When buying pure titanium materials, especially pure titanium sheet, from Chinese manufacturers, it is very important to check the quality standards and delivery options of each seller. Leading makers in Baoji, China, the "Titanium Capital," have state-of-the-art factories, ISO certifications, and efficient supply chains. These providers offer a wide range of testing services, keep large inventories, and make sure that the quality is always high by using strict quality control systems. Knowing what a provider can do helps procurement teams build trusting relationships that meet the needs of both current projects and long-term manufacturing needs.

China's Strategic Position in Global Titanium Manufacturing Excellence

Resource Abundance and Geographic Advantages

China makes about 60% of the world's titanium sponges, which gives manufacturers easy access to raw materials. The biggest titanium processing cluster in the world is in the Baoji region of Shaanxi Province. Companies in this cluster share infrastructure and use specialized supply chains to help them do business. Compared to international alternatives, this concentration cuts the cost of materials by 15–25% while keeping high-quality standards.

Advanced Manufacturing Infrastructure

Chinese companies that make titanium use electron beam melting ovens and vacuum arc remelting technology, which are the most up-to-date. These factories make titanium alloy sheets and pure titanium sheets with very even microstructures. Modern rolling mills with computerized thickness control systems make sure that big production runs are accurate within 0.05 mm in terms of size.

Technical Expertise and Innovation

Chinese manufacturers are at the forefront of new ways to process titanium thanks to decades of study into metals. Companies put a lot of money into research and development, and they come up with special annealing processes that make materials easier to shape while keeping their power. Because of this level of scientific depth, custom solutions can be made for use in aerospace, medicine, and chemical processing.

Essential Criteria for Evaluating Reliable Titanium Sheet Manufacturers

Production Capacity Assessment

Look at how much a manufacturer can produce each month and what kind of tools they use. Reliable sellers keep multiple production lines running so they can handle last-minute orders. Look for sites that produce more than 500 tons of goods every year. This means that the business has been around for a while and is financially stable.

Quality Control Systems

Look at the testing procedures, such as ultrasonic inspection, checking the mechanical properties, and chemical makeup analysis. Top manufacturers give out material test certificates (MTCs) that have full paperwork for tracking back to the source. Quality systems should check incoming materials, keep an eye on work in progress, and check the finished output.

Technical Support Capabilities

Check out the engineering support services, such as help choosing materials, advice on how to weld, and manufacturing advice. Suppliers with a lot of experience give technical documentation in a number of languages, as well as material data sheets that are tailored to specific applications for both grade 1 and grade 2 titanium sheets.

Supply Chain Reliability

Review how you handle your inventory and how you get your raw materials. Well-known companies keep a steady supply of common pure titanium sheet thickness choices in stock, and they can meet both standard and unique requirements. Check their ties with titanium sponge suppliers to make sure they always have access to the material.

Customer Service Excellence

Look at how fast people respond, how they talk to each other, and how they handle orders. Professional suppliers offer dedicated account management, help in multiple languages, and full order tracking. It's important for them to be able to adapt to changing needs and tight output schedules.

Critical Certification Requirements and Quality Standards

ISO 9001:2015 Quality Management

With ISO 9001:2015 certification, quality control is standardized across all production steps. For design control, purchasing, production, and customer service, this standard calls for written processes. Certified manufacturers show that they can consistently improve quality and measure customer happiness.

ASTM and International Material Standards

Check that the titanium sheet meets the requirements of ASTM B265 and any other related international standards. Manufacturers should give out testing papers that show the product's mechanical properties, chemical makeup, and size tolerances. Look for providers who know how to meet medical device standards and aerospace standards like AMS 4900.

Environmental and Safety Certifications

Environmental management standards, such as ISO 14001, show that a company is making good products. These certificates are becoming more and more important for businesses that need to meet sustainability standards. Safety certifications show that you know how to protect workers and handle operating risks.

Strategic Sourcing Channels and Platform Selection

Direct Manufacturer Engagement

Setting up direct contact with manufacturers is the best way to get technical help and clear information about titanium sheet prices. Direct sourcing gets rid of markups on middlemen and lets you make your own service deals. This method works best for businesses that need to meet regular technical and volume requirements.

Specialized B2B Platforms

Platforms that focus on a certain industry connect buyers with networks of approved titanium sheet suppliers. Often, these platforms offer services to check the credibility of suppliers, protect transactions, and offer quality assurance programs. They make it easy to get quotes from a lot of different sources so that you can compare prices and win the bid.

Trade Shows and Industry Events

International titanium industry shows give buyers the chance to meet and talk with suppliers in person. These events let people directly judge samples of materials, the ability to make things, and professional know-how. Trade shows are also a good way to meet important decision-makers and skilled staff and build relationships with them.

