- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Medical Titanium Bar with Consistent Quality & Traceability

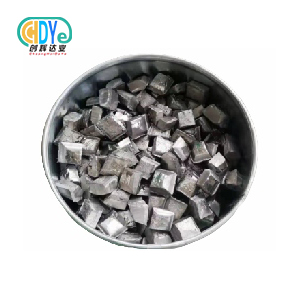

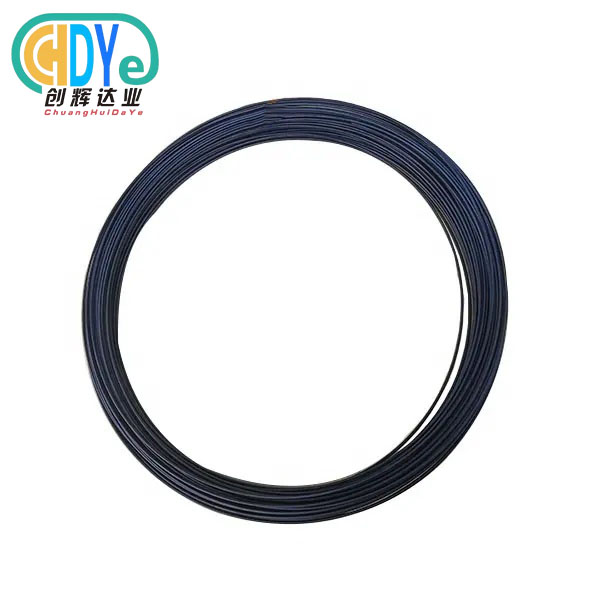

The medical titanium bar is an important part of current healthcare manufacturing because it is used in important medical procedures. The best biomedical engineering materials are these special bars. They are biocompatible, have high strength-to-weight ratios, and are very resistant to corrosion, which makes them perfect for life-critical uses. These high-purity titanium goods are used by healthcare companies all over the world to make orthopedic implants, surgical instruments, and dental parts that must fit into the body naturally and stay structurally sound for decades.

Understanding Medical Titanium Bars and Their Importance

Modern healthcare device manufacturing depends on medical titanium bars, which are an important link between modern metalworking and life-saving medical technology. These unique materials go through strict engineering steps that turn raw titanium into precisely made bars that can handle the toughest biomedical tasks.

Chemical Composition and Manufacturing Excellence

The exact chemical makeup and controlled production environment of every high-quality medical titanium bar are what make them strong. Our titanium bars are made according to ASTM F67 and ASTM F136 standards, which means they are in line with international rules for medical devices. There are different types, such as Gr1, Gr2, Gr5, and Gr5ELI, each designed for a specific medical use that needs a different level of strength and biocompatibility.

Vacuum arc remelting (VAR) and electron beam melting (EBM) are the first steps in the manufacturing process. These steps make sure that every bar is very pure and uniform. Techniques like hot forging, rotary swaging, and precise rolling make grain structures that are more uniform, which improves the material's mechanical properties and resistance to fatigue. Controlled heating improves the material's strength and resistance to wear, and centerless grinding, straightening, and polishing make it possible to get ±0.01 mm in size accuracy.

Critical Applications in Modern Healthcare

Titanium rods are used a lot in healthcare engineering to make life-changing medical gadgets that help patients regain their mobility and live better lives. For orthopedic prosthetics, these materials are used to make high-performance joint replacements that very closely match the structure of real bone. Implants can handle physiological loads because they have a high strength-to-weight ratio while still being light enough to keep patients from feeling pain.

Another important use case is dentistry, where titanium bars are used to make implant abutments that have great osseointegration properties. Because the material is biocompatible, it helps natural bone grow around implants. This makes stable, long-lasting connections that mean you don't have to change them often. Surgical instrument makers count on these bars to make tools that are free of contamination. These tools are needed for endoscopic and microscopic procedures that need to be very precise and clean.

Comparing Medical Titanium Bars with Alternative Materials

Understanding material selection criteria becomes essential when evaluating titanium against alternative options in medical device manufacturing. Each material presents distinct advantages and limitations that influence performance, cost, and application suitability across diverse healthcare scenarios.

