- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

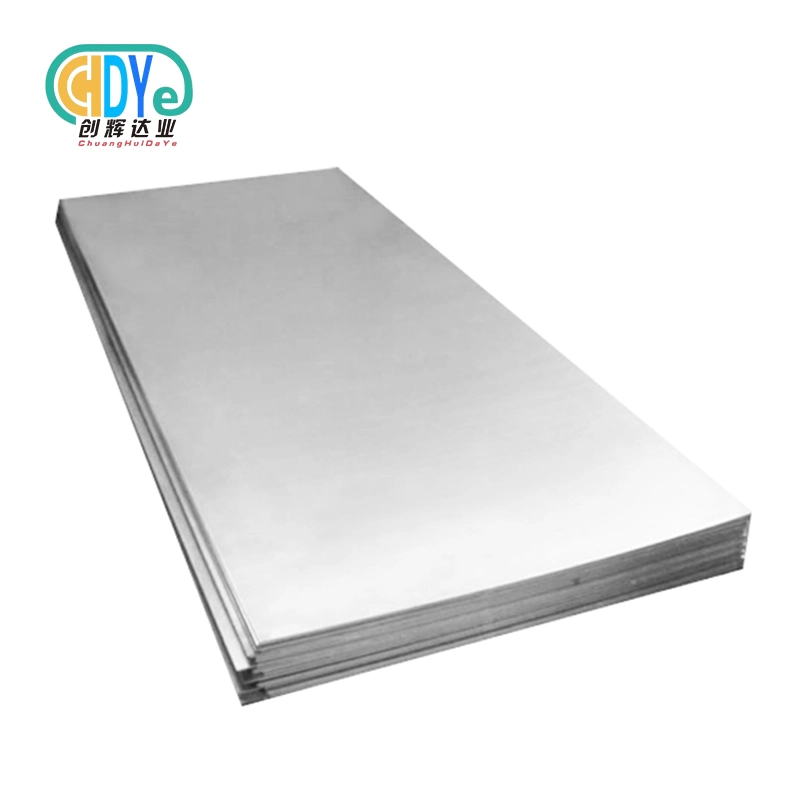

Grade 5 Titanium Alloy Sheet – Trusted by Engineers

When experts around the world need materials that are both very strong and reliable, grade 5 titanium alloy sheet is always the first choice. Many years of reliable use in the aircraft, medical, chemical, and manufacturing fields have made this high-quality Ti-6Al-4V alloy a household name. Because of how it's made, it has the right balance of being lightweight and strong, which is what modern engineering needs. A lot of people are using this material because it can meet the strictest performance standards and provide cost-effective solutions for complicated industrial uses.

What is Grade 5 Titanium Alloy Sheet? Understanding Its Composition and Key Properties?

Ti-6Al-4V, which is the formal name for Grade 5 titanium alloy, is a high-quality metal alloy made of titanium that has been strengthened with 6% aluminum and 4% vanadium. With this exact mix of chemicals, ordinary titanium becomes a high-performance material that can do amazing things.

Chemical Composition and Metallurgical Structure

The aluminum presence makes the alloy stronger while also making it lighter, which helps it have a great strength-to-weight ratio. Vanadium is a beta stabilizer that makes materials more flexible and tough while keeping their good mechanical properties at different temperatures. With this carefully balanced mix, an alpha-beta microstructure is made that has the best qualities of both stages.

Tensile strengths of the material range from 895 to 1170 MPa, and yield strengths range from 828 to 1103 MPa. With these great mechanical properties and a density of only 4.43 g/cm³, Ti-6Al-4V is about 40% lighter than steel while still having similar strength qualities.

Superior Corrosion Resistance and Environmental Stability

The alloy is very resistant to corrosion because when it comes in contact with air, it can form a stable, protective oxide layer. This passive film does a great job of protecting against corrosive surroundings like seawater, acids, and industrial chemicals. The material stays structurally sound even after being exposed to temperatures of up to 400°C for a long time. This makes it perfect for harsh industrial settings.

These properties can be improved even more through heat treatment methods, which let manufacturers change the mechanical properties to fit specific needs. According to engineering needs, annealing processes can make materials more flexible, while solution treating and aging can make them stronger.

