- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Gr2 Titanium Plate – Excellent Weldability & Formability

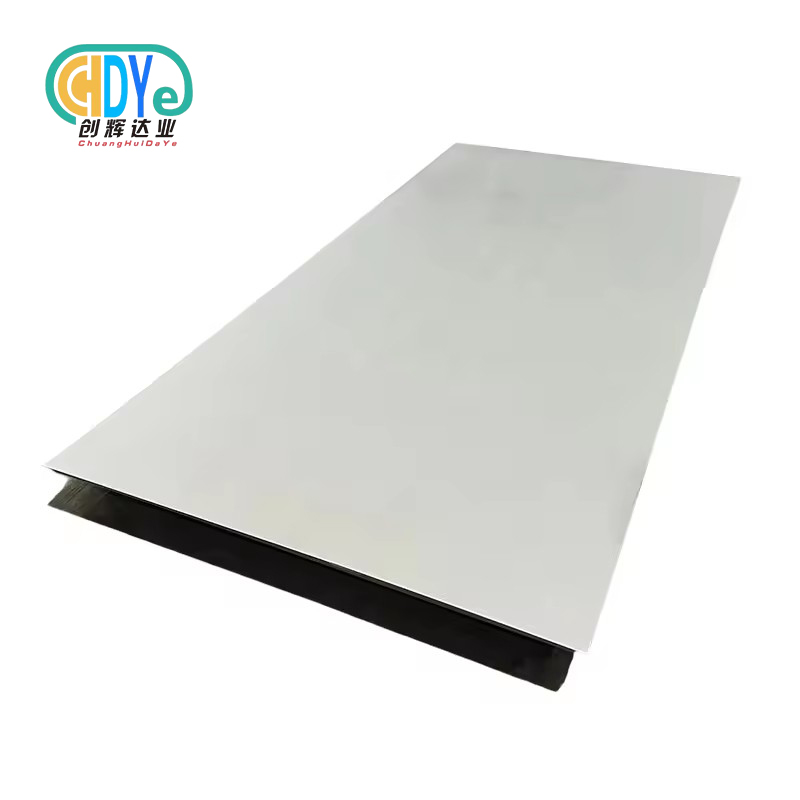

It is known that Gr2 Titanium Plate is one of the best and purest industrial titanium products because it is so easy to weld and shape. This commercially pure titanium material has a great mix of moderate strength and superior corrosion resistance, which is why it is used so extensively in medical device manufacturing, aerospace engineering, and marine engineering. A special set of properties makes it possible for makers to make complicated structures that stay strong and work well in harsh industrial settings.

Understanding Gr2 Titanium Plate: Properties and Characteristics

The main thing that makes economically pure titanium Grade 2 appealing is that it has a clear chemical makeup, with mostly titanium and only a few alloying elements. These ingredients give the material good mechanical qualities, making it the best choice for uses that need both strength and workability.

Chemical Composition and Mechanical Properties

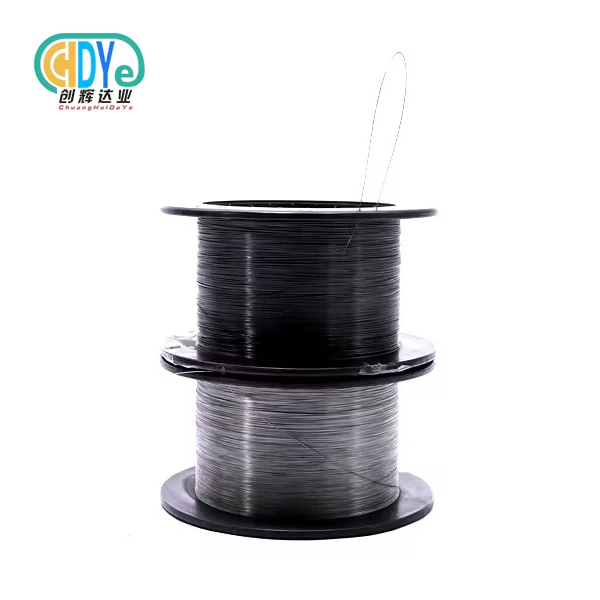

Gr2 Titanium Plate keeps up a titanium substance of roughly 99.2%, complemented by controlled amounts of press (0.25%), carbon (0.03%), oxygen (0.08%), and nitrogen (0.015%). This carefully adjusted composition straightforwardly upgrades the material's weldability and formability, while protecting its auxiliary judgment. The mechanical properties incorporate noteworthy malleable quality characteristics, amazing ablation quality execution, and exceptional stretching capabilities that encourage complex shaping operations.

