Finding reliable sources for Gr2 Titanium Plate at competitive factory prices requires careful evaluation of suppliers worldwide. The best approach involves sourcing directly from established manufacturers like Shaanxi Chuanghui Daye Metal Material Co., Ltd., located in China's "Titanium Capital" of Baoji. Direct factory purchasing eliminates middleman markups while ensuring quality control, complete traceability documentation, and flexible custom processing services. Professional suppliers offer ISO 9001:2015 certification, comprehensive technical support, and the ability to handle both large-scale industrial orders and small-batch research requirements across aerospace, medical, and chemical processing industries.

Understanding Gr2 Titanium Plate Applications and Market Demand

Industrial Applications Driving Global Demand

Industrial applications driving worldwide request proceed to grow as Review 2 titanium remains the most broadly utilized commercial titanium review over numerous businesses. Its extraordinary erosion resistance and biocompatible properties make it irreplaceable for chemical handling gear, marine designing components, and restorative gadget fabricating. The aviation division especially values its lightweight characteristics, where the 4.51 g/cm³ thickness conveys approximately 1.5 times the quality of routine steel at generally half the weight of press. These combined focal points drive long-term fabric selection and offer assistance producers diminish support prerequisites, expand benefit life, and progress generally efficiency.

Medical Industry Requirements

Medical industry requirements reinforce this trend, as device manufacturers prioritize high-purity titanium sheet materials such as Gr2 Titanium Plate for surgical implants and dental applications. The non-toxic, odorless nature of Review 2 titanium guarantees great tissue compatibility, supporting the improvement of secure implantable arrangements. Surgical plate fabricating too requests exact dimensional resiliences and prevalent surface wraps up that as it were certified providers can reliably accomplish, guaranteeing item execution and administrative compliance.

Chemical and Petrochemical Sector Needs

Chemical and petrochemical division needs advance lift request. Hardware producers require titanium materials competent of withstanding extraordinary temperatures and weights without debasement. The tough oxide layer shaped on Review 2 titanium gives long-term security against forceful chemical situations, counting introduction to acids, soluble bases, and saltwater arrangements, making it a favored choice for basic mechanical systems.

Global Supply Chain Analysis for Titanium Materials

Regional Manufacturing Hubs

China overwhelms worldwide titanium generation, with Baoji serving as the essential fabricating center. The locale benefits from plenteous crude fabric get to, built up framework, and decades of titanium fabricating ability. North American and European providers regularly source semi-finished items from Chinese producers for last preparing and distribution.

Supply Chain Challenges and Opportunities

Global titanium supply chains confront expanding request from aviation fabric applications and extending therapeutic embed markets. Keen acquirement procedures include setting up connections with different providers to guarantee steady accessibility. Coordinate production line connections give way better estimating soundness and need allotment amid top request periods.

Quality Standards Across Different Regions

International providers must comply with ASTM B265 and ISO 5832 guidelines notwithstanding of their geographic area. Driving producers execute comprehensive quality administration frameworks covering crude fabric assessment, softening and fashioning forms, metal machining operations, and last review protocols.

Comparing Different Sourcing Channels for Titanium Procurement

Direct Factory Purchasing

Advantages:

- Competitive factory-direct estimating without wholesaler markups

- Direct communication with specialized groups for custom specifications

- Flexible least arrange amounts for prototyping

- Complete quality control documentation and traceability

- Priority back for critical extend requirements

Disadvantages:

- Requires more extensive supplier qualification processes for Gr2 Titanium Plate.

