- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Lightweight Gr5 Titanium Wire – Ideal for 3D Printing & AM

Modern additive manufacturing requires high-performance, efficient materials. Gr5 Titanium Wire is the best option for advanced 3D printing due to its high strength-to-weight ratio, longevity, and precision. This premium titanium alloy wire revolutionizes complex component production in aerospace, medical, and industrial applications with unrivaled reliability.

Introduction

Gr5 Titanium Wire leads 3D printing and additive manufacturing technologies to meet modern manufacturing's need for lightweight, strong materials. Ti-6Al-4V, a premium alloy, optimizes product performance and manufacturing efficiency in various industrial applications.

Materials that provide structural integrity and operational efficiency have tremendous prospects due to additive manufacturing use. Manufacturers worldwide know that traditional materials often fail to meet the complicated needs of modern 3D printing. Competitive industrial environments require materials with constant mechanical qualities, dimensional stability, and environmental resistance.

This thorough reference covers technical, commercial, and logistical considerations needed for worldwide purchasing decisions. B2B procurement professionals will learn how adding this sophisticated titanium alloy to their manufacturing supply chains may improve productivity, cost, and product reliability. The next sections discuss the material's specific features, manufacturing benefits, and strategic procurement considerations for additive manufacturing success.

Understanding Gr5 Titanium Wire: Properties and Manufacturing Process

Chemical Composition and Core Properties

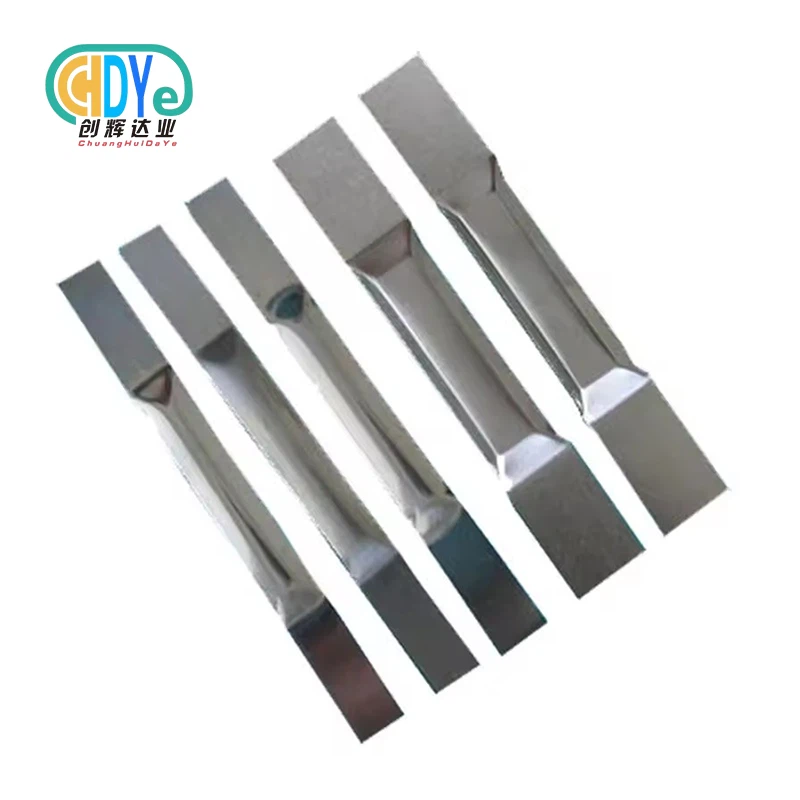

Gr5 Titanium Wire performs well due to its precise chemical makeup. About 6% aluminum and 4% vanadium make up the alloy, which is mostly titanium. This composition produces a material with tensile strength above 925 MPa and yield strength above 870 MPa, as well as elongation of at least 10%.

The material is 45% lighter than steel but nevertheless strong due to the regulated aluminum concentration. Vanadium boosts the alloy's high-temperature performance and cyclic loading resistance. These compositional features work together to generate a material that excels in demanding situations where weight reduction cannot sacrifice performance.

