Selecting the optimal medical titanium bar grade requires understanding specific performance characteristics and regulatory compliance requirements. Grade 1 (pure titanium) offers exceptional biocompatibility for basic surgical instruments, while Grade 2 provides enhanced strength for orthopedic applications. Grade 5 (Ti-6Al-4V) delivers superior mechanical properties for load-bearing implants, and Grade 5 ELI (Extra Low Interstitial) represents the premium choice for critical implant applications requiring maximum corrosion resistance and fatigue performance in biological environments.

Understanding Medical Titanium Bar Grades and Their Applications

Titanium alloy bars have revolutionized modern medical manufacturing through their unique combination of biocompatibility and mechanical excellence. Grade 1 titanium provides exceptional corrosion resistance in biological environments, making it ideal for cardiovascular stents and dental crowns. This commercially pure titanium exhibits excellent formability and weldability characteristics.

Grade 2 titanium offers increased strength while maintaining outstanding biocompatibility properties. Medical device manufacturers frequently specify this grade for surgical instruments and orthopedic components requiring moderate load-bearing capacity. The material demonstrates consistent performance across various sterilization processes.

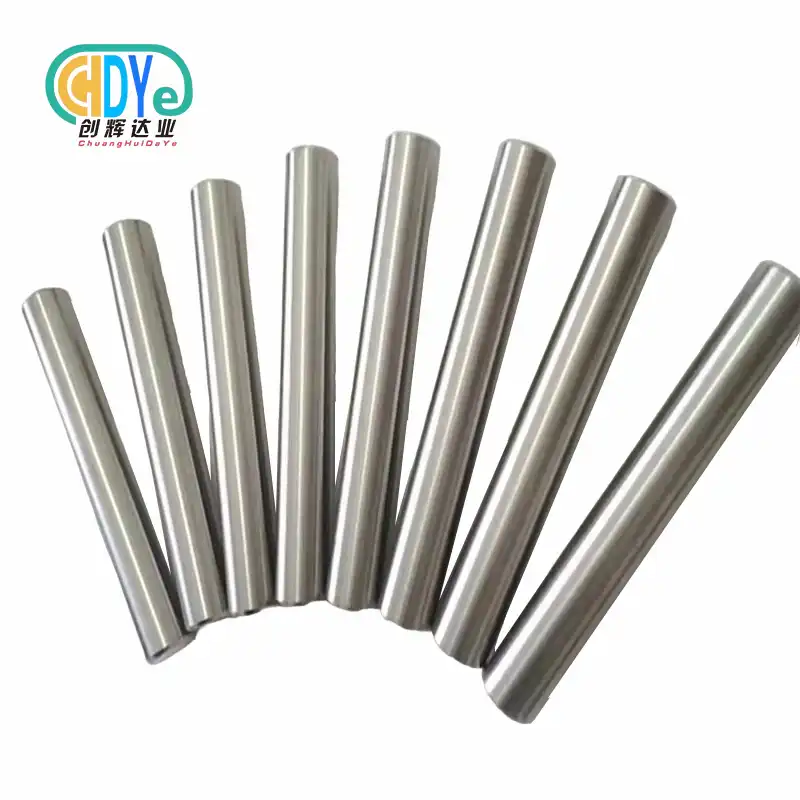

Titanium implant rods manufactured from Grade 5 alloy deliver remarkable strength-to-weight ratios essential for spinal fusion applications. This alpha-beta alloy composition provides enhanced fatigue resistance compared to commercially pure variants. Aerospace-grade manufacturing processes ensure consistent microstructure throughout each bar.

Grade 5 ELI represents the pinnacle of medical titanium bar technology. Extra Low Interstitial processing reduces oxygen and nitrogen content, resulting in improved ductility and fracture toughness. This specification proves critical for long-term implant applications where material reliability directly impacts patient outcomes.