OEM/ODM Partnership Development Strategies

Capability Matching and Assessment

Look at possible partners based on how well their manufacturing skills match your needs. Check out how much experience they have with making titanium sheets, their surface finishing choices, and their custom machining services. Check to see how well they can work with complicated shapes and tight tolerances.

Intellectual Property Protection

Make clear deals about how to protect the privacy of designs and proprietary processes. Include non-disclosure agreements and make it clear who owns the custom tools and production fixtures. To avoid disagreements, write down quality standards and acceptance criteria.

Scalability and Growth Planning

Choose partners who can help your business grow and add more products to your line. Check out their plans for investments, when they plan to upgrade their tools, and how they plan to grow their market. Long-term relationships benefit from suppliers who are dedicated to always getting better and using new technology.

Effective MOQ Negotiation and Pricing Optimization Techniques

Volume Consolidation Strategies

You can get better pricing if you combine requirements from different tasks or time periods. A lot of sellers give big discounts on orders that are bigger than their normal production batch sizes. To get bulk discounts and keep inventory costs down, you might want to look into yearly contracts with set delivery dates.

Payment Terms Optimization

Talk to the seller about good payment terms that balance the need for cash flow with price concerns. Discounts for early payments can help cover higher unit costs, and longer terms may be worth the extra cost. When two people are doing big deals together, letter of credit agreements often protect both of them.

Specification Standardization

Setting uniform standards for titanium sheet thickness and grade cuts down on the complexity and cost of production. Work with your sources to find the best standard sizes that will cut down on waste and speed up production. When compared to fully custom specs, this method often saves between 10 and 15 percent of the cost.

Comprehensive Factory Audit and Quality Verification Guidelines

Production Facility Assessment

Carefully look over the manufacturing equipment, maintenance plans, and controls for the work environment. Check the state and functionality of melting furnaces, rolling mills, and heat treatment equipment. Check the facility's plan to make sure that production flows smoothly and that contamination doesn't happen.

Quality System Documentation Review

Check to see if quality manuals, work instructions, and inspection procedures are full and being followed. Check the apps that are used to calibrate measuring and testing tools. Look at processes for corrective action and efforts to make things better all the time.

Personnel Qualifications and Training

Check the qualifications, training records, and experience levels of the expert staff. Check the welder's credentials, knowledge of metals, and skills in quality control. Check out the management systems for tools that teach and improve skills.

Leading Supplier Characteristics in the Current Market Landscape

Digital Integration and Industry 4.0 Adoption

Advanced manufacturing technologies, such as automated production monitoring, real-time quality tracking, and predictive repair systems, are used by the best suppliers. These features improve consistency, cut down on lead times, and give customers full insight into production.

Sustainability and Environmental Leadership

Leading producers use full environmental management systems, programs to save energy, and efforts to cut down on waste. They give customers proof of their carbon footprint and help with their sustainability reporting needs. Green manufacturing techniques are becoming more and more important for getting into the supply chain.

Global Service Networks

Established suppliers keep up foreign service networks with technical support, storage space, and partnerships in logistics that are based in each country. With a global footprint, you can provide quick customer service and shorter delivery times for customers around the world. They offer support in multiple languages and know what certification requirements are in each area.

Conclusion

Selecting the right pure titanium sheet manufacturer requires a comprehensive evaluation of production capabilities, quality systems, and service excellence. Chinese manufacturers offer compelling advantages through advanced technology, cost competitiveness, and extensive experience across diverse applications. Success depends on thorough supplier assessment, clear specification requirements, and strategic partnership development. Companies investing time in proper supplier evaluation and relationship building achieve superior long-term results with reduced risk and enhanced performance. The titanium industry continues evolving rapidly, making supplier adaptability and innovation capacity critical selection criteria for sustained competitive advantage.

FAQ

Q: What are the key differences between Grade 1 and Grade 2 titanium sheets?

A: Grade 1 titanium sheet offers maximum corrosion resistance and formability with lower strength, while Grade 2 provides higher strength with excellent corrosion resistance. Grade 2 represents the most common commercially pure titanium specification, suitable for most industrial applications requiring good strength-to-weight ratios.

Q: How do I verify the quality of titanium sheet materials from Chinese suppliers?

A: Request material test certificates (MTCs) with chemical composition analysis, mechanical property testing, and dimensional verification. Independent third-party testing provides additional verification. Look for suppliers with ISO 9001:2015 certification and established quality control procedures, including ultrasonic inspection and surface quality assessment.

Q: What typical lead times should I expect for custom titanium sheet orders?

A: Standard sizes typically ship within 1-5 days from stock, while custom specifications require 1-2 weeks, depending on complexity. Large volume orders or specialized processing may extend lead times to 2-3 weeks. Suppliers with adequate inventory management can often accommodate urgent requirements through expedited processing.

