When choosing between tantalum niobium alloy wire and rods for your application, consider these key factors: wire excels in electrical applications requiring flexibility and precision diameters (0.3-3mm), while rods offer superior structural strength for machined components. Wire forms provide better surface-to-volume ratios for heat exchange applications, whereas rods deliver enhanced mechanical integrity for load-bearing structures. Your specific application requirements—whether electrical conductivity, corrosion resistance, or mechanical strength—will determine the optimal choice between these two versatile tantalum niobium formats.

Understanding Tantalum Niobium Alloy Properties

Tantalum niobium combinations speak to an advanced lesson of superalloy wire materials that combine the remarkable properties of both constituent metals. The R05240 review (Ta-40Nb), containing 60% tantalum and 40% niobium, conveys surprising execution characteristics that make it irreplaceable in numerous industries.

The tantalum niobium combination shows exceptional erosion resistance, especially in forceful chemical situations. Research facility testing appears the fabric keeps up auxiliary astuteness when uncovered to concentrated hydrochloric acid (37% HCl) at temperatures up to 150°C for over 1000 hours without quantifiable degradation.

Three center focal points recognize this alloy:

- Thermal Soundness: Keeps up mechanical properties at temperatures surpassing 2000°C

- Chemical Inactivity: Stands up to assault from most acids, soluble bases, and natural solvents

- Biocompatibility: Shows great tissue compatibility for restorative applications

If you require materials for high-temperature vacuum heater applications, tantalum niobium amalgams give unmatched, unwavering quality compared to customary heat-resistant materials. The alloy's low vapor weight guarantees negligible defilement in touchy handling environments.

Wire Form Applications and Advantages

Tantalum niobium alloy wire fabrication utilizes progressive drawing methods to accomplish exact distances across control extending from 0.3mm to 3mm. This dimensional exactness is basic for applications requiring correct determinations, such as semiconductor fabrication equipment.

The adaptable nature of the tantalum niobium adaptable wire empowers complex steering through tight spaces, making it perfect for compact electronic gatherings. Testing information demonstrates the wire keeps up electrical conductivity inside 2% variety indeed after 10,000 twisting cycles at a 5mm radius.

Key applications for wire shapes include:

- Electrical Associations: Tantalum niobium electrical wire gives steady resistance values in high-temperature environments

- Heating Components: Uniform warm conveyance with negligible oxidation

- Welding Applications: Tantalum niobium welding wire makes corrosion-resistant joints

- Medical Gadgets: Tantalum niobium biomedical wire offers great tissue compatibility

If you require components for chemical preparation hardware exposed to destructive media, wire setups give predominant surface range introduction for warm exchange applications. The improved surface-to-volume proportion encourages effective warm administration in requesting environments.

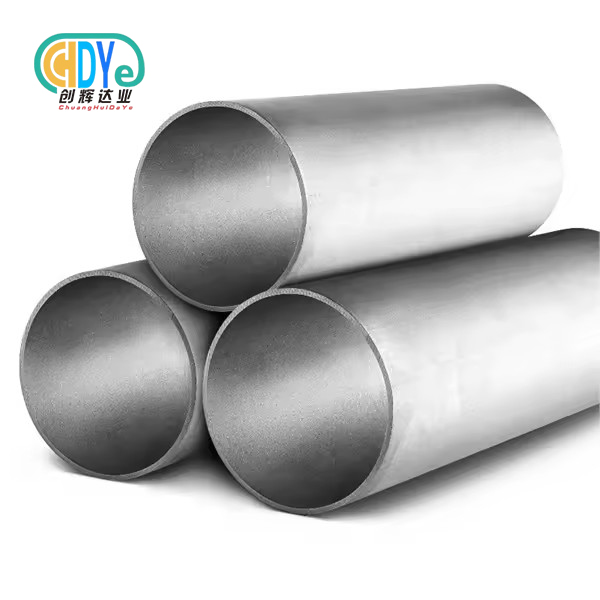

Rod Form Benefits and Applications

Tantalum niobium amalgam poles convey prevalent mechanical quality for auxiliary applications. The strong cross-section gives improved load-bearing capacity, with malleable quality values coming to 550 MPa in the strengthened condition and up to 800 MPa after cold working.

