventilation and dust collection systems prevent the accumulation of metal particles in the work environment.

Partner with Chuanghui Daye for Premium Niobium Wire Solutions

Shaanxi Chuanghui Daye delivers exceptional quality niobium wire products backed by three decades of rare metal industry expertise. Our ISO 9001:2015 certified facility in China's "Titanium Capital" ensures consistent quality and reliable supply chains for global customers. Whether you need standard configurations or custom specifications, our experienced team provides technical support throughout your project development process. As a trusted high-purity niobium wire supplier, we maintain comprehensive inventory levels and offer competitive factory-direct pricing. Ready to discuss your specific requirements? Contact us at info@chdymetal.com for personalized technical consultation and quotations.