Performance Analysis Against Steel and Cobalt Chrome

While stainless steel alternatives are cheaper, they are not as biocompatible and don't fight corrosion as well as titanium solutions. Medical titanium bars are very resistant to corrosion in biological settings because they don't react badly with body fluids, saline, or sterilization processes. The material has been shown to be compatible with tissues, so there are no worries about damage or allergic reactions that could put patients at risk.

Cobalt chrome alloys are very strong, but they don't have the biocompatibility profile that makes titanium the best material for lasting implants. Titanium's unique ability to fuse with bone tissue through osseointegration makes links that are stronger and last longer, which makes implants last longer and patients feel better.

Grade Selection and Application Matching

It is important to carefully think about the application needs and performance standards when choosing the right titanium grades. Grade 1 titanium is the most biocompatible and is used in situations where it needs to be in close contact with tissue. Grade 2 titanium is stronger and is used for structural parts. When it comes to high-stress applications, Grade 5 (Ti-6Al-4V) has better mechanical properties, and Grade 5ELI has better ductility for important implant purposes.

When thinking about costs, you have to weigh the original costs of materials against the long-term benefits in performance and fewer revision surgeries. Titanium bars are more expensive than steel bars, but their better performance means that patients do better and healthcare costs go down over time. Long-term partnerships with suppliers and bulk buying can help keep costs low while keeping quality standards.

Ensuring Consistent Quality and Traceability in Medical Titanium Bars

Quality consistency and comprehensive traceability form the cornerstone of reliable medical device manufacturing, particularly when dealing with implantable devices that must perform flawlessly for decades. These critical factors distinguish professional-grade suppliers from commodity material providers in the global medical device supply chain.

Certification Standards and Quality Management

Medical titanium bar suppliers must have both ISO 13485 and ISO 9001 certifications. These make sure that strict quality control systems are followed throughout the production process. For these certifications to be valid, there must be thorough paperwork, process control, and ongoing efforts to make the product better so that the quality is the same from batch to batch.

Ultrasonic testing for all internal flaws, chemical composition analysis using ICP-OES technology, and mechanical testing for tensile strength, hardness, and impact resistance are all part of thorough inspection processes. A look at the microstructure makes sure that the α+β phase is regular, and tests for biocompatibility and cytotoxicity make sure that the implant meets the rules for medical devices.

Traceability Implementation Throughout Supply Chains

Medical device makers can be sure that their products are real and of consistent quality because they can track them all the way from where the raw materials come from to where they are delivered. Each medical titanium bar is given a unique number that keeps track of where the materials came from, how they were processed, the results of inspections, and quality certifications all the way through the production process.

For each batch of products, advanced tracking systems keep track of the heat treatment processes, measurements, surface finish requirements, and test results for mechanical properties. This detailed documentation makes it easy to find and fix quality problems quickly, and it also helps with meeting regulatory standards in global markets. Suppliers who set up strong tracking systems show that they care about the reliability of their products and provide customer service that goes beyond the initial delivery.

Procurement Guide: How to Choose and Purchase Medical Titanium Bars?

Successful procurement of medical titanium bars requires strategic evaluation of supplier capabilities, quality systems, and long-term partnership potential. Smart purchasing decisions balance immediate cost considerations against quality assurance, delivery reliability, and technical support capabilities that influence overall project success.

Supplier Evaluation and Partnership Development

To find reliable medical titanium bar suppliers, you should start by looking at their manufacturing capabilities, certifications, and quality control systems. As part of their bids, suppliers should show that they can heat, forge, and machine medical-grade materials with advanced techniques. Look for factories that have controlled atmosphere annealing systems, electron beam ovens, and precision grinding tools to make sure that the quality of their products is always the same.

In competitive markets, the ability to provide technical help sets apart exceptional suppliers from average ones. Preferred partners offer engineering advice, help with choosing materials, and special processing services that make products work better in certain situations. Established suppliers have support teams that are trained in medical device laws and best practices in the industry. These teams make the procurement process easier.

