- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Implant-Grade Medical Titanium Plate for Precision Engineering

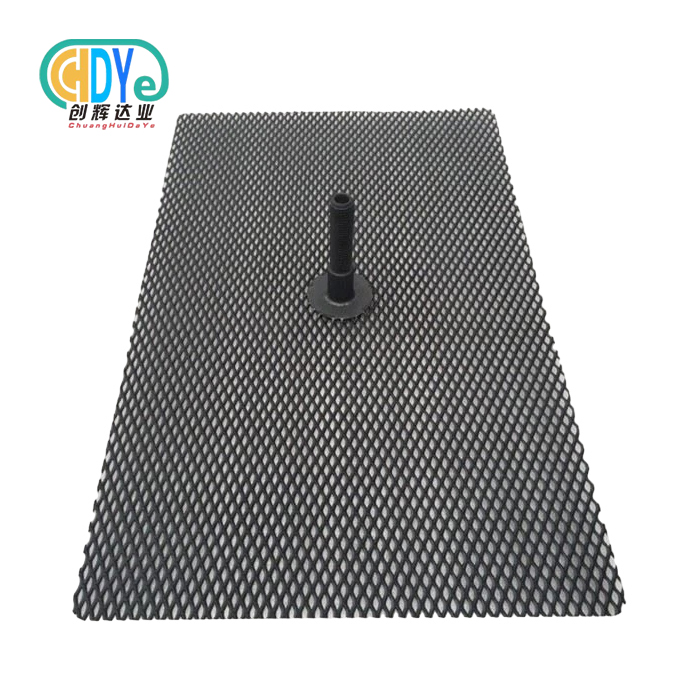

When precise engineering meets medical innovation, an implant-grade medical titanium plate is essential for healthcare technologies. These titanium components are the pinnacle of biomedical engineering, combining superior mechanical qualities and biocompatibility. Titanium plates become the material of choice for orthopedic implants, dental prosthesis, and surgical tools that need long-term performance and patient safety.

Understanding Medical Titanium Plates: Properties, Types, and Applications

Stabilizing and supporting bone structures, medical titanium plates are vital. Their implant-grade titanium has excellent biocompatibility, corrosion resistance, and mechanical strength for long-term use. Titanium is suited for medical applications because material performance directly affects patient outcomes due to its unique characteristics.

Essential Properties of Implant-Grade Titanium

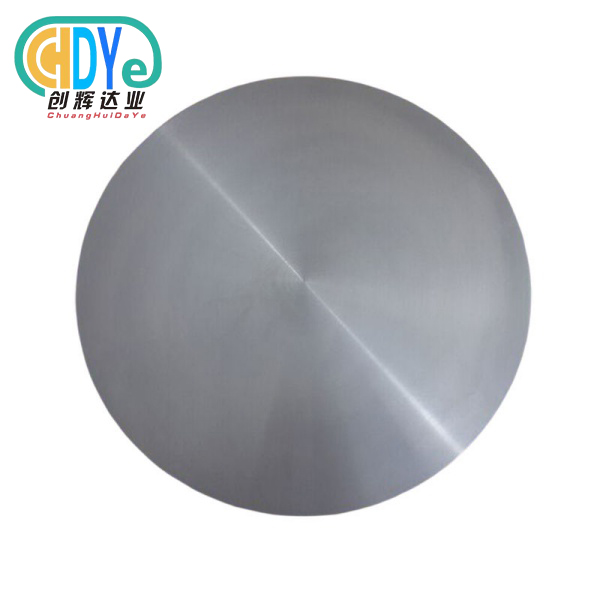

Medical-grade titanium is distinguished by its high strength-to-weight ratio, biological corrosion resistance, and biocompatibility. Titanium forms a persistent oxide layer that protects human tissue. The material's modulus of elasticity mimics human bone, eliminating stress shielding that can impair implant success.

Titanium's non-magnetic characteristics allow MRI imaging without safety issues. The material's thermal expansion coefficient matches bone tissue, reducing mechanical stress at the implant-bone interface during temperature changes.

