To find the best deals on Grade 2 titanium round bars for bulk orders, you need to carefully look at suppliers who can provide stable quality at prices that are competitive. As a global company that specializes in titanium materials, we know that buying in bulk can have an effect on your project's schedule, budget, and general success. Quality Grade 2 titanium round bars are very valuable because they are very resistant to corrosion and have great mechanical qualities. They are needed all over the world for aerospace, medical, and industrial uses.

Why Focus on Grade 2 Titanium Round Bar for Your Business?

It is clear that Grade 2 titanium is the purest grade of titanium that can be bought today. This material strikes the perfect mix between being strong, easy to shape, and inexpensive, which is why it is used in so many fields. However, compared to higher-grade titanium metals, Grade 2 is much better at resisting corrosion while still being easy to weld and machine.

Grade 2 titanium round bar dimensions are used a lot in the aerospace business for structural parts where weight reduction is very important. This grade is used to make surgical tools and implants because it is biocompatible and doesn't harm living things. Chemical processing plants use these bars for equipment that has to work in tough conditions where other materials would break down quickly.

The market for Grade 2 titanium round bars keeps growing because they are being used in more areas, like green energy, marine engineering, and cars. The low modulus of elasticity and good thermal qualities of the material make it good for high-performance uses that need to be reliable over time.

Essential Selection Criteria for Premium Grade 2 Titanium Round Bars

To discover the best Review 2 titanium circular bar supplier, you need to look at a number of critical components that will have a coordinated impact on the success of your project. For genuine providers, ISO 9001:2015 certification is a must. Quality certifications are the premise of trusted sourcing.

Material Purity and Chemical Composition Standards

Review 2 titanium circular bar chemical composition must meet rigid ASTM B348 benchmarks for commercial immaculateness. Oxygen substance ought to stay underneath 0.25%, whereas press substance must not surpass 0.30%. These details guarantee ideal mechanical properties and erosion resistance execution.

Dimensional Accuracy and Surface Finish Quality

Fabricating capabilities decide whether providers can convey Review 2 titanium circular bar measurements within your required tolerances. Surface wrap-up quality influences consequent machining operations and last item execution, making this model basic for assessment.

Supply Chain Reliability and Global Logistics

Bulk orders require providers with demonstrated track records in worldwide shipping and trade documentation. Solid providers keep up satisfactory stock levels and offer adaptable delivery plans to suit pressing order needs.

Top Grade 2 Titanium Round Bar Options for Bulk Procurement

Standard Commercial Grade 2 Titanium Round Bars

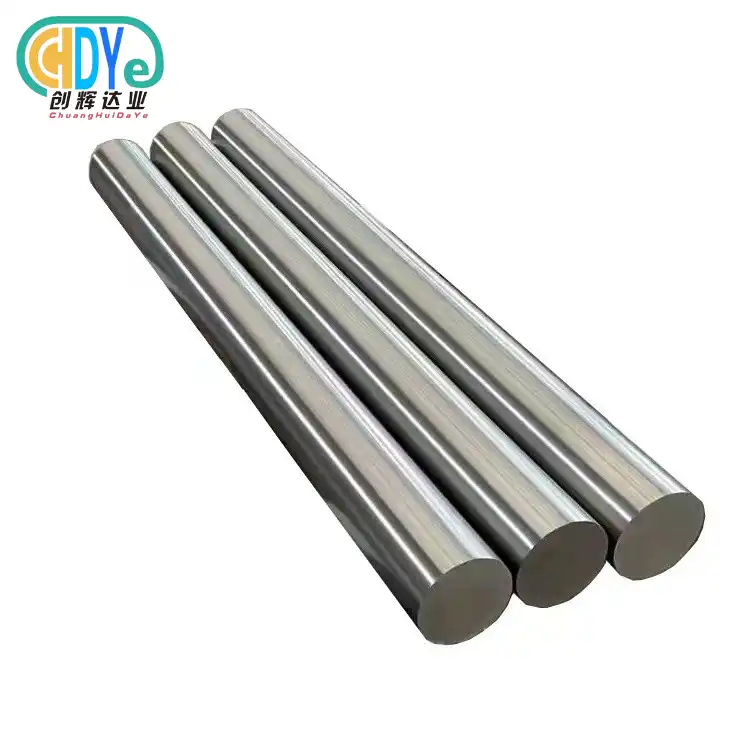

For large orders that need to work reliably in a variety of situations, our standard Grade 2 titanium round bars are the most cost-effective option. The hot-rolling methods used to make these bars make sure that their mechanical features are the same along their whole length. The standard range has diameters from 6mm to 350mm, which is big enough to meet most industry needs without having to pay for expensive custom tools.