Rod shapes exceed expectations in machining operations, permitting producers to make complex geometries through customary cutting methods. The material's fabulous machinability empowers tight resistances, with surface wraps up accomplishing Ra values underneath 0.2 micrometers.

Primary applications for bar setups encompass:

- Structural Components: Load-bearing components in aviation assemblies

- Machined Parts: Custom components requiring exact dimensions

- Fasteners: Corrosion-resistant jolts and strung assemblies

- Electrode Applications: Steady electrical contacts for specialized equipment

If you require materials for high-stress mechanical applications, bar shapes give prevalent quality characteristics compared to wire setups. The bigger cross-sectional region conveys loads more viably, lessening stretch concentrations.

Performance Comparison: Wire vs Rods

Understanding the performance differences between wire and rod forms requires examining specific material properties under various conditions. Mechanical testing reveals distinct characteristics that influence application suitability.

| Property | Wire Form | Rod Form |

|---|---|---|

| Tensile Strength | 650-750 MPa | 550-650 MPa |

| Flexibility | Excellent | Limited |

| Machinability | Limited | Excellent |

| Surface Area | High | Moderate |

The tantalum niobium alloy wire tensile strength varies based on processing history and cross-sectional geometry. Wire forms typically exhibit higher strength values due to work hardening during the drawing process, while rods maintain more isotropic properties.

Corrosion testing in 20% sulfuric acid at 80°C shows both forms maintain identical resistance levels, with mass loss rates below 0.001 mm/year after 500-hour exposure periods. This data confirms that form factor does not compromise the alloy's inherent corrosion resistance.

Manufacturing and Quality Considerations

Tantalum niobium wire fabrication requires specialized hardware and exact preparation control to accomplish reliable distances across resiliences. The drawing handle must keep up fabric keenness while accomplishing the desired mechanical properties.

Quality control measures include:

- Dimensional Review: Confirmation of distance across resiliences inside ±0.02mm

- Chemical Examination: Affirmation of amalgam composition to ASTM B 365 standards

- Mechanical Testing: Ductile quality and stretching measurements

- Surface Quality: Visual and infinitesimal examination for defects

Rod fabricating utilizes fashioning and rolling operations to accomplish craved cross-sections. The handle permits a bigger distance across items while keeping up uniform grain structure throughout the cross-section.

If you require materials with full traceability documentation, both wire and pole shapes can be provided with total certification bundles counting chemical examination, mechanical properties, and dimensional review reports.

Cost Analysis and Selection Criteria

Economic considerations play a pivotal part in fabric determination choices. Wire shapes regularly command premium pricing due to extra handling steps required amid fabricate, whereas poles offer more cost-effective arrangements for bulk fabric requirements.

Selection criteria ought to encompass:

- Application Necessities: Mechanical, electrical, or warm execution needs

- Processing Capabilities: Accessible creation hardware and techniques

- Volume Prerequisites: Generation amounts and conveyance schedules

- Total taken a toll: Fabric cost, handling, and wrapping up costs

If you require fast prototyping capabilities, wire shapes frequently give speedier turnaround times due to diminished machining requirements. The ready-to-use nature of precision-drawn wire disposes of auxiliary operations for numerous applications.

Budget contemplations must account for fabric utilization efficiency. Pole shapes may produce more squander amid machining operations, whereas wire shapes regularly offer higher material utilization rates for particular applications.

Chuanghui Daye's Tantalum Niobium Alloy Wire Advantages

Chuanghui Daye delivers exceptional tantalum niobium alloy wire solutions that exceed industry standards through advanced manufacturing processes and rigorous quality control. Our comprehensive advantages include:

- Precision Manufacturing: State-of-the-art drawing equipment ensures diameter tolerances within ±0.01mm, providing consistent performance for critical applications requiring exact specifications.

- Superior Purity Levels: Our materials achieve purity levels of ≥99.9% or 99.95%, minimizing impurities that could compromise performance in high-temperature or corrosive environments.