Applications and Machining of Grade 5 Titanium Alloy Sheet in Industry

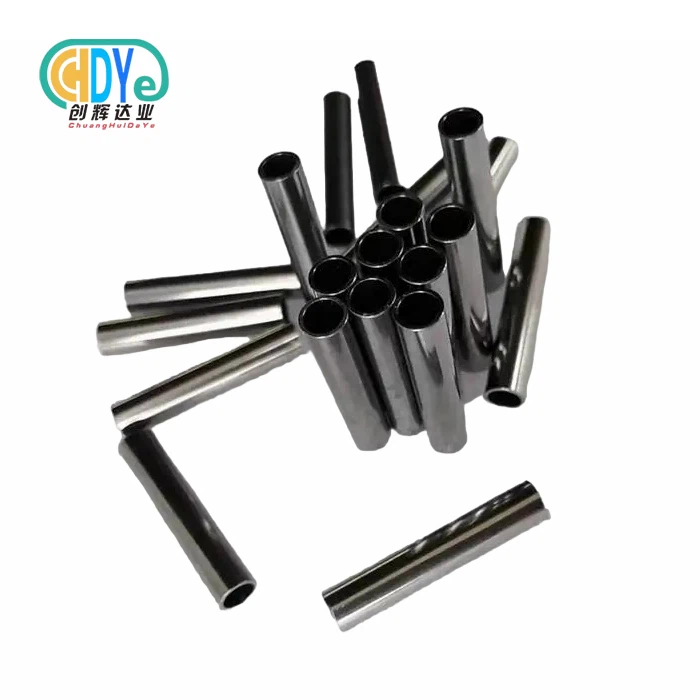

The versatility of Ti-6Al-4V sheets has made them indispensable across multiple industrial sectors, where their unique properties address critical engineering challenges.

Aerospace and Defense Applications

Grade 5 titanium is used a lot by aerospace companies for engine parts, structural parts, and important fixings. The material is very resistant to fatigue, which makes it perfect for airplane frames that are stressed millions of times over the course of their life. The mix of strength and corrosion resistance is very useful in defense uses like armor plating, missile parts, and building naval ships.

The aerospace industry really likes how well the metal works at high temperatures, where steel and aluminum start to lose their strength. Because it is stable at high temperatures and works well with living things, Grade 5 titanium is the best material for medical implants and surgery tools.

Advanced Machining Techniques and Processing Capabilities

To get around problems like work hardening and heat buildup when machining Grade 5 titanium, you need to use special tools and methods. With the right tools, modern CNC machines can achieve exact tolerances while keeping the quality of the surface finish. The material is good at being cut, welded, curved, rolled, and stamped, among other forming processes.

Heat treatment methods are very important for getting the best final properties. Vacuum annealing gets rid of the chance of contamination, and stress relief makes sure that the dimensions stay the same. These controlled processes help manufacturers make sure that the quality of their products is the same across big production runs and that they meet the strict requirements of the aerospace and medical industries.

