- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Medical Titanium Plate with High Fatigue & Load Resistance

Medical titanium plates revolutionize orthopedic surgery by providing fatigue and load resistance for long-term implant stability and patient safety. These precision-engineered components are essential for bone fixation, cranial reconstruction, and other surgeries due to their lightweight and mechanical strength. Medical titanium plates' unique metallurgical composition and superior manufacturing procedures provide unsurpassed durability under physiological stress.

Understanding Medical Titanium Plates and Their Superior Performance

Composition and Manufacturing Excellence

Medical titanium plates, precision-engineered implants made from high-grade titanium alloys, are known for their strength-to-weight ratio and biocompatibility. Medical applications mainly use Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI (Grade 23), and commercially pure titanium versions that fulfill strict ASTM F67 and ASTM F136 criteria. High-quality vacuum melting, precision rolling, and advanced heat treatment optimise the microstructure of these materials for surgical use.

Electron beam melting, controlled environment processing, and precision machining ensure plate mechanical qualities are consistent. Advanced annealing creates homogeneous grain structures that improve fatigue resistance, while surface treatments boost osseointegration. For product reliability, each production batch undergoes chemical composition analysis, mechanical property verification, and ultrasonic fault identification.

Comparative Performance Advantages

Titanium plates outperform stainless steel and ceramics in corrosion resistance and biological response risk, improving patient safety. Despite their low cost, stainless steel implants have greater elastic modulus values that may stress-shield bone remodeling. Titanium's elastic modulus matches bone, improving natural load transmission and decreasing implant problems.

Ceramics are biocompatible but lack ductility and impact resistance for high-stress applications. Titanium plates can withstand unexpected impact forces under dynamic loading circumstances. Titanium has much better corrosion resistance than stainless steel in physiological settings, lowering metal ion release and inflammatory effects.

Clinical Applications and Specialized Design Features

Medical titanium plates come in locking, dynamic compression, and reconstructive designs for specific fracture patterns and anatomical needs. Threaded screw-plate interfaces give angular stability, improving osteoporotic bone fixation with locking plates. Dynamic compression plates manage fracture site compression with a unique hole geometry to promote natural healing.

Complex geometric designs that accept varied anatomical differences while preserving mechanical performance are possible with titanium. Cranial reconstructive plates have sophisticated contouring to match patient anatomy. Titanium's biocompatibility allows pediatric plates to stay in place during growth without generating side effects or necessitating removal.

High Fatigue and Load Resistance: Key Factors That Make Titanium Plates Ideal

Understanding Fatigue Mechanisms in Medical Applications

Implants subjected to repetitive physiological loads must have fatigue resistance to sustain cyclic forces. Ordinary activities strain bones millions of times per year, causing fatigue that challenges implant materials. Titanium alloys preserve structural integrity under recurrent physiological loads, minimizing failure risk during long-term healing and service.

The crystalline structure and alloy composition of titanium plates prevent crack initiation and propagation under cyclic loading, improving fatigue performance. While stainless steel can acquire stress concentrations that cause premature failure, titanium maintains its mechanical properties throughout fatigue life. Ti-6Al-4V outperforms other materials in similar testing settings with fatigue strengths of 500 MPa at 10 million cycles.

Real-World Performance Data and Clinical Evidence

Multiple decades of clinical case studies demonstrate titanium's superior fatigue performance in orthopedic applications. Studies of titanium plate fixations over 20 years show survival rates of 95%, with biological reasons rather than mechanical fatigue causing failure. These results demonstrate the material's structural integrity under physiological loading situations that would compromise other materials.

ASTM F382 load resistance testing shows that medical-grade titanium plates may endure ultimate tensile strengths over 900 MPa and yield strengths over 800 MPa. Clinically, these mechanical qualities allow repair of complicated fractures that require significant mechanical support. Titanium alloys' ductility permits controlled deformation under severe loading conditions, preventing catastrophic brittle failure modes that could threaten patients.

Cost-Effectiveness Analysis and Lifecycle Value

Titanium plates have greater initial material costs than stainless steel, but their fatigue and stress endurance provide them with lifecycle value advantages. Healthcare systems and patients gain from cost-effectiveness due to lower revision rates, implant lifetime, and complication rates. Titanium plates often offer better long-term performance value to procurement teams considering the total cost of ownership.