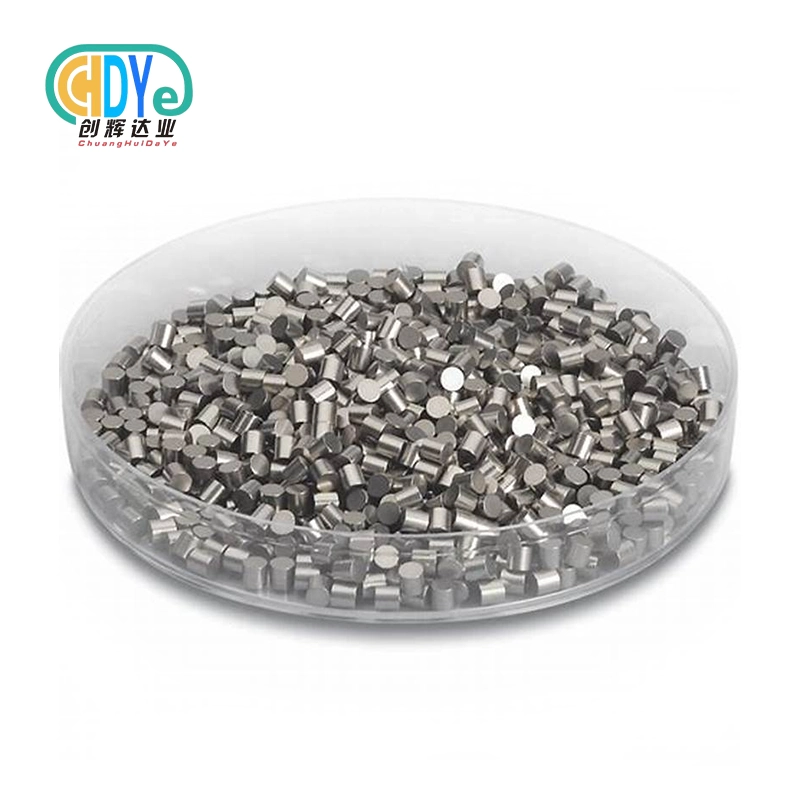

Common Medical Titanium Alloy Grades

Medical applications mostly use Grade 5 (Ti-6Al-4V), Grade 5 ELI (Extra Low Interstitial), and Grade 23 ELI. Each grade has advantages based on use. Grade 5 titanium is suited for load-bearing implants, including hip replacements and spinal devices, due to its mechanical strength and fatigue resistance.

Grade 23 ELI is the purest, with reduced interstitial components for biocompatibility and corrosion resistance. This grade is ideal for long-term implants that require tissue compatibility. The Extra Low Interstitial classification denotes strict oxygen, nitrogen, carbon, and hydrogen control, improving ductility and fracture toughness.

Clinical Applications and Device Types

In orthopedic, neurosurgical, and maxillofacial surgery, titanium plates are widely used. Reconstruction plates are versatile for anatomical repair, whereas locking plates stabilize complex fracture patterns. Miniplates are used in facial reconstruction and pediatric orthopedics to minimize implant profile.

Dynamic compression plates manage fracture site compression for optimum healing. These devices have advanced design features that allow surgeons to compress implants precisely while retaining stability. Titanium machining allows unique plate designs for individual anatomical needs and surgical methods.

Comparative Analysis for Informed Procurement Decisions

Choosing the best titanium plate necessitates comparing it to stainless steel, cobalt chrome, and bioabsorbable plates. Titanium is recommended due to its corrosion resistance and biocompatibility, but some surgeries may prefer other materials. Understanding material properties helps procurement professionals balance performance and cost on evidence.

Material Performance Comparison

Stainless steel implants are cheaper but stiffer and more corrosive than titanium ones. The magnetic characteristics of stainless steel limit imaging and may cause patient pain during MRIs. Nickel-containing cobalt chrome alloys are wear-resistant but may cause allergic reactions in susceptible persons.

Bioabsorbable plates, an emerging category, eliminate implant removal. For load-bearing applications, these materials cannot match titanium's mechanical strength. The breakdown timescale of bioabsorbable materials must match tissue healing rates, complicating device selection and surgical planning.