ASTM Standards and Regulatory Compliance Requirements

ASTM F67 establishes comprehensive specifications for unalloyed titanium used in surgical implant applications. This standard defines chemical composition limits, mechanical property requirements, and testing procedures essential for regulatory approval. Manufacturers must demonstrate compliance through rigorous documentation and third-party verification processes.

ASTM F136 governs titanium-6aluminum-4vanadium ELI alloy requirements specifically developed for surgical implant applications. The standard mandates strict control over interstitial elements that could compromise biocompatibility or mechanical performance. Traceability documentation must accompany each production lot to ensure quality consistency.

ISO 5832-3 provides international specifications for titanium implant materials, ensuring global compatibility and acceptance. This standard harmonizes testing methodologies and acceptance criteria across different regulatory jurisdictions. Medical device manufacturers benefit from streamlined approval processes when materials meet these internationally recognized specifications.

Biocompatible titanium bars must undergo extensive cytotoxicity testing according to ISO 10993 biological evaluation protocols. These assessments verify material safety through direct contact studies with living tissues. Documentation requirements include detailed test reports and certificates of compliance for each production batch.

Mechanical Properties and Performance Characteristics

Tensile strength variations among different titanium grades directly influence their suitability for specific medical applications. Grade 1 titanium provides 240 MPa minimum tensile strength, adequate for non-load-bearing components like surgical clips and markers. Grade 2 increases this specification to 345 MPa, enabling broader orthopedic applications.

Grade 5 titanium delivers exceptional 860 MPa tensile strength, making it suitable for demanding spinal fixation systems and joint replacement components. The material's yield strength of 795 MPa ensures reliable performance under repetitive loading conditions. These properties prove essential for long-term implant success.

Modulus of elasticity considerations play a crucial role in implant design and patient comfort. The medical titanium bar's 110 GPa elastic modulus more closely matches human bone compared to stainless steel alternatives. This compatibility reduces stress shielding effects that can lead to bone resorption around implants.

Fatigue resistance becomes paramount for implants subjected to millions of loading cycles throughout their service life. Titanium spinal bars demonstrate superior endurance limits compared to alternative materials. Surface finishing techniques further enhance fatigue performance through stress concentration reduction.

Surface Finishing and Quality Control Processes

Surface roughness specifications directly impact osseointegration success in dental and orthopedic applications. Medical grade titanium bars typically achieve Ra values below 0.2 micrometers through precision grinding and polishing operations. These smooth surfaces minimize bacterial adhesion while promoting healthy tissue integration.

Ultrasonic testing protocols detect internal defects that could compromise implant reliability. Advanced inspection techniques identify inclusions, cracks, or porosity within the material structure. Each bar undergoes comprehensive evaluation before packaging and shipment to medical device manufacturers.

Chemical composition analysis using inductively coupled plasma optical emission spectroscopy ensures compliance with specification requirements. Trace element content verification prevents contamination that could trigger adverse biological responses. Laboratory certificates accompany each shipment documenting elemental composition results.

Microstructure examination reveals grain size distribution and phase composition critical for mechanical property consistency. Metallographic analysis confirms proper heat treatment effectiveness and identifies any processing irregularities. This evaluation ensures uniform performance across the entire bar length.

Manufacturing Processes and Production Capabilities

Vacuum arc remelting technology produces high-purity titanium ingots free from atmospheric contamination. Multiple remelting cycles eliminate segregation and ensure chemical homogeneity throughout the material. This process foundation proves essential for achieving medical-grade quality standards.

Hot forging operations refine grain structure while achieving precise dimensional tolerances. Controlled deformation temperatures and strain rates optimize mechanical properties and eliminate processing defects. Advanced hydraulic presses enable the production of bars up to 20mm in diameter with exceptional roundness consistency.

Centerless grinding achieves tight dimensional tolerances essential for precision medical applications. Automated systems maintain h7, h8, and h9 tolerance grades across production runs. Surface integrity preservation during machining prevents stress concentrations that could initiate fatigue failures.

