- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Buy Gr5 Titanium Wire (Ti-6Al-4V) – Aerospace & Medical Grade

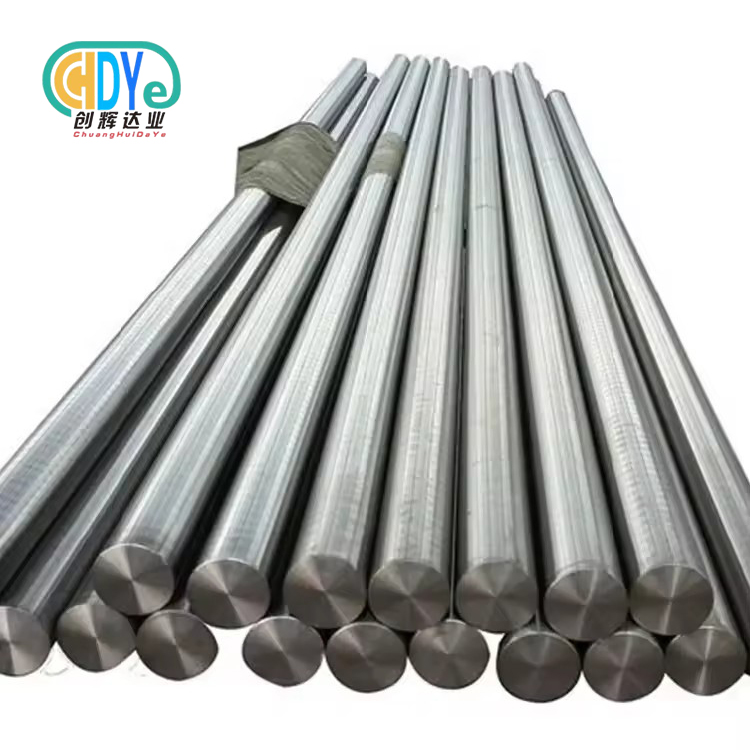

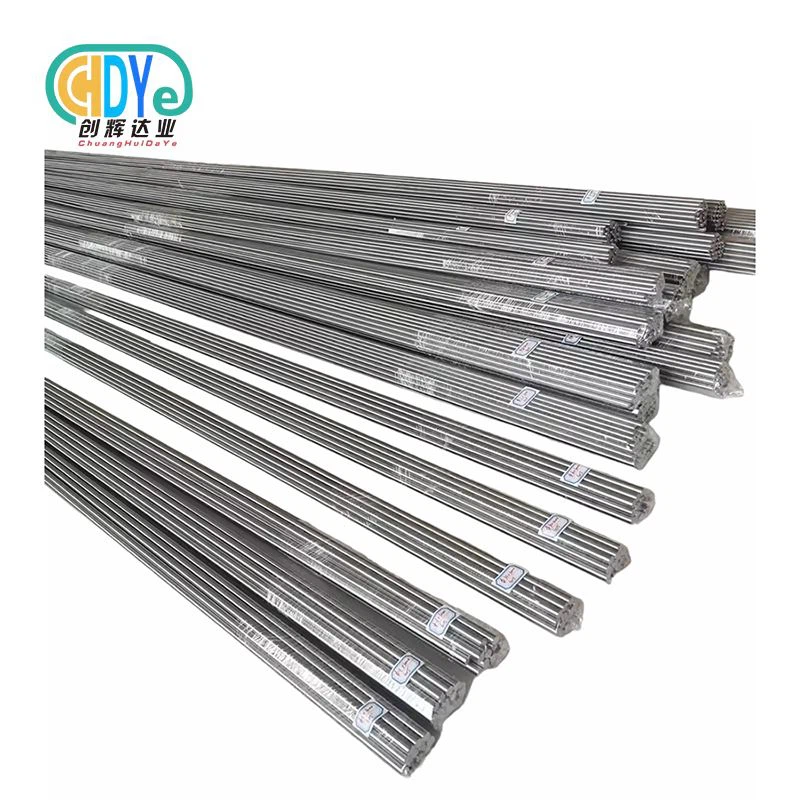

Gr5 Titanium Wire is the standard for aerospace and medical firms seeking superior titanium alloy materials for sensitive applications. This Ti-6Al-4V alloy wire is ideal for applications where material failure is not an option due to its high strength-to-weight ratio, corrosion resistance, and biocompatibility. This aerospace and medical-grade titanium wire performs consistently in the harshest settings in straight wire and coil configurations with diameters from 0.5mm to 6.0mm.