Industry Standards and Quality Benchmarks

Stryker, Zimmer Biomet, and Medtronic set titanium plate quality and performance standards. Research and development are substantially funded by these companies to improve implant designs and manufacturing. Supplier capabilities and product specifications are assessed using their quality systems.

Manufacturer certifications like ISO 13485 and FDA compliance should be considered when buying. Supplier audit records and customer comments reveal long-term cooperation possibilities. As regulations change, material traceability and certification paperwork become more critical.

Cost-Benefit Analysis Framework

Successful procurement techniques evaluate implant durability, revision rates, and patient outcomes in addition to initial material prices. Titanium plates cost more than other materials, but their performance often justifies it. Healthcare costs decrease due to fewer complications and longer implant lifespans.

Large-scale purchasing and long-term supply contracts can lower material prices and stabilize supply chains. Custom processing and engineering support add value beyond material supply, especially for specialist applications with unique specifications.

Procurement Strategies for Medical Titanium Plates in B2B Markets

Certified, reputable providers of implant-grade titanium plates with customizable possibilities are essential for global B2B buying. This part emphasizes supplier evaluation and relationship management to find credible wholesale distributors and manufacturers in key locations.

Supplier Qualification and Assessment

Comprehensive supplier qualification methods assess production, quality, and regulatory compliance to ensure successful procurement. Suppliers must comply with FDA QSR and European MDR medical device rules. Site audits and capability assessments evaluate production and quality control facilities.

Financial stability studies ensure supplier sustainability for long-term collaborations, especially for medical device applications requiring regular supply. Intellectual property and confidentiality agreements safeguard private designs and specifications in joint development.

Global Sourcing Considerations

International procurement offers specialist manufacturers and competitive costs, but regulatory compliance and quality requirements must be assessed. Suppliers in established medical device manufacturing countries offer infrastructure, expertise, and regulatory understanding. Transportation logistics and lead times are crucial for inventory management and cost reduction.

Currency changes and trade rules affect procurement costs and delivery times. Geopolitical and supply chain disruption risks are reduced by diverse supplier networks. Performance monitoring and supplier scorecards optimize relationships and boost performance.

Risk Management and Quality Assurance

Medical device procurement requires risk management to address supply disruptions, quality difficulties, and regulatory changes. Material specifications, testing criteria, and documentation standards are defined in supplier quality agreements. Before materials reach manufacturing, incoming inspections check purchase parameters and quality.

For manufacturing continuity, contingency planning comprises alternate sources and strategic inventory management. Regular supplier performance reviews and remedial action assure quality and delivery compliance.

Company Introduction and Product & Service Information

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a leading implant-grade medical titanium plate manufacturer with over 30 years of rare metal industry experience. In Baoji High-tech Development Zone, China's "Titanium Capital," our company has excellent infrastructure and industry cluster advantages that improve manufacturing and supply chain efficiency.

Manufacturing Excellence and Technical Capabilities

Our modern production facilities include vacuum melting furnaces, precision rolling mills, and machining centers for total titanium plate manufacturing control. Medical titanium plates are precisely rolled, annealed, straightened, and surface finished to ensure grain structure and mechanical consistency. ISO 9001:2015 certifies our quality management excellence and ongoing improvement.

The company custom-machines orthopedic implants, bone plates, and dental devices in addition to plate production. Our engineers work closely with clients to create custom solutions that fulfill application and dimensional tolerances.

Product Portfolio and Specifications

Our medical titanium plates are Grades 5, 5 ELI, and 23 ELI, made to ASTM F67 and F136 standards. They have excellent biocompatibility, mechanical strength, and corrosion resistance for surgical applications. Our plates are suitable for precision machining of implant components due to their varied thicknesses and customized sizes.

Our titanium materials are lightweight and strong, allowing medical device manufacturers to optimize implant designs for patient comfort and surgical outcomes. Custom machinability allows precise implant component processing with tight dimensional accuracy for important medical applications.

Quality Assurance and Testing Protocols

From raw material inspection to final product verification, quality control is performed throughout production. Our testing processes include ICP-OES chemical composition analysis, tensile and yield strength testing, and ultrasonic flaw identification to assure material integrity. Inspections of surface roughness and flatness ensure dimensional accuracy and finish.