Economic assessments show that the titanium material premium price is covered by reduced revision procedures and healthcare expenditures during normal implant service life periods. The high corrosion resistance reduces concerns about long-term degeneration that could require implant removal or replacement. These qualities make titanium plates a good financial choice for orthopedic applications that require long-term durability.

Procurement Insights: How to Select and Source the Best Medical Titanium Plates?

Quality Certification and Regulatory Compliance Requirements

Medical titanium plate procurement needs rigorous review of quality certifications, regulatory compliance status, and supplier credibility indicators to ensure product safety and performance. FDA approval, ISO 13485 certification, and CE marking compliance are essential for qualified vendors. These certifications verify medical device manufacturing compliance with strict quality management systems and regulatory control.

Purchasers should check suppliers' quality documents, including material certificates, manufacturing records, and traceability records that meet regulatory criteria. Materials acquired fulfill medical industry standards by meeting ASTM F136 for Ti-6Al-4V ELI materials and ASTM F67 for commercially pure titanium grades. Third-party testing and certificate of compliance paperwork ensure material quality and consistency.

Supplier Evaluation and Partnership Development

Assessing production capacities, quality systems, and technical support resources to meet procurement goals is necessary to find competent titanium plate manufacturers. Suppliers should have vacuum melting, precise machining, and thorough testing labs to ensure product quality. Manufacturing and quality system capabilities are verified by site audits and supplier qualification.

Medical applications sometimes require custom geometries, surface treatments, and dimensional specifications that transcend normal product offers, making customization capabilities crucial. OEM partnerships provide cost-effective, application-specific solution development to improve healthcare results. Metallurgical and application engineering support helps with product selection and implementation.

Supply Chain Logistics and Pricing Strategies

Procurement strategies must optimize the total cost of ownership and product availability through supply chain logistics, inventory management, and pricing negotiations. Bulk purchasing agreements can save money and provide adequate inventory for planned and emergency procedures. Supplier proximity to manufacturing or distribution centers increases delivery times and transportation costs, affecting procurement economics.

Titanium plate price should account for raw material cost variations, manufacturing complexity, and market demand dynamics. Long-term contracts allow suppliers to expand capacity and enhance quality while ensuring pricing consistency and supply certainty. Negotiations over payment terms, delivery timelines, and quality guarantees affect procurement value and risk management.