Advanced Manufacturing Processes

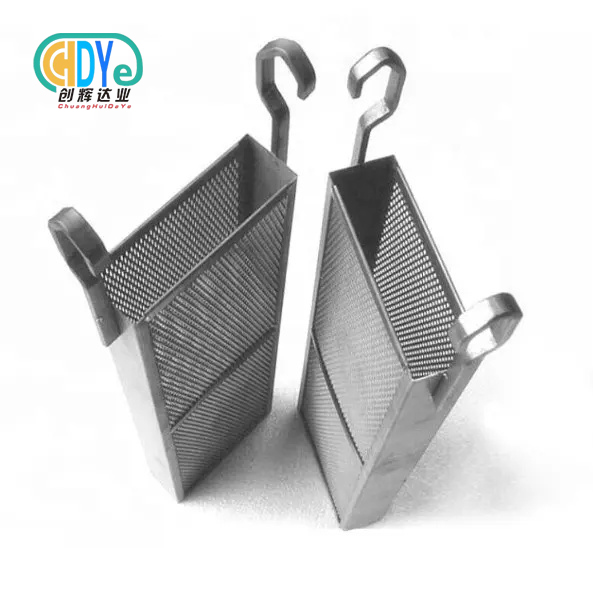

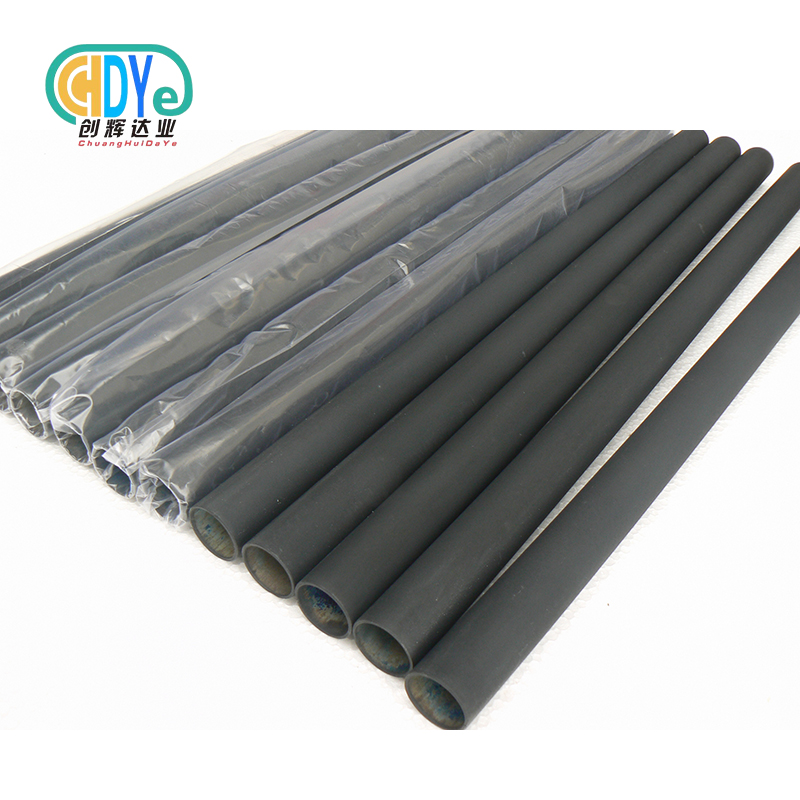

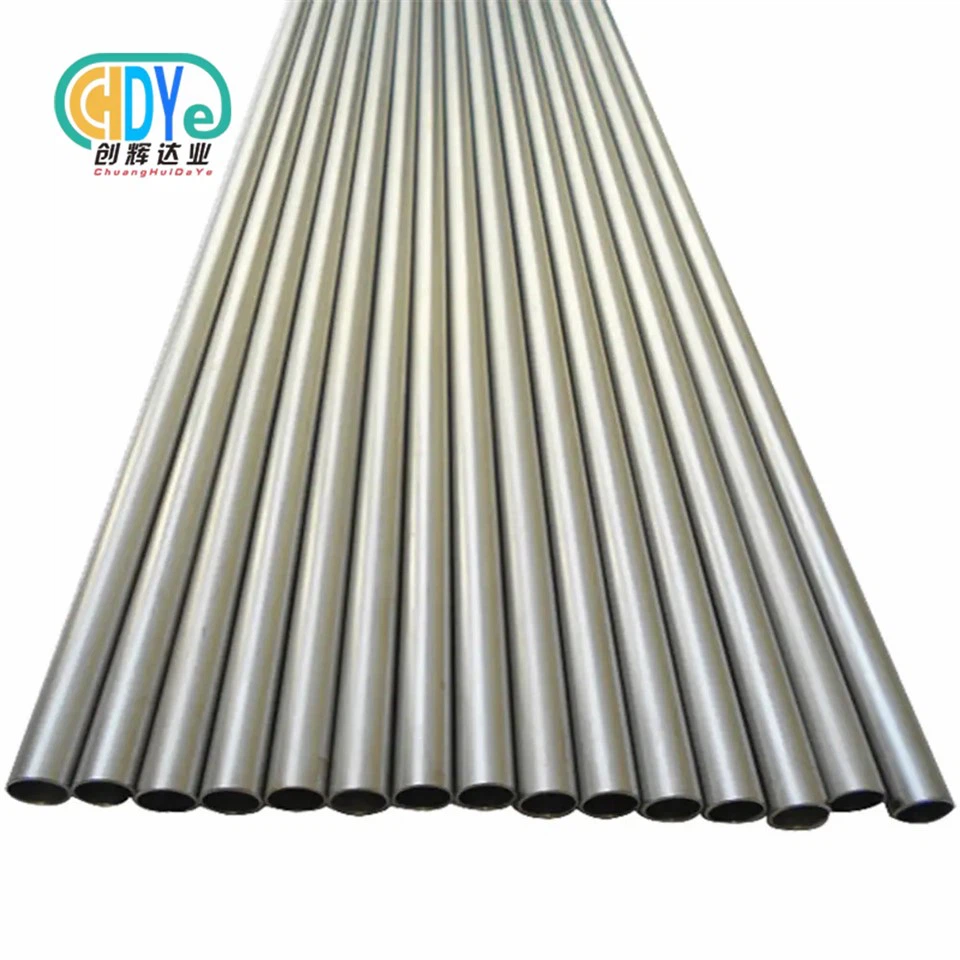

Grade 5 titanium wire manufacture requires advanced processing to assure material property consistency. Modern production facilities use vacuum melting to remove impurities and homogenize alloy distribution. For 3D printing, multi-pass drawing techniques produce fine dimensional tolerances with diameters from 0.5mm to 6.0mm.

Mechanical qualities are optimized via heat treatment methods. Controlled annealing reduces internal stresses while keeping the microstructure that improves fatigue resistance. A constant feedstock for additive manufacturing is provided by quality control techniques that ensure each wire satisfies strict international standards.

Performance Comparison with Grade 2 Titanium

Procurement professionals can choose the best Grade 5 or Grade 2 titanium for certain purposes by understanding the differences. Grade 2 titanium has good corrosion resistance and formability, whereas Grade 5 is stronger and better for structural purposes. Grade 5 can handle higher stress and work in harsher settings due to its aluminum and vanadium content.

Grade 5 titanium wire performs well at temperatures up to 400°C for lengthy periods. Its heat stability and improved mechanical qualities make it ideal for aerospace components, medical implants, and industrial equipment that must work well under extreme situations.

Advantages of Using Gr5 Titanium Wire in 3D Printing and Additive Manufacturing

Superior Strength-to-Weight Performance

Grade 5 titanium wire's strength-to-weight ratio revolutionizes additive manufacturing component design. Engineers can reduce structure weight without compromising mechanical performance, improving aerospace fuel efficiency and medical device portability. Satellite and aircraft structural components, where every gram counts, benefit from this trait.

Manufacturing teams benefit from the material's dimensional stability during printing. The wire's constant mechanical qualities ensure printed components fulfill design standards and behave predictably under operating loads. This stability streamlines production workflows and improves manufacturing efficiency by reducing post-processing and quality validation.

Enhanced Corrosion Resistance and Environmental Durability

The corrosion resistance of grade 5 titanium wire extends the life of components used in harsh situations. The material excels in seawater, organic acids, and alkaline solutions, making it perfect for marine and chemical processing equipment. Corrosion resistance reduces maintenance and extends component lifecycles, saving money over standard materials.