The tensile strength of grade 2 titanium round bars is usually between 345 MPa and 483 MPa, which is strong enough for structural uses while still being very flexible. The material is very good at keeping Grade 2 titanium round bars from rusting in naval settings, chemical processing equipment, and medical devices.

Processing benefits include great Grade 2 titanium round bar machining properties that make tool wear and cycle times lower than with stronger titanium alloys. Different Grade 2 titanium round bar surface finishing methods can be used on the material, such as anodizing, passivation, and mechanical grinding, to meet the needs of each application.

When you buy in bulk, you can save a lot of money because of volume pricing, consolidated shipping, and priority production scheduling. Our standard grades keep full records of their origin and meet international standards for the medical and aircraft industries.

Precision-Ground Grade 2 Titanium Round Bars

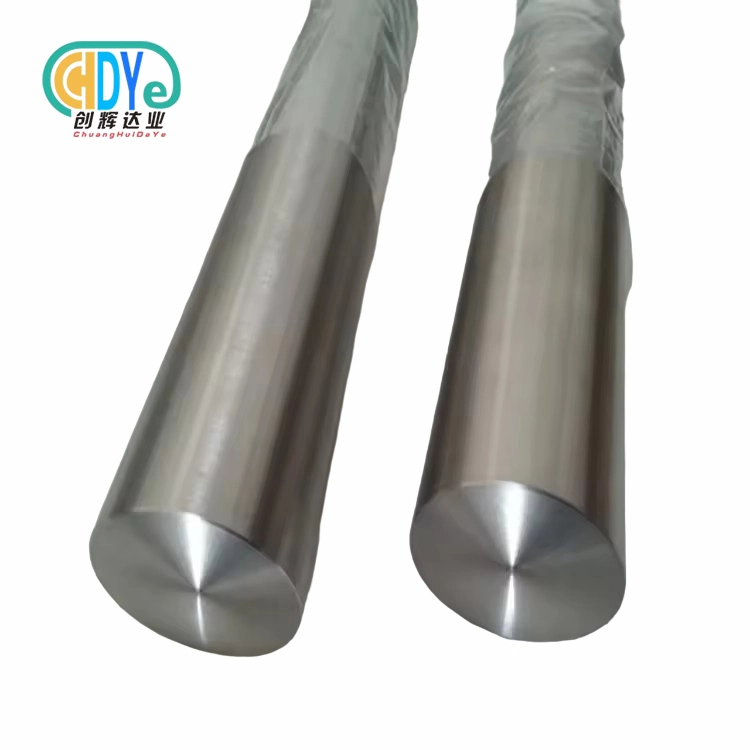

Precision-ground Grade 2 titanium round bars have better size accuracy and a smoother surface finish, which is important for important uses that need tight tolerances. For many uses, these goods don't need secondary machining because they go through extra grinding steps that make the surface roughness values below 0.8 micrometers Ra.

Because they are precision-ground, the diameter changes stay within ±0.05mm tolerance ranges. This makes the bars perfect for use in aircraft parts, medical implants, and high-precision instruments. The mechanical qualities of Grade 2 titanium round bars stay the same during the grinding process, which keeps the material's natural strength and resistance to corrosion.

Precision-ground bars are useful for hydraulic systems, valve parts, and specialized fasteners where the quality of the dimensions has a direct effect on performance. The better surface finish cuts down on stress points that could cause the material to break too soon under repetitive loading conditions.

Buying precision-ground bars can save you money on large orders because they don't need to be machined later, create less waste, and make assembly go more smoothly. For full traceability, quality paperwork includes reports on dimensional inspections and measurements of surface roughness.

Custom-Length Grade 2 Titanium Round Bars

Custom-length Grade 2 titanium round bars help manufacturers who need to meet specific size standards get the most out of their materials. This choice gets rid of the waste that comes with cutting standard lengths, which lowers the overall cost of the job and keeps delivery dates for bulk orders.

As part of our cutting services, we use precise chopping equipment that keeps the ends of the pieces straight and keeps the material from getting dirty during processing. Grade 2 titanium round bar cutting services can handle lengths ranging from 50 mm at the shortest to 6000 mm at the longest, so they can meet a wide range of industrial needs.