Density and Strength Advantages

One of the most compelling characteristics of this fabric is its uncommon strength-to-weight ratio. With a thickness of 4.51g/cm³—approximately half that of iron—Grade 2 titanium conveys quality about 1.5 times higher than standard steel. This combination makes it a perfect lightweight auxiliary fabric for applications where weight reduction without quality compromise is basic.

Superior Corrosion Resistance Performance

The erosion resistance capabilities of Review 2 titanium outperform numerous ordinary metals, counting stainless steel and aluminum, especially in forceful situations. This fabric illustrates momentous soundness when exposed to air conditions, most water arrangements, and different corrosive and soluble base situations. Indeed, when subjected to profoundly destructive specialists such as water regia, titanium plates maintain their auxiliary judgment and execution characteristics.

Heat Treatment and Processing Flexibility

Warm treatment choices can optimize the mechanical properties of Review 2 titanium plates, whereas exact thickness and thickness resiliences empower precise building applications. The handling innovation includes advanced fabricating strategies, such as hot rolling and cold rolling methods. Hot rolling forms include warming titanium plates to high temperatures, sometimes recently rolling, whereas cold rolling operations happen at room temperature. Extra treatment forms counting toughening and corrosive washing, advanced upgraded fabric properties, and surface characteristics.

Comparing Gr2 Titanium Plate with Alternatives: Making the Right Choice

To choose the right materials for industrial projects, you need to know a lot about how Grade 2 titanium stacks up against other choices. This analysis helps people who work in procurement make smart choices based on performance needs and price concerns.

Gr2 vs. Stainless Steel Performance

In terms of corrosion protection and weight reduction, Gr2 Titanium Plate is much better than stainless steel. Stainless steel is good at resisting corrosion in general, but titanium is better in chloride-filled settings and high-temperature situations. Titanium's lighter weight is especially useful in aerospace and marine uses, where optimizing payload is very important.

Aluminum Comparison and Applications

Compared to aluminum options, Grade 2 titanium is stronger and can handle higher temperatures better. Aluminum has lower material costs, but titanium's durability and long life often make it a better choice for demanding uses where total cost of ownership is important. Metals that are biocompatible, like titanium, are better for making medical devices than metals like aluminum.

Higher-Grade Titanium Alternatives

When compared to higher-grade titanium metals like Grade 5 (Ti-6Al-4V), Grade 2 is easier to shape and weld. Even though Grade 5 is stronger, its alloying elements can make bonding more difficult and make it harder to shape. The commercially pure makeup of Grade 2 makes it easier to work with and make, especially for uses that need a lot of shaping or complicated welding.

Unlocking the Advantages of Gr2 Titanium Plate: Weldability & Formability in Focus

Because it is chemically pure, Grade 2 titanium is known for being very easy to weld. This is because it reduces the risk of welding defects and makes joining processes more reliable in many industry settings.

Welding Techniques and Best Practices

Because Grade 2 titanium is commercially pure, it can be welded successfully using a number of ways, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). It is possible to do these things with only a small chance of cracking or other welding problems that happen with other titanium types. Because it doesn't contain any complicated alloying elements, it doesn't need as many special welding techniques and is easier to work with when it comes to fabrication.

Formability and Fabrication Capabilities

Because Grade 2 titanium is so easy to shape, it can be made into complicated shapes without losing any of its power. In custom engineering situations where normal shapes don't meet design needs, this feature is very important. Several shaping methods, such as bending, deep drawing, and pressing, work well with the material.

Real-World Industry Applications

Grade 2 titanium is used in aerospace manufacturing to make it easier to make lightweight structural parts that need to work well in harsh circumstances. Its resistance to corrosion and ability to be shaped make it possible to make complex hull parts and pipe systems that are used in marine settings. Medical device makers use both biocompatibility and formability to make complicated implants and surgical tools that need to be made with exact measurements.

Biocompatibility in Medical Applications

Grade 2 titanium is very useful for making medical devices because it is non-toxic, has no smell, and doesn't irritate the skin. Artificial joints, dental implants, and surgical tools are all examples of uses where it is very important that the material is compatible with human tissue. Because it is biocompatible and easy to shape, it can be used to make custom medical products that meet the needs of each patient.

Procurement Insights: Sourcing Quality Gr2 Titanium Plate for Your Business

To buy Grade 2 titanium plates correctly, you need to know a lot about international standards, quality certifications, and how to evaluate suppliers in a way that makes sure the materials are real and the project is a success.