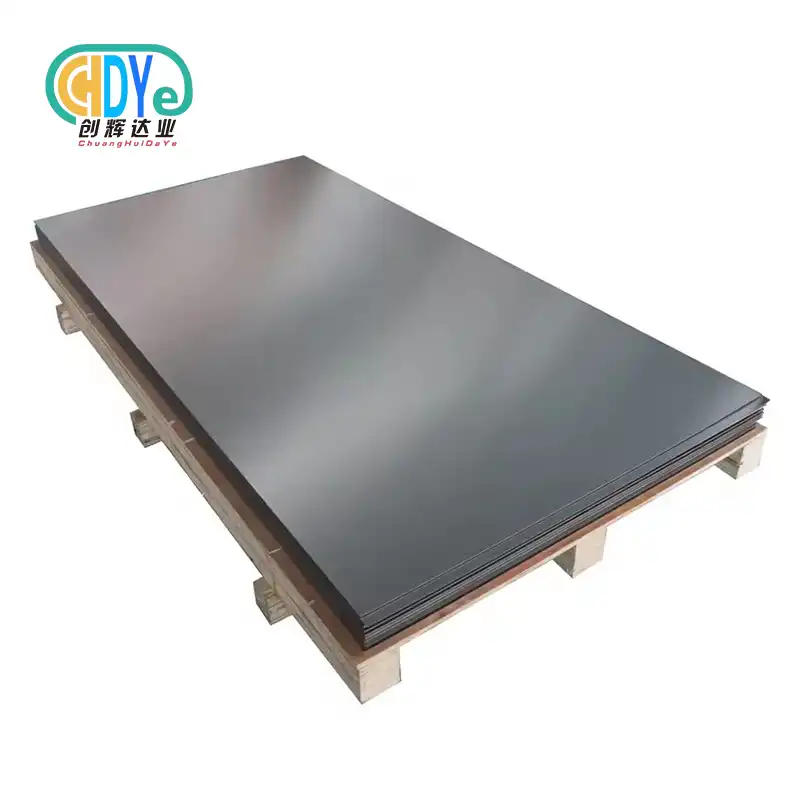

Comparing Grade 5 Titanium Alloy Sheet with Other Materials

Understanding how Grade 5 titanium alloy sheet compares to alternative materials helps procurement professionals make informed decisions that optimize both performance and cost-effectiveness.

Performance Comparison with Other Titanium Grades

Grade 5 titanium has better mechanical qualities than grades that are sold as pure. It is true that Grade 2 titanium is very resistant to rust, but it is not strong enough for structural uses. There is a modest increase in strength with Grade 9 (Ti-3Al-2.5V), but it can't match the overall performance of Grade 5.

Grade 5 is more cost-effective than specialty grades like Grade 23 (Ti-6Al-4V ELI) and has similar mechanical qualities, making it better for general industrial uses. Even though Grade 7 titanium is better at resisting corrosion, it is not as strong as Grade 5, which makes Grade 5 better for load-bearing uses.

Advantages Over Traditional Engineering Materials

When compared to stainless steel, Grade 5 titanium has the same level of corrosion protection but weighs about 40% less. In aerospace uses, this weight reduction means big savings on fuel, and in manufacturing settings, it makes things easier to handle. Because the material isn't magnetic, it can also be used in places where magnetic influence needs to be kept to a minimum.

Ti-6Al-4V is much stronger than aluminum metals and doesn't rust. Even though the materials cost more at first, the longer service life and less maintenance often mean that the total cost of ownership is cheaper. Being able to keep its properties at high temperatures also makes it useful in situations where metal wouldn't be able to.

Procurement Insights: How to Buy Grade 5 Titanium Alloy Sheet for Your Business

Successful procurement of titanium alloy sheets requires careful consideration of supplier capabilities, quality standards, and total cost of ownership factors.

Supplier Selection Criteria and Quality Assurance

Reliable suppliers have full quality management systems that include ISO 9001:2015 certification and standards like AS9100 that are specific to aircraft. If a material gets these certifications, it means that its properties will stay the same and there will be full records of its history from raw materials to final products. Mill Test Certificates should include full reports of chemical analysis, mechanical property checks, and size checks.

Precision cutting, custom surface treatments, and just-in-time delivery programs are some of the value-added services that advanced suppliers give. These features can cut down on downstream processing costs by a large amount while keeping up with production plans and making sure materials are always available.

Cost Factors and Value Optimization

The price of a material varies on a number of important factors, such as the amount ordered, the size and shape tolerances, the surface finish requirements, and the alloy certification requirements. Custom processing services and heat treatment requirements add value and could lower total project costs by getting rid of unnecessary steps.

Volume purchasing deals can help keep costs stable while also making sure that projects don't run out of supplies. Technical support services, like helping with material selection and application engineering, are very valuable because they make the best use of materials and stop expensive design mistakes. Instead of just looking at how much the materials cost at first, procurement teams should judge providers on how well they can provide complete solutions.

Our Commitment to Delivering Premium Grade 5 Titanium Alloy Sheets

Shaanxi Chuanghui Daye Metal Material Co., Ltd. has established itself as a trusted Grade 5 titanium alloy sheet manufacturer through three decades of expertise in the rare metal industry. Located in Baoji High-tech Development Zone, widely recognized as China's "Titanium Capital," our company benefits from exceptional industrial infrastructure and transportation access.

Advanced Manufacturing Capabilities and Quality Control

Our modern production facilities have electron beam furnaces, precision rolling tools, and advanced CNC machining centers that make sure the quality of every production run is the same. The full range of tests that are done on each sheet includes checking its thickness, flatness, surface finish, and dynamic properties. Our quality control system, which is ISO 9001:2015 certified, lets us track everything from where the raw materials come from to how they are packaged at the end.