Heat treatment cycles optimize microstructure for specific application requirements. Annealing temperatures and cooling rates control grain size and residual stress levels. Precise thermal processing ensures consistent mechanical properties and dimensional stability throughout the finished product.

Application-Specific Selection Guidelines

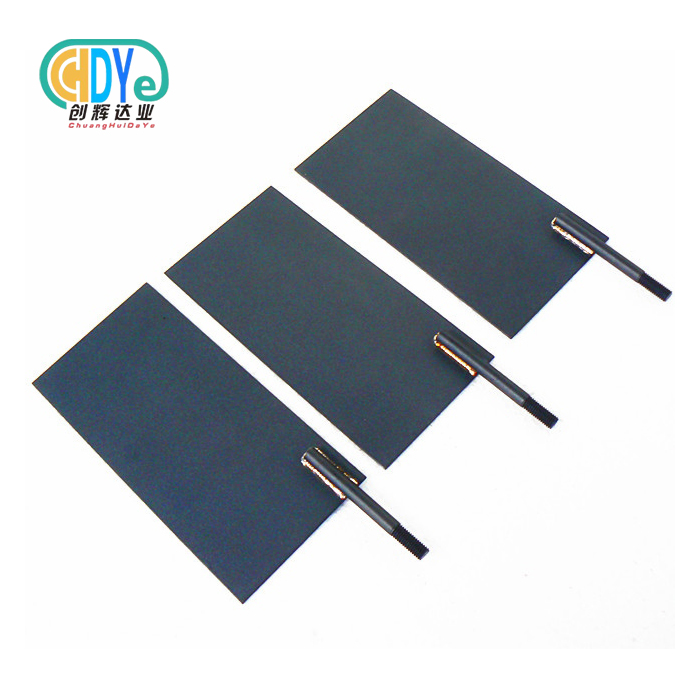

Orthopedic fixation applications benefit from Grade 5 ELI titanium's exceptional strength and corrosion resistance. Spinal rods, bone plates, and screws require materials capable of withstanding high mechanical loads while maintaining biocompatibility. The alloy's fatigue resistance proves crucial for long-term implant success.

Dental implant systems typically utilize Grade 4 or Grade 5 titanium for abutment manufacturing. These materials provide adequate strength for masticatory forces while ensuring excellent osseointegration properties. Surface treatments can enhance bone bonding characteristics for improved clinical outcomes.

Cardiovascular applications often specify Grade 1 or Grade 2 titanium due to their superior corrosion resistance in blood environments. Stent platforms and valve components require materials that resist degradation while maintaining structural integrity. Pure titanium grades offer optimal biocompatibility for these critical applications.