International Standards and Certifications

Grade 2 titanium plates made according to ASTM B265 and ISO 5832 standards make sure that the mechanical qualities and thickness are always the same. These certifications show that the materials are of high quality and can be used for large-scale fabrication, building pressure vessels, and lining titanium machinery. Knowing these standards helps buyers choose the right products and make sure that suppliers are following them.

Supplier Evaluation and Selection Criteria

To find reliable suppliers, you have to look at a lot of things, such as their manufacturing skills, their quality control systems, and the reliability of their supply chains. Suppliers should show that they are certified to ISO 9001:2015 and keep full quality control systems that include checking raw materials, melting and forging, machining and shaping, and final inspection methods.

Customization Options and Lead Times

Good suppliers give customization services, such as precise cutting, sizing, and custom packaging, to meet the needs of each project. Knowing the customization options that are out there makes sure that the materials that are bought match the standards for manufacturing and assembly. Expecting realistic lead times can help with planning projects and keeping track of inventory, especially for large-scale commercial uses.

Our Company and Product Offerings

The Baoji High-tech Development Zone in Shaanxi Province is home to Shaanxi Chuanghui Daye Metal Material Co., Ltd. This place is known as China's "Titanium Capital." Our location is very good because it gives us access to good transportation systems and well-established industry networks that help our clients around the world.

Our company is based on more than 30 years of experience in the rare metals business. This lets us offer high-quality Grade 2 titanium plates with full approvals and a wide range of customization options. We run complex melting, forging, and rolling facilities that are only used to make titanium materials. This makes sure that the quality and performance are always the same.

Some of the things we can make are vacuum-melted metal, hot-rolled metal, and precision-leveled metal that has a regular thickness and great flatness. The processing power can handle large-format plates up to 2000 mm wide, making it possible to reliably serve large-scale fabrication projects. Quality management with ISO 9001:2015 approval makes sure that all steps of the production process are strictly controlled, from checking the raw materials to packaging and shipping them.

Conclusion

When it comes to performance, weldability, and shapeability, Gr2 Titanium Plates are the best of the best. They meet the strict needs of industries like aerospace, marine, chemical processing, and medical device making. The fact that these materials are very resistant to corrosion, biocompatible, and easy to work with makes them perfect for uses that need stable, long-term performance. By learning about the qualities, benefits, and buying factors, you can make smart choices that match the material choice with the needs of the project and the organization's goals. Strategies for getting titanium that work are based on finding good sources with a wide range of manufacturing skills and high certification standards.

FAQ

Q: What makes Grade 2 titanium more weldable than other titanium grades?

A: The commercially pure composition of Grade 2 titanium, with minimal alloying elements, significantly enhances its weldability compared to higher-grade titanium alloys. The absence of complex alloying elements reduces the risk of welding defects and makes the material more forgiving during TIG and MIG welding processes.

Q: How does Grade 2 titanium compare to stainless steel for marine applications?

A: Grade 2 titanium offers superior corrosion resistance compared to stainless steel, particularly in chloride-rich marine environments. While stainless steel may suffer from pitting and crevice corrosion in saltwater conditions, titanium maintains its integrity and performance over extended periods.

Q: What are the key considerations for bulk ordering Grade 2 titanium plates?

A: Bulk ordering requires verification of ASTM B265 or ISO 5832 compliance, supplier ISO 9001:2015 certification, and comprehensive quality documentation. Consider lead times, customization requirements, packaging specifications, and logistics coordination to ensure smooth delivery and project execution.

Partner with Chuanghui Daye for Your Gr2 Titanium Plate Requirements

Shaanxi Chuanghui Daye stands ready to support your titanium procurement needs with our comprehensive Grade 2 titanium plate manufacturing capabilities. Our ISO 9001:2015 certified facilities, advanced processing equipment, and experienced technical team ensure delivery of premium-quality materials that meet your precise specifications. Contact us at info@chdymetal.com to discuss your requirements with a trusted Gr2 Titanium Plate supplier committed to excellence in every order.

References

1. ASM International Handbook Committee. "Properties and Selection: Nonferrous Alloys and Special-Purpose Materials." ASM Handbook Volume 2, 2015.

2. Donachie, Matthew J. "Titanium: A Technical Guide." ASM International Materials Engineering Series, 2018.

3. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate." ASTM B265-20, 2020.

4. International Organization for Standardization. "Implants for Surgery - Metallic Materials - Part 3: Wrought Titanium 6-Aluminium 4-Vanadium Alloy." ISO 5832-3:2016.

5. Boyer, Rodney R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering Research Journal, 2019.

6. Lutjering, Gerd and James C. Williams. "Titanium Engineering Materials and Processes." Springer Materials Science Series, 2017.

Learn about our latest products and discounts through SMS or email