Understanding Gr5 Titanium Wire – Composition, Properties, and Benefits

Ti-6Al-4V's outstanding performance comes from its well balanced composition of 6% aluminum, 4% vanadium, and 90% pure titanium. Alpha-beta titanium alloys provide good mechanical characteristics and workability throughout industrial processes.

Chemical Composition and Microstructure

Aluminum strengthens and decreases density in this titanium alloy, while vanadium hardens and stabilizes at high temperatures. This creates a dual-phase microstructure with appropriate strength-ductility ratio. Heat treatment refines the alloy's microstructure, allowing manufacturers to customize qualities.

Mechanical Properties and Performance Characteristics

Ti-6Al-4V wire has unique mechanical properties compared to other titanium grades. The material has yield strengths of 870 MPa and tensile strengths over 925 MPa (135 ksi). Elongation characteristics frequently surpass 10%, suggesting good forming ductility. These mechanical properties are robust throughout a large temperature range, making the wire appropriate for thermal cycling.

The fatigue resistance of this titanium alloy wire is useful in aircraft applications where components are loaded repeatedly. Study shows that correctly made Ti-6Al-4V wire can resist millions of stress cycles without failure, ensuring aircraft system and medical implant reliability

Corrosion Resistance and Environmental Performance

A persistent, protective oxide layer on Ti-6Al-4V makes it corrosion-resistant. This natural passivation resists saltwater, most acids, and alkalinity well. The material's low compatibility with boiling sodium hydroxide solutions should be considered during application design.

Comparing Gr5 Titanium Wire with Other Grades and Materials

Knowing titanium grade performance differences helps choose materials. Each grade has advantages depending on use and operating conditions.

Gr5 vs. Gr2 Titanium Wire

Review 2 titanium speaks to commercially immaculate titanium with fabulous erosion resistance but lower quality compared to Ti-6Al-4V. Whereas Gr2 offers prevalent formability and lower fetched, its malleable quality ordinarily ranges from 345-480 MPa, essentially underneath Gr5's capabilities. This quality differential makes Gr5 the favored choice for basic applications requiring tall performance-to-weight ratios.

The temperature execution moreover varies considerably between these grades. Review 2 titanium starts losing quality at temperatures around 200°C, whereas Gr5 keeps up basic keenness at temperatures surpassing 400°C for amplified periods. This high-temperature steadiness demonstrates basic in aviation motor applications and chemical handling gear.

Comparison with Alternative Materials

Stainless steel wire, whereas advertising great erosion resistance and lower introductory taken a toll, carries essentially higher thickness than titanium amalgams. The weight punishment of stainless steel gets to be especially risky in aviation applications where each gram influences fuel effectiveness and execution. Furthermore, stainless steel's defenselessness to chloride-induced stretch erosion splitting limits its adequacy in marine environments.

Niobium wire presents amazing erosion resistance and biocompatibility but needs the quality characteristics of Ti-6Al-4V. The higher fetched and constrained accessibility of niobium moreover confine its utilize to specialized applications where its one of a kind properties legitimize the premium.

Industry Preferences and Certifications

Strength, weight savings, and durability make Gr5 titanium wire a favorite among aerospace makers for key components. The material fulfills AMS 4954 and ASTM B863 aerospace standards for quality and traceability. Ti-6Al-4V meets ASTM F136 biological requirements, thus implant and surgical device manufacturers favor it.

How Gr5 Titanium Wire is Manufactured and Quality Assured?