Shaanxi Chuanghui Daye: Your Trusted Medical Titanium Plate Manufacturer

Advanced Manufacturing Capabilities and Quality Excellence

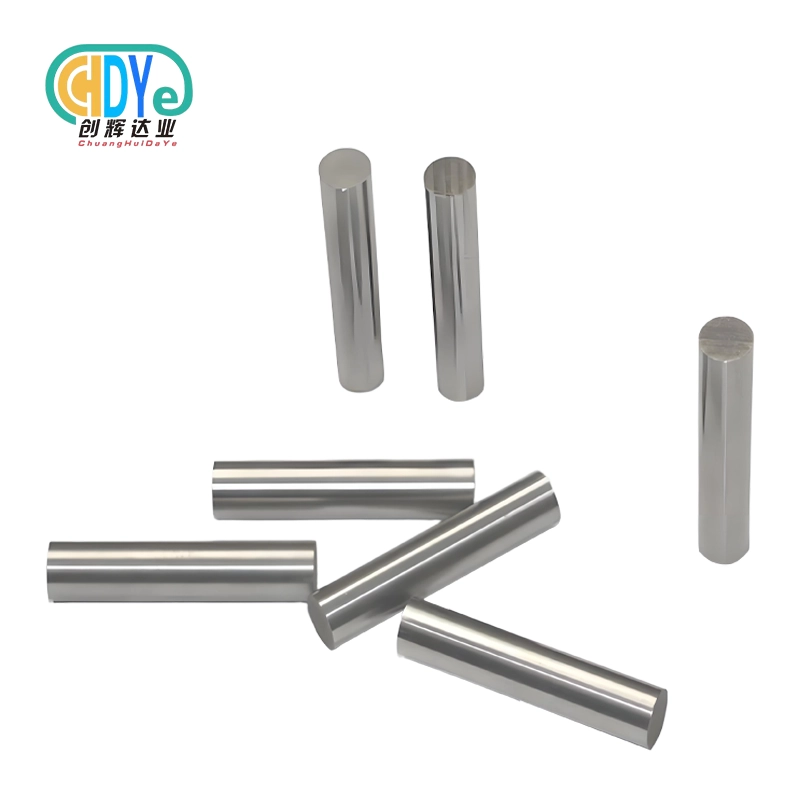

Over 30 years of rare metal processing and manufacturing experience make Shaanxi Chuanghui Daye Metal Material Co., Ltd. a leading medical titanium plate manufacturer. Our company is located in Baoji High-tech Development Zone, China's "Titanium Capital," with excellent industrial infrastructure and premium raw resources for consistent product quality. Our modern manufacturing facilities have vacuum melting furnaces, precision rolling mills, and advanced machining centers for excellent dimensional accuracy and mechanical properties.

Our medical titanium plates are precision-engineered from Grades 5, 5 ELI, and 23 ELI titanium alloys to fulfill ASTM F67 and F136 requirements. Appearance and dimensional inspection, ultrasonic testing, eddy current evaluation, and mechanical property verification through in-house and third-party laboratory testing are part of the production process. Each batch is 100% straightness inspected and tensile strength validated for consistent performance.

Comprehensive Product Portfolio and Customization Services

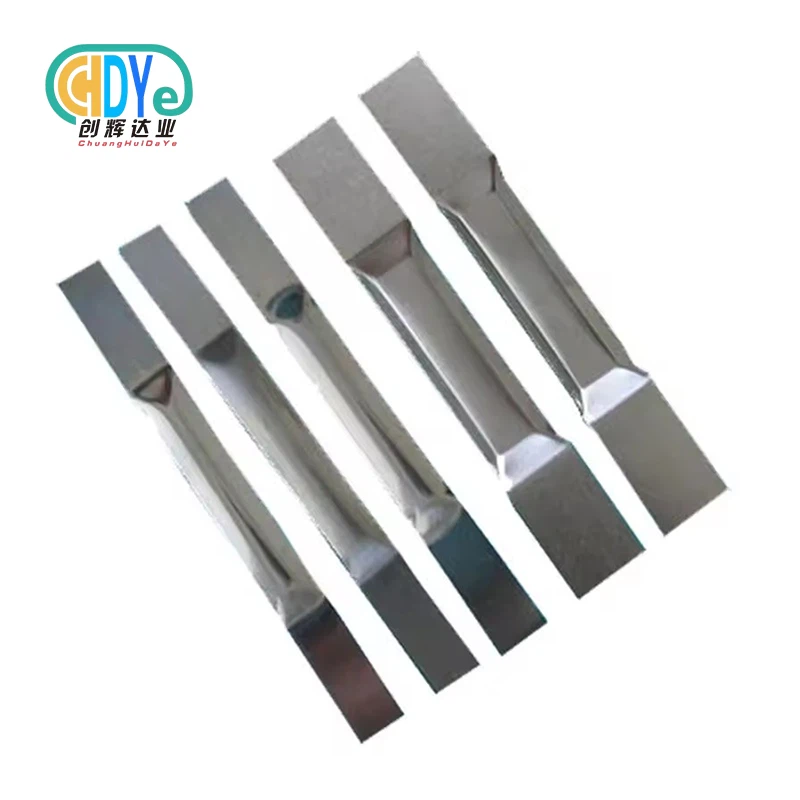

Chuanghui Daye makes medical titanium plates with excellent fatigue and load endurance in varied thicknesses and adjustable dimensions for various surgical needs. We sell bone fixation plates, cranial reconstruction components, and orthopedic, dental, and neurosurgical implant substrates. Lightweight titanium plates with good strength-to-weight ratios improve surgical outcomes and patient comfort.

Our sophisticated processing allows precision machining of complex shapes with tight dimensional tolerances for medical device applications. Custom machining services provide patient-specific implant designs and clinically relevant settings. Passivation and biocompatible coatings improve osseointegration and implant durability.