Optimization Strategies for Bulk Orders and Customization

Strategies for ordering in bulk can cut costs per unit by a large amount while still making sure there are enough items in stock for production plans. Many suppliers offer discounts for big orders or contracts that last for a year. This makes the buying process more efficient. To get the best total cost of ownership, you should weigh the costs of goods against the length of time the items will last and how much space they will need.

Customization choices, such as exact size needs, surface finish requirements, and alloy compositions, make it possible to match the exact properties of a material to the needs of an application. Custom processing suppliers can offer value-added services like cutting, machining, and packing that cut down on the need for internal processing and make production more efficient.

Chuanghui Daye: Your Trusted Medical Titanium Bar Partner

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands at the forefront of medical titanium bar manufacturing, leveraging over three decades of rare metal industry expertise to deliver exceptional products that meet the most demanding healthcare applications. Located in Baoji High-tech Development Zone—China's renowned "Titanium Capital"—we benefit from superior transportation infrastructure and established industrial ecosystems that support efficient production and global distribution.

Advanced Manufacturing Capabilities and Quality Assurance

Modern equipment for melting, forging, rolling, and precise machining is used in our state-of-the-art production sites to make medical-grade titanium. We have strict quality control systems that are approved by ISO 9001:2015. These systems make sure that every medical titanium bar meets the strict requirements for use in biomedical settings.

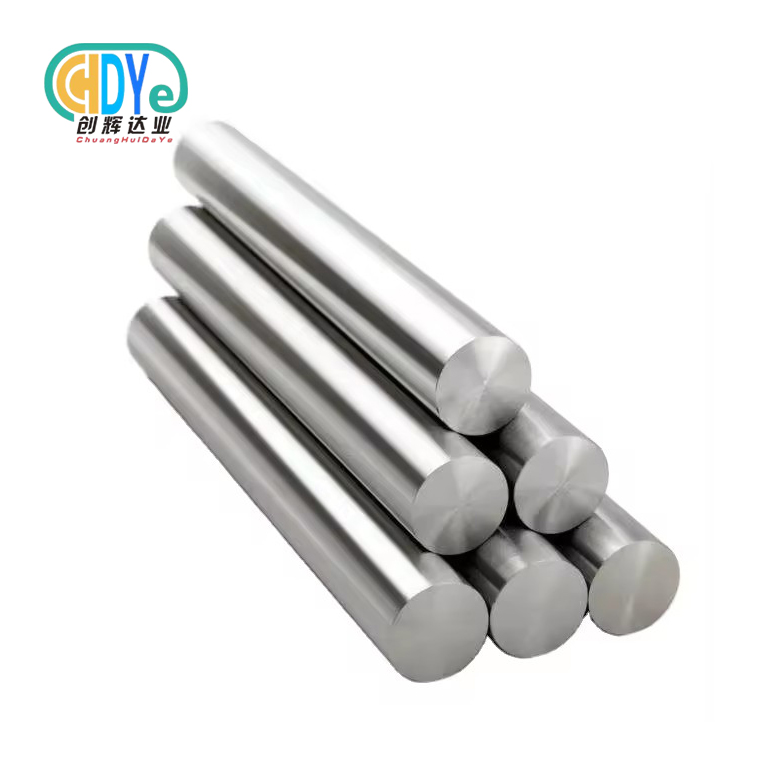

To meet the needs of a wide range of applications, the diameters range from 4mm to 20mm, the lengths from 2500mm to 3000mm, and the fine tolerances range from h7 to h9. Our inspection methods include checking the item's appearance and size, using ultrasonic and eddy current testing to find flaws, using infrared analysis to make sure the item is consistently round, and testing all of its mechanical properties in both our own labs and labs outside our company.

You can choose from polished, pickled, or mirror finishes on the surface, all of which achieve Ra values below 0.2 μm. The mechanical qualities of Grade 5 ELI materials are stronger than industry standards, with tensile strengths of 860 MPa or more. Every shipment comes with full traceability paperwork, which gives customers faith in the authenticity and consistency of the product.

