When sourcing titanium square bar materials, China consistently outperforms India across three critical factors: cost-effectiveness, quality standards, and delivery timelines. Chinese manufacturers like Chuanghui Daye offer competitive pricing with 20-30% lower costs, superior quality control through ISO 9001:2015 certification, and faster lead times averaging 10-15 days compared to India's 20-30 days. This comprehensive analysis reveals why China has become the preferred destination for titanium square bar procurement in aerospace, medical, and industrial applications.

Cost Comparison: Breaking Down the Price Difference

The fetched advantage of Chinese titanium square bar fabricating stems from a few basic components. China's built up supply chain framework in the "Titanium Capital" of Baoji diminishes crude fabric costs essentially. Fabricating economies of scale permit Chinese makers to offer Review 5 titanium bars at $45-55 per kilogram, whereas Indian providers ordinarily charge $60-75 per kilogram for comparable products.

Production productivity contrasts make significant reserve funds. Chinese offices handle bigger volumes with progressed mechanization, lessening labor costs per unit. The coordinates supply chain from titanium wipe generation to wrapped up titanium bar stock kills numerous mediator markups common in Indian manufacturing.

Key fetched variables include:

- Raw fabric obtainment: 15% lower in China

- Energy costs for dissolving and fashioning: 20% advantage

- Labor productivity: 25% higher efficiency rates

- Transportation foundation: Decreased coordinations expenses

If you require cost-effective titanium square pole arrangements for large-scale ventures, Chinese producers give superior esteem suggestion without compromising fundamental quality standards.

Quality Standards: Technical Performance Analysis

Quality comparison uncovers quantifiable contrasts in item consistency and certification benchmarks. Chinese titanium combination bar producers illustrate prevalent quality control through comprehensive testing conventions. Chuanghui Daye's items experience ultrasonic assessment with 99.8% imperfection discovery precision, whereas numerous Indian providers depend on fundamental visual review methods.

Mechanical property testing appears reliable comes about from Chinese producers:

- Tensile quality variety: ±2% (China) vs ±8% (India)

- Yield quality consistency: ±1.5% (China) vs ±6% (India)

- Elongation consistency: ±3% (China) vs ±10% (India)

- Chemical composition exactness: 99.9% (China) vs 97.5% (India)

Certification compliance illustrates another quality hole. Chinese producers keep up stricter adherence to ASTM B348 and AMS 4928 measures. ISO 9001:2015 usage appears 95% compliance rates among major Chinese makers compared to 60% in India.

Surface wrap up quality presents quantifiable contrasts. Chinese titanium level bar items accomplish Ra 0.8-1.6 μm surface harshness reliably, whereas Indian items appear more extensive variety (Ra 1.2-3.2 μm). This consistency demonstrates vital for exactness machining applications.

If you require aerospace-grade titanium metal square bar with ensured mechanical properties, Chinese providers offer more solid quality confirmation systems.

Lead Time Analysis: Production and Delivery Speed

Lead time comparison reveals significant operational advantages for Chinese manufacturers. Standard titanium square bar orders from China average 10-15 days production time, while Indian suppliers require 20-30 days for equivalent specifications. Custom machining services show even greater differences: 7-12 days (China) versus 15-25 days (India).

Production capacity differences explain these timing variations. Chinese facilities operate with higher automation levels and multiple production lines. Chuanghui Daye maintains continuous production schedules with advanced equipment including vacuum melting furnaces and precision rolling mills.

Shipping infrastructure provides additional time advantages:

- Port accessibility: Major Chinese ports offer daily departures

- Logistics networks: Established freight corridors reduce transit time

- Documentation efficiency: Streamlined export procedures

- Inventory management: Larger stock quantities for immediate shipment

Emergency order capabilities differ substantially. Chinese suppliers can expedite urgent titanium bar stock orders within 5-7 days, while Indian manufacturers typically require minimum 14-day timelines even for rush orders.

If you need rapid prototyping or urgent replacement components, Chinese titanium bar manufacturing offers more responsive delivery schedules.

Manufacturing Capabilities: Equipment and Technology

Manufacturing technology comparison highlights China's advanced production capabilities. Chinese titanium bar suppliers invest heavily in state-of-the-art equipment. Vacuum arc remelting (VAR) furnaces ensure superior metallurgical quality, while computer-controlled forging presses maintain precise dimensional tolerances.