Each batch is biocompatibility and cytotoxicity tested for human implantation. Every shipment includes material traceability paperwork for medical device manufacture and regulatory compliance.

Conclusion

Precision engineering and biocompatibility requirements make implant-grade medical titanium plates essential in medical device manufacturing. Titanium alloys are essential for orthopedic implants and cranial reconstruction due to their strength-to-weight ratios, corrosion resistance, and tissue compatibility. Material performance, supplier reliability, and cost must be balanced with rising regulatory criteria in successful procurement strategies. Medical titanium uses will grow as production processes improve, and novel alloy compositions match clinical needs.

FAQ

Q: Is medical-grade titanium safe for long-term implantation?

A: Medical-grade titanium demonstrates exceptional safety for long-term implantation due to its outstanding biocompatibility and non-toxic properties. The material's ability to integrate with human bone tissue, known as osseointegration, makes it ideal for permanent implant applications. Titanium's inert nature prevents adverse tissue reactions and corrosion in physiological environments.

Q: Why are titanium plates preferred in surgical procedures?

A: Titanium plates are considered the gold standard for internal fixation in craniomaxillofacial surgery and orthopedic procedures. Their biocompatible nature, combined with mechanical properties that closely match human bone, provides optimal healing conditions. The material's radiolucent characteristics allow clear visualization during imaging procedures without interference.

Q: What distinguishes Grade 5 ELI from standard Grade 5 titanium?

A: Grade 5 ELI (Extra Low Interstitial) contains reduced levels of oxygen, nitrogen, and carbon compared to standard Grade 5 titanium. This reduction in interstitial elements enhances ductility, fracture toughness, and biocompatibility, making it particularly suitable for medical implant applications requiring maximum tissue compatibility.

Q: Do titanium plates interfere with metal detection systems?

A: High-grade medical titanium alloys typically do not trigger standard metal detectors due to their low magnetic permeability and minimal iron content. However, some security systems with enhanced sensitivity may detect titanium implants, and patients should carry medical documentation when traveling.

Q: How do manufacturers ensure consistent quality in medical titanium plates?

A: Quality assurance involves comprehensive testing protocols, including chemical composition analysis, mechanical property verification, ultrasonic flaw detection, and biocompatibility testing. ISO 13485 certification and ASTM standard compliance ensure consistent manufacturing processes and material properties across production batches.

Partner with Chuanghui Daye for Premium Medical Titanium Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. combines three decades of rare metal expertise with advanced manufacturing capabilities to deliver superior medical titanium plate solutions. Our ISO 9001:2015 certified facility in China's Titanium Capital ensures consistent quality and competitive pricing for global medical device manufacturers. Contact our technical team at info@chdymetal.com to discuss your specific requirements and discover how our implant-grade materials can enhance your product development. As a trusted medical titanium plate supplier, we provide comprehensive support from initial consultation through delivery, ensuring your procurement success.

References

1. Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses and Medical Applications, Brunette, D.M., et al., Springer-Verlag Berlin Heidelberg, 2001.

2. ASTM F136-13 Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI Alloy for Surgical Implant Applications, ASTM International, West Conshohocken, PA, 2013.

3. Biocompatibility and Clinical Applications of Titanium and Titanium Alloys in Orthopedic Implants, Williams, R.L., Journal of Materials Science: Materials in Medicine, Volume 18, Issue 7, 2007.

4. Mechanical Properties and Microstructure of Medical Grade Ti-6Al-4V ELI Alloy, Kumar, S., et al., Materials Science and Engineering: C, Volume 78, 2017.

5. Quality Assurance in Medical Device Manufacturing: ISO 13485 Implementation Guide for Titanium Implant Production, Medical Device Quality Assurance Institute, 2019.

6. Clinical Performance of Titanium Plates in Craniomaxillofacial Surgery: A Comprehensive Review, Thompson, A.R., et al., International Journal of Oral and Maxillofacial Surgery, Volume 45, Issue 3, 2016.

Learn about our latest products and discounts through SMS or email