Quality Assurance and Certification Excellence

Our competitive edge is quality, reinforced by ISO 9001:2015 Quality Management System accreditation that ensures strict control throughout the production process. Our quality assurance approach includes raw material inspection, melting and forging monitoring, precision machining verification, and final inspection to ensure product reliability. ICP-OES chemical composition analysis, mechanical property verification, and ultrasonic fault detection enable various quality checks.

Biocompatibility and cytotoxicity testing assure our medical titanium plates exceed the highest human implantation safety standards. Surgical applications require surface roughness and flatness inspections to ensure dimensional correctness and quality. Beyond manufacturing, we provide thorough documentation, traceability systems, and continuous improvement methods to improve customer satisfaction and product performance.

Conclusion

Medical titanium plates with exceptional fatigue and load resistance are the gold standard for orthopedic fixation, ensuring successful surgeries and patient safety. Titanium materials are selected for demanding medical applications globally because to its outstanding mechanical characteristics, biocompatibility, and clinical track record. Understanding the technical benefits, quality requirements, and supplier evaluation criteria that drive effective purchasing decisions in this specialist market area helps procurement professionals.

FAQ

Q:What makes medical titanium plates superior to other materials?

A: Medical titanium plates offer exceptional biocompatibility, corrosion resistance, and mechanical properties that surpass alternative materials like stainless steel or ceramic options. Titanium's elastic modulus closely matches human bone, reducing stress-shielding effects while promoting natural healing processes. The material's excellent fatigue resistance ensures long-term implant stability under repetitive physiological loading conditions that occur during normal patient activities.

Q: How long do titanium plates typically last in the human body?

A: High-quality medical titanium plates can function effectively for decades when properly implanted and maintained. Clinical studies demonstrate survival rates exceeding 95% at 20-year follow-up periods, with many implants remaining functional throughout patients' lifetimes. The exceptional corrosion resistance of titanium in physiological environments eliminates concerns about material degradation that might necessitate premature removal or replacement procedures.

Q:What grades of titanium are used for medical plate applications?

A: The most commonly utilized grades for medical titanium plates include Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI (Grade 23), and commercially pure titanium variants that meet ASTM F67 specifications. Grade 23 (Ti-6Al-4V ELI) represents the extra-low interstitial version that offers enhanced ductility and fatigue resistance properties, particularly suited for demanding surgical applications. These grades provide optimal combinations of strength, biocompatibility, and processing characteristics required for medical device manufacturing.

Partner with Chuanghui Daye for Premium Medical Titanium Plate Solutions

Chuanghui Daye stands ready to support your medical titanium plate requirements with precision-engineered products that deliver exceptional fatigue and load resistance performance. Our ISO 9001:2015 certified manufacturing processes, comprehensive quality assurance protocols, and extensive customization capabilities ensure optimal solutions for your specific applications. Contact our experienced technical team at info@chdymetal.com to discuss your medical titanium plate supplier needs, request detailed specifications, or explore bulk purchasing opportunities that deliver superior value and reliable performance for your surgical device requirements.

References

1. American Society for Testing and Materials. "Standard Specification for Titanium-6Aluminum-4Vanadium ELI Alloy for Surgical Implant Applications." ASTM International, 2018.

2. Chen, Q., & Thouas, G. A. "Metallic Implant Biomaterials: Mechanical Properties and Fatigue Performance in Orthopedic Applications." Materials Science and Engineering Review, 2021.

3. Niinomi, M., et al. "Fatigue Characteristics of Titanium Alloys for Biomedical Applications: A Comprehensive Analysis." Journal of Biomedical Materials Research, 2020.

4. Rack, H. J., & Qazi, J. I. "Titanium Alloys for Biomedical Applications: Processing, Properties and Clinical Performance." Materials Science and Engineering Reports, 2019.

5. Williams, D. F. "Biocompatibility and Clinical Applications of Medical Grade Titanium Alloys in Orthopedic Surgery." Biomaterials International, 2022.

6. Zhang, L., et al. "Long-term Clinical Performance of Titanium Plates in Orthopedic Fixation: A 20-Year Retrospective Study." Clinical Orthopedics Research, 2023.

Learn about our latest products and discounts through SMS or email