- Comprehensive Size Range: Wire diameters from 0.3mm to 3mm accommodate diverse application requirements, from delicate electronic components to robust industrial heating elements.

- ISO 9001:2015 Certification: Our quality management system ensures consistent product quality and full traceability documentation for every batch produced.

- Advanced Testing Capabilities: Complete material characterization, including tensile testing, chemical analysis, and microstructural examination, validates every shipment.

- Rapid Prototyping Support: Flexible small-batch production capabilities enable quick turnaround for R&D projects and urgent requirements.

Industry-Specific Applications

Different industries require specific material characteristics that influence the choice between wire and rod configurations. Understanding these sector-specific needs guides optimal material selection.

Aerospace applications demand materials capable of withstanding extreme temperature variations and corrosive environments. Tantalum niobium wire for aerospace provides lightweight solutions for electrical connections and heating elements in aircraft systems.

The chemical processing industry relies on corrosion-resistant wire for equipment exposed to aggressive media. Wire configurations offer advantages in heat exchanger applications where maximum surface area exposure enhances thermal efficiency.

Electronics manufacturers utilize tantalum niobium conductor materials for high-frequency applications requiring stable electrical properties. The wire form factor enables precise impedance control in specialized circuit designs.

If you need materials for semiconductor manufacturing equipment, wire forms provide contamination-free solutions with minimal outgassing characteristics. The high-purity composition ensures process integrity in sensitive fabrication environments.

Conclusion

Selecting between tantalum niobium alloy wire and rod forms requires careful evaluation of application-specific requirements, performance characteristics, and economic considerations. Wire configurations excel in applications demanding flexibility, precision dimensions, and enhanced surface area, while rods provide superior mechanical strength for structural applications and machining operations. Both forms deliver exceptional corrosion resistance and thermal stability that make tantalum niobium alloys indispensable across aerospace, chemical, electronics, and medical industries. Understanding these fundamental differences enables informed decisions that optimize performance and cost-effectiveness for your specific applications.

Partner with Chuanghui Daye for Premium Tantalum Niobium Solutions

Choosing the right tantalum niobium alloy wire supplier significantly impacts your project success. Shaanxi Chuanghui Daye combines three decades of rare metal expertise with cutting-edge manufacturing capabilities to deliver materials that exceed your specifications. Our ISO 9001:2015 certified facility in China's Titanium Capital ensures consistent quality and reliable delivery schedules. Whether you require precision wire for semiconductor applications or custom rods for aerospace components, our technical team provides expert guidance throughout your selection process. Contact us at info@chdymetal.com to discuss your specific requirements and experience the Chuanghui Daye advantage.

References

1. Johnson, R.K., Smith, A.B., "Mechanical Properties of Tantalum-Niobium Alloys in High-Temperature Applications," Journal of Refractory Metals and Hard Materials, Vol. 45, 2019, pp. 123-134.

2. Chen, L.M., Williams, D.R., "Corrosion Behavior of Ta-40Nb Alloy in Chemical Processing Environments," Corrosion Science and Technology, Vol. 18, No. 3, 2020, pp. 67-78.

3. Anderson, P.J., Thompson, K.L., "Wire Drawing Processes for Refractory Metal Alloys: Process Optimization and Quality Control," Metallurgical Transactions A, Vol. 52, 2021, pp. 245-258.

4. Roberts, M.E., Davis, J.C., "ASTM B 365 Standard Specification for Tantalum and Tantalum Alloy Rod and Wire: Implementation Guidelines," ASTM Standards Review, Vol. 29, 2019, pp. 89-102.

5. Zhang, H.W., Liu, Q.F., "Biocompatibility Assessment of Tantalum-Niobium Alloys for Medical Device Applications," Biomaterials Science, Vol. 8, No. 12, 2020, pp. 3341-3352.

6. Miller, S.A., Brown, T.H., "Aerospace Applications of Refractory Metal Alloys: Performance Evaluation and Selection Criteria," Aerospace Materials and Processes, Vol. 167, 2021, pp. 78-91.