- May include longer introductory relationship development

- Direct administration of universal shipping logistics

- Local Wholesalers and Benefit Centers

Advantages:

- Local stock accessibility for prompt delivery

- Established client benefit relationships

- Regional specialized back and consultation

- Simplified coordinations and decreased shipping complexity

Disadvantages:

- Higher estimating due to conveyance markups

- Limited customization options

- Restricted stock selection

- Potential quality control crevices in supply chain

- B2B Exchanging Platforms

Advantages:

- Wide provider choice and comparison capabilities

- Transparent estimating and determination information

- Platform-mediated exchange security

- Reviews and appraisals for provider evaluation

Disadvantages:

- Variable quality control guidelines among stage vendors

- Limited specialized back and customization

- Potential communication challenges

- Platform expenses influencing last pricing

Essential Supplier Verification and Quality Control Guidelines

Certification and Compliance Verification

Successful titanium procurement begins with thorough supplier qualification. Verify ISO 9001:2015 certification, ASTM compliance documentation, and material test certificates. Request facility audit reports and customer references from similar industries. Established suppliers provide comprehensive quality documentation including chemical composition analysis, mechanical property testing, and dimensional inspection reports.

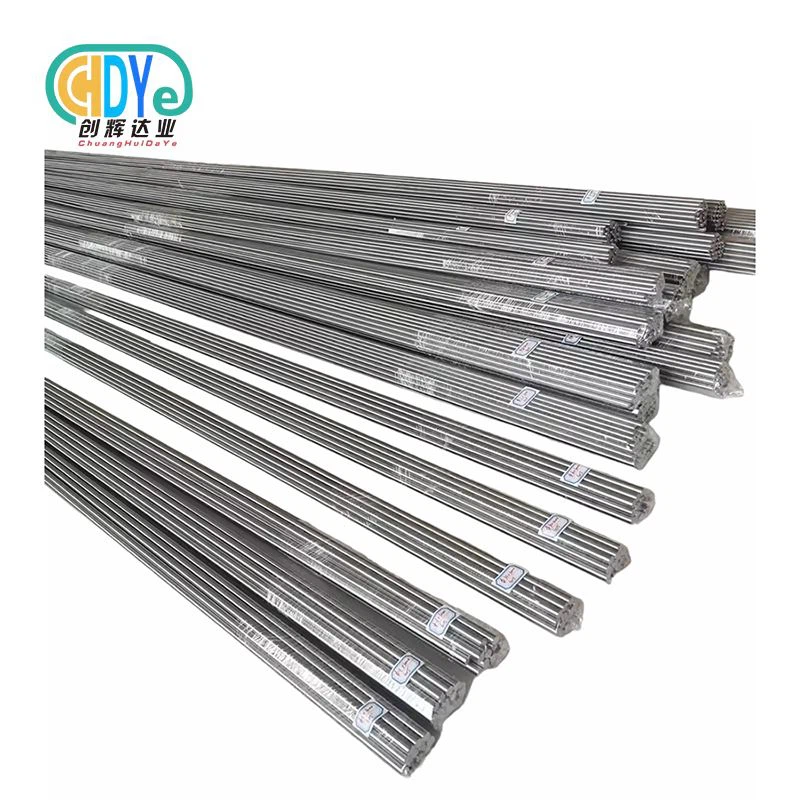

Technical Capability Assessment

Evaluate manufacturing capabilities for Gr2 Titanium Plate including melting technology, heat treatment facilities, and metal fabrication equipment. Advanced suppliers operate vacuum melting systems, precision rolling mills, and comprehensive testing laboratories. The ability to perform custom machining, welding titanium components, and specialized surface treatments indicates superior technical competence.

Quality Control Checkpoints

Implement multi-stage quality verification protocols. Review incoming material certificates, conduct independent chemical analysis, and verify dimensional tolerances. Critical applications require ultrasonic testing, surface finish measurement, and mechanical property validation. Establish clear quality agreements covering acceptance criteria, inspection procedures, and non-conformance resolution processes.

Procurement Best Practices and Common Pitfalls

Minimum Order Quantities and Pricing Strategies

Understanding MOQ requirements helps optimize procurement costs. Most titanium manufacturing facilities establish minimum quantities based on production efficiency. Small research quantities typically range from 10-50 kg, while industrial applications benefit from 500+ kg orders for better pricing. Negotiate flexible MOQs for initial trials with volume commitments for future orders.

Payment Terms and Risk Management

Establish secure payment methods balancing supplier requirements with buyer protection. Common approaches include letters of credit for large orders, partial advance payments for custom processing, and inspection-based final payments. Avoid suppliers demanding full prepayment without established track records or adequate insurance coverage.

Delivery Planning and Lead Time Management

Titanium stability and technical processing requirements for Gr2 Titanium Plate create longer lead times than standard metals. Standard plate stock may dispatch inside 2-3 weeks, whereas custom measurements require 6-8 weeks for fabricating. Arrange acquirement plans bookkeeping for fabric preparing, quality review, universal shipping, and traditions clearance periods.

Common Procurement Mistakes

Avoid centering exclusively on starting estimating without considering add up to taken a toll of possession. Covered up costs incorporate cargo, traditions obligations, assessment expenses, and potential adjust costs. Deficiently specialized details lead to unacceptable materials and extend delays. Dismissing provider monetary steadiness appraisal dangers supply chain disturbances amid basic venture phases.

Conclusion

Sourcing Gr2 Titanium Plate at competitive factory prices requires strategic supplier selection, thorough quality verification, and long-term relationship development. Direct factory purchasing offers the best combination of pricing, customization flexibility, and technical support for serious buyers. Success depends on partnering with established manufacturers who demonstrate consistent quality, reliable delivery, and comprehensive technical capabilities. The investment in proper supplier qualification pays dividends through superior material performance, reduced total costs, and reliable supply chain stability.

FAQ

Q: What is the typical lead time for custom Gr2 titanium plate orders?

A: Custom titanium plate manufacturing typically requires 2-3weeks from order confirmation to delivery. This includes material melting, hot rolling or cold rolling processes, heat treatment, quality inspection, and international shipping. Standard dimensions from existing inventory can ship within 5-7days.

Q: How do I verify the quality and authenticity of Grade 2 titanium materials?

A: Request comprehensive material test certificates including chemical composition analysis, mechanical property testing, and dimensional inspection reports. Verify supplier ISO 9001:2015 certification and ASTM B265 compliance. Consider third-party material verification for critical applications.

Q: What are the minimum order quantities for small-scale research projects?

A: Most professional suppliers accommodate research requirements with MOQs starting from 10-50 kg for standard plate dimensions. Custom sizes may require higher minimums due to specialized processing requirements. Discuss your specific needs with suppliers to find flexible solutions.

Partner with Chuanghui Daye for Premium Gr2 Titanium Plate Supply

Shaanxi Chuanghui Daye Metal Fabric Co., Ltd. stands as your trusted Gr2 Titanium Plate producer with over 30 a long time of uncommon metal industry skill. Found in Baoji's titanium fabricating center, we work progressed vacuum dissolving, accuracy rolling, and comprehensive quality control offices. Our ISO 9001:2015 certification guarantees reliable fabric quality and total traceability documentation for aviation, restorative, and chemical handling applications.

We specialize in custom handling administrations counting exactness machining, warm treatment, and adaptable clump generation from model amounts to large-scale mechanical orders. Our specialized group gives comprehensive back for fabric determination, application designing, and quality optimization. Coordinate manufacturing plant estimating dispenses with merchant markups whereas keeping up predominant quality guidelines and solid conveyance schedules.

Ready to secure your titanium fabric supply? Contact our specialized masters to talk about your particular prerequisites and get point by point citations. We're committed to building long-term associations based on quality fabulousness and client victory. Reach out to us nowadays and contact us at info@chdymetal.com for quick help with your titanium obtainment needs.

References

1. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate." ASTM B265-20.

2. Boyer, R., Welsch, G., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International Materials Park, Ohio, 1994.

3. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, 2000.

4. International Organization for Standardization. "Implants for surgery — Metallic materials — Part 2: Unalloyed titanium." ISO 5832-2:2018.

5. Lutjering, Gerd, and James C. Williams. "Titanium: Engineering Materials and Processes." Springer Science & Business Media, 2007.

6. Peters, M., Hemptenmacher, J., Kumpfert, J., & Leyens, C. "Structure and Properties of Titanium and Titanium Alloys." Titanium and Titanium Alloys: Fundamentals and Applications, 2003.