Biocompatible wires allow medical device manufacturers to use materials that interface securely with human tissue for long-term implantation. Grade 5 titanium wire components have good osseointegration, speeding healing and decreasing medical rejection.

Heat Treatment Flexibility and Performance Optimization

Manufacturers can customise mechanical properties via heat treatment. Depending on the application, controlled thermal processing can boost yield strength, fatigue resistance, or ductility. This versatility lets engineers optimize component performance for specific applications while preserving the underlying material's benefits.

Applications in aircraft, medical devices, and automobiles show the material's adaptability in satisfying varied performance needs. Grade 5 titanium wire is biocompatible and used for implant fabrication by medical device businesses and structural fasteners by aircraft makers. Automotive manufacturers praise its weight reduction efforts to increase fuel efficiency without jeopardizing safety.

Gr5 Titanium Wire Compared to Other Materials for Additive Manufacturing

Performance Analysis Against Traditional Materials

Grade 5 titanium wire exceeds stainless steel and aluminum alloys in additive manufacturing performance parameters. While corrosion-resistant, stainless steel is heavier and lacks biocompatibility for medical uses. Stainless steel and Grade 5 titanium have different densities, saving 45% weight for similar component quantities.

Aluminum alloys are lightweight yet weaker than Grade 5 titanium at high temperatures. Aluminum alloys degrade in high-temperature or corrosive situations, compromising reliability. Grade 5 titanium is preferred for cyclic loading components due to its fatigue resistance.

Specialized Titanium Alloy Comparisons

Grade 5 titanium has benefits over other titanium alloys that make it suitable for demanding additive manufacturing applications. Grade 23 titanium (Ti-6Al-4V ELI) has higher ductility but lower strength. Grade 23 shines in medical applications needing maximum biocompatibility, although Grade 5 performs better in structural applications requiring strength.

Nickel-titanium alloys have form memory but less application diversity than Grade 5 titanium. Grade 5 titanium wire's cost-effectiveness, proven production processes, and extensive availability make it a feasible alternative for producers seeking reliable performance in various applications.

Cost-Benefit Analysis for Procurement Teams

When choosing additive manufacturing materials, procurement experts must weigh upfront expenses against long-term benefits. Grade 5 titanium wire costs more than conventional materials, but its greater performance frequently justifies the investment through lower component replacement costs, operating efficiency, and product reliability.

Its good machinability and welding decrease processing time and expense. Standard processing equipment allows manufacturers to achieve tight tolerances and high surface finishes without specialist tooling or costly post-processing. These processing efficiency and material durability create advantageous total cost of ownership profiles for most applications.

Procurement and Supply Chain Insights for Gr5 Titanium Wire

Sourcing Strategies and Supplier Verification

Grade 5 titanium wire must be carefully selected from suppliers to assure authenticity and quality. Verified suppliers meet international standards and have the technical skills to make high-quality titanium alloys. Suppliers with ISO 9001:2015 certification and quality management systems should be prioritized by supply chain managers.

Regional market availability varies, but established US and European suppliers offer consistent access to approved materials. Building ties with many qualified suppliers reduces supply risks and ensures operations under high market demand. Suppliers with enough inventory and flexible ordering terms benefit manufacturing businesses with variable production schedules.

Bulk Purchasing Benefits and Custom Sizing Options

Volume purchase can save money and ensure material consistency across production batches. Suppliers provide discounts for larger purchases and bespoke sizing for 3D printing applications. To fulfill varied industrial needs, straight wire and coil wire formats are available in diameters from 0.5mm to 6.0mm.

Manufacturers can maximize material use and avoid waste with custom lengths. Cutting service providers can customise wire segments for printer layouts, enhancing operating efficiency and decreasing material handling. Sample ordering allows testing and validation before ordering in bulk.

Market Trends and Lead Time Considerations

Demand for aeronautical, medical, and industrial products is growing, with lead times depending on order parameters and supplier capacity. Standard configurations arrive in 2-4 weeks, but special requests may take longer. Procurement schedules should match production demands to assure material availability and avoid costly production delays.

Prices fluctuate with raw material costs and market demand, but are generally constant. Long-term supply agreements offer pricing stability and guaranteed availability for enterprises with predictable material needs. Supply chain managers should monitor market conditions and maintain strategic inventory levels to ensure production continuity.