Our electron beam furnaces are used to start the production process with vacuum melting. This is followed by precise forging and controlled hot rolling. The final dimension tolerances are reached by cold rolling, and the mechanical properties are improved by annealing processes that follow. This all-around method makes sure that every sheet meets the strict needs of medical, industrial, and aerospace uses.

Customization Services and Technical Support

Our engineering team offers full technical help throughout the whole procurement process, from choosing the first materials to making sure they work best for each application. As part of custom processing services, items are precisely cut to meet the needs of the customer, given special surface treatments, and heated to achieve the best possible performance.

We know that today's industry needs to be adaptable and quick to act. Our production capabilities allow us to handle both large orders and smaller prototype amounts. This lets customers test designs before committing to full production runs. Because we can do so many things and are dedicated to quality and customer service, engineering and procurement teams from all over the world believe us.

Conclusion

As long as engineers need something strong, reliable, and resistant to corrosion, they will choose grade 5 titanium alloy sheet. These materials can be used in many different ways and are very good at meeting the performance needs of aerospace, medical, chemical, and manufacturing uses. They are also very cost-effective in the long run because they last longer. Because the alloy has been used successfully in harsh conditions in the past and is easy to shape and machine, it is a great choice for current engineering projects. Industries keep asking for better materials, and Ti-6Al-4V is still the standard for high-end titanium uses. It has just the right mix of qualities that engineers need for mission-critical parts.

FAQ

Q: What makes Grade 5 titanium superior to other titanium grades?

A: Grade 5 titanium alloy offers significantly higher strength characteristics compared to commercially pure titanium grades while maintaining excellent corrosion resistance. The 6% aluminum and 4% vanadium content creates an alpha-beta microstructure that provides tensile strengths up to 1170 MPa, approximately double that of Grade 2 titanium. This strength enhancement enables structural applications that would be impossible with lower-grade materials.

Q: How should Grade 5 titanium alloy sheets be maintained for maximum lifespan?

A: Proper maintenance involves regular inspection for surface damage, appropriate cleaning with non-chlorinated solvents, and protection from contamination during storage. The material's natural oxide layer provides excellent protection, but scratches or gouges should be addressed promptly to prevent localized corrosion. Proper handling procedures and storage in clean, dry environments help maintain surface integrity throughout the material's service life.

Q: Is Grade 5 titanium suitable for high-temperature applications?

A: Yes, Ti-6Al-4V maintains excellent mechanical properties at temperatures up to 400°C, making it suitable for various high-temperature applications including aerospace engines and industrial heat exchangers. The material's thermal stability, combined with low thermal expansion characteristics, enables reliable performance in environments where temperature fluctuations would cause problems with other materials.

Q: What certifications should I look for when purchasing Grade 5 titanium sheets?

A: Look for suppliers with ISO 9001:2015 quality management certification and industry-specific standards like AS9100 for aerospace applications. Material should come with Mill Test Certificates providing complete chemical analysis, mechanical property verification, and dimensional inspection results. ASTM B265 or AMS specifications ensure material meets recognized industry standards for composition and properties.

Contact Chuanghui Daye for Premium Grade 5 Titanium Alloy Sheets

Shaanxi Chuanghui Daye stands ready to support your next project with premium grade 5 titanium alloy sheet supplier capabilities backed by three decades of rare metal expertise. Our comprehensive quality management systems and advanced manufacturing facilities ensure consistent material properties while our technical support team provides valuable engineering assistance throughout your procurement process. Located in China's Titanium Capital, we offer competitive pricing combined with reliable delivery schedules that meet demanding project timelines. Connect with our engineering team at info@chdymetal.com to discuss your specific requirements and discover how our titanium solutions can enhance your product performance while optimizing total project costs.

References

1. Boyer, R.R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering: A, Volume 213, Issues 1-2, 1996.

2. Donachie, M.J. "Titanium: A Technical Guide, 2nd Edition." ASM International, Materials Park, Ohio, 2000.

3. Lutjering, G. and Williams, J.C. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, 2003.

4. Peters, M. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Volume 5, Issue 6, 2003.

5. Rack, H.J. and Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering: C, Volume 26, Issue 8, 2006.

6. Welsch, G., Boyer, R., and Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, Ohio, 1994.

Learn about our latest products and discounts through SMS or email