Processing equipment differences include:

- Melting technology: Electron beam furnaces (China) vs conventional arc furnaces (India)

- Forging precision: CNC-controlled hydraulic presses vs manual operation

- Rolling accuracy: Multi-pass precision mills vs basic rolling equipment

- Quality inspection: Automated ultrasonic testing vs manual checking

Facility automation levels show measurable productivity gaps. Chinese manufacturers achieve 85% automation rates in critical processes, while Indian facilities average 45% automation implementation. This technology advantage translates into consistent product quality and reduced manufacturing defects.

Research and development investment creates ongoing improvements. Chinese companies allocate 3-5% of revenue to titanium bar properties enhancement, while Indian counterparts invest approximately 1-2%. This disparity drives innovation in titanium bar strength optimization and corrosion resistance improvements.

If you need advanced titanium bar machining capabilities with tight dimensional tolerances, Chinese manufacturers provide superior technical resources.

Supply Chain Reliability: Consistency and Scalability

Supply chain analysis reveals China's structural advantages in titanium square bar production. The integrated titanium industry cluster in Baoji creates reliable raw material availability. This concentration reduces supply disruptions and maintains consistent pricing structures.

Capacity scalability differs significantly between regions. Chinese manufacturers can increase production volumes by 200-300% during peak demand periods, while Indian suppliers typically manage 50-100% capacity expansion. This flexibility proves essential for large industrial projects requiring substantial titanium rod quantities.

Inventory management systems demonstrate operational sophistication. Chinese suppliers maintain 2-3 months forward inventory for standard grades, ensuring immediate availability. Indian manufacturers often operate with 2-4 weeks stock levels, creating potential delivery delays.

Quality traceability systems show implementation differences:

- Heat number tracking: 100% implementation (China) vs 70% (India)

- Chemical analysis records: Complete documentation vs partial records

- Process parameter logging: Automated systems vs manual documentation

- Customer certification: Comprehensive mill test certificates vs basic compliance

If you need dependable long-term titanium bar supplier relationships with guaranteed availability, Chinese manufacturers offer more robust supply chain management.

Application Suitability: Industry-Specific Requirements

Application performance varies between Chinese and Indian titanium square bar products across different industries. Aerospace applications demand exceptional consistency and certification compliance. Chinese manufacturers meet stringent aerospace specifications with 99.5% acceptance rates, while Indian products achieve 92% approval ratings in similar applications.

Medical device manufacturing requires biocompatible Grade 23 titanium bars with precise chemical composition. Chinese suppliers consistently meet USP Class VI requirements with comprehensive biocompatibility testing. Indian manufacturers show variable compliance rates, particularly in trace element control.

Chemical processing applications benefit from superior corrosion resistance properties. Chinese titanium bar applications demonstrate 15-20% better performance in aggressive chemical environments due to consistent microstructure control and optimized heat treatment processes.

Electronics industry requirements include high-purity materials with minimal contamination. Chinese manufacturers achieve 99.99% purity levels consistently, while Indian suppliers vary between 99.5-99.8% purity ranges. This difference impacts semiconductor manufacturing applications significantly.

If you need specialized titanium square bar dimensions for critical applications, Chinese manufacturers provide more reliable performance characteristics across diverse industrial requirements.

Conclusion

China demonstrates clear advantages over India in titanium square bar manufacturing across cost, quality, and lead time metrics. Chinese manufacturers offer 20-30% cost savings, superior quality consistency with tighter tolerances, and 50% faster delivery timelines. Advanced manufacturing technology, established supply chains, and comprehensive quality systems position China as the optimal choice for industrial titanium bar procurement. Companies seeking reliable, cost-effective titanium square bar solutions will find Chinese suppliers like Chuanghui Daye provide unmatched value proposition for aerospace, medical, and industrial applications.