Company Introduction and Product & Service Information

Baoji High-tech Development Zone—China's "Titanium Capital."—is home to Shaanxi Chuanghui Daye Metal Material Co., Ltd., the titanium alloy manufacturing leader. Over three decades of rare metal production experience have made the company a trusted partner for global makers of premium titanium materials.

The organization manufactures everything from raw materials to final parts. Electron beam furnaces, precise annealing systems, and cutting-edge machining equipment ensure product quality and accuracy. The company's ISO 9001:2015 certification shows its dedication to quality management and process control throughout manufacturing.

Chuanghui Daye offers customized wire arrangements for certain applications. Customers and the company's technical team work together to create custom additive manufacturing requirements that improve performance. A customer-centric approach and competitive factory-direct pricing offer value propositions that foster long-term business partnerships.

Quality assurance covers raw material inspection to final packaging in the company's production process. Each shipment includes detailed material pedigree paperwork to assist customers' quality management requirements. Beyond product delivery, technical support includes application guidance and performance tuning.

Conclusion

Advanced 3D printing and additive manufacturing applications requiring high performance should use Gr5 Titanium Wire. Its high strength-to-weight ratio, corrosion resistance, and biocompatibility enable new aerospace, medical, and industrial component designs. Manufacturers seeking reliable, high-performance materials favor the material's processability, heat treatment flexibility, and proven track record in demanding applications. Successful procurement needs careful supplier selection, strategic planning, and market dynamics to assure constant access to quality materials for operational excellence and competitive advantage.

FAQ

Q: Why is Grade 5 titanium wire preferred for 3D printing applications?

A: Grade 5 titanium wire offers an optimal combination of strength, weight, and corrosion resistance that surpasses other materials commonly used in additive manufacturing. Its biocompatibility makes it essential for medical applications, while its strength-to-weight ratio provides significant advantages in aerospace and automotive components where weight reduction directly impacts performance and efficiency.

Q: How does heat treatment affect the properties of Grade 5 titanium wire?

A: Heat treatment processes can significantly modify the mechanical properties of Grade 5 titanium wire, allowing manufacturers to optimize characteristics for specific applications. Controlled thermal processing can enhance yield strength, improve fatigue resistance, or increase ductility depending on the intended use, providing flexibility in component design and performance optimization.

Q: What factors should buyers consider when selecting suppliers for bulk orders?

A: Key considerations include ISO 9001:2015 certification, quality management systems, inventory capacity, and technical support capabilities. Suppliers should demonstrate consistent product quality, provide comprehensive traceability documentation, and offer flexible ordering terms that accommodate varying production requirements while maintaining competitive pricing structures.

Partner with Chuanghui Daye for Your Gr5 Titanium Wire Requirements

Shaanxi Chuanghui Daye delivers premium-quality Grade 5 titanium wire specifically engineered for demanding additive manufacturing applications. Our ISO 9001:2015 certified manufacturing processes ensure consistent material properties and dimensional accuracy that meet international standards. Contact our technical team at info@chdymetal.com to discuss your specific requirements and discover how our comprehensive product range, competitive pricing, and reliable supply chains can enhance your manufacturing operations as a trusted Gr5 titanium wire supplier.

References

1. Boyer, R.R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering: A, vol. 213, 1996, pp. 103-114.

2. Frazier, W.E. "Metal Additive Manufacturing: A Review." Journal of Materials Engineering and Performance, vol. 23, 2014, pp. 1917-1928.

3. Liu, S. and Shin, Y.C. "Additive Manufacturing of Ti6Al4V Alloy: A Review." Materials & Design, vol. 164, 2019, pp. 107552.

4. Niinomi, M. "Mechanical Properties of Biomedical Titanium Alloys." Materials Science and Engineering: A, vol. 243, 1998, pp. 231-236.

5. Peters, M. and Leyens, C. "Titanium and Titanium Alloys: Fundamentals and Applications." Wiley-VCH, 2003.

6. Wohlers, T. and Gornet, T. "History of Additive Manufacturing." Wohlers Report 2014: 3D Printing and Additive Manufacturing State of the Industry, 2014.

Learn about our latest products and discounts through SMS or email