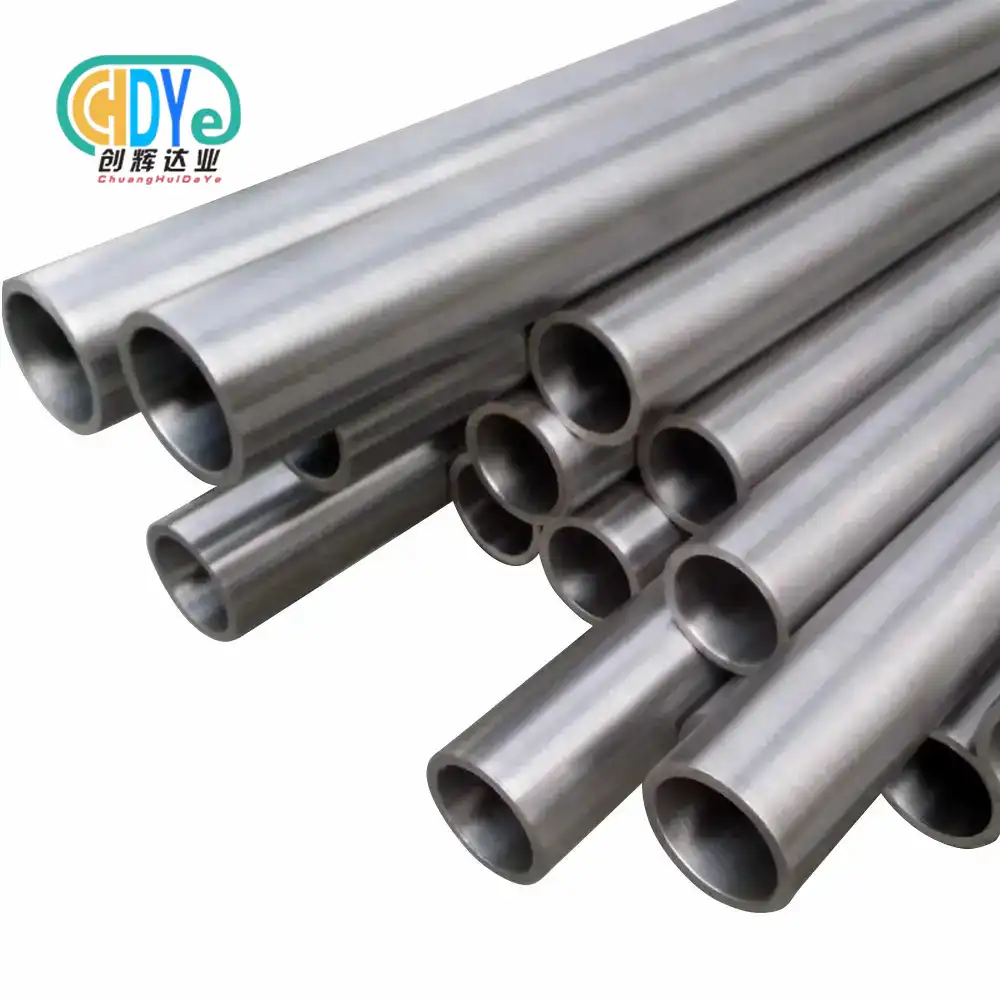

To choose the right gr2 titanium pipe for chemical processing, you need to know about material specifications, performance characteristics, and what the industry needs. This all-inclusive guide covers everything from resistance to corrosion to standards for manufacturing. It helps engineers and procurement experts make smart choices. If you're designing heat exchangers, reactors, or process piping systems, commercial-grade titanium 2 is great for tough working conditions because it lasts a long time and works well with many chemicals.

Understanding Grade 2 Titanium Pipe Properties

Grade 2 titanium is the most commonly used type of commercially pure titanium in a wide range of industries. This material is very useful because it resists corrosion very well and is also easy to shape into different forms. Its strength and ability to resist harsh chemicals make it very useful for chemical processing.

The chemicals in the gr2 titanium pipe are made up of 99.2% pure titanium and a few other metals. The amounts of iron, oxygen, and nitrogen are still below 0.30%, 0.25%, and 0.03%, respectively. This material maintains a good level of performance in environments where oxidation happens and is strong enough for most processing uses.

Grade 2 titanium tubing is great for fabrication processes because of its mechanical properties. The tensile strength is anywhere from 345 to 483 MPa, and the yield strength is at least 275 MPa. The great stretching properties of the material make it possible to form it into complicated shapes without breaking or failing.

Thermal properties play a big part in how easily something can be made. Grade 2 titanium stays stable at temperatures ranging from very cold to 300°C. In piping systems that go through thermal cycling, low thermal expansion coefficients lower the amount of stress that builds up in one place.

Titanium Pipe Corrosion Resistance in Chemical Environments

Chemical processing settings need materials that can survive strong corrosion. Titanium seamless pipe can stand up to a lot of different chemicals, which makes it very important for certain uses.

Titanium performs better in environments with oxidising acids. Nitric acid, chromic acid, and wet chlorine environments cause very little damage to materials. This resistance comes from titanium's ability to make protective oxide layers that heal themselves when they are hurt.

Titanium pipe corrosion protection is very helpful for titanium pipes that are used in seawater. If you put regular materials in water that has salt, sulphate, and oxygen in it, it usually speeds up corrosion. Grade 2 titanium keeps its strength and shape even after being exposed for decades.

Titanium is also very useful in the processing of chlorinated hydrocarbons. A lot of organic chlorides that damage stainless steel do not affect titanium. This trait is very useful in making drugs and speciality chemicals.

Careful thought must be given to how temperature affects the ability to resist corrosion. Titanium works great at moderate temperatures. But when the temperature gets high in a setting where there is little oxygen, the titanium may absorb hydrogen, which will make the metal more brittle.

Manufacturing Standards and Titanium Pipe Specifications

International rules oversee the making of titanium pipes to make sure that they are always of a certain quality. ASTM B861 covers how seamless gr2 titanium pipe should be made, and ASTM B337 covers how both seamless pipes and welded pipes should be made. ASME SB338 adds more rules for the use of pressure vessels.

System design and installation must take dimensional tolerances into account. The standard thickness for walls that can handle different pressure levels is between 0.89 mm and 25.4 mm. The outside diameters range from 6.35 mm to 610 mm, covering everything from small instrumentation lines to big process vessels.

The needs for surface finish change based on the needs of the application. Bright annealed surfaces are the best at resisting corrosion and are the easiest to clean. If performance is more important than appearance, pickled finishes are an inexpensive option.

Quality control makes sure that the material can be traced back to its source and that it really does what it's supposed to do. Each production lot undergoes chemical analysis, mechanical testing, and non-destructive examination. Before shipping, hydrostatic testing checks that the pressure ratings are correct.

Every shipment comes with certification paperwork that includes compliance statements, reports on tests of the material, and dimensional inspections. This paperwork is very important for regulatory compliance in pharmaceutical and nuclear applications.

Titanium Pipe Applications Across Chemical Industries

The biggest use for grade 2 titanium tubing is in building heat exchangers. Titanium's ability to conduct heat and resist fouling are advantages in shell-and-tube designs. Power generation condensers use titanium because it works well with seawater.

Titanium parts are often used in the reactor vessel internals. Agitator shafts, baffles, and coil assemblies can handle corrosive reaction media without changing shape or size. Pharmaceutical reactors benefit greatly from titanium's biocompatibility.

When they carry fluids that eat away at the metal, process piping systems connect different unit operations. Gr2 titanium pipe fittings make connections that don't leak and resist galvanic corrosion. Valve bodies and pump parts make the system more reliable.

The insides of distillation columns use titanium's mix of strength and resistance to rust. Packing supports, redistributors, and tray parts keep things running smoothly while also avoiding getting dirty and rusting.

Wastewater treatment plants use titanium pipes to handle aggressive effluents. Because titanium is chemically compatible and lasts a long time, ion exchange columns, neutralisation tanks, and scrubber systems can work better.

Titanium Pipe Welding and Fabrication Considerations

When titanium pipe welding is done correctly, it makes use of special methods and controls of the environment. Welding can hurt the atmosphere, which can make the joint quality and corrosion resistance much worse.

For the weld to turn out well, it's very important to pick the right shielding gas. High-purity argon is the main protection, and back-purging stops oxidation on the root side. It's important to get the right balance between gas flow rates and coverage areas.

The joints need to be cleaned and get ready for welding. Chemical cleaning removes chemicals from the surface that could lower the quality of the weld. A good fit-up keeps things from warping and lowers the amount of heat that needs to be used.

There needs to be a balance between the amount of heat that can be used and the amount of penetration that is needed in the welding parameters. It keeps the resistance to corrosion high and the grain growth slow by lowering heat inputs. The multiple pass method is usually useful for parts that are thick.

After welding, operations include checking the work and possibly relieving stress. Radiographic testing finds problems that aren't visible on the surface, and visual examination finds problems that are. Annealing might be necessary for parts that are thick or hard to make.

Cost Analysis and Economic Benefits

When procurement professionals think about the first price of titanium pipes, they often have worries. But looking at the lifecycle cost usually shows that it is much cheaper to use this material than others.

The cost of materials is only one part of the overall system cost. The overall economics are greatly affected by the cost of installing, maintaining, and regularly replacing parts. The long life of titanium often makes the high cost of materials reasonable.

Titanium's resistance to corrosion and fouling means that it doesn't need to be looked after as much, which lowers maintenance costs. Cleaning cycles take a lot more time, which lowers the amount of time the machine is not working and the cost of labour. It is less common and less harsh for chemical cleaning to be done.

Improvements in energy efficiency can be seen as a result of titanium's ability to conduct heat and its unique surface. Lowered fouling keeps the heat transfer coefficients up during the whole service life. Lowering the pressure needed to pump fluids cuts the cost of running the system.

Insurance and liability issues favour materials that have been used successfully in the past. The safe history and predictable behaviour of titanium lowers the risks and costs that come with it.

Selection Criteria for Chemical Processing Applications

The environmental compatibility assessment is the first step in the material selection process. The basic needs of a material are defined by its chemical makeup, temperature range, and pressure requirements. Titanium pipe corrosion resistance charts show you how titanium pipes react to different liquids and gases.

It is necessary for mechanical properties to depend on structural loading and the need to hold pressure. Grade 2 titanium is strong enough for most uses, and higher grades have better properties when they are needed.

The way that things are made affects the choice of materials and the design of the system. It might be necessary to improve formability for complex shapes. On the other hand, welded assemblies need good weldability.

Economic factors include upfront costs, costs for installation, and thoughts about the product's entire lifetime. Value engineering analysis helps balance performance requirements against budget constraints.

Regulatory compliance needs differ from industry to industry and from application to application. Food processing, pharmaceutical manufacturing, and nuclear applications impose specific material qualification standards.

Quality Assurance and Supplier Selection

ISO 9001:2015 certification means that there are very good systems in place to manage quality. Titanium pipe suppliers should show that they are always doing quality control during the manufacturing process. As long as they are used properly, documentation systems must let you see every step of the process.

Testing capabilities make sure that the material is verified and the quality is confirmed. Chemical analysis, mechanical testing, and dimensional inspection show that a supplier knows what they're doing. Third-party testing gives extra proof when it's needed.

Technical support services help make the process of choosing and using materials more efficient. During the whole life of a project, suppliers with a lot of experience help with engineering, fabrication, and fixing problems.

How well deliveries are made impacts the schedules and inventory planning of projects. Trustworthy suppliers keep enough stock on hand and make sure that their customers know how long delivery will take. Being able to make emergency deliveries is useful for very important applications.

Geography plays a big role in choosing suppliers, especially for big projects. Local representation makes it easier to talk to people and lowers the costs and times for delivery and transportation.

Conclusion

Grade 2 titanium pipe represents an optimal solution for chemical processing applications requiring exceptional corrosion resistance and long-term reliability. Understanding material properties, manufacturing standards, and application requirements enables informed procurement decisions that deliver superior value. The combination of excellent chemical compatibility, proven performance, and reasonable cost makes titanium an increasingly popular choice across diverse industrial sectors. Proper supplier selection, quality assurance protocols, and technical support ensure successful implementation and sustained performance throughout extended service life.

Partner with Chuanghui Daye for Your Gr2 Titanium Pipe Requirements

Shaanxi Chuanghui Daye Metal Material combines three decades of rare metal expertise with ISO 9001:2015 certified manufacturing capabilities. Our gr2 titanium pipe manufacturer facilities in China's Titanium Capital deliver consistent quality and competitive pricing for global chemical processing applications. If you have any requirements about titanium pipe, pls feel free to Contact us at info@chdymetal.com for technical consultation and competitive quotations.

References

1. American Society for Testing and Materials. "Standard Specification for Seamless Titanium and Titanium Alloy Pipe." ASTM B861-22. West Conshohocken, PA: ASTM International, 2022.

2. American Society of Mechanical Engineers. "Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers." ASME SB338-20. New York: ASME, 2020.

3. International Organisation for Standardisation. "Titanium and Titanium Alloys - Chemical Composition and Form of Wrought Products." ISO 5832-2:2018. Geneva: ISO, 2018.

4. National Association of Corrosion Engineers. "Corrosion Performance of Titanium in Chemical Process Industries." NACE Publication 6A186. Houston: NACE International, 2019.

5. American Welding Society. "Specification for Welding of Titanium and Titanium Alloys." AWS D1.9/D1.9M:2015. Miami: AWS, 2015.

6. Titanium Development Association. "Guidelines for Design with Titanium in Chemical Plant Equipment." TDA Design Manual DM-102. Dayton: TDA, 2021.