The generation of aviation and medical-grade titanium wire includes advanced fabricating forms planned to guarantee fabric consistency and dispense with abandons that may compromise execution.

Primary Manufacturing Stages

The manufacturing process begins with titanium sponge, aluminum, and vanadium feedstock vacuum arc remelting (VAR). This melting procedure is done under regulated ambient conditions to prevent contamination and assure alloy homogeneity. The ingots are remelted numerous times to ensure chemical homogeneity and eliminate segregation.

Forging and rolling use thermomechanical processes after melting. These steps improve microstructure and mechanical characteristics. For optimal material flow and grain structure, forging happens at 900-1000°C.

Wire Drawing and Final Processing

Wire drawing dies turn forged bar material into precise wire. The material is work-hardened and reduced in diameter by successive die passes. Intermediate annealing between drawing passes maintains workability and prevents strain building and cracking.

To prevent oxidation and maintain surface quality, vacuum annealing is the ultimate heat treatment in controlled atmospheres. This method reduces residual stresses and enhances microstructure for applications. Based on application and mechanical qualities, temperature and time are carefully controlled.

Quality Control Protocols

Comprehensive quality assurance methods ensure every titanium wire batch fulfills specs. Chemical analysis using XRF spectroscopy verifies alloy composition within tight tolerances. Performance attributes are confirmed by tensile, hardness, and fatigue testing.

Dimensional inspection checks diameter tolerances and surface polish with precise measurement equipment. Ultrasonic inspection and eddy current testing find interior faults that could affect performance. Each shipment includes material traceability documents for certifying quality records.

Buying Gr5 Titanium Wire – Procurement Considerations and Market Insights

Effective obtainment of Ti-6Al-4V wire requires understanding showcase elements, provider capabilities, and calculated contemplations that affect venture timelines and costs.

Supplier Evaluation and Selection Criteria

Quality management systems, particularly ISO 9001:2015, ensure reliable suppliers. Advanced melting equipment, controlled environment processing, and extensive testing should be available. Supplier audits ensure production and quality systems meet client needs.

Complex applications require technical help. Suppliers should offer metallurgical expertise, application advise, and bespoke processing to suit dimensional or property requirements. Engineering teams seek manufacturing flexibility that allows tiny prototypes and large production runs.

Pricing Structures and Market Factors

Raw material costs, production complexity, and market demand affect titanium wire prices. Discounts for annual contracts or large single orders are common with volume agreements. Understanding market cycles improves purchasing and cost management.

Custom dimensions and testing requirements cost more. However, crucial applications where ordinary items may not satisfy performance requirements frequently justify the expenditure. Early supplier involvement in design helps optimize specs and reduce costs.

Lead Times and Supply Chain Management

Standard diameter titanium wire takes 4-8 weeks, but bespoke specifications can take 12-16 weeks depending on processing. Project delays and expedited delivery can be avoided by scheduling procurement around these lead periods.

Shipping, customs clearance, and documentation are global supply chain considerations. To simplify foreign shipping, established suppliers have excellent logistical networks and complete export documents.

Company Introduction and Product & Service Information

Shaanxi Chuanghui Daye Metal Fabric Co., Ltd. brings over three decades of ability in uncommon metal fabricating to serve the worldwide aviation and restorative gadget businesses. Found in Baoji, China's famous "Titanium Capital," our office benefits from built up framework and nearness to crude fabric sources that empower competitive estimating without compromising quality.

Manufacturing Capabilities and Product Range

Our progressed fabricating office houses state-of-the-art gear counting electron pillar heaters, exactness rolling plants, and mechanized wire drawing lines. This comprehensive gear portfolio empowers total control over the generation prepare from crude fabric softening through last review and packaging.

The item extend includes Gr5 Titanium Wire in distances across from 0.5mm to 6.0mm, accessible in both straight lengths and coil setups. Custom length necessities get settlement based on client determinations and application needs. Test orders bolster client assessment and capability forms, illustrating our commitment to client victory.