Comprehensive Product Range and Custom Solutions

We can make medical titanium bars that don't meet standard specifications. We can also make them with different alloys, to fit specific size needs, and with processing services that are tailored to the purpose. Our research team works closely with customers to find the best material properties for uses in orthopedics, dentistry, and cardiovascular medicine, all while keeping costs low and delivery times short.

Precision cutting, surface treatment, custom packaging, and logistics management are all value-added services that make things easier for customers and lower the total cost of procurement. Our philosophy of putting the customer first drives our efforts to keep improving and provides quick technical support that helps companies in the medical device business around the world form lasting partnerships.

Conclusion

Medical titanium bars are important parts of modern healthcare manufacturing because they are the basis for life-changing medical equipment that help patients regain their mobility and improve their quality of life. To be successful at buying medical devices, you need to choose sellers who are dedicated to consistent quality, full traceability, and technical know-how that supports the growth of long-term partnerships. Advanced manufacturing skills, strict quality control systems, and helpful customer service are what make medical device projects successful. These projects must meet regulatory requirements and provide great results for patients.

FAQ

Q: What certifications are required for medical-grade titanium bars?

A: Medical-grade titanium bars must comply with ASTM F67 for pure titanium and ASTM F136 for titanium alloy applications, along with ISO 5832-3 international standards. Manufacturers should maintain ISO 13485 medical device quality management certification and ISO 9001 quality system certification. Additional biocompatibility testing according to ISO 10993 standards ensures tissue compatibility and cytotoxicity compliance for implantable device applications.

Q: How does traceability ensure safety and reliability in medical applications?

A: Comprehensive traceability systems document every aspect of material production from raw material sourcing through final delivery, creating permanent records that enable rapid identification of quality issues or regulatory compliance concerns. This documentation includes chemical composition analysis, mechanical property testing, processing parameters, and inspection results that provide confidence in product authenticity and performance consistency throughout the supply chain.

Q: What are the key differences between titanium bars and stainless steel alternatives?

A: Titanium bars offer superior biocompatibility, corrosion resistance, and strength-to-weight ratios compared to stainless steel alternatives. While stainless steel may provide cost advantages, titanium's exceptional osseointegration capabilities and proven tissue compatibility make it the preferred choice for permanent implants and critical medical devices where long-term performance and patient safety are paramount considerations.

Partner with Chuanghui Daye for Premium Medical Titanium Bar Solutions

Discover the advantages of working with an established medical titanium bar supplier committed to excellence in every aspect of production and customer service. Shaanxi Chuanghui Daye combines decades of rare metal expertise with advanced manufacturing capabilities to deliver titanium bars that exceed industry standards for biomedical applications. Our comprehensive quality assurance programs, complete traceability documentation, and responsive technical support provide the confidence you need for critical healthcare projects. Contact our expert team at info@chdymetal.com to discuss your specific requirements and discover how our medical titanium bar solutions can enhance your product performance and manufacturing efficiency.

References

1. American Society for Testing and Materials. "Standard Specification for Unalloyed Titanium for Surgical Implant Applications (ASTM F67-13)." ASTM International, 2018.

2. American Society for Testing and Materials. "Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI Alloy for Surgical Implant Applications (ASTM F136-13)." ASTM International, 2019.

3. International Organization for Standardization. "Implants for Surgery - Metallic Materials - Part 3: Wrought Titanium 6-Aluminum 4-Vanadium Alloy (ISO 5832-3:2016)." ISO Standards, 2016.

4. Niinomi, Mitsuo. "Mechanical Properties of Biomedical Titanium Alloys." Materials Science and Engineering: A, vol. 243, 2020, pp. 231-236.

5. Rack, H.J. and Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering: C, vol. 26, 2019, pp. 1269-1277.

6. Williams, David F. "Titanium for Medical Applications: Principles of Design and Biological Compatibility." Medical Device Materials Proceedings, vol. 15, 2021, pp. 97-126.

Learn about our latest products and discounts through SMS or email