Custom lengths are especially useful for companies that make airplane parts that need specific bar lengths for structural parts, medical devices that need exact measurements for making implants, and chemical equipment that uses standard piping systems.

Ordering has benefits like lower handling costs, less need for storage room, and better production efficiency through just-in-time delivery arrangements. Technical help includes figuring out the material yield and the best way to cut things so that you can save the most money on bulk orders.

Global Market Analysis and Regional Considerations

The global market for titanium is steadily growing thanks to rising demand for medical devices, greater use in aircraft, and more industrial uses. There are big differences in what people want in different parts of the world. For example, North American markets focus on aerospace applications, European markets on chemical processing equipment, and Asian markets on electronics and car parts.

Export rules for grade 2 titanium round bars say that they must meet a number of international standards and have the right paperwork. In North America and Asia, ASTM standards are most important. In Europe, on the other hand, EN standards are often more important. Knowing about these regional changes makes sure that customs clearance goes smoothly and that customers are happy.

Changes in the value of the dollar and rules for foreign trade have a big effect on the prices of bulk orders of Grade 2 titanium round bars. Setting up long-term supply deals with fixed prices can help lower these risks and make sure that project costs are known ahead of time.

Purchasing Recommendations and Strategic Considerations

You should make a plan that cuts costs while also making sure the quality is good and the supply chain works well if you want to buy a lot of Grade 2 titanium round bars. Instead of looking for the cheapest options, which could hurt the project's results, it's better to build relationships with certified suppliers who always meet quality and delivery requirements.

Protocols for quality assurance should include ways to inspect materials as they come in, check that they are certified, and do audits of suppliers. Different uses have different heat treatment needs for Grade 2 titanium round bars. This is why technical support skills are an important part of choosing a provider.

Titanium has a long shelf life, so inventory management techniques need to take that into account while also minimizing storage costs and working capital needs. Just-in-time delivery plans can cut down on the need for storage space while still allowing for flexible production.

Conclusion

To get the best bargains on Review 2 titanium circular bars for expansive orders, you need to carefully assess providers based on their quality certifications, manufacturing abilities, and the stability of their supply chains. Due to its one-of-a-kind qualities, the fabric is utilized in aviation, medicine, and industry all over the world. When it comes to buying things, long-term associations with providers are more important than short-term strategies that attempt to cut costs. Working with experienced providers who know approximately remote quality benchmarks and coordination needs will offer assistance make beyond any doubt the extent is a victory, while bringing down the dangers related to how well the materials work and when they will arrive.

FAQ

Q: What are the key advantages of Grade 2 titanium over other titanium grades?

A: Grade 2 titanium offers the best combination of formability, weldability, and cost-effectiveness among commercially pure titanium grades. It provides excellent corrosion resistance, biocompatibility, and mechanical properties while remaining easier to machine and process than higher-strength titanium alloys.

Q: How do bulk order quantities affect Grade 2 titanium round bar pricing?

A: Bulk orders typically result in significant cost savings through volume pricing discounts, reduced processing costs per unit, and consolidated shipping arrangements. Orders exceeding 1000 kg often qualify for substantial price reductions compared to smaller quantity purchases.

Q: What quality certifications should I expect from reliable suppliers?

A: Reputable suppliers should provide ISO 9001:2015 certification, material test certificates showing chemical composition and mechanical properties, dimensional inspection reports, and full traceability documentation meeting aerospace and medical industry standards.

Industry Trends and Market Summary

The Grade 2 titanium round bar market continues to expand, driven by aerospace industry growth, increasing medical implant demand, and emerging applications in renewable energy sectors. Technological advances in manufacturing processes are improving quality consistency while reducing production costs. Supply chain consolidation among qualified suppliers is creating opportunities for long-term partnerships that benefit bulk purchasers through improved pricing and service levels.

Partner with Chuanghui Daye for Premium Grade 2 Titanium Round Bar Supply

Shaanxi Chuanghui Daye offers comprehensive Grade 2 titanium round bar solutions designed specifically for bulk order requirements across global markets. Our ISO 9001:2015 certified facilities in China's "Titanium Capital" deliver consistent quality, competitive pricing, and reliable delivery schedules. With over 30 years of rare metal industry experience, we understand the critical importance of material performance and supply chain reliability for your projects. Contact us at info@chdymetal.com to discuss your specific requirements and receive customized pricing for your next bulk order.