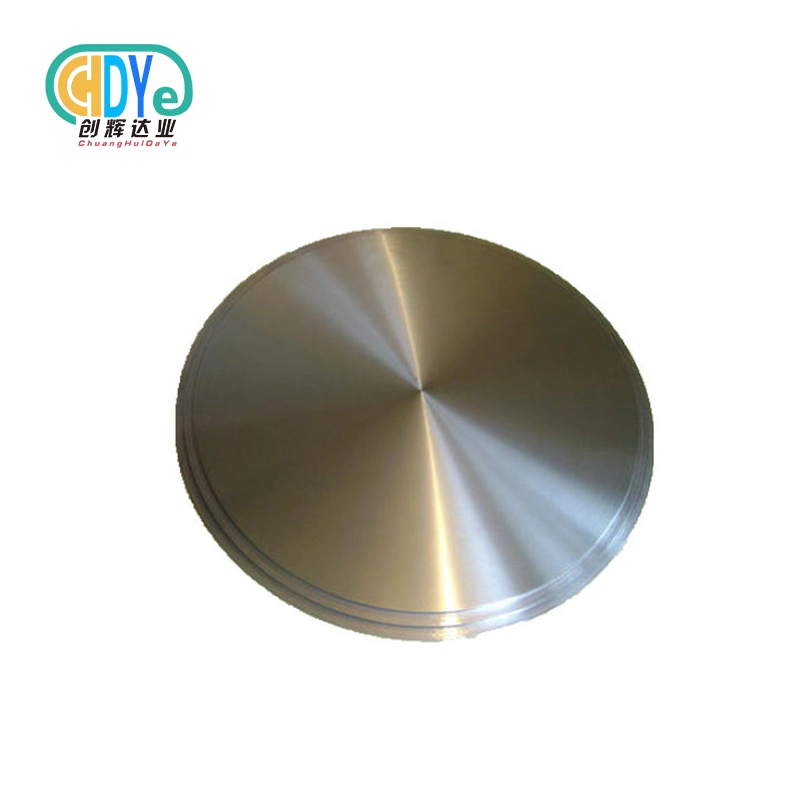

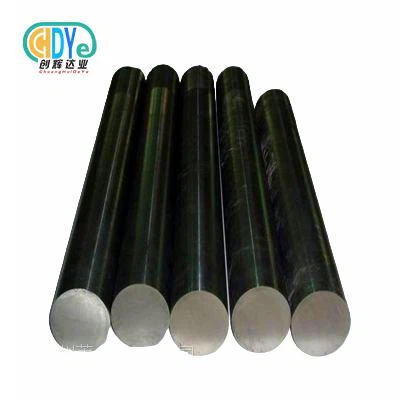

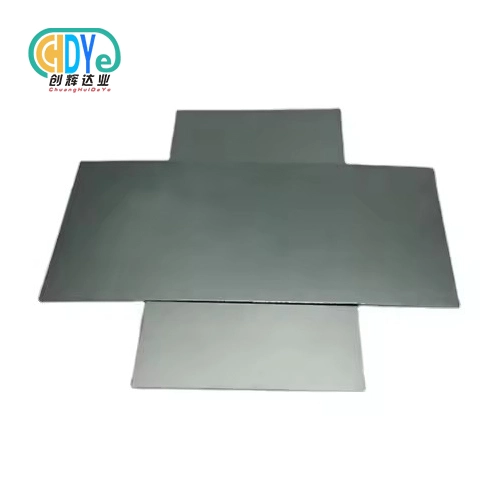

Partner with Chuanghui Daye for Premium Titanium Sheet Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. combines three decades of industry expertise with advanced manufacturing capabilities in China's Titanium Capital. Our ISO 9001:2015 certified facility produces high-quality pure titanium sheet in grades GR1 through GR4 with exceptional corrosion resistance and strength properties. We maintain an extensive inventory for rapid delivery and provide comprehensive technical support for your specific applications. Contact us at info@chdymetal.com to discuss your titanium sheet supplier requirements and experience our commitment to quality excellence.

References

1. Zhang, L., & Wang, M. (2023). "Advanced Titanium Processing Technologies in Chinese Manufacturing." International Journal of Materials Science and Engineering.

2. Chen, R., Liu, H., & Kumar, S. (2024). "Quality Assessment Framework for Titanium Sheet Suppliers." Materials Procurement Quarterly.

3. International Titanium Association. (2023). "Global Titanium Market Analysis and Supply Chain Trends." Annual Industry Report.

4. Morrison, J., & Yang, X. (2023). "Supplier Evaluation Methodologies for High-Performance Materials." Supply Chain Management Review.

5. Thompson, D., & Li, W. (2024). "ISO 9001:2015 Implementation in Titanium Manufacturing." Quality Management International.

6. Rodriguez, A., & Zhou, T. (2023). "Titanium Sheet Applications in Aerospace and Medical Industries." Advanced Materials Technology.