Quality Systems and Certifications

ISO 9001:2015 certification shows our dedication to quality management across all company activities. The quality control process includes incoming material inspection, in-process monitoring, and final product verification to customer standards. Statistical process control ensures production quality and identifies improvements.

Raw material chemistry to final shipping is documented by material traceability systems. This paperwork facilitates client certification and ensures crucial application material pedigree.

Custom Processing and Technical Support

Specialized processing includes precise cutting, surface treatments, and custom packaging for customers. Engineering support services help customers choose materials, optimize applications, and solve problems during product development.

Our technical team works with customers to determine application needs and material specifications. This consulting approach optimizes cost and performance while providing customers with materials that meet their needs.

Conclusion

Gr5 Titanium Wire speaks to the ideal choice for aviation and restorative applications requiring uncommon strength-to-weight proportions, erosion resistance, and biocompatibility. The material's demonstrated execution in basic applications, combined with comprehensive fabricating capabilities and quality confirmation conventions, gives clients with certainty in fabric unwavering quality and consistency. Understanding the composition, properties, and fabricating forms empowers educated obtainment choices that optimize both execution and fetched contemplations for requesting applications.

FAQ

Q: What makes Ti-6Al-4V suitable for both aerospace and medical applications?

A: The unique combination of high strength, excellent biocompatibility, and corrosion resistance makes this titanium alloy ideal for both industries. Its strength-to-weight ratio exceeds most alternatives while maintaining compatibility with human tissue, meeting the stringent requirements of both aerospace engineering and medical device manufacturing.

Q: How does the pricing of Ti-6Al-4V wire compare to other materials?

A: While titanium wire commands premium pricing compared to stainless steel or aluminum, the performance benefits often justify the investment. The weight savings in aerospace applications and long-term biocompatibility in medical devices provide value that exceeds the initial material cost difference.

Q: What customization options are available for specific applications?

A: Manufacturers can provide custom diameters, special length cuts, and enhanced surface finishes to meet application requirements. Mechanical property modifications through heat treatment and special packaging for contamination-sensitive applications are also available through qualified suppliers.

Q: What quality certifications should buyers expect?

A: Reputable suppliers provide materials meeting ASTM B863 for wire products and ASTM F136 for medical applications. ISO 9001:2015 quality system certification and complete material traceability documentation should accompany every shipment to ensure compliance with industry standards.

Call to Action – Start Your Gr5 Titanium Wire Inquiry Today

Shaanxi Chuanghui Daye stands ready to support your titanium wire requirements with comprehensive technical expertise and reliable supply capabilities. Our experienced team provides personalized quotations, bulk pricing options, and engineering support tailored to your specific project needs. As a trusted Gr5 Titanium Wire manufacturer with over 30 years of industry experience, we deliver consistent quality and responsive service to customers worldwide.

Contact our technical sales team at info@chdymetal.com to discuss your requirements and receive detailed specifications for your applications. Whether you need prototype quantities for product development or large-scale production supplies, our flexible manufacturing capabilities and competitive pricing structures support your success in aerospace, medical, and industrial markets.

References

1. Boyer, R.R., "An Overview on the Use of Titanium in the Aerospace Industry," Materials Science and Engineering A, Volume 213, Pages 103-114.

2. Niinomi, M., "Mechanical Properties of Biomedical Titanium Alloys," Materials Science and Engineering A, Volume 243, Pages 231-236.

3. ASTM International, "ASTM B863-17 Standard Specification for Titanium and Titanium Alloy Wire," ASTM Book of Standards, Volume 02.04.

4. Leyens, C. and Peters, M., "Titanium and Titanium Alloys: Fundamentals and Applications," Wiley-VCH Publishers, Weinheim, Germany.

5. Lutjering, G. and Williams, J.C., "Titanium Engineering Materials and Processes," Springer-Verlag Berlin Heidelberg, Second Edition.

6. Peters, M., Kumpfert, J., Ward, C.H., and Leyens, C., "Titanium Alloys for Aerospace Applications," Advanced Engineering Materials, Volume 5, Issue 6, Pages 419-427.

Learn about our latest products and discounts through SMS or email