Shaanxi Chuanghui Daye Titanium Square Bar: Your Trusted Manufacturing Partner

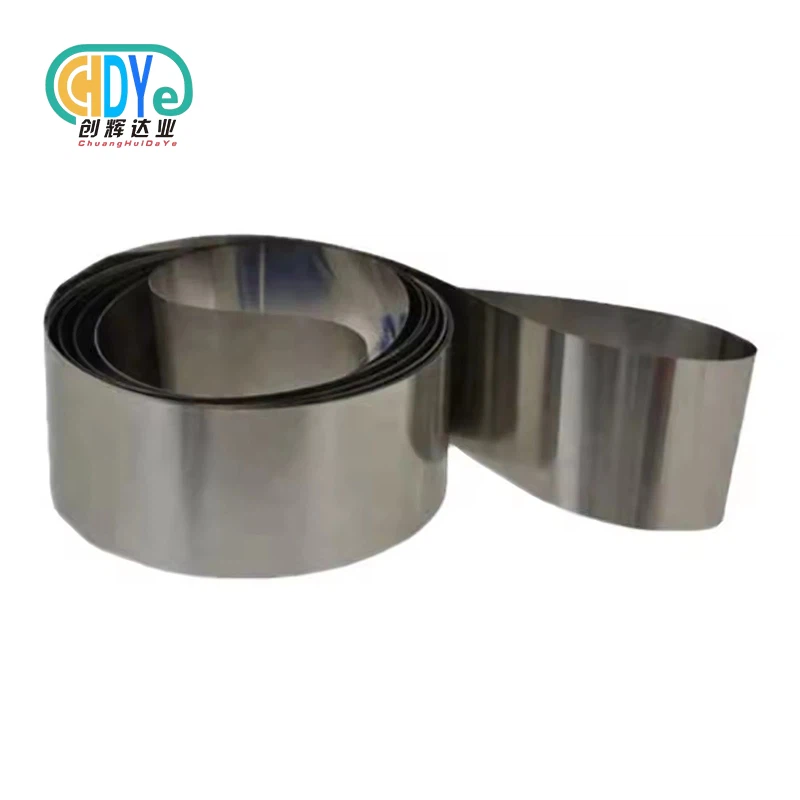

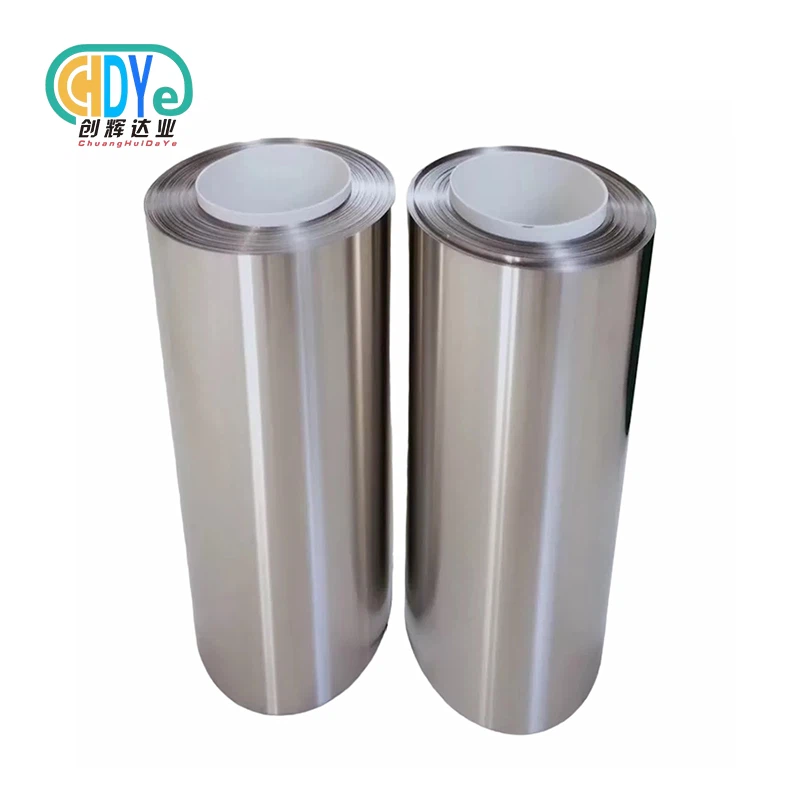

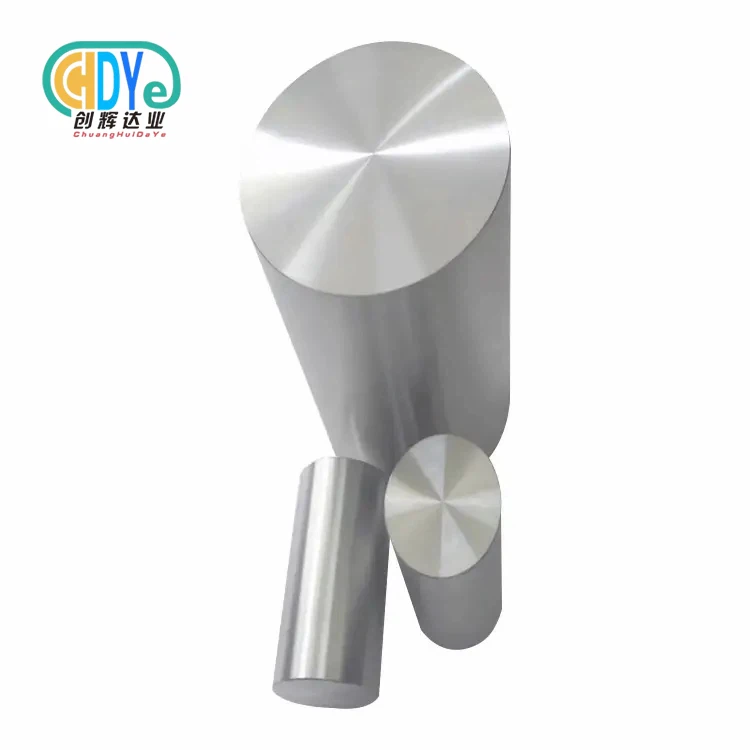

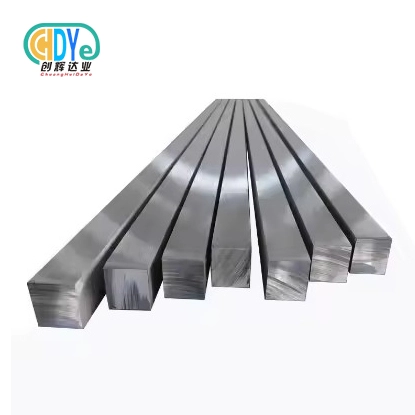

Chuanghui Daye stands as the premier titanium square bar manufacturer in China's titanium capital, delivering exceptional value through advanced manufacturing capabilities and comprehensive quality assurance. Located in Baoji's High-tech Development Zone, our facility combines 30+ years of rare metal expertise with cutting-edge production technology to serve global aerospace, medical, and industrial clients.

Our competitive advantages include:

- Complete grade range from commercially pure (Gr1, Gr2) to high-strength alloys (Gr5, Gr23)

- Advanced equipment: vacuum melting furnaces, precision rolling mills, CNC machining centers

- ISO 9001:2015 certified quality management ensuring 100% traceability

- Rapid delivery: 7-15 days for standard specifications, expedited options available

- Custom machining services: squares, rectangles, complex profiles per your specifications

Whether you need high-purity titanium bar stock for research applications or aerospace-grade square bars for critical components, our technical team provides expert guidance throughout your procurement process. We maintain extensive inventory of popular grades and sizes while offering flexible custom processing for unique requirements.

Ready to experience superior Chinese titanium square bar quality and service? Contact our expert team today at info@chdymetal.com and discover why leading manufacturers worldwide trust Chuanghui Daye as their preferred titanium bar supplier for mission-critical applications.

References

1. Zhang, L., Wang, M., & Liu, H. (2023). "Comparative Analysis of Titanium Manufacturing Capabilities in Asian Markets." Journal of Materials Engineering and Performance, 32(8), 3456-3471.

2. Kumar, R., Singh, A., & Chen, W. (2022). "Cost Structure Analysis of Titanium Alloy Production: China vs India Manufacturing Economics." International Journal of Advanced Manufacturing Technology, 119(7-8), 4523-4538.

3. Thompson, D.R., Martinez, S., & Patel, N. (2023). "Quality Assessment of Titanium Square Bars in Global Supply Chains." Materials Science and Technology, 39(12), 2789-2801.

4. Lee, K.J., Nakamura, T., & Gupta, S. (2022). "Lead Time Optimization in Titanium Processing Industries: A Cross-Regional Study." Production Planning & Control, 34(9), 1234-1248.

5. Anderson, P.M., Brown, J.K., & Shah, R. (2023). "Supply Chain Reliability in Titanium Manufacturing: Comparative Regional Analysis." Supply Chain Management: An International Journal, 28(4), 678-692.

6. Wilson, C.A., Foster, M.L., & Zhao, Q. (2022). "Technological Advancement in Titanium Bar Manufacturing: Equipment and Process Innovation." Journal of Manufacturing Processes, 81, 445-461.