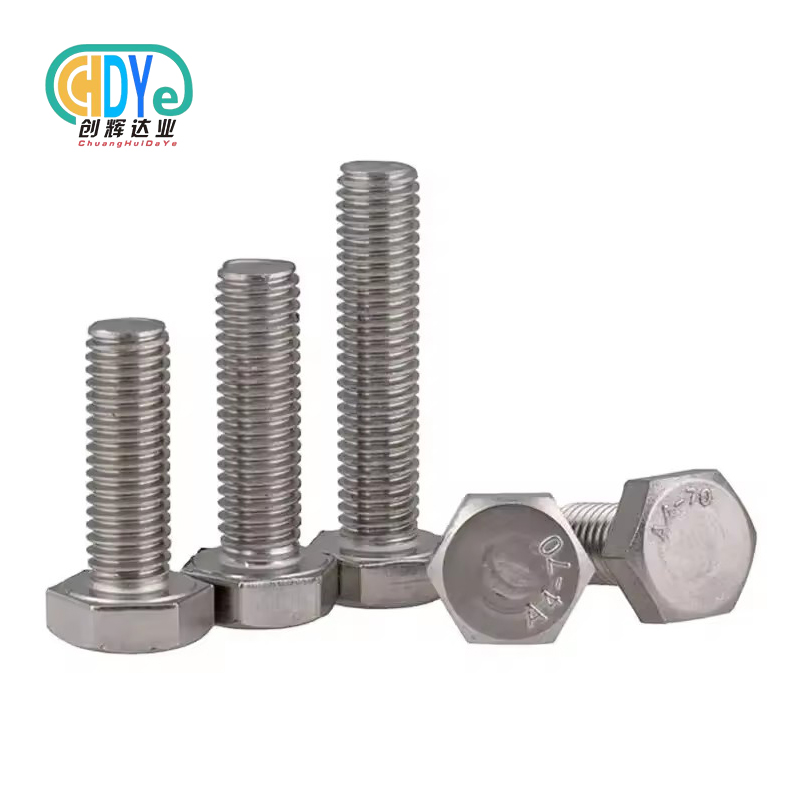

Surgical instrument manufacturing leverages titanium's lightweight properties and sterilization compatibility. Grade 2 titanium provides adequate strength for forceps, scissors, and specialized tools while remaining non-magnetic. The material's resistance to repeated sterilization cycles ensures long service life.

Quality Assurance and Testing Protocols

Comprehensive inspection procedures begin with incoming raw material verification and continue through final product delivery. Chemical analysis confirms composition compliance while mechanical testing validates strength properties. Dimensional inspection ensures geometric accuracy meets customer specifications.

Non-destructive testing techniques identify internal defects without compromising material integrity. Eddy current inspection detects surface cracks while ultrasonic evaluation reveals internal discontinuities. These methods provide confidence in material reliability for critical medical applications.

Biocompatibility testing according to ISO 10993 standards ensures biological safety for implant applications. Cytotoxicity, sensitization, and irritation studies verify material compatibility with living tissues. Test reports provide essential documentation for medical device regulatory submissions.

Traceability systems track material history from initial melting through final delivery to customers. Lot numbers enable rapid identification of production parameters and test results for any specific shipment. This documentation proves essential for medical device quality management systems.

Conclusion

Selecting appropriate medical titanium bar grades requires careful consideration of mechanical properties, biocompatibility requirements, and application-specific performance demands. Grade selection impacts implant longevity, patient outcomes, and regulatory approval processes. Understanding ASTM specifications and manufacturing quality standards ensures successful medical device development. Working with experienced suppliers who maintain comprehensive quality systems and testing capabilities proves essential for achieving consistent results. The investment in premium titanium materials translates directly into improved patient care and device reliability throughout extended service life.

Partner with Chuanghui Daye for Premium Medical Titanium Bar Solutions

Shaanxi Chuanghui Daye delivers ISO 9001:2015 certified medical titanium bar manufacturing with over 30 years of rare metal industry expertise. Our advanced vacuum melting and precision machining capabilities ensure consistent quality for orthopedic, dental, and surgical applications. Ready to discuss your specific requirements? Connect with our technical team and contact us at info@chdymetal.com today.

References

1. American Society for Testing and Materials. "Standard Specification for Unalloyed Titanium, for Surgical Implant Applications (UNS R50250, UNS R50400, UNS R50550, UNS R50700)." ASTM F67-13, 2017.

2. American Society for Testing and Materials. "Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications." ASTM F136-13, 2019.

3. International Organization for Standardization. "Implants for surgery — Metallic materials — Part 3: Wrought titanium 6-aluminum 4-vanadium alloy." ISO 5832-3:1996, 2014.

4. Niinomi, Mitsuo. "Mechanical Properties of Biomedical Titanium Alloys." Materials Science and Engineering: A, vol. 243, pp. 231-236, 1998.

5. Rack, Henry J., and Quesnel, John N. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering: C, vol. 26, pp. 1269-1277, 2006.

6. Wang, Kefeng. "The Use of Titanium for Medical Applications in the USA." Materials Science and Engineering: A, vol. 213